Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

I don't think a compression test is going to tell you much about the cam. Not that you shouldn't do it, but unless the intake valve isn't opening at all, the cylinder will probably get enough air to compress and look like it is working. I think the only way to find out about the cam, short of pulling it, is to pull the valve covers and measure the travel.

And, wiped lobes would do what you've been seeing. Especially having half the cylinders not running, or not running much, given the exhaust temps.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Good point Gary.

I will still try to do the compression test just to see what is happening. Although, I am at a bit of a loss as to what else could be causing my issues but all things considered, I'd really rather not have to pull the cam but I would like to find SOMETHING that could explain this funky lobing once I'm in gear... 🙃

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

I had a 351W that had bad valves on three cylinders, two of which were adjacent in the firing order. It idled horribly. You wanted to shift to Neutral at a shop or you were sure the mirrors were going to come off.

A bad cam can do the same thing. And you have four cylinders which aren't truly running. But, for grins you might check out the intake manifold and see which runners go to which cylinders. In other words, does one side of the carb feed those four cylinders? And, can you borrow that 500 CFM carb again and put it in gear using it? Lots easier than pulling valve covers and checking rocker movement.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I knew that motor was not hitting on all 8 and why I kept saying firing order.

After the fire you went with a new intake? What kind of gasket does it use between heads & manifold? If it is a metal type what type of sealer is used at the water & intake ports? See where I am going with this? If the heads & manifold angles are not the same and don't use enough sealer you could have a vacuum leak to the inside / valley. If you did get it on the road you might find it going thru oil and not know where it is going. If you think the can went flat I would pull the covers and crank it over / run it just to check movement. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

In reply to this post by Ferdinand

Some of last nights work:

Working on getting a few more loaded. More narrative later. (Got home from Bible study too late to crank any tonight but I did snag a compression test gauge to try tomorrow night. Also snagging that friends 500cfm Edelbrock)

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by FuzzFace2

Dave,

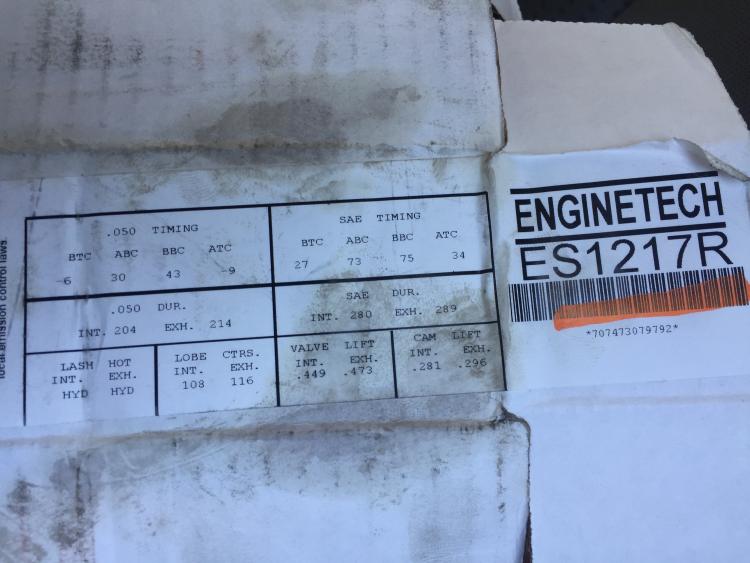

Thanks for all the advice. After the fire I had the motor completely rebuilt. I had a slightly larger cam (280/289) put in but I had a really reputable shop do all the work. That's way above my pay grade! Anyhow, I went with an Edelbrock Airgap intake. I had to pull it once already because of an internal coolant leak caused by burs on the lower mating surfaces of the heads on both sides. The aftermarket intake sets in a little deeper than factory and kept me from getting a good seal. I filed all that down, and used Felpro Performance Gaskets with Printoseal for my rail gaskets and straight Permatex for front and rear. I did also put a thin coating of Permatex at the water jackets. I believe it is sealed rather well at this point. (I have been using Ultra Black Permatex and have had great results) Also, I do hope to do the compression checks tonight to see where I am there, but as you and a few others have suggested it does seem smarter to pull the valve covers again and measure from there. Plenty of work left to do, that's for sure! Thanks for following along.

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Ferdinand

A few clips from the other night.

These are all mid changes so I just wanted to show the vacuum and see if anyone thinks the air in the fuel line would be an issue? I have heard a lot of opinion but am a little short on proof or documentation as to it being a real issue: I am going to try and pull valve covers here one of the next few nights and see if I can measure valve movement, but I need to research and figure out which valves are which and how much movement there should be. I'd rather do that, the compression check and maybe a compressed air check for each cylinder before I pull the cam.

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Gary Lewis

Gary,

Your comment from a while back on what I did in the longer video, I must apologize. I have tried so many things at this point I lost track. And I edited that video 🙃 However, I don't believe it was anything significant. A simple throttle stab would dramatically change the way things sounded when I had the vac advance hooked up. Since being unhooked, the idle (and timing) has been a great deal smoother. I have also listened to a lot of videos of guys running a motor 180 degrees out (which is one of the problems I thought could be possible in my situation) but they barely could keep them running... Mine fires at the bump of the key when I am at 15-18 degrees BTDC timing and it takes gradual throttle all the way to nearly full throttle and it doesn't die. So, at this point I am thinking that I couldn't run as "well" as I have been so far if I was that far out timing-wise... Thoughts on that? I am going to try the smaller carb tomorrow evening as well. If it runs smoothly again, and we check it under load as well, I would say that it would have to be fuel at that point but I'm not ruling anything out at this point...

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Ferdinand

EVTM in action‼️

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

In reply to this post by Ferdinand

I don't think it could possibly run "that" well if it was 180 degrees out. But, the fact that it runs much better (less poorly) with the vacuum disconnected is interesting. That suggests that timing is an issue.

Have you checked to make sure the damper is correct? Bring #1 up on TDC and see that the mark aligns. Maybe you have the order correct but are way off on timing? But, that doesn't really work when we think about 1/2 of the cylinders running and 1/2 not.  Anyway, something more to check. As for the EVTM, that's a laptop in a holder in your shop? That's cool!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Ferdinand

The Great Mystery Is Solved!

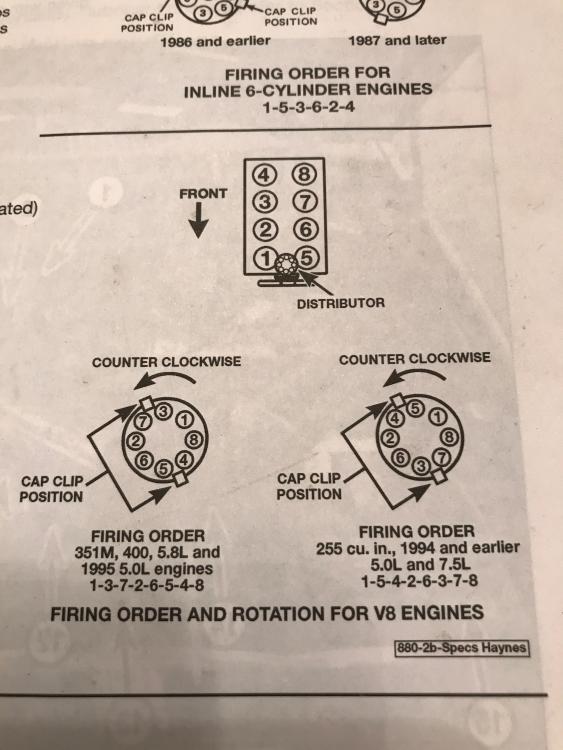

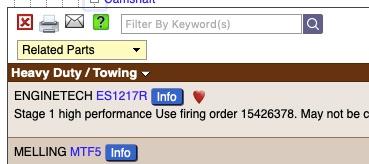

I have been chasing a timing/fuel/vacuum problem now for more than two months until just tonight I finally discovered the problem… FIRING ORDER (Seriously, firing order... one of the things I checked 20 times AT LEAST!) I have nearly memorized the 5.8L firing order from Ford, 1,3,7,2,6,5,4,8. What I did not know is that it is possible to have a cam installed that would revert you back to the 5.0L V8, firing order 1,5,4,2,6,3,7,8.  I started noticing that the firing order for cams are printed on the box or in the paperwork they come with but I had an engine shop build mine and the box they gave me that the cam came in did not have any firing order listed anywhere on it.  Out of sheer desperation and grasping at straws thinking my problem could be anything from a distributor 180 degrees out all the way to having washed out my cam during break-in, I did a Google search on what the firing order for my cam would be and there it was… The proper firing order for the cam that was installed was indeed the firing order for the 5.0L and NOT the 5.8L!  Then it all started falling into place. Even the cylinder temps that were indicative of a potentially washed cam started taking on new meaning: Cylinder Temps taken at the header tubes: 1-709, 2-590, 3-190, 4-131 5-152, 6-650, 7-194, 8-505 When you consider there are 4 cylinders that are different between the two firing orders: 1,3,7,2,6,5,4,8 1,5,4,2,6,3,7,8 Hence, 1,2,6,8 are the same and 3,4,5,7 are different, this corresponds to the cylinders that were very low temperature wise. Once I realized the potenetial fix, I couldn’t stay in my seat. The Bronco has only open headers and I live very close to my neighbors. Not to mention, my sleeping family in the house (it was nearly 11:00 "on a school night"). I couln’t help it… I HAD TO GO TRY IT. Sure enough the thing jumped to life at the bump of the key, ran like a dream, took the throttle stabs, and even stayed smooth and even once in gear! I am utterly amazed the engine ran as smooth as it did with 4 cylinders out of sequence! Many have said the firing order was the issue. So, to all those folks, thank you!! I would have never guessed that the firing order would have been different than that which was referenced. Now to get Ferdinand’s front clip on and finish this!!

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

I'm glad to see you got it figured out finally. I thought it had to be something small that was getting over looked. I was thinking timing, and I guess in a way it was, albeit by the timing order.

1981 F 150 Custom 300 ci with a fully rebuilt 1968 240 head Carter YFA T-18 3.25 9" rear 2WD

dual gas tanks 1990 Lincoln Town Car 5.0 AOD Home town Mc Kenzie, TN |

|

In reply to this post by Ferdinand

Congrats! And good job sticking with it and researching and finding the cause.

I have not heard of this happening before as far as I remember. (But, my rememberer ain't too good!) Not my Bronco and I almost got up and did a happy dance!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

In reply to this post by Ferdinand

In the 302 world, this topic comes up all the time, especially with people buying used engines. When I suggested the other night that you might have a cam issue, I thought briefly...I wonder if this thing has a 302 cam in it?...lol. Anyway, the thought came and went... When I was shopping for a cam for my 302 last year, I noticed that some of them (Lunati comes to mind) only offer certain performance grinds in the 351 firing order. In any case, I'm happy to hear that you've got that part sorted out. Now you can move on to dialing the thing in even further. PS: Ferdinand, a tip of the hat to you for holding on to the reins all this time. A lesser man would have thrown in the hat long ago. You're tough as nails. PSS: It would have also been nice of the engine shop to maybe tie a tag to the engine indicating it had the 302 firing order...lol.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

In reply to this post by Ferdinand

Yippee!!!! Glad you hung in there, and glad you finally solved it. Well done!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Frank Wyatt

Thanks White Knight,

Yes, I was sure it was something right under my nose. What a sense of relief... I am still smiling over it

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by grumpin

Grumpin,

Thanks for sharing in the victory! I was seriously dancing around in the garage last night!!! What a weight lifted.

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

Banned User

|

|

In reply to this post by Gary Lewis

Gary I am sure you can only imagine how much I looked like that little guy jumping up and down when I finally connected the dots and got her to fire up so smooth!!!

Rom 12:15a Rejoice with them that do rejoice, -thanks for everything brother

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Steve83

Great idea Steve!

I sure would like to save someone else the hassle going forward!!!

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

| Edit this page |