Fuel Injection upgrade

|

Administrator

|

IIRC, the issue is the header hitting the engine? I wonder if the heads AFR heads aren't quite as wide?

I hope you get this sorted easily. But my experience of being the guy in the middle isn't good. Good luck!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

The header is hitting the cylinder head, Cylinder #5 tube is smashed up against the bottom edge of the head where the head meets the block. Its tilting the flange at the head resulting in the bottom of the flange not even touching the surface of the head. Another issue I have is I need to shave some off the bottom of the header flange as the ledge on the AFR heads is not allowing the header to fit, I think 1/16" to a 1/4" shaved off the bottom of both flanges should give me the clearance I need to easily sit flush without binding on the ledge. The driver side how ever will still have the same problem with the tube being smashed against the cylinder head. The circle shows where the tube is smashed against the cylinder head.  I know the headers should work they are 1 1/2" primary tubes and lots of people online are running 1 1/2" primary tube hedman headers on these Renegade 165 heads. Some claimed the ports are D shaped on the heads and thus dont seal in the corners but AFR`s paperwork makes no mention of port shape just that its in the stock location. Summit lists the port shape as being square and the hedman headers I have are listed as having square ports as well.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

That really is TIGHT! How thick are the gaskets?

And I see the interference at the bottom of the flange. The gasket will help some there as well, so maybe it won't take much trimming? I hope not.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

The gaskets I have are the Felpro 1415 header gaskets in "small race port" style that is 1.480" H x 1.250" W that Speedway states is 0.07" thick which I dont think is thick enough to take up the gap and get the tube off the head. With the location I seriously feel that the headers are not made right, I sent a installation question to Summit who I bought the headers from to see if I can get a answer in a more timely manner as I emailed Hedman back not even half an hour after they emailed me and no reply. Hopefully Summit can get back with me about these headers if they are defect or not cause they do have a lifetime warranty on them for defects and I would swap them out and then if the flange hits the ledge still I will just take a sanding disc to the bottom side of the flange and just clearance it to fit properly before I send it out for ceramic coating. This is a cropped image before paint that shows the head where it meets the block.  Then here is a E7TE OE cylinder head  and a factory cast iron GT40 cylinder head  As you can see my cylinder head isnt sloped but even with the slope of the OE castings I do not believe the header will clear it as I need a good bit of clearance to get the flange to sit flat and the gasket would move it out some but only 0.07". Like wise why would you make a header that would only fit OE cylinder heads and not aftermarket stock patterned heads such as the AFR`s I have. That is a serious over sight on hedmans part if that is true. Worse case I may just end up having to run OE exhaust manifolds if I cant get this all straightened out cause I dont mind dinging the header to reshape it for clearance as well as grinding on the bottom of the flanges to clearance the ledge. But I have to make fully sure that there wont be any exhaust leaks cause all of this work and having an exhaust leak is not something I want.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

I agree that the thickness of the gasket probably isn't enough to make the header clear. Perhaps Summit will get you an answer.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Hope so too, only other option is to take the headers to work and heat tube 5 up with the torch and ding it in some and then grind the bottom flange down to clear the ledge. Thankfully I have it mounted on the heads all I would have to do is just mark how much to grind down on the flanges and mark where the tube needs to be shifted. At least doing it now would mean that when I have the headers ceramic coated everything will be coated.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Did a little work over the weekend while I am awaiting the shipment of my pushrods which should be tomorrow unless they delay it yet again.

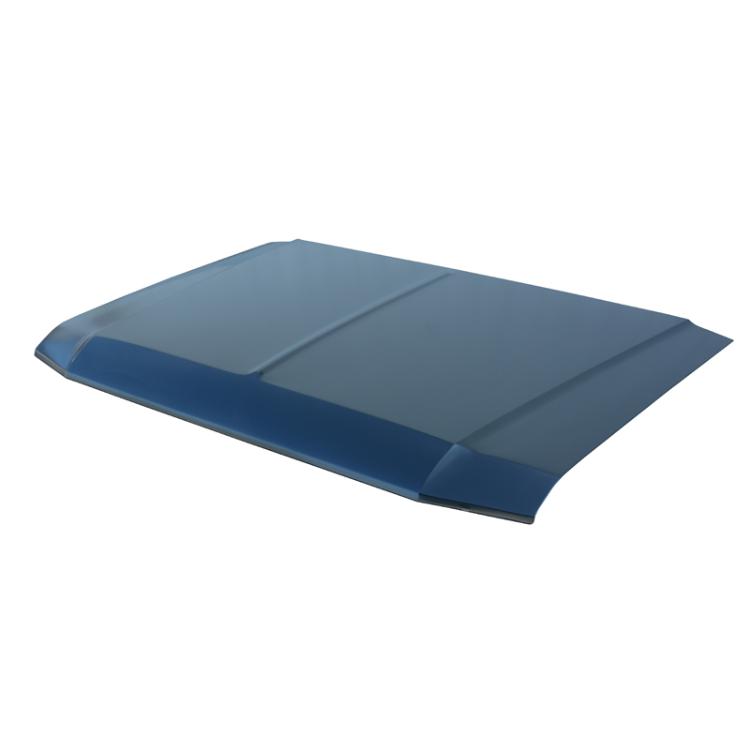

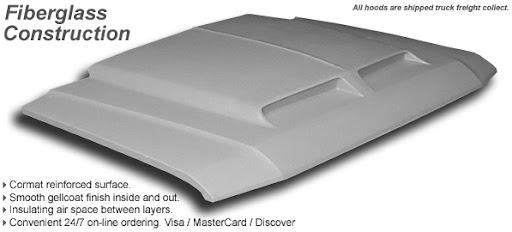

I started off with mocking up the 3/8" hardline by using some scrap hardline from work that is a coated copper line (can see the copper on the inside). Figured it would be more cost effective to use some scrap than to use my actual stainless steel hardline. My plan was to have the -6 tee mounted with the center leg pointing up and bringing the forward line down into the top of it. After mocking it up I found out that wouldnt be viable where you could read the fuel pressure gauge screwed in. I decided what I will do is place the tee inline where front and rear lines meet to opposite ends of the tee with the center leg pointing down which would be the feed line. It will move the fuel pressure gauge up where you can easily read it even though it will be covered by the OE air cleaner which will require its removal to check fuel pressure.  I also mounted temporarily the alternator bracket which is coated in eastwoods zinc phosphate, the flash makes the coating look lighter than it really is. The coating is a dark charcoal gray color which I am on the fence, part of me likes the look but the other part of me feels I should coat it in eastwoods cast gray for the natural fresh cast iron look which would be considerably lighter. I also need to still decide what hose clamps I want to use for the bypass hose, I dont mind using traditional worm gear hose clamps but Id like to source a hose clamp that is built more like the old clamps were that didnt strip out easily.  I also marked the driver side header and removed both headers and boxed them up to take them to work this week and modify them to fit cause I havent heard back from hedman since last week and summit has yet to reply to my inquiry about the fitment as well. So I will be shifting the header to clear the head and will be using a sanding disc on one of my air grinders to lightly shave some material off the bottom of the flange to try and get a better fit on the heads. I also removed the brackets for the power steering pump and the dealer installed AC compressor which I found out two things. First thing I found out was that the OE intake has a raised square pad with a large 5/8" bolt I believe it is that the support brace for the compressor mounts to. My Performer intake doesnt have this point but it does have the mount just behind it like my OE intake which I may be able to use that mount if it clears my aftermarket valve covers. If not I may have to modify the brace or build my own to take this into account. All this brace is for is to stiffen up the compressor mount. The second thing I found out is that the frame work of my hood is rotting out for some reason but yet the outside of the hood is just fine. I stripped the hood years ago and repainted it and now I was able to push my finger through one spot of the frame work that 2 years ago was not rotten but is now. So now I have to decide what I want to do about a hood. Do I stick with this hood and just let a body shop use body filler which I hate the thought of, do I source a reproduction hood and hope it fits like the original hood and is of quality, do I get the steel cowl hood which I am not too sure about, or do I skip all of that and go with the GT500 mustang inspired fiberglass hood. These brackets will be stripped at work using my wire brush wheel on one of my air angle grinders after I let the parts washer wash away all the grease and grime from the brackets. I will be painting the steel brackets low gloss (10% - 20% gloss) under hood black, the pulleys will be underhood black as well. The powersteering pump bracket which I havent removed I will clean up and paint along with the aluminum flex fan spacer in eastwoods cast aluminum color. I am leaning more towards repainting the alternator mount the cast gray for a lighter natural cast iron look. After looking at the following I think I will probably just spend the money and get a stock steel hood from Dennis Carpenter as it is the cheapest and I just dont know how a truck would look with these two optional hoods with KO2 tires with a grill guard and possibly a roll bar. I think they would look better on a lowered truck with wheels more like what you would find on a car. Made in the USA Steel hood from Dennis Carpenter $495.95  Goodmark 2" steel cowl hood $731.79  Composite-Tech Fiberglass GT500 series Hood $689.00  I do really like the GT500 scoop look of the fiberglass hood but I just cant find enough photos of the hood from all angles installed on an 80-86 truck to make a good decision on if I will get it or not but I still have time to think on this, I will just knock the rust out as best as I can shoot some paint on it to slow it down and come to a final decision on the hood when I take the truck for paint and body work.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

I think the stock hood is the way to go. I don't think a scoop or scoops would look right on a serious truck. As you said, maybe on a lowered truck with street tires, but not your truck. Just my opinion.

Good luck on the header. Apparently no one wants to fess up that it is their fault. As for the pressure gauge, might you be able to get it where you can read it with a mirror? Or by getting down close to the fender? The one on Big Blue requires you to be in just the right spot, but it sure is nice to be able to tell w/o pulling the air cleaner. Anyway, it is looking good!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

That is what keeping me from saying "yes I want x hood" but more so just going back with the same style hood thats on the truck now. It is sad cause the headers have a life time warranty on them as per hedmans website. I asked on fb on a small block ford group Im on and many are saying that they have no header fitment issues with the AFR 165 Renegade heads given they arent using the same specific header but they are using shorties for their application which makes me think its a screw up on their part. But its no big deal I can use my sanding disc and clean the headers up some smooth it out some from the shoddy welding I found in a few spots such as some welding splatter on the header gasket surface and one on the OE ball collector. I took a orange paint pen I use at work for marking my fabrications and I marked where the header is touching at and where it is closer than I would like so I have a wider area to shift. On the pressure gauge I am not too concerned with the location cause if there is a problem with the engine not running I would be pulling the air cleaner off anyways to check the injectors are spraying. Like wise if Dakota Digital ever offers a RTX Retro cluster for our trucks I will be buying it and installing in the gauges place a pressure module and a 0 to 100 psi pressure sensor. That way I can read the pressure on the dash and set up a warning to flash on the dash when the fuel pressure moves outside of the 55 - 65 psi pressure range. Same with the fuel gauge I can set it up to warn me with Low Fuel warning in the message center when I get down to 10% or 15%. I thought about locating the pressure gauge where you could see it but it would require a break in the hardline and I am trying to limit the number of connections where possible. Thats what I have to decide is how I want to route the feed line on the engine cause the OE line comes forward between the ignition coil and the distributor then it makes a gentle curve around the distributor cap then it angles down towards the timing cover to clear the power steering pump bracket and the dealer AC bracket. I dont know if I want to route the hardline like that cause it may have been fine with 5/16" hardline but now going with 3/8" hardline I am a bit concerned with the appearance it will have. I thought about bringing it over the intake manifold runner for cylinder one and coming around the back side of the distributor then down the front of the block like OE. It will hide the line a bit more, give it more of a natural route than curving back and forth unnecessarily. But I have to say I do like the cheaper Inline Tube`s 37* flare turret and die set for use with my Eastwood vice mount flare tool. I just have to watch some videos and verify cause for the 37* flare it has a op 0 to set the die and the tube in position then you have a op 1 to start the first stage of a double flare and then op 2 to complete the double flare. I believe AN flares are only single not double flare so I just did op 0 and op 2 for a single flare on the hardline I made. First flare I made I screwed up cause I was tempted to do like I do with my standard flare set and bottom the tool lightly. Doing this with the AN turret and die actually split the tubing as it made the flare too large. I found out there is a sweet spot when you are doing the flare the tube will flare easily then youll hit a detent part where the tube has flared properly and requires a little more force to keep the flare tool moving.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Will have to upload photo tomorrow on my lunch break but I tossed my Dealer AC bracket in the parts washer at work turned the heat on for 4 hours and set the wash cycle to 2 hours. When I pulled the part out all the grease and grime was gone as well as all the paint. Only thing that was left was spots of rust that was under the paint that my wirebrush wheel on my air grinder quickly wiped away. Since I still have a lot more to clean and strip before I can paint I hosed the bracket down with some zep penetrating oil hopefully it will keep the rust at bay till I can finish cleaning everything up for painting this weekend.

I also am hopeful to take the headers to work this friday if I can get everything else cleaned up before then after hours so I can get them clearanced and test fitted this weekend before I contact the ceramic coater that I will be using cause Jet Hot coating told me they wont fix the pipes for shifting them and they dont do welding. That is a no go for me cause even though the guy I will be using doesnt offer a life time warranty on his coatings he does how ever blasts the parts clean and checks the welds and do repairs that are needed. Which I do want I want him to go over both headers and make sure there is no exhaust leak points in them before ceramic coating I dont want no leaks or noise. This weekend I will also be bringing my powersteering pump pulley remover tool from work to pull the powersteering pump pulley and also unbolting the aluminum powersteering pump bracket to clean both up and paint as well. Looking at my setup it looks like my powersteering pump pivot bolt screws into the larger 7/16" thermactor plug which means it will all bolt up on my AFR Renegade heads and the best part, once all this bracketry is installed youll never see the AFR Renegade logo on the front of the heads. Only thing people could possibly see to know they are AFR aftermarket heads and not OE castings is the AFR cast into the forward and rear mating surface of the heads which for the most part should be hidden by the header tubes unless you start jockying around to view around them.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Seems like you are making good progress, Rusty. Getting all the grease and grime, as well as paint, off is a big help in the painting/coating process.

I assume the A/C bracket is steel, but if you are dealing with aluminum I wouldn't do the penetrating oil step. From experience, cast aluminum has lots of open pores that absorb oil, and it'll bite you when you try to paint. And when powder coating, since you have to raise the temp of the part up to 400 degrees, the oil flows out and ruins the finish. In fact, the only way I know of to get rid of it is to bake the part for an hour at 400 to burn off the oil, and then wash it with brake cleaner. Anyway, if your part is steel you should be fine with just a wash with brake cleaner before painting. And I'm sure you know that. As for the heads being incognito, the truck is going to surprise people, and they'll be amazed and how much power the EFI gave it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

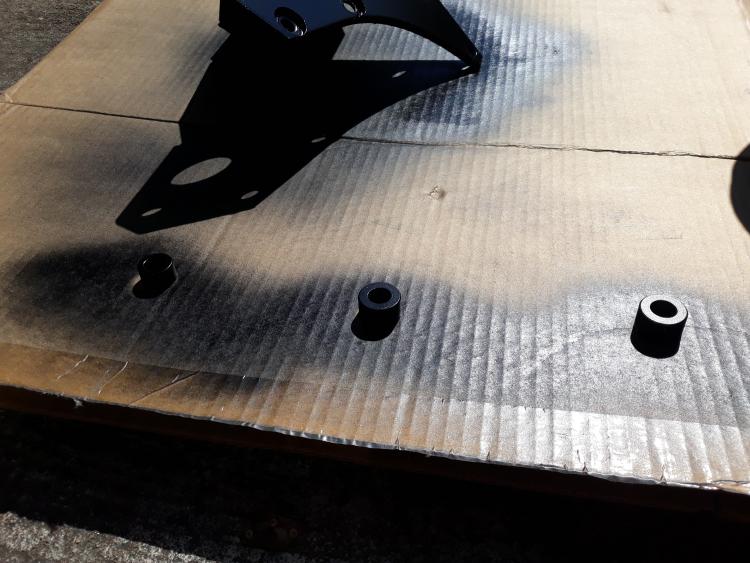

The parts washer washing away the paint and grime is helping to accelerate my cleaning, all I have to wirebrush is stubborn paint which is very little and wirebrush the rust out of the metal. The penetrating oil I am only spraying on steel parts to prevent rust. Aluminum is getting nothing but carb cleaner sprayed on them to clean them as the chemicals in the parts washer will turn the aluminum black from oxidation which I dont want. I thought about powder coating but started thinking it would make it harder for touch ups down the road. Plus I learned powder coating chips fairly easy just like paint. I did find black paint on all the parts for the dealer AC so it looks like even what I take to be cast steel parts were painted black as well. So only bare metal would be the cast iron alternator bracket that I have to repaint, the aluminum flex fan spacer, and the aluminum mount for the power steering pump. Dealer AC bracket before being tossed in the automated parts washer.  Dealer AC bracket after washing with cool water (parts washer heater gets the parts hot enough you cant hold them in your bare hand) and wire brushing the obvious rust. Might take more time and go over it again and maybe use a sanding disc to smooth out the weld splatter I found on the front side.  The flat adapter plate that bolts to the driverside cylinder head that bolts to the two back bolts on the AC compressor bracket. This is after the wash but before wire brushing.  Box of cleaned and uncleaned parts. AC compressor bracket, powersteering pump bracket, AC compressor bracket to head bracket, fan pulley, fan spacer, and dealer AC tensioner are all cleaned and ready for paint. I did not spray penetrating oil on the cast steel tensioner out of fear it may soak in too deep with its cast pattern. The AC adapter pulley still needs to be cleaned as well as the three spacers, the two equal length ones fit between the AC compressor bracket and the water pump bolts and the shorter one fits on the head for the bracket which I may not need with the AFR heads as they are flat smooth and the OE heads are recessed lightly.  And this is where I am at as of today when I left work, everything but the three spacers and AC pulley adapter have been cleaned. I am still unsure if I can make the compressor brace work with the further back mounting point and I will have to source a larger diameter washer to cover the larger hole since the mounting boss that I will have to use if it will clear the valve covers is a small 3/8" bolt. I thought about just not even having the brace since you have the compressor bracket mounted to the water pump and the head but this brace goes from intake to the top of the compressor I think its more for stabilizing the compressor since all that holds it is the four bolts on the bottom.  Yep that was always my goal, look stock sound stock for the most part and idle like stock. The 112* LSA should give a nice rumble to the exhaust but the engine should still idle stock smooth. The engine vacuum should still be between 15" and 18" at idle as well. Its also why I picked out the 6" round muffler like OE from magnaflow in their XL 3 chamber, just have to source a 2 1/2" inlet and outlet version as I have 2 1/4" as I had planned on running a replacement 2 1/4" tail pipe. I have since decided might as well just run it all 2 1/2" from the merger of the Y pipe straight out to the tail pipe. I asked jegs yesterday via chat if my order shipped from Manley for my pushrods and they told me that they havent got the tracking information from Manley yet but the customer service rep said he emailed Manley and will email me when he hears back. 24 hours later and nothing. If I dont see information on my pushrods shipping before midnight I will be flooding their customer service chat with inquires daily on my pushrods. 3 months have been long enough of a wait someone needs to light a fire and get me my product which jegs already took my $244.63 for the order back on Aug 5, 2020 which means it is becoming excessive for me to not have them after 3 months.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Good progress. And you are right, powder coating will chip, so it is easier to touch up paint.

And I like the plan to make it look stock but RUN! And I think it will. But it is a shame that it is taking so long to get the push rods. But I think you mean Aug 5, 2021. Surely the parts are from the US so they shouldn't be sitting on a ship. And I know that there is a shortage of drivers, but still... Hope you rattling cages will do some good.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Yep, I also didnt want to be sitting at a red light and having every kid with a mustang or honda wanting to race me every single day so I figured lets tone everything back make it run good pull hard but idle and sound fairly stock. August 5, 2021 is when I bought them correct, I keep hitting 0 in place of 1 since 2020 was so screwed up with the shut down it just doesnt feel like 2021 to me even here in November. They are from the US, the pushrods are Manley push rods its their swedged end 5/16" push rods with 0.120" wall thickness in 6.400" length. Its the length that Crane recommended for my camshaft in their catalog length wise, When I did the 1/2 lift method I was getting between 6.533" and 6.580" length which I would have to round down to 6.500" length or round up to 6.600" and when I set the pushrod to that length it put the resting position of the roller tip on the outboard side of the center of the valve which I did not like. The 6.400" puts the roller tip just barely inboard of the center line of the valve which I am more comfortable with. I hope so too and I hope the cam gear bolt doesnt pose me any issues down the road its the only thing in the back of my head but Ive never torqued them down so I dont think there is any real force on the bolt and I have blue locktite on the threads which should keep it from backing out.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

This post was updated on .

Finally got word this week pertaining to my pushrods that were supposed to ship on Nov 8, yesterday after a week Jegs finally informed me they are rescheduled to ship on Nov 15 so they were delayed for a third time.

The brackets and pulleys minus powersteering pump mount and the pulley have been stripped to bare metal and primered and painted. Will be painting the front side tomorrow as it takes 24 hours for the paint to cure fully so I can flip them over. I am not too impressed with the underhood black which I have never used before, it just looks too dull to me but it is supposed to be the correct OE low gloss formula 10-15% gloss. I also yesterday brought my headers to work to modify them to fit, I used the torch to heat cylinder 5 header tube in the area where it was hitting the cylinder head and then I used a large 2 lb sledge hammer and let the weight fall on the header tube after it was glowing red. I flattened the spot out enough to where I thought it would clear and sure enough my test fit shows that it fits with enough of an airgap that there shouldnt be an issue with radiant heat. Two photos of the spot that I flattened out. This flat spot did not collapse the tube enough to cause any adverse effect to exhaust flow I feel.   And a photo of the clearance with the felpro header gasket with two header bolts finger tight. Without the gasket there was enough gap to see light between the head and the header with the gasket once crushed down I do not believe it will close the gap up to that point.  So now I need to decide on what ceramic coating to get color wise and the ship them out to be coated. Once I get them back I can install them and tighten the bolts up as I plan on dropping the engine in with the headers on since they are no more than exhaust manifolds. I will have to post photos of the brackets and the pulleys later cause I may very well strip them down and re do them cause I am not fully happy with how they have came out but maybe they will come out better tomorrow when I spray the front side and recoat the back side with a second coat. I will post how everything came out with the 2K engine primer though.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Well, at least you have a date for them shipping. Hopefully they will.

On the headers, I don't think you've hurt them at all.  But before you ship them out do you still need to trim the bottom of the flange a bit where it hits the angle of the head? Show us some pics of the painted parts, although pics don't really tell much about gloss.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I took a 80grit cookie on my angle grinder and knocked the under side of the flange down then came back with a flat file and trued them all up to one another to be flat and level. Then I came back and filed a bevel into the back side they seem to clear the head just fine on the driverside. I need to mock up the passenger side see if they clear there too if not I can file them down a little more. This is what I have photo wise of the under hood black on the parts. Back side of the crank pulley, it appears there is grey primer bleeding through with the flash but considering I sprayed 3 heavy coats on it there should be none. But I am thinking of a way to suspend it so I can paint both sides with a heavy coat tomorrow to blend it all in.  This is the AC bracket back side and the back side of the AC crank pulley, I sprayed a second heavy coat on the AC bracket as it was the first I painted and I went a little thin I think as it had varying textures.  This one is hard to tell due to the flash but its the powersteering pump bracket, the AC compressor head bracket, the AC compressor brace, the AC compressor bracket spacers, the AC compressor bracket tensioner and the fan spacer. Everythign here was painted with Underhood black but the fan spacer which was painted with a heavy coat of aluma blast cast aluminum paint to bring back that fresh cast aluminum color and get away from that dull dark gray finish.  And a photo of the fan pulley, I was able to paint the back side then set the pulley on a spray can to paint the pulley groove and the face of the pulley so this pulley should be fully cured by tomorrow and may or may not get another coat depending on how it cures.  For me I am not real happy with how its coming out cause its either change in textures where I touched the part to flip it to primer the other side such as with the back side of the powersteering pump bracket or the paint is just not providing a smooth sheen and part of me also thinks the sheen is way too little. I know its supposed to replicate the OE finish of 10% - 15% gloss but even the OE would reflect a little and this paint only attempts to do that when you put a super heavy wet coat down on the verge of running.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Sounds like you have the header flange trimmed nicely, at least on one side.

And the Alumablast looks really good. But I can't tell about the black. Just no way to take a pic of black and get the gloss to look right. Good luck.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Yep the black just doesnt photograph well unless you can get it in natural sunlight. I ran out of sunlight when the paint was dry enough to move it so I hope to get it coated tomorrow and get some good photos of it in natural light then go from there. I just have to pull the kitchen sink apart tomorrow to pull out the disposal and replace it with just a plain drain and then find out why hot and cold water has just lost volume. Right now how ever I am in photo shop starting to work on a driverside and passengerside photo recoloring my headers in the Zirconia color of ceramic coating to see if I really want to go with that. Part of me is leaning away from black as it will just be too much black and blue on this engine and need to throw in a different color. Would love to just send to Jet Hot and let them do it but they estimated some $400 to coat my headers where I can get these coated locally for under $300. Like wise the local shop I am mailing them to they if I remember right said they check the welds and make repairs if necessary before coating. Jet Hot told me they do no repairs all they will do is coat what I send in and if there is a leak too bad.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Painted the front side of the brackets and pulleys and things came out a bit better, I may how ever go back over the AC crank pulley again cause it was hard trying to get black paint on the inside of the four ribs that connects the pulley to the pulley mounting base.

All the pieces I repainted today in underhood black  Water pump pulley in natural sunlight to show off the 10% - 15% low gloss sheen.   Flex fan spacer in natural sunlight   Flex fan spacer atop water pump pulley  AC Compressor bracket   AC Compressor head bracket to main bracket and Powersteering pump bracket  Powersteering pump bracket  Crank pulley   AC Crank pulley  AC Bracket spacers two equal size one thinner. Two equal size ones goes on the water pump and the thinner one off sets the uneven head surface for the rear compressor bracket plate. I shouldnt have to use that spacer but painted it anyways.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

| Edit this page |