Fuel Injection upgrade

|

Did a little work today, had to order more fasteners cause ARP just doesnt know how to make packaged sets.

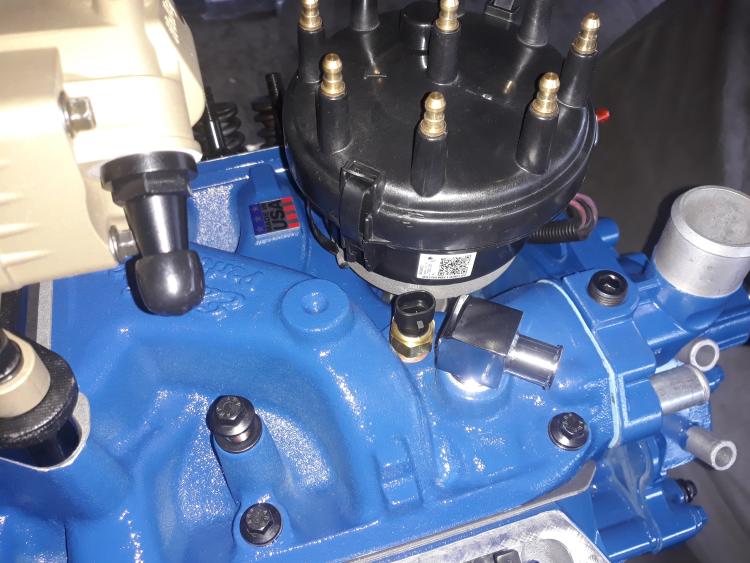

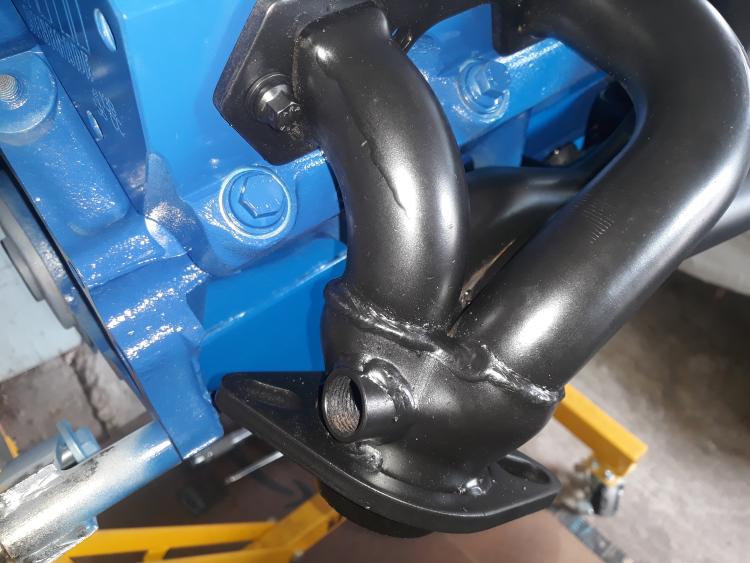

First off I installed the thermostat housing with the Motorad Failproof 195*F thermostat but only one bolt is loosely holding it in place, the ARP thermostat bolt set came with 2 bolts both the same length and one of them needs to be 1 1/2" in under head length which will be around 1 7/16" under head length with the washer. The set only came with 1" bolts strangely, I got another set ordered from summit. Only people to have them in stock so it was $12.99 for the 5 pack of fasteners and $11.99 with the shipping which is insane but what can I say, I usually buy when its over $100 to get free shipping but Summit just doesnt have anything else I need. They dont have a HD flexplate for my C6, they dont have any OE dipstick tubes, they dont have any OE block plates, they did have OE style coil strap mounts but they dont have the extra metal piece for the capacitor to bolt to. I plan on keeping all the capacitors I can to ensure I dont get any kind of interference on my sniper. I also mocked up the new distributor to make sure the sniper temp sensor will fit properly and its close but it should work. I also found out for some reason the distributor wont fully seat. I think it has to do with the drive shaft for the oil pump, if I rotate the rotor out of where it needs to be I can tap it with a adjustable hammer to almost fully seat but still doesnt. I think the clamp may pull it the rest of the way down. But I dont want to do this as I still have to send the distributor out to have the thing recurved. I got the motor mounts bolted up to the engine as well, I got the top of the line brand wise and I am glad I did, they cost me some $7.99 a piece and they have got to be the best looking mounts. They were packaged in each box with two puff bags of air for packing. The black paint on them was nice and shiny almost show car quality. I ended up getting the ARP engine mount bolts to 45 ft lbs and left it there. Lots of people swear those 7/16" coarse threaded bolts should be at 50 ft lbs min but I just couldnt get it there and said screw it. That bolt isnt going anywhere at 45 ft lbs. I also mocked up the headers as well to see fitment and if the black paint looks good to help decide what color to ceramic coat the headers. Sad to say the header on the driver side wont fit. The tube for Cylinder 5 is smashed up against the cylinder head holding the flange off the head on the bottom side. I have two choices, I emailed Cradin Industires who will be doing my ceramic coating that is based out by Austin. I asked him if he has the ability to tweak the header tube as the tube nearer the collector side needs to be tweaked inward towards the other tubes and it should give me clearance. I am hopeful he is able to do the tweaking cause I am sure there wont be tube distortion. If he cant do it my only choice is to mark the header take it off and take it to work and heat it with a torch and ding it in with a ball peen hammer for shaping and a 2lb sledge hammer for striking. This I prefer not to do as it will collapse the tube on just that cylinder. Only other option besides this would be to try and source long tube headers that will fit and forgo the OE style exhaust and have a shop make the exhaust for me. I prefer not to do this as I just know I am going to get the cops called on me running as well as driving the truck to the exhaust shop. I do have some things on my list to resolve how ever. I need to find a OE throttle cable bracket, OE part number has been bringing up nothing on line including ebay. I also am still looking for the coil mounting strap I think its E1TZ-12043-A DY318 and I havent been able to find a hit on this either. Then there is the dipstick and tube assembly. Then I am waiting on someone to get back with me from the holley forum or from holley directly on what the inlet fitting size is that threads into the sniper 4150 stealth. The one that have is too long and gives me no room to bend a 90* to clear the ignition coil so I need to source shorter fittings. I also am trying to decide what clamps to use for my heater hose and bypass hose. Part of me wants to still use the spring clamps as they constantly get tighter as the rubber hose shrinks but I dont know if you can get to them on the bypass without pulling everything else off the engine. Im trying to think long term service and if I ever have to replace this bypass hose I wouldnt want to have to strip the whole front of the engine down to get to the clamps. I think conventional screw clamps would probably be the best. Then there is the problem with what brand to get cause lots of screw clamps today are junk and strip out easily. Now for the photos. This is the Cardone brand new distributor that is for the DSII foxbody mustang with the roller cam. This is the one I will be sending out to have recurved. I have a NOS blue cap adapter and I will have to modify the harness on the new distributor to make the NOS cap fit. I am not sure if I want to do that I am thinking about instead trying to match the type of blue in paint form and just painting the cap adapter blue or just simply leave it black. After all if I go with full timing control later on the holley distributor is a small cap distributor that is all black with a billet silver housing.  Showing how close the Sniper temp sensor is to the distributor. Hopefully the distributor doesnt introduce RFI into the coolant temp sensor circuit.  And the header mocked up which has me deciding to go with the black ceramic coat.  And where tube for cylinder 5 is smashed against the cylinder head but can see there is a good gap where this tube can be moved towards the cylinder 6 tube and should get me clearance. This is without gaskets mounted so the gaskets will give me a little but not enough to resolve that.  And the passenger side where the tubes are a mile away from the head. I dont know why the made the driver side tubes so close. Its not like the gear box sits there the gear box is more forward.  Up side is that all the spark plugs are easily accessible and the Ford Motorsport 9mm plug wires I have will fit nicely without burning on the headers. Now I just have to wait for the bolt I need for the thermostat to come in so I can bolt that on fully, need to decide on hose clamps and order some so I can install the bypass hose. Next sunday on the 31st I should have a notification of my pushrods shipping from manley so first week of November I should be installing them and setting lifter preload and doing a pressure check of the oil system as well as checking for proper lubrication on every pushrod. I think 2 quarts of break in oil should be enough for this pressure testing of the lubrication system. It will help keep the weight down as I plan on stabbing the engine complete minus accessory brackets and pulleys.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Wow! That was a "mouthful"! But you are making progress working out all the details.

The issue with the distributor would bother me. It should drop down fully, and if you pull it down with the clamp you may cause a problem. I assume you've rotated the engine? I've seen them refuse to drop down until the engine was turned. And I think you will have to heat the #5 exhaust tube and bend it. How would the other guy know how much to bend it? On the color, black radiates the most heat possible. I chose the lightest color I could get to keep the heat in the pipes, and to prevent heating under the hood as much as possible.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

See thats the thing, even when I rotate the rotor and get it where it falls on the oil pump drive shaft it doesnt easily drop all the way down. I have to tap it down and tap it up to get it off I dont know if its fitting tight on the block if I need to go over it with a knife if there might be paint on the block but I already went over it with a knife some and it made no difference. The only thing I need to check tomorrow is make sure this is a 302 distributor and not a 351W. cause when tapping it down it starts to go all the way but then it stops before resting fully on the block. I dont know if the shaft is in a bind there or not as I have no way of turning the engine by hand till I get the crank bolt installed. Thats why I wont be sending this distributor out till it fits like it should. I may dig out my old distributor that I replaced in my truck and see how it fits on this block. Could be a defeat in the dorman distributor which would be a pain for me but I could just buy another one and if it works then send this one back claiming its defective and I just ended up buying local and get a refund. Thats the thing if I have him do the bending I would just have him bend the pipe as much as he can to get clearance. If I do it, it would be a multi day process as I would have to take it to work and do a little bending then bring it back home and test it then take it back the next day for more fitting. But that is the least of my worries as of right now my main focus is this distributor issue as well as trying to source new parts for other areas. I did find Bronco Graveyard has a 86 - 88 302 dipstick tube in stock but its not the same as the one I am looking for and I dont even know what the difference would be. Might just pull my dipstick out and clean it up and use it. I dont think a lot of oil will spray out of the dipstick tube opening in the little bit of running I will do to move the truck into place to pull the engine. On the color would it really make that big of a difference? I know black will absorb solar radiation such as heat from the sun but would it really expel heat from with in the header outward when the ceramic is insulating the metal? ~Update~ Reading online lots of people are saying if the drive shaft is laying to the side you wont be able to get the distributor to fully seat. Mine is laying to the side so I guess that is what my problem is. They say that the clip to keep the shaft from pulling out is supposed to keep it centered in the opening. I dont see how but I did pull the clip down slightly cause it was smashed up against the block and I was concerned about it putting shavings in the oil. Looks like I should have left it alone cause I screwed myself over now I have to get some thick grease to prop the shaft more in the middle to get the distributor in. That is unless I want to disassemble the engine to pull the oil pump and move the clip back where it needs to be.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Took some measurements today, from the retaining washer to the flange the distributor gear rides on and from the flange to the mounting flange on the top side of the block. Found out there is no reason for the distributor to fully seat with free play. I reinstalled it and installed the bolt temporarily till I bring my 1/2 drive torque wrench home from work to do final bolt installation, I then rotated the engine with slight pressure on the distributor and it sucked down and fully seated with no problem. Removal how ever required tapping the bottom of the distributor.

I think the tightness is the distributor gear is dry as I didnt want to oil or grease it since its going to be sent out for recurving the distributor. I also have no grease or oil on the gear on the cam so I think its binding since both are new and havent worn in and polished to be a nice slip fit. I do need to order another small tube of the Driven assembly grease cause the one I ordered I cant find. I will apply it to the cam gear before installing the distributor via a flat blade screw driver and rotating the engine and I will do the same to the distributor gear. Currently I have the distributor sitting in the block just to keep the opening covered but I did play around and get the rotor to point at the number one terminal with the balancer set to 12* btdc which is where I want to set initial timing if the tuner can get a total of 32* - 36* I think it was total timing with 12* initial. I dont want too much initial as I havent fully decided if I want to run a PMGR starter or just go back with the OE starter. 9.45:1 compression should not require a PMGR starter in my opinion.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

It won't require a PMGR starter, but it sure would benefit from one. However if you already have a good starter then that'll save some money.

Anyway, glad the dizzy slipped down nicely. That makes you feel much better.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Rusty_S85

Hey Rusty, If it's any help, when I had the engine shop build my 302, I paid extra to have a dyno day with it for break-in and tuning. When all was said and done, we had the ignition set at 12* initial, and 20* mechanical, for a total of 32 obviously. A couple points here...the engine builder said that he really didn't like going over 32* long term, but we tried 32, 33, 34, etc...and it made the best power numbers at 32 degrees. Now, I have to mention that this shop does mostly Chevy's, so they weren't necessarily Ford experts. Later on, I pulled that distributor and ordered a new custom curved unit from Parkland Performance. I gave him my engine specs, and what he came back with was 15* initial, 17* mechanical, and 17* vacuum advance. Funny, I didn't tell him what I had done on the dyno day, but he selected 32* for the best performance. The engine worked the very best with his distributor, and I even ran it with 16* initial for a while too. Starts were crisp, as was the low end power and response. The only reason I'm mentioning all of this, is that my 35 year old OE starter worked just fine, even at the 16* initial timing. The engine started like it was EFI. Mind you, that was with 9.0:1 compression, so a little less than yours. The only time I ever did have an issue with starting was when I installed a new "Ford Motorcraft" DSII IGN module from Amazon, and later determined that it did not have the retard during start function. Once I reinstalled the 35 year old OE DSII module, all starts were fine again. In any case, good luck with it! 32 degrees seems to be the target number, at least from two sources that I worked with.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

It does, now I can sit back and wait for my pushrods to ship next Sunday. In the mean time I ordered a pair of -6AN O ring fittings to -6 AN to get rid of the long AN fittings installed in the throttle body. I was going to buy the steel ones since I will be running stainless steel line but the steel fittings had some kind of weird gold coating on them that I didnt care for. Hopefully the black aluminum fittings wont deform being used with stainless steel hardline. I might upgrade the starter later on when this starter I currently have stops working but its been on the truck since Ive had it and I think its original from '82. I didnt get specifics from Parkland Performance from my emails back in 2019 but he did say the Cardone new distributor I have isnt a bad unit but it would require welding up the advance plate and recutting to get the advance to around 32 degrees. I think my 351W in my '78 Mercury is 12* initial and I bumped it up to 14* initial. I probably could run 14* initial but I am just wondering would I really notice that much improvement with 14* initial over 12* initial. The cam has a 107* intake center line which from everyone I have talked with said it should make the throttle very snappy and responsive down low. I guess its something I need to discuss with Parkland Performance when I go to ship my distributor to him. I still need to have it on hand to custom bend my hardline for the fuel injection before I box it up and contact Parkland Performance to find out the turn around time and give him the most accurate specs I have to date and what he thinks on initial and mechanical advance and what vacuum advance does he believe I should be shooting for under cruise.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Talked with the engine builder I know after work to see if he knew of any exhaust shop that could tweak header tubes. He gave me an idea I hadnt thought of, he said to find some tubing cut it in half so it will fit around the tube then heat the tube up and use the half cut tubing to hit with a hammer which should spread the force out and shift the whole tube vs dinging the header.

Once I found that out I decided to browse exhaust cause the Flowmaster Y pipe I will be using is a 2 1/2" pipe and I decided that I will not use my 2 1/4" Magnaflow 6" round offset chambered muffler and decided I will get the 2 1/2" version I found that is the same exact dimensions just a 1/4" bigger inlet and outlet. Problem is though that is a part number 13646 which is listed as not in stock with Magnaflow themselves, summit lists it as out of stock with no date nor pre order listed, I found one site listed it as discontinued but I found two places that has it listed to buy, one is some 4wd shop I never bought from and the other is from Speedway which we have bought from at work so I would buy from there. $100 for the muffler which isnt bad but its listed as shipping from the manufacturer estimated on or before November 17. I hate to spend the $100 on this and be waiting on the muffler when I could have used the $100 else where on my build and wait till all this supply issues get straightened out and hope that Magnaflow still plans on making that 6" round case 3 chamber muffler. So between the Y pipe and the muffler I am looking at $511.95 but the converter that I wont be using from the Flowmaster pipe I should be able to sell to a scrap yard for the converter material and maybe recoup $100 or $200 on it. I will be plugging the O2 port in the header as talking with others on the Sniper Forum and they agree with me that the O2 port in the header is way too close on this design and would not get a good balanced reading. Question becomes now where to place the O2 sensor if not in the header where the header designer placed it. One helpful guy on the forum said he would drill and weld a O2 bung in the down pipe before the Y and cross over tube at 4 inches below the ball and socket collector flange. I would have to how ever look at my truck and see about where I can put it on the pipe and I will take it to an exhaust shop to do because I dont have the equipment to weld stainless steel. With this exhaust setup I intend to run 2 1/2" straight pipe to the 2 1/2" Magnaflow muffler if they didnt discontinue it and I can still get it. Only thing I would have to do is either take the truck and the OE tail pipe I have to an exhaust shop tell them to make a 2 1/2" stainless tail pipe if possible in the OE shape and cut off the OE hanger off the 2 1/4" tail pipe and weld it on the 2 1/2" tail pipe. Or I could buy the Flowmaster multi piece tail pipe set in 2 1/2" and just piece it together myself but I just am not crazy about the angle of the pipe that kicks out to the side. The OE pipe came out at a 90 to the side behind the rear tire. Other choice is to go back the same way I have the truck now and forgo the tail pipe and just put a 2 1/2" turn down on the muffler. I prefer not to do this since I want a OE look for everything hence the spending of money on a round muffler in the same dimensions as the OE muffler. Just something I been looking at tonight to get my mind off trying to find tubing that will have a ID similar to the 1 1/2" primaries so I can get a good fit to shape the header. I also am trying to decide to I send the headers off to the guy I plan to which only has black, silver, and zirconia ceramic coatings or do I just go with Jet Hot and pay their price get the life time warranty and have more color options which I would want to go with the off road coating for the 2000*F coating and color wise if I go with Jet Hot would be between Titanium, Graphite, Satin Black, or maybe white but I dont think I want to go white as I am building a street truck not a 50's 60's hotrod.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Rusty, the O2 sensor location on the later OBDI trucks is back behind the Y, just before the cat. I am using that location on Darth for my wideband sensor. I have the control sensors in each downpipe from my manifolds as my OBDII system uses one for each bank allowing it to tweak the injectors more precisely.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Correct, on a factory fuel injection system and if I had one that is what I would do as well. Holley like FiTech isnt capable of reading both banks with individual sensors and they state to place the sensor so many inches from the collector which means they want the single sensor to read just one bank. Not sure if there would be an adverse effect moving the sensor to read both banks but from my understanding the father you get from the collector the more lag time you have for adjustments and the closer you are the less lag time you have for adjustments but too close and the heat kills the O2 sensors so you have to find a good compromise between lag time and not getting too hot. I dont know how hot my headers will have the exhaust at the O2 sensor location in the collector but considering I will be doing highway driving quite a bit at 75 mph @ 2,750 rpm ideally that could kill the O2 sensor as well.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

My O2 bungs are in the reducers or adapters that connect the headers to the exhaust pipes. Right now I'm only using one and it is for the wide-band AFR meter. But when I put the EEC-IV EFI system on I'll use those for the EFI system and have to add one downstream for the AFR meter.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Mine is positioned here which I am going to plug with a O2 sensor plug.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

That is CLOSE!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

lol Yep thats why I was worried about it cause you have the pipes for cylinder 3 and 4 pointed right at the sensor and because the sensor is so close cylinders 1 and 2 wont be blowing exhaust across the sensor. I have a few O2 sensor plugs I will just send the headers out to ceramic coat after I clearance the headers to fit then I will plug the header. Then when I get the Y pipe from Flowmaster I will plug the one in the cross over pipe in the Y and mark it and take it to a local exhaust shop to weld a bung in on the stainless pipe.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Gary Lewis

Probably designed for a non-heated O2 sensor. The one on my feedback carbed 300 is also right at the collector. The idea was by putting the sensor there it would get enough heat from the exhaust to function.

I since redid mine to use a heated O2 sensor (rerouted the O2 grounding wire, bonded to heater ground at the connector, and ran heater power and ground wires to the existing EEC power circuit) so I could move it if I wanted to... but no need; it works fine as-is (all the heated O2 does is get me into closed loop faster and provide an easier to obtain sensor).

1984 F150: 300 L6, AOD, RWD. EEC IV / TFI, Feedback Carter YFA Carb. Stock everything but radio (for now).

|

It very well could be cause these headers are 1986 - 1996 fitment. Should work perfectly fine on my '82 as the part number for Y pipes were the same up to 1986 in the parts and illustration guide. If they fit just fine in the end then these headers would be a great bolt in for people that want a little more performance but dont want to go full length header.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Not progress to report as of today. I did get my 1 1/2" long ARP bolts in to tighten up the thermostat housing and I got that done. But I havent done anything else as the stainless steel AN tube nut and sleeves I ordered last Wed which should have been thrown in a mailer due to how small wont be delivered till Monday. The pushrods I ordered August 5, 2021 have not been shipped as of today and today was the listed day it should ship, on Jegs site it is now listing Nov 8 as the ship date on the product page which I need to check with them tomorrow if the ship date has been pushed back cause this is starting to bother me and there is no other option for me to use in another brand to get it sooner. I might have to start calling them daily till they get this straightened out for me cause I think I have been understanding for well more than I should seeing as Nov 5 will be the start of 3 months waiting and that is unacceptable for something as simple as a set of pushrods. You cant tell me that the economy got so screwed up that people in their time off bought up all the pushrods and that something as oddball as a 5/16" x 6.400" pushrod with a swedged tip and 0.120" wall thickness is completely out of stock.

Aside from that the fittings I bought for the sniper were wrong, they were -6 straight cut O ring to -6 male AN, what I need is a -8 straight cut O ring to a -6 male AN which I have on order and should get it from Summit Tuesday. I also ordered a Hays HD SFI 29.1 flexplate for my build, 164-tooth (correct tooth count for a sbf C6 truck), 50 oz external imbalance. The flexplate is 14.240" diameter with a 1.750 center bore register diameter and a 11.50" converter bolt pattern. Strangely enough Summit states this flexplate in the fitment page cites it as fitting 82 - 95 302 small block windsors with a AOD, AODE, or C4. No mention of a C6 fitment, I double checked Hughes XTM converter as thats what I will be using on my truck with the new C6 it lists the F43XTM as having a 11.50" converter bolt pattern and a 1.375" converter pilot. Jegs as well as holley states this flex plate will fit with no mention of transmission. So I have this flex plate on order and should be here tuesday as well. Only thing that wont be in till November 15th is my -6AN male tee with a 1/8" pipe pressure port in the tee itself. I have a pressure port take off which I was going to use with my carb setup but now going sniper stealth I didnt want to have an extra fitting when I can just use a tee with the pressure port made into it. So I dont know when I will get started on making some real progress on my engine build. Dont know when my pushrods will ship cause there is no estimate on my order page on Jegs, I have to wait till later on in November to get my tee so I can start making the fuel injection lines, I still have to pull brackets off my old engine so I can clean them up and paint them I need to also figure out exactly what size the large bolt in the front of the head is I suspect it is 7/16" cause I need to buy a new bolt for my alternator bracket. I also have to decide if I want to leave it in the Eastwoods Zinc Phosphate which is a charcoal greyish color not to be confused with a cast iron grey or if I should scuff it up and shoot it with some low gloss under hood black. I know the steel brackets for the AC compressor and the steel support bracket for the powersteering pump will be paint black as they are steel. I also saw a post the other day about this one guy not having the head bolt in his AFR 185 heads for his ford powersteering pump pivot bolt. That is something I am afraid of myself right now as AFR states it has all the OE mounting points on the heads to accept factory brackets. I dont know if the guy is using a obsolete bracket from the early 60s and AFR is using later model bracket mounts but I know my alternator/airpump bracket lines up with the three bolts in the passenger head.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Rusty, the one who posted about not having the pivot bolt hole for the power steering. You may be correct in the thought he has an earlier pump mount. Ford had some interesting accesory brackets in the 80s. Each head had a "universal" bracket, oval shaped on the passenger side and similar with no AC on the driver side. With AC the compressor mount had two threaded holes for the power steering pump as it wasn't a direct match to the holes. The upper hole was used on 302s, lower on 351s, on the passenger side, oval bracket went threaded hole up on a 302, down on a 351. This way the accesories were in the same location relative to the crank and water pump so the stamped plates for alternator and power steering pump were the same along with the drive belts.

An FYI, any stamped brackets are steel, cast ones are grey iron unless aluminum. Thankfully the front dress on the EFI 460s all the cast brackets are aluminum, not iron. The alternator/air pump mount on Darth was a huge chunk of cast iron.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

This post was updated on .

Why I want to double check mine to make sure but it should be the same cause the accessory bolts on the front of the heads look similar to that of the OE mountings. Right, on the material and I know they wouldnt have painted the cast iron they would have left them natural color just like the cast aluminum would have been left natural. The color I have my alternator bracket which is cast iron painted now looks some what like cast iron just a bit darker, but since I am going to be buying the black paint most likely from east wood for the stamped steel plates for the ac compressor and powersteering pump to paint them black as well as the pullies Im thinking about getting their cast aluminum and cast iron paint color as well. The add on pulley to the crank that bolts on to add the dealer AC option to my truck looks to be cast iron in its rough texture not stamped steel like the regular pulley so I am tempted to paint that one cast iron as well. I will be mounting hopefully the alternator bracket this weekend if I can get the bolts ordered for it then I can post a photo to see if I should just leave it the zinc phosphate color or respray it in the cast iron gray color. ~Update~ I dont know if anyone ever bought from Allens Fasteners but I came across them when trying to find a 7/16-14 x 1" bolt for the OE alternator bracket to the cylinder head. ARP doesnt offer one on their site unless its custom order and Summit has no listing but Allens Fasteners has ARP bolts individually in that size so I purchased from him the following fasteners x2) 3/8-16 x 1" hex x4) 7/16-14 x 1" hex x4) 7/16" x 0.660" OD x 0.120" thick washer w/chamfer x4) 3/8" x 0.625" OD x 0.063" thick washer w/ chamfer so 6 bolts and 8 washers, which is 1 bolt and 3 washers more than a standard ARP package which goes for $25.00, the base price was $23.32 and I got hit for $9.45 USPS Priority shipping bringing my total to $32.77. I will post a little review on here if the company seems to be legit and is quality. I will also update my initial post if I can after all this time and add their link to where I would start getting my fasteners for since they are cheaper than through summit or amazon.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Hedman finally emailed me today during lunch. The reply I got was asking me what heads do I have then with a statement that the Hedman headers are set up for stock heads and wont clear aftermarket heads. I replied to the email to state that I have AFR Renegade 165cc street heads which are a stock patterned aftermarket head that accepts all factory components outside of emissions on my specific model. I even checked Hedmans website and it states on my headers that the headers fit Stock Profile Heads which is what mine is.

I havent gotten a reply back probably tomorrow but I did email AFR asking them if stock manifolds/headers will fit as I am being told the Hedman street headers only fit stock heads. Something else I need to look into is the ledge at the bottom of the heads below each exhaust port. The headers I have is fitting snug against these ledges and it seems many people in the early 2000s had that issue with other brand of headers and the quick and dirty fix is to cut off the bottom of the flange for clearance. Im tempted to try this as I dont have the gaskets installed but many state with gaskets the flange will fit properly.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

| Edit this page |