Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

Bear with me while I figure out this "quote" routine 😉 I have double checked the firing order and am going off the one in the Haynes manual for the 5.8L. I thought I remember someone mentioning there may be a different one for the H.O., which I have, but I don't ever remember seeing a different firing order for the H.O. designation. I am a bit curious how to get the rotor in the distributor back to #1 pin unless you just pop the cap and rotate the motor by hand? I am willing to try it though! As far as timing goes, I put paint marks on 0, 10 & 30 degrees BTDC  That has been very east to see but like discussed before I certainly can't make out individual marks when the engine is running. I guess I would expect the engine to run rather rough or at least be hard to start if I was missing on one or more cylinders, but I don't know, that's just a guess. That is one of the things that has me the most stumped. It runs seemingly well until I put it in gear... 🤔

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Gary Lewis

Thanks Gary. I've read through the information now I just need time to trouble shoot... My wife decided she needed a new coffee table built. I think she may have been getting a little jaded with all the wrenching lately and no carpentry projects for her 🙃 Hopefully this will do for a while.

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

Banned User

|

In reply to this post by Ferdinand

That should be correct, but here it is again:  Only the 5.0L HO, which I think uses the 5.8L order. If you can get a grip; otherwise, use a wrench on the harmonic balancer bolt. Only turn it in the "tighten" direction. Of course, it's much easier with the plugs out. |

|

This post was updated on .

In reply to this post by Steve83

Yikes, so I tried the quote thing on this one (the thread where Steve is inserting info in Gary's comments) and I am a bit stumped. I get about 3 deep in the quote lines, so I will just try to reply here.

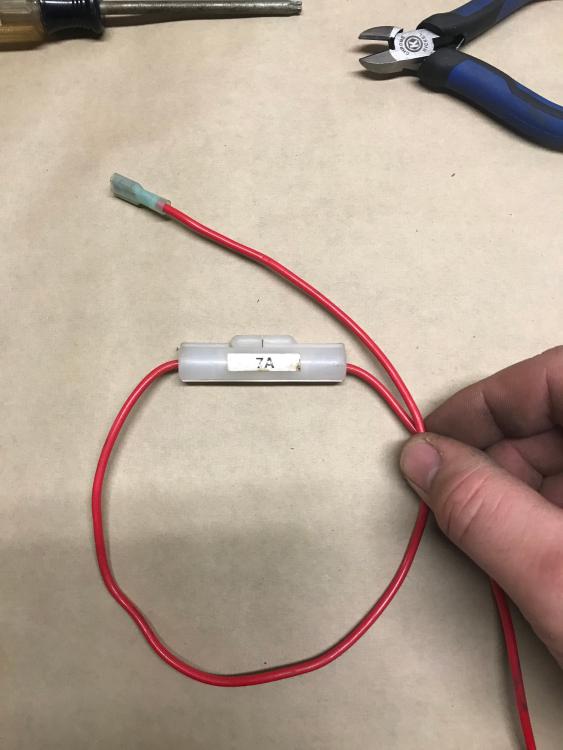

I am trying to wire up the choke tonight and I am a bit unclear as to how to wire the hot for the choke... From what I understand, it should be wired to something that comes on with the key. But should it be wired to something that has constant power while the engine is running? I have a typical fuse block:  Does anyone have a preferred fuse to tie an electric choke to? I also made up the connections this evening, but am curious if an inline fuse is helpful or a headache and waste of time... I only ask because digging around in my wire bin I found a red wire with an inline fuse already attached:  A comparison of a pre-made end and one with heat shrink that made tonight:  The ground connection.  Lastly, does anyone have a preferred route out of the firewall?

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Ferdinand

I may regret this later since I am not really that public of a person, but for what it's worth, and because I am incredibly grateful to Gary and all you guys for your help, information, and projects, I put a "shout-out" to the forum.

Let's keep peeling them onions!!

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

Banned User

|

In reply to this post by Ferdinand

Depends on the choke heater element - is it (modern aftermarket) 12V, or (old factory) 6V? The only places to get ~6V on these trucks is the ICVR (not practical for this) or the alternator "S" terminal (where the factory wired the 6V choke heater). Read the carb manual to be sure, but I think I can almost make out "12V" molded into the heater in your last pic. Again: depends... If you use the "S" terminal, no fuse. If it's 12V, just splice into a 12V circuit on the engine that's only hot when the engine is running (like the coil or ignition system positive). A fuse is necessary for NEW circuits. A 6V heater isn't new because the factory built the truck that way - you'd just wire it to the factory circuit. If it's 12V: since this is such a low-current addition (probably ~1A or less), it's safe to add it to a much-higher-current factory circuit (one with a 5A or higher fuse). If you have to add a fuse (for ANY circuit), the best place to put it is with all the other fuses, so you can find it when it blows. Read the first 4 captions in this album:  Through the factory firewall grommet, inside the factory harness. Use a semi-blunt probe (like a long phillips screwdriver) to spread the wires inside the grommet, and feed your new wire(s) through before they shift back into place. |

|

Good job on the coffee table!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

I would say Steve got you heading down the right path.

I will not say anything more on the plug wires, it was all based off what I heard when running. Yes good job on the table. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

In reply to this post by Ferdinand

Wow! Thanks for the shout out! Well done!

And, well done on the coffee table.  That's a lot of pieces, which takes a lot of patience. I'm impressed. Never was good at woodwork. That's a lot of pieces, which takes a lot of patience. I'm impressed. Never was good at woodwork.

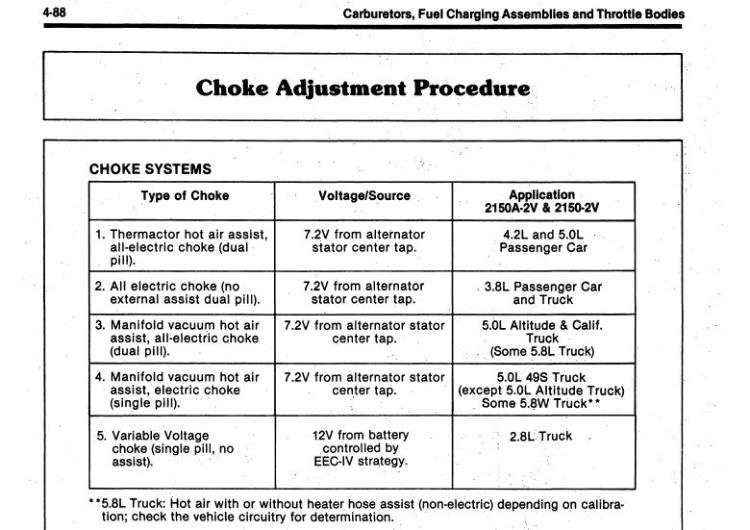

On the choke, as it is an Edelbrock it will be 12v. But it can be run by the ~7v off the stator on the alternator, and that makes it pretty simple as you run a short wire. However, it takes longer for the choke to come off so you have to adjust the choke pretty lean. So using 12v is better. And a good source for that under the hood is the white/light blue wire near the ignition module. Not "at" the module, but just ahead of connector C321, as shown here. But, that source is hot when the key is on, whether the engine is running or not. So if you turn the key on and leave it the choke will heat up and come off. But, it is a fused source so you don't have to add another one. So, a cleaner, albeit more tedious, solution is to use the power off the stator on the alternator to pull in a relay, and have the relay power the choke. That way the choke will only get power when the engine is running. And in that case you'll need to fuse the power lead as you'll probably want to take it from the hot terminal of the solenoid.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I'm running my Holley choke from the factory stator source. I didn't check it with my meter, but I understood it to be half of the ALT output voltage, so it *should be in the area of 7.25vdc? I know a 12vdc source is recommended, but there are a lot of Ford/Holley people that have used the factory stator source without issue. I read a thread on one of those hotrod forums where the guys tested/compared the two different voltage sources, and they claimed that the difference in time was negligible. Now, I know that's an anecdotal internet claim...but still, a lot of people do run them that way.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

I ran the Edelbrock on Rusty that way. It worked fine, but it was a bit touchy to set the choke as it didn't come off as quickly as it would have on 12v. But, it worked, and would be fine for at least testing, so that's what I'd do right now.

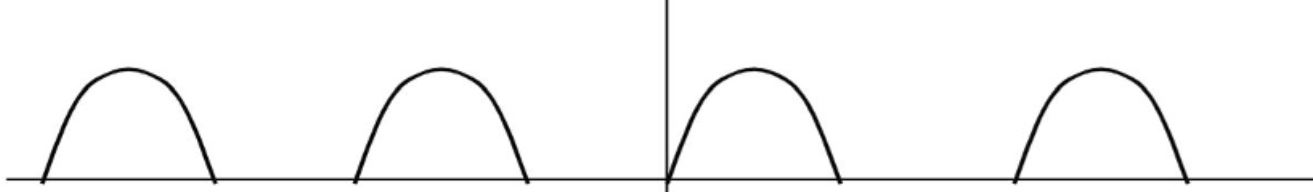

What the actual voltage of the stator connection is escapes me. I tend to remember that the stator connection on a Ford alternator is a half-wave rectified output from one of the three windings. If so, then the voltage is actually half of a sine wave and will look something like this, although if it is 1/3 of the windings the blips will be further apart:  The peaks will probably be something like 15 or 16 volts, and what a voltmeter will show you is an average of the voltage. And each DVM can have a different way to "average", so the results can vary. But the result is that you are getting something like 1/2 of the energy into the heating coil of the choke than you would with 12v. So it heats up more slowly and never gets as hot. But if you adjust the choke to accommodate that it will work - just not as cleanly as if it had 12v.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

I wish I had some that said Fluke! I'm impressed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Ferdinand

Thanks for the compliments on the Coffee Table.

My oldest doesn't care much for wrenching, but she regrets that I set down the construction company 😉

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Gary Lewis

This guy comes in crazy handy too!

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Steve83

Thanks for the info and suggestions. I am going to go ahead and wire it to a 12v source like you and Gary have eluded to. I think with the trouble shooting I am under, the less variables to contend with the better. I keep getting out to the garage too late now to run this thing without waking my family (and the neighbors). I need to get it running well enough to get the exhaust put on so I can run it a bit more!! Now that I'm thinking of it, I may flat bed it over to the muffler shop (it's only 4 miles away) and have them put the exhaust on it so when I can bring it back I can tune on it a little later in the evenings. 🤔

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Gary Lewis

All I knew was that it was supposed to be about half of what the typical output voltage would be (14.5vdc). According to my 1984 FSM:  Interesting to note, I kept coming across mentions of a full 12vdc choke. You can see in the chart above. It was done with battery voltage through and oil pressure switch. That would be a nice way of doing it if you were running a full 12vdc...although it would require an extra oil pressure port. One of the reasons I personally stuck with the factory 7.2vdc was that I wanted a run-only signal. I can guarantee you that I'd be that guy that left the key on at some point and baked the element...lol. Now, if I had an easy place to install and oil pressure switch....hmmm...

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

Banned User

|

Extend the stock sender away from the block, and add a common plumbing T. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

In reply to this post by Ferdinand

You do your woodworking outside?

And what does "set down" mean? Sold? As for the IR thermometer, I have a Chinese version. So cheap that recently the plastic trigger folded. But it was hollow and I straightened it out, put it in the vise, and filled it with hot glue. Once that set up it was better than new. But, the IR thermometer is extremely handy.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |