Fuel Injection upgrade

Hopefully, it all depends on how quick Ed at FlowTech Industries send the order over to Manton but I should have them before April which is when Manley told me would be the earliest they would get material in to start making pushrods. If it works out like I am hoping then next weekend I will be bringing home from work a oil pressure tester threading it into my oil pressure sender extension and add a quart of motor oil to the crank case and then spin the oil pump over and prime the system and pump up the lifters.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Gary Lewis

Just wanted to say, your fuel line work is great, I feel inspired by it and I will try my hand at something similar later this year.

Love following your project.

1985.5 F-150 XL Explorer standard cab 5.0 EFI AOD 4x4

Daily Driver. We call her Eunice the Ute. 1982 Bronco XLT Lariat 351W AOD 4x4 Code name Esperanza, or Espy to her friends. Please see my Project thread for the blow by blow. 1984 F-350 XL Centurion crew cab 460 T19 4x4 "Eylza Dual-little" |

Thanks, big reason why I decided to start documenting this project, give people ideas for trying something different than going OE stock always. It also to help show the proper right way of doing some of these systems, such as the fuel tank that I am going to have fun cutting open and figuring out how I want to weld in some baffling so I can avoid using the OE dual pump setup Ford ran on the stock fuel injection systems. I also keep throwing around the idea of cutting one end off and adding 3" of material to the length or cut both ends off and adding 1 1/2" of material on both ends. If my math is right adding just 3" of material on the front of a 16 gallon fuel tank will increase the capacity to nearly 25 gallons. Splitting the difference between the shorter height front and taller height rear would be closer to 27 gallons. Id love to do this project but I am not sure if the extra weight would cause a problem with how the truck sits from side to side nor if it would cause a problem with the mounting straps in how they are spaced for the extra weight the tank would end up weighing. Aside from that, my pushrods were shipped today and I should have them via FedEx by Thursday. Now the fun part of getting Jegs to cancel the order with Manley and refund my money. The customer service rep via Jegs chat informed me they emailed Manley to request a cancel and once Manley emails them back it will be 3 days till the money is back in my account. I informed the guy to call them not email them as they dont respond to emails, I grabbed screen shots of the entire chat between me and customer support cause I clearly stated to him I hate to have to bring PayPal in on this to get my money back on an order I am requesting to be canceled this friday. One way or another I am getting the order canceled by Friday either through jegs or through Paypal.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Pushrods arrived thursday and they were exactly what I needed. I spent almost 4hrs today adjusting the guide plates, cleaning and lubing the push rods and setting valve lash as well as testing oil pressure and checking for all pushrods oiling. Have some issues I am kind of concerned about but will have to wait and see when the engine is installed and running.

First off the pushrods are made by Manton is what I was told and they are 6.400" length which is just perfect with 1 turn on the poly locks (7/16-20 rocker arm studs 1/2 turn = 0.025" 1 turn = 0.050"). Only issue I had is with the oiling. I tried rotating the engine and tried spinning the oil pump in different positions but intake pushrod on cylinder #5 just was pouring oil out of it and filling the head forcing me to stop before I could see if the other pushrods would start oiling. I think they are trying to oil cause I do have oil collecting in the passenger side head but the AFR rails are so low I just couldnt sit there and spin the pump up. So I installed the valve covers and spun the pump up full speed and built full oil pressure up but after a moment oil pressure started to drop and I could hear snapping of air bubbles inside the engine. I would have thought 3 quarts would have been well over enough to spin the oil pump so I am praying this pump isnt a high volume pump when its supposed to be a standard volume pump with a high pressure bypass spring. Needless to say my battery powered drill was able to get the oil pump to put out 70 psi before it started to drop down to 60 - 65 psi with the snaping of air bubbles telling me I was sucking air with the OE pickup. I think everything is good I just hope I dont have any lifter problems considering I have one pumping lots of oil out even at low speed and the others I just couldnt get nothing to come out of but a little. I hope its just a side effect of the engine not spinning at the same time. First two sets of photos are showing the oil build up in the heads from spinning the oil pump. Driverside has one that is pumping so much it is filling the head up so quick it is flowing over the valve cover rail which kept me from sitting there and spinning the pump steadily to see what happens.   Next two photos are showing the valve covers installed with the Mildon oil separator breather cap complete with hose barb fitting for me to connect to the OE PVC filter in the air cleaner.   Final photo is of the zinc plated steel 3/8" line clamp with 3/8" mounting hole installed holding the engine fuel line to the timing cover.  Seeing the complete assembly I am back leaning towards having my headers ceramic coated black. I thought doing them in black would be too much black but I think it will be fine. Im also happy to see with 10w40 break in oil I was able to get 70 psi oil pressure with an battery powered drill, the engine should be capable of producing 70 psi oil pressure at idle when cold and hopefully it works like it does on my 351W in my '78 Mercury which idles around 75 psi cold and 55 psi hot with 10w30. Only thing left now is to send the headers out for ceramic coating, send distributor out for recurving, and cleaning up some minor brackets here and there such as coil bracket and throttle cable bracket. Need to then get the 3/8" stainless fuel line for the frame, the swb metal fuel tank so I can weld in some baffles around the sump, a 85-86 sending unit assembly, a Walbro 255 lph electric fuel pump, the 18way fuse/relay block to wire everything up and the 3G alternator which I am still flip flopping between the 95A and 130A version. I do have the voltage regulator with the soft start function but not sure if the 130A one is backwards compatible with the 95A model. I think that would have me set for completing my conversion and installation.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

I think your oiling problems are due to the engine not spinning. But the oil pressure looks good.

Man, this has been a long time coming, but you are getting there.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I think it is a combination of lack of spinning and the fact I only poured 3 quarts of oil in. I still have to install the engine and I dont know if I want all the extra weight of 6 quarts worth of oil. I know the FL1A filter will hold right around 1 quart once it is pressurized. Might be why cylinder 5 intake is oiling so good is its right above the oil passage for the oil pump into the block. Might be losing oil and sucking air cause I know even with 3 quarts added the intake pushrod for cylinder 5 has good oil volume but there is also a lot of air bubbles as well. I am just glad I am going to have good oil pressure finally, with 70 psi achieved with my drill then my OE oil pressure gauge should be on the high side of normal vs with my current engine being on N and O of normal. It has been a long time, I didnt realize I started collecting these parts way back in 2018 to do this build it doesnt feel like that long but I am in the final stretch for the engine stage. Once I get the engine stage done I hope to be able to drive the truck in the mean time till I can get my credit card and paypal credit paid off then I will order a custom built C6 transmission and a Hughe XTM tow converter to swap my old worn out C6 with. Then all that is left for me is to rebuild my rear end with a Currie tru trak 3.25:1 9" third member to complete the package. From there its just body work/paint, wood bed, and interior which I dont know on the interior, part of me wants to gut the whole interior pull the dash and everything out and start with a empty interior then rebuild with new firewall pad and a new rubber floor mat. But I dread doing something like that with how broken up parts of my plastic dash is plus the dealer installed AC unit mounts to the dash itself not the firewall.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Got a little ahead of myself, I went from engine to exterior/interior today. I found last night that Green Sales had some parts I was looking at including a NOS oil dipstick tube which sadly was out of stock now. But he did have two of the other items I called about, one was the NOS black with silver burst center seat belt assembly which he let go for $60 that I snagged up so now all I need is to source a NOS passengerside seat belt assembly and I will have all three new. The other item I snagged was the complete passengerside pinstrip kit for the Type 6 pinstrip for my '82 in the correct dark/medium blue for $150. My plan is not to install it but to use it as a pattern for the eventual paintshop trip so they can mask the truck off properly and color match the paint to the NOS pinstriping to spray it on both sides. The tail gate wont be hard its just a simple box. The only other hard part is going to be the Type 1 cab roof pinstriping for the two tone roof. That part number sadly is not bringing up any hits but I will keep searching. I couldnt let that deal go as it was the first pinstriping kit I found for my truck that is supposed to be specifically for mine in the correct color.

Aside from that, I am seriously tempted to add the final 3 quarts of oil to my 302 on the stand and try pressure testing the system again to see if I keep getting air bubbles with in the engine.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Good job on finding those things. You have to keep searching at all times, and you never know when something will pop up.

As for the oil, I don't think you'll notice the weight of three more quarts. I'd put it in and test now while it is easier to correct any problems you might find.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Thats what I am thinking. I can always put some ARP thread sealer in place of the teflon on the NOS motorcraft sender since I already screwed it in place. I can also pull the valve covers and make sure all pushrods are oiling as well properly at risk of making a mess. On the parts I made a step back today. Green Sales contacted me this morning to inform me that they couldnt locate the center seat belt I ordered but they were able to locate a red one in the ware house if I absolutely needed the seat belt. I told him I didnt need it mine are functional I just wanted to replace them all with new when I restore the interior. So as of now I am only getting the passenger side pinstripe kit so my order is a good $60 cheaper which is always good.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

This post was updated on .

Couldnt do anything today, was cold and raining and wasnt going to go out in it.

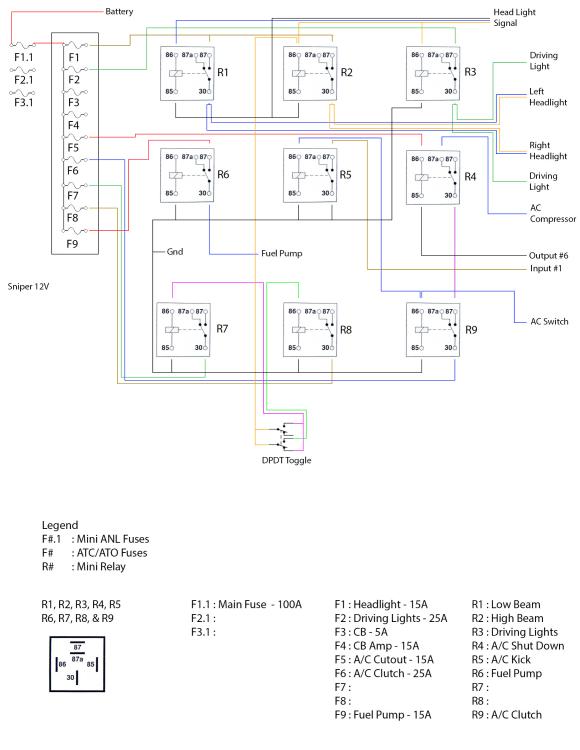

I did how ever get the auxiliary fuse/relay box that I ordered, will post some photos of it tomorrow. I didnt get any photos taken today as I have spent half a day figuring out what I need to get wire wise and so far below is what I have currently and need to get. Currently I have in my stash the following wire from Wiring Depot SXL Cross-Linked Wire, 16 AWG, 20ft cut, Blue SXL Cross-Linked Wire, 16 AWG, 20ft cut, Brown SXL Cross-Linked Wire, 16 AWG, 20ft cut, Green SXL Cross-Linked Wire, 16 AWG, 20ft cut, Black SXL Cross-Linked Wire, 14 AWG, 12ft Cut, Orange SXL Cross-Linked Wire, 20 AWG, 40ft cut, Green From my initial diagram I have colors listed but they are not the colors I decided on when I started buying this wire. With that said below is what I have listed for the non sniper related wiring circuits. Low Beam Trigger/Power : 18Ga/14Ga Blue High Beam Trigger/Power : 18Ga/14Ga Yellow Headlight Ground : 18Ga Black Headlight Power : 14Ga White Driving Light Power : 12Ga Green I think I decided to run 16 AWG for the trigger/power as I realized for the length of wire I would be using 16 AWG would be overkill for the relay trigger circuit as well as the power side to the headlights. I settled on 16 AWG for the power for the pair of 100w driving lights and the white wire which I think I will just use red wire, its supposed to be the wire inside the fuse box from the fuse to the battery side of the relay. The brown, orange and 20 AWG green I am unsure what I got them for. The orange wire I have marked for the power wire for the CB Amp and radio and I believe I got the 16 AWG brown for the choke wire as my initial schematics has me using a relay triggered by the alternator stator to send 12V battery power to the 12v choke on the Summit 600 cfm carb which I wont be using anymore so I will have to see if I can repurpose the 16 AWG brown wire I currently have for another circuit on my build. Below pertains to the sniper wiring. The 7 pin connector breaks down as follows. Pin E, 12G, Red : 12V Battery (+) Pin G, 12G, Black : 12V Battery (-) Pin C, 12G, Blue : 12V Fuel Pump (+) Pin A, 20G, Violet : Engine Speed Signal Input (+) Pin B, 20G, Dark Green : Engine Speed Signal (-) Pin D, 20G, Yellow : Coil (-) Input Pin F, 20G, Pink : Switched Ignition (+12v) I am looking at sourcing the following wires 122XF : SXL Cross-Linked, 12 AWG Red 120XF : SXL Cross-Linked, 12 AWG Black 126XF : SXL Cross-Linked, 12 AWG Blue 197XF : SXL Cross-Linked, 20 AWG Yellow 193XF : SXL Cross-Linked, 20 AWG Pink For the 10 pin connector, it breaks down as follows Pin A, 20G, Orange : Input #1 (-) A/C Triggered Relay Pin B, 20G, Yellow : Input #2 (-) Programmable Ground Input Pin C, 20G, Light Blue : Output #1 (-) Fan #1 Relay trigger Pin D, 20G, Light Green : Output #2 (-) Fan #2 Relay Trigger Pin E, 20G, Grey, Output #6 (-) A/C Shutdown Relay Trigger Pin F, 20G, White, Points Output CD or Coil Driver trigger Pin G, 20G, Dark Brown, Tach Output Pin H, 20G, Tan, Digital Gauge Output I am looking at sourcing the following wires for this. 191XF : SXL Cross-Linked, 20 AWG Orange 190XF : SXL Cross-Linked, 20 AWG Black (replacement for the Holley Grey color) I really dont want to have duplicate colors but it appears I will have to run duplicate colors but thankfully they will be in different gauges so it still will allow me easy diagnosis down the road long as I keep a record of the wiring for wire colors and gauges. Below is the relay box diagram I created over the last couple years with changes.  My plan is to have leads coming out of the box end around 1 to 2 feet in a metri-pack connector. This will allow me to unplug the fuse/relay box for removal so I can service box at the work bench. It also will allow me to make changes if I decide to pull some fuses out and add another relay. It also will allow me to wire up relay 7 and relay 8 which will be for four auxiliary lights I might add down the road if I decide to add a roll bar on the truck in the bed. I can wire the relays up as well as the DPDT toggle and just simply leave those terminals plugged on the truck side of the harness connector. That way I can add those circuits on the truck itself down the road. For those that dont know what I am trying to do with the DPDT toggle switch is to provide the ability to link the roll bar lights to the driving light circuit. The switch I found is a On-Off-On and when in the Off position the roll bar lights will not be activated through the driving light relay. In Position 1 On setting it will allow the driving light relay to supply power to just Relay 7. In Position 2 On setting it will allow the driving light relay to supply power to both Relay 7 and Relay 8. Purpose of this is I am thinking about running two spot lights and two flood lights if I do install a roll bar. The spot lights will be in Position 1 which will help supplement my driving light for dark back country roads, the spot lights will be set to shine to the side of the road to illuminate any possible deer that may get missed by my regular driving lights which is triggered by my high beam circuit. Position 2 will throw on all the roll bar lights spot as well as flood and this Position 2 setting would be strictly off road only. I dont think I would want to use floods on the highway as many of the dark country roads Ive driven on has houses close to the road and the floods would be throwing light into their houses which I really dont want to do. If I think I will be possibly switching the DPDT toggle on the fly I will switch the circuit to the ground side of Relay 7 and 8 since there will be sparking inside the switch if switched while powered up. Relay 7 and 8 through the DPDT Toggle wouldnt receive power unless the high beam is switched on and it would be more of a set it and forget it type circuit. Relay 9 I wish I could figure out a way to remove that redundant A/C compressor relay since its a relay going through to another relay. But Relay 4 is the AC cut out relay and there is no way to take my AC switch and have it trigger a relay instead of triggering the clutch itself. Relay 4 is wired up on the normally closed 87a pin till the relay is activated so it might as well not even be there in majority of the driving conditions. Relay 1 and 2 I wish I could consolidate them into a single relay but I just cannot figure out a way to have low beam/high beam controlled by one relay. I thought about using the center 87a pin for low beam and have the high beam trigger the relay to switch to high but there would be no way to turn the low beam off as battery voltage would flow right through 87a pin constantly. I also am contemplating the fuses as well. Im thinking about isolating the fuses into two different circuits, the box has three locations for Mini ANL fuses, I could use two of these locations to fuse the main power wire to the two groupings of fuses just as a precaution so I dont lose everything if one fuse decides to go out. Im thinking one Mini ANL fuse to cover the fuses for important circuits, Headlight circuit and EFI circuit and then another mini ANL fuse to cover the fuses for minor circuits such as CB, CB amp, AC Compressor. But I am not sure, I wont start assembling the circuits in the box just yet now that I have the box in hand I will be playing around with it in my head to try and figure out how I want to do it. I do like how ever having all relay ground leg of the trigger circuit being linked together and then run out as one single ground. Will clean up having a bunch of ground wires coming out of the box for each relay. Same with the power, my idea is to bring power in to one Mini ANL fuse and then if I decide to run a second Mini ANL fuse to split the circuits to two main fuses I will run a jumper wire from before the first Mini ANL fuse to the second Mini ANL fuse, this way both circuits are still protected but with two fuses it allows one circuit to fail from drawing too much amp or a short but wont take out everything.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

And I thought I had long posts!

I assume that part of why you post all of that is to get down on "paper" what you are thinking. That is a big reason I post lots of stuff. Another is so I can go back to it later. And a third is if people have suggestions or questions, so here I go: Headlight Ground : 18Ga Black. Is this a ground to the relay or a ground to the headlight? If the headlight I'd go with at least 16 if not 14. Yes, the wire is probably only going to be a foot or so long, but I don't like feeding a device with a 14 and taking the same current to ground with an 18.Connectors: I like the idea of having connectors close to the box so you can take it out to change something. I wish I'd done that on the passenger's PDB on Big Blue as I did have to change something and it was a pain to do it in the truck.Future Use: And I like the idea of already wiring things up so you can use them later. You can wire the trigger circuits any which way external to the box, and take the power wherever you want as long as there's fused power to the relay and trigger and output wires come to the connector.Headlight Relays: I don't think there's a good way to run the headlights with just one relay. I spent a lot of time trying to come up with a way, and the only way I found was to have the low beams on whenever the key was on, which I didn't want.Fuses: How about having one set of fuses be always hot, another set switched-power, and a third set for lighting that is powered by the headlight relay? That might make it easier to wire to the relays, and having the fuses for the lights powered from the headlight relay would mean you could blow the fuse to the floods or the spots or the driving lights and still have headlights. However, I run one of Fords auto-reset circuit breakers in my PDB for the headlights. That way they'll come back on should something trip it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

A lot of my posts are made the way they are as a back up reference in case the handfull of notepad papers get shuffled up and misplaced. Its why I also keep records in my external hard drive as WordPad documents to ensure I have a way to go back and double check.

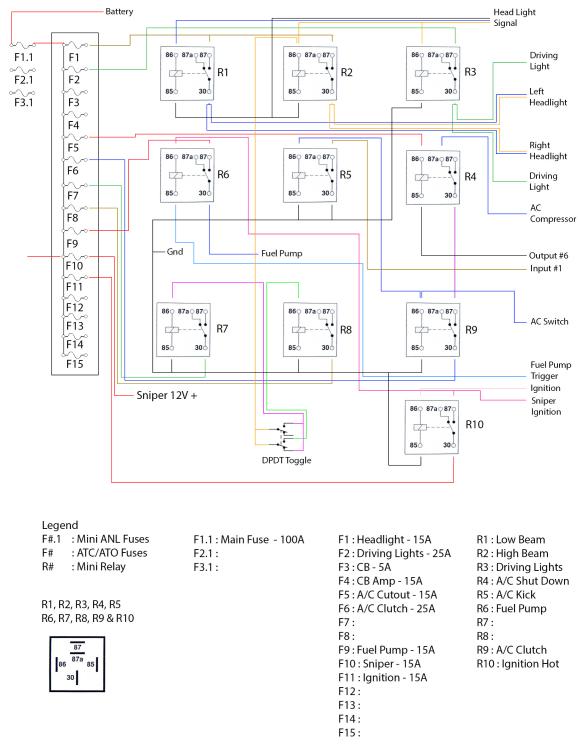

Right now I dont have the original paper anymore and I cant find what happened to it for why I picked the colors I did and why I went with the size wire I did but I have been able to break it down and figure out what I was planning at the time. For the headlight ground I was looking at 18ga as it is the most common primary wire gauge to use on vehicles. What I ended up doing is upsizing everything to 16ga which is why I have 16ga blue wire for the low beam and 16ga black for grounds and 16ga green for the driving lights. I probably should up to 14ga for the driving lights since they are 100w H3 bulbs but I am currently running 18ga with no adverse effect so 16ga should be fine. What I am doing is I am making a jumper wire for the trigger which honestly I could drop from 16ga down to 20ga since all it will be providing is the trigger for activating the low beam/highbeam/driving light relays. Ground wise all relays will have their trigger grounds jumpered together with a single ground wire to ground. I am thinking of doing the same thing with the headlights and driving lights have the two H3 and two H4 bulb grounds merge into a single ground wire which if I do this I will be upping from 16ga to 14ga or 12ga to ensure each 16ga wire has well over enough ability to ground through a single ground wire. I found some Metri-Pack style connectors on amazon that I might use I just have to figure out how many wires I will be dealing with cause for $12 I can get a two pack of male/female connectors with weather seals and pins and each connector has 16 pins. So I could use one connector for 16 wires but I know the wires will not be all going the same way. Some will be going forward to the passengerside headlight connector to be plug and play for the relay triggers and then ill have the other wires that will go for the two headlights and the two driving lights. So for the connectors this is what I have came up with so far but still trying to revise it since I have not taken the Holley supplied harness apart to see how holley wired up the fuel pump circuit. I am assuming there will be a ground trigger wire for the sniper to engage the fuel pump relay and there is a leg coming off the 12V battery hot to supply power to the relay trigger and for supplying power for the switched side of the fuel pump relay. Fuel Pump out : Blue wire A/C Compressor Kick : Orange A/C Compressor Shutdown : Black I also have the follow circuits but they wont be connected directly to the fuse box but will be to the battery itself. Battery Positive Battery Negative I would like to have the switched ignition pink wire going into the fuse box but I wont have enough relays then if I use one of the two spare relays for a switched ignition relay like i would like to. I have to plan out how many fuses I need I might be able to source these modules individually to replace one of the three fuse modules for a extra relay module. So at most I will need 4 wires for the sniper at the relay box not counting the trigger wire that will be needed for the sniper to activate fuel pump relay since the fuel pump relay does time out if there is no rpm signal. I could just use the large 16 pin connector but I would need I believe 25 terminals total. I could do 16 pin connector for the wires that goes to the sniper and ones that crosses over the engine to the passenger side to go inside the truck on the driverside for supplying fused power for my CB and CB amp, that would require I think 8 terminals I think. This is a big time consuming project I am on currently cause I have to plan things out and my idea is to mount the box where the side opening allows for the power wires to come in and out of the box as well as maybe using it to run the headlight/driving light circuits out of. THe other two holes in the edge facing the engine one side will be for the sniper circuits and the circuits for my CB power. The other hole I will route the single 12ga blue fuel pump wire out of along with the 16ga power and ground wires for the future roll bar lights if I ever do add them. This wire will run down the frame on the passenger side and the fuel pump wire will cross over further back to reach the fuel tank. I dont think I want to pass the fuel pump power wire across the engine to run it down the driver side frame rail. Id be concerned it will introduce RFI since its power for running the electric in tank fuel pump. On the fuses, I thought about running one as battery hot and one as key hot, I even thought about running a key hot that is hot even under crank to this box to trigger a relay to supply straight battery voltage to the sniper. But to do this will result in me giving up one of the two spare relay ports I have which I would need both of them for the auxiliary lights on the roll bar as I do not believe I could power four halogen bulbs with a single 30 amp relay. This box does have modules with in it that you can pop out to rearrange but I cant find a place that sells the modules individually but I could spend another $40 and buy another box and swap out one of the fuse modules for an extra relay module to do this but I dont know as of yet. I know I have way more fuses than I need. This box has 15 fuses and going by my schematics I am looking at 9 fuses currently. F1 : Low Beam/High Beam F2 : Driving Light F3 : CB Power F4 : CB Amp Power F5 : A/C Compressor Shut Down trigger power F6 : A/C Compressor Clutch power F7 : Relay 8 power F8 : Relay 7 Power F9 : Fuel Pump Power So I could remove one of the fuse modules for a relay module and still would have a 3 fuse module left over. Why I am struggling with trying to create a plan for this so I know what I am doing what I will need and can properly buy what wires I need to still get. If I could run a pair of KC spotlights and floodlights off a single 30A relay I would seriously consider doing that, I know if I got their LED spot/flood in the Daylighter housing I can without a doubt run all four off a single 30A relay. But I dont know how bright two spots and two floods using LEDs would be. KC uses just two LED chips that fire the light into a cut reflector to create a light pattern and just two single LED chips make it sounds like it would be no where near as bright as a 50w spotlight/floodlight. For the grouping of the wires, currently every circuit has its own dedicated fuse, But there isnt currently a fuse to fuse the whole system to protect the main power wire coming into the box. I had planned on just one fuse here but became afraid of losing everything if that fuse goes as I will not just lose all my lights but I would lose my CB, CB Amp and even my fuel injection. That is a catastrophic failure so I decided to run one main power wire in and daisy chain it between two Mini ANL fuses to isolate the circuits into two groups so I dont lose everything if I end up with a circuit pulling more amps than the wire is fused for. Currently I am taking apart the Holley harness to see how they have it wired up and in PS I am updating my wiring diagram 2.0 posted above to include the actual sniper wiring so I can get an idea of where to go.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Broke down the harness provided by Holley for the sniper and I am not surprised by how they did the harness.

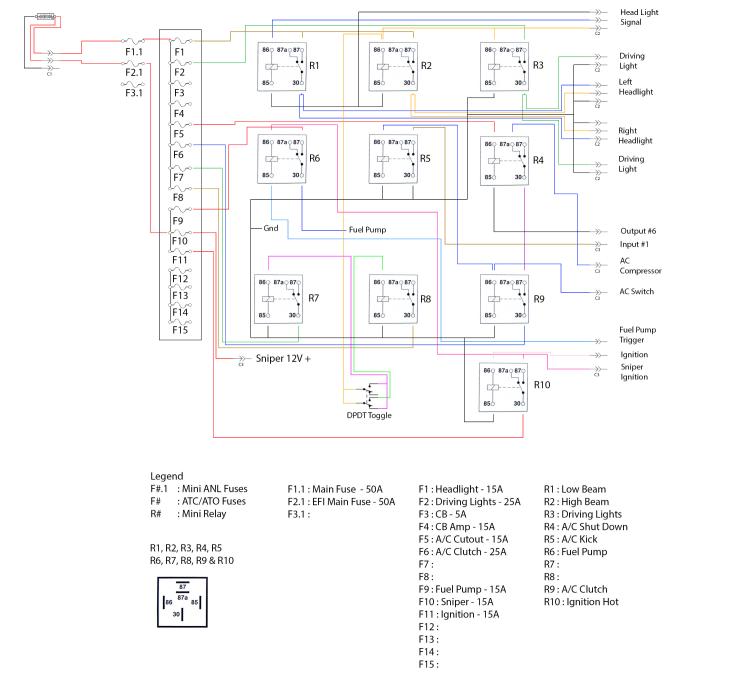

The main 12V battery in is one wire to a inline fuse. This single wire after the fuse terminates into two wires, one of these wires goes to the battery side of the fuel pump relay and the other continues to the battery in for the sniper at the Sniper connector. The 12V ignition is equally as interesting. The ignition wire branches off with one side going to the fuel pump relay trigger and the other going to the Sniper connector. Wires that are left in this Sniper harness is a light 20ga Blue wire to the trigger of the fuel pump relay that allows the sniper to ground the relay and activate the fuel pump. There is a heavy 12ga Blue wire from the fuel pump relay to the fuel pump. Then there is battery negative straight to the sniper terminal, a 20ga Yellow wire to the negative coil terminal for rpm signal. The twisted pair 20ga Green/Purple wire will be removed from the connector, this is for a plug and play if you have a MSD ignition module which I do not have and wont run as I have no confirmation the MSD Module would operate the OE tach on the dash properly. So I have revised my wiring diagram but going to have to think more on it to figure out where I want to go from here. First change is I added Relay #10, I forgot the box I bought has 10 relays not 9. This relay was wired up to be a ignition relay that will be activated by a ignition hot source that is hot in run and crank positions. This relay will have its battery voltage output on Pin 87 branch out of the box to the ignition hot for the sniper and the other branch will go to Relay 6 as the power in for Pin 86. Second change is Pin 85 on Relay 6 was taken out of the main ground and has a light blue wire where it comes out of the box and connects to the Sniper connector for the Sniper to activate the fuel pump relay by triggering the ground. Third change is adding the extra fuses to achieve a total of 15 fuses as my box has, while doing this I isolated Fuse 10 to be connected straight to the battery to ensure the sniper itself gets straight battery voltage. Not shown is an idea I have of running the sniper main ground through the relay box not connected to anything just using the box as a pass through to tidy the wiring up. Can also utilize a stand alone connector on both sides for this. Down side is I am looking at Aptiv brand connectors, from what I am seeing these connectors are formerly known as Delphi. Below is the connectors I am looking at. Aptiv 12045808 & 12047937 : 150-Series Male/Female 10-Pin connector black (20Ga - 16Ga) Aptiv 12186400 & 12084891 : 280-Series Male/Female 5-Pin connector grey (22Ga - 12Ga) Aptiv 1212960 & 12129565 : 280-Series Male/Female 4-Pin connector grey (22Ga - 12Ga) Aptiv 12065863 & 12052613 : 480-Series Male/Female 2-Pin connector black (12Ga - 10Ga) It sucks cause I cant get them all in the same color connector, like wise I would prefer to use the 280-Series for the 10pin connector cause you can get pins capable of taking 20ga wires. But Aptiv doesnt offer a 10pin connector in anything but the 150-Series. Same with the 480-Series, there isnt a 1-Pin connector which I could run for the main power into the box so it appears I will be running two, 2-Pin 480 series connectors, one with a power/ground and one with two power since I cant get a single connector. Another alternative is I could do a 3-Pin 480-series connector and install two powers and one ground to consolidate. I do plan on running a 10ga wire to supply power to the box seeing as how many circuits this one wire will have to power. Its also why I am thinking of daisy chaining the wire off one Mini ANL fuse to a second ANL fuse to create two distinct circuits to isolate important circuits from less important circuits. Like maybe keep my headlights and fuel injection on one circuit and everything else on another circuit. At least the fuel injection and headlights would have a very low chance of blowing the fuse and even if it did, my driving lights would still be powered by being on the other circuit that will house the potential roll bar lights and my CB radio/amp. Once I get all this squared away on how many connectors I need and what number of pins I will revisit the color coding of the wires. I really dont want every powered circuit in the fuse box to be a red wire from the fuse to the relay it is powering. But WireDepot has limited color choices even though they do have a larger selection of colors. I want to use WireDepot as they offer SXL-Cross Link wire which has a thicker more abrasive resistant coating with its intended use being heavy duty use. In my case my goal is to over kill the upgrades on my truck to ensure reliability and dependability. Only thing I need to get before I start making this wire harness is I need to buy some of this woven loom material that I found that has a built in Rodent Guard to prevent rodents from gnawing on the wires. I cant do it for all the wires on my truck cause the loom isnt split, so for the OE wiring on my truck it will be covered with the standard woven loom material to make everything look more uniform. It just will have ends taped in place vs the harness I am building which will have heat shrinked ends.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Did some more work on the schematic as well as picking out the connectors I will need.

First is a updated schematic after adding connectors so I can number them and keep track of number of terminals per connector.  So far I have three connectors. Connector 1 will be a Delphi Metri-Pack series 480 3-Pin rated at 50A per terminal continuous. This connector will have two 10 AWG SXL Crosslink wires directly to battery positive and one 10 AWG SXL Crosslink wire directly to battery negative. One of the 12V circuits will power up one branch of fuses through a Mini ANL fuse rated at 50A? and the other 12V wire will power up the branch for the Sniper which consist of three fused circuits. I may make adjustments and shift more items to the sniper circuit but think I might want to keep that circuit bare bones to prevent interference with the electrical circuit.  Connector 2 and 3 will be a Delphi Metri-Pack series 280 15-Pin rated at 30A per terminal continuous.  Connector 2 will consist of the trigger connector that will plug into the OE headlight harness to activate Relay 1 and 2. Connector 2 will also house two High beam and two Low beam headlight wires and two headlight grounds as well as two driving light and two driving light ground for a total of 13 circuits. All the grounds I will attempt to splice into fewer wires with in the box. Connector 3 will consist of the Battery Ground for the Sniper, Battery Hot for the Sniper, the Ignition trigger, Ignition hot for the Sniper, the Fuel pump trigger, the AC switch in, AC Compressor out, and Sniper Input #1 and Output #6. This same terminal will also house the battery hot circuits for the CB and CB Amp for a total of 11 circuits Connector 4, I am unsure how I want to do this. Connector 4 will have to be a Metri-Pack 280 series to house the circuits for Relay 7 and 8 for additional auxiliary lights. If I link the DPDT Toggle together with the Relay 7 and 8 circuits then I am looking at a total of 11 circuits if I run double wires off terminal 87 of each relay to provide power for two pair of auxiliary lights as well as 4 independent grounds. The Grounds is my biggest issue as I want to terminate the grounds to the best possible ground for my auxiliary circuits and not sure how I can do all these ground wires. I really want to splice the grounds together to reduce the number of grounds to cut down on clutter of wiring at the battery itself. I know there is a brass threaded terminal on the inside of the box for using as a terminal block but I wouldnt want to try and stack that many grounds on such a small terminal. I might have to source a stand alone terminal block for grounds. I found some real nice ones I could in theory bolt to the side of my fuse/relay block, only thing I would be worried about is having RFI introduced with my EFI if I run the 10 AWG ground wire to this terminal block and then make all my ground connections to this terminal block. I think 10 AWG for a ground would be well over enough to ground everything but I know Holley stresses having the sniper with the 12V power and 12V ground hooked directly to the battery. Not sure if jumpering the sniper ground to a terminal block would be considered not directly to the battery even though the terminal block is grounded straight to the battery. Once I get all this figured out then onto the next step of figuring out what color wires to source as I would prefer to have the wires inside the box to not be all the same for power from fuse to relay. I guess the smart thing would be to use the same color wire as the circuit is outside of the box and I can always size the wire to what the circuit is to cut down on crowding on the inside of the box. Lots of the circuits are going to be 20 AWG as they are low amperage computer circuits. Next step will be the 3G wiring and how I want to wire in the megafuse for the charge wire. I thought about using the Mini ANL fuse in the fuse/relay box as you can buy a Mini ANL fuse up to 200A. But I was fearful of having the alternator charge wire with in the box and possibly introducing interference with the Sniper system. Im thinking about mounting the mega fuse down off the charcoal canister mounting bracket that way the charge wire will be pulled down and away from any of the auxiliary circuits going across to the engine.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

I think you have good plans, but have a suggestion. Why not make the body & frame grounds and then tap into them near the load? I have an extensive ground system and my headlights and fog lights tie into the radiator support, which is heavily grounded.

I think running heavy grounds to the frame, fenders, cab, and radiator support would provide a better path to ground than running multiple smaller wires to the loads.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I thought of doing that but I know the sniper will have to go straight back to the battery for power and ground to help stop RFI issues. What I am thinking of doing is get some bare metal crimps without the insulator and then run the grounds together and daisy chain them via crimps. So have the two Apollo driving lights grounds come together and crimp into one ground. Then I can do the same for the headlights now instead of having four ground wires I have only two. I could also bring those two ground wires together and crimp them together and have one wire. But every time I do that I will have to enlarge the single wire to ensure there is no grounding issue. Its why I was thinking of running them back to the box. If I were to ground the headlights I would have to sit it atop the factory headlight ground as I am using that ground and power wires to activate Relay 1 and 2 making the headlight relay circuit plug and play. That way if in the off chance my relay goes out I could always simply unplug the connectors for the relay circuit and plug in the OE connectors to get me home. The ground wires for the apollo driving lights, they would have to run between the body panel and bumper then under the core support and up to the OE headlight ground if I ground it to the core support. If I run the wire that far it wouldnt hurt to run it back to the fuse/relay box. But what I could do is instead of running it up to the fuse/relay box I could mount a terminal block and ground it and use it as my grounding point. My big thing is I am trying to avoid drilling new holes as I prefer to be able to revert back to original without having to fix holes that shouldnt be there. I have to do some reading and see how to properly size a ground wire when you splice two grounds into one single wire. Like wise I need to see about four grounds into one single wire cause if I can get away with it for my lights I can link the grounds together with in the wiring harness that will be covered by a woven loom wrap and youll just have one ground for all the lighting up front. I how ever wont do that for the sniper out of fear of creating issues.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

If, for instance, you run #14 to two headlights you could then run two #14's into one #12 for the ground. The Wire Barn calculator says that #16 is good for 10 amps to 5' with a 2% drop. But #14 is good to 5' at 20 amps with the same drop.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

You use WireBarn calculator as well, thats what I been using to size the wires properly. For the headlights thy are 55w low beam 60w high beam. That is 110w low beam for two bulbs and 120w high beam for two bulbs. @ 12.8V battery voltage is 8.6A low beam and 9.38A highbeam. @ 13.8V battery voltage is 7.97A low beam and 8.69A highbeam At the highest amperage which is 9.38A if I run 16 AWG like I plan with 2% drop I can run 7ft of wire but that amperage is for both loads. If I split it up by load which is 7.97A at the highest @ 13.8V I can run 16 AWG at just over 8 1/2 ft length. For my driving lights they are a pair of 100w driving lights. @ 12.8V battery voltage is 15.63A @ 13.8V battery voltage is 14.49A For the total of 200w @ 14.49A I can run 16 AWG in 4 3/4 ft run. But at 7.25A which each bulb is drawing and will have its own dedicated power wire from the relay I can run 16 AWG at almost 9 1/2 feet. Now for the grounds, if I link them together like the factory did in many instances by splicing two grounds into one ground wire I used Wire Barn`s wire combination calculator. This gives you an effective gauge based off how many wires of a given gauge. So in this instance I have two 16 AWG ground wires from my driving lights, if I crimp them to the same terminal the effective gauge of these two 16 AWG wires is equal to a 13 AWG wire. So when I splice the two ground wires from the driving lights into one it will be two 16 AWG wires into a single 12 AWG wire which would be slightly bigger than I need. Now if I take the two 16 AWG headlight grounds and splice them into one 12 AWG ground as well I now have two 12 AWG wires, which has an effective gauge of 9 AWG. So seeing 12 AWG is already slightly bigger than required by 1 gauge size, I can splice the two 12 AWG wires into a single 10 AWG wire and it would perfectly balanced if I am thinking of this correctly. The total circuit at 13.8V would be 8.69A for the headlights on high beam and 14.49A with the driving lights on which they would be as they are linked to the high beam trigger. This is a total of 23.18A @ 13.8V in a 10 AWG size which the 10 AWG would be carrying the complete load back to ground I can run 10 AWG for almost 12 feet with a 2% drop. If I am thinking of it correctly then I can effectively splice all the ground wires together from 16 AWG to 12 AWG to finally 10 AWG which would then either go straight to the battery negative terminal or a terminal board bolted to the side of the fuse/relay box. I would prefer to do it this way to ensure my headlight circuits has the best power and ground leg of the circuits as possible for maximum brightness. If I was running LED bulbs then I probably wouldnt be going to these extra lengths. The one that will be interesting is the ground for the roll bar lights. The KC Daylighters come in either 50W or 100W bulbs. I was leaning towards the 100W bulbs like my KC Apollo driving lights. But in this case running four of them would be 400W worth of bulbs which even at 13.8V comes out to 29A of power draw. Considering the wire running back to the roll bar will be down the frame then up through the bed and up the roll bar I would guestimate from the relay to the bulbs I am looking at I say 16 feet of wire give or take. Given that they will be in pairs on a relay that would be 200w pairs at 14.49A. I could get away with 16 AWG wire in this case if it wasnt for the length At 200W pair @ 14.49A I am looking at needing a 10 AWG power and ground wire to get me 19ft of wire run. But I would be pairing the wires up with two power wires off the relay for each bulb so I am not powering two bulbs off one wire. That would still come out to 7.25A for a single 100W bulb @ 13.8V which means I can run a 12 AWG wire for almost 24 feet of length and this is not even taking into account the length of the ground wire which I really should be taking into account as it is part of the length of the circuit as well. But in the way of the auxiliary roll bar lights it would be two dedicated power wires and two dedicated grounds for the four lights. I wont even attempt to splice them into fewer wires as it would put me at a gauge of wire that wont fit the connectors. Many of these connectors I have been looking at has a cut off of 10 AWG in some instances.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Yes, I use Wire Barn, for sure. The ability to tailor wire lengths is great.

I like your plan on the headlight and driving light grounds. Take them all into one and ground it at the battery and your wire lengths will be short and you'll have the fewest connections. But on the roll bar, I'd take the ground to the frame below the bed. That will cut the run length in half.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Yep I might do that. After all I might have to drill a hole in my frame to mount my corvette fuel filter/regulator as I just dont know if there is a existing hole I can use. Plus the Corvette filter has a little folded over ear to fit into a locating hole to keep the filter from twisting when you tighten it into the frame and it has to be tight as the filter has a grounding strap from the filter to the mount. The roll bar lights is a questionable thing cause I dont know if I will even do them. I know my goal is for a 1980s - 1990s look to my truck but the big thing that will determine if I use a roll bar or not is how it attaches in the bed. I have found photos of the bars in styleside trucks but nothing with a flare side. If the bars will sit directly on the wood then that would be great, I can place a rubber insulator between the wood and the bars and then run bolts through the wood with huge fender washers on the back side. Then for the wire I can run it down one of the tubes and out the bottom of the wood. But now if the bars sit atop the bed strips then I probably wont get a roll bar then cause I dont want to drill holes into the bed strip. The wood I can always pull those two to four boards out and replace them if I ever change my mind. But drilling the bed strips out I would have to get another whole set cause I dont think you can buy just one of the polished stainless steel strips. This truck was the only photo I ever could find with a roll bar and an aftermarket one at that I believe. But never a photo of the bed itself and how it sits on the wood in the bed.  And the same truck it was posted on here with new KO2 tires like I have. This is basically the look I am going for on my truck just with the addition of a chrome grill guard which I am playing around with if I want to have it rechromed when I pull the bumpers for repaint or if I want to just blast it to bare metal and powder coat it a gloss black.  Im even contemplating the whole billboard style bug shield in a transparent blue to go with my truck and then get some lettering painted on it for that full on 80s/90s look. As far as the wire goes, I will be looking into terminals this weekend, need to find some double width terminals for crimping two wires to and I really want to see if I can find gold plated terminals over the tin plated. I know tin plated terminals will be fine but they do degrade over time and gold plated terminals wont. I also dont know if I want to after assembly plug the back side of my box with silicone to weather proof every terminal point.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

| Edit this page |