Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

Good find on the chokes and voltages. Interesting that Ford said 7.2V. That's awfully precise for something that surely varies significantly.

Anyway, I agree with Steve. You can put a tee on the oil pressure port and put a switch on it. That's the way I have Big Blue set up, with the switch running the fuel pump relay and the other side of the tee going to the gauge.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Ferdinand

I think this melted thing by my pinky finger is the radio noise capacitor... I am wondering, in the picture below, if this is the same thing? This part of the harness is what I took out of the Boneyard '86 but there are obvious differences between the two so I don't want to assume anything. This red wire with the yellow dashes and the bare metal plug at the end has 12 volts to it when the key is in the on position and when the engine is running:  I am actually thinking of powering my choke from there. Thoughts?

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

The capacitor would have a red wire with light green dashes or stripes, and the light green could be taken for yellow. And, it would have 12v on it with the key on. http://www.garysgaragemahal.com/start--ignition.html

But, it shouldn't really have 12v when the engine is running as it should be toggling between ~7v and 12v as the ignition fires. Anyway, you don't actually have to have it. If you don't have ignition noise in the radio don't worry about it. And note that the 4.9L didn't even get one.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by Ferdinand

The RFI cap is always a short pigtail off the coil positive. I can't think of any problem using that wire to power the choke heater.

BTW All RFI caps are interchangeable, regardless of make, model, or year. In '96 Ford trucks switched from the traditional Aluminum can to a molded black plastic cap, with the same connector as '95 (& many previous years). My '83 300ci originally had one, and all the documentation I've seen shows it for all engines. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

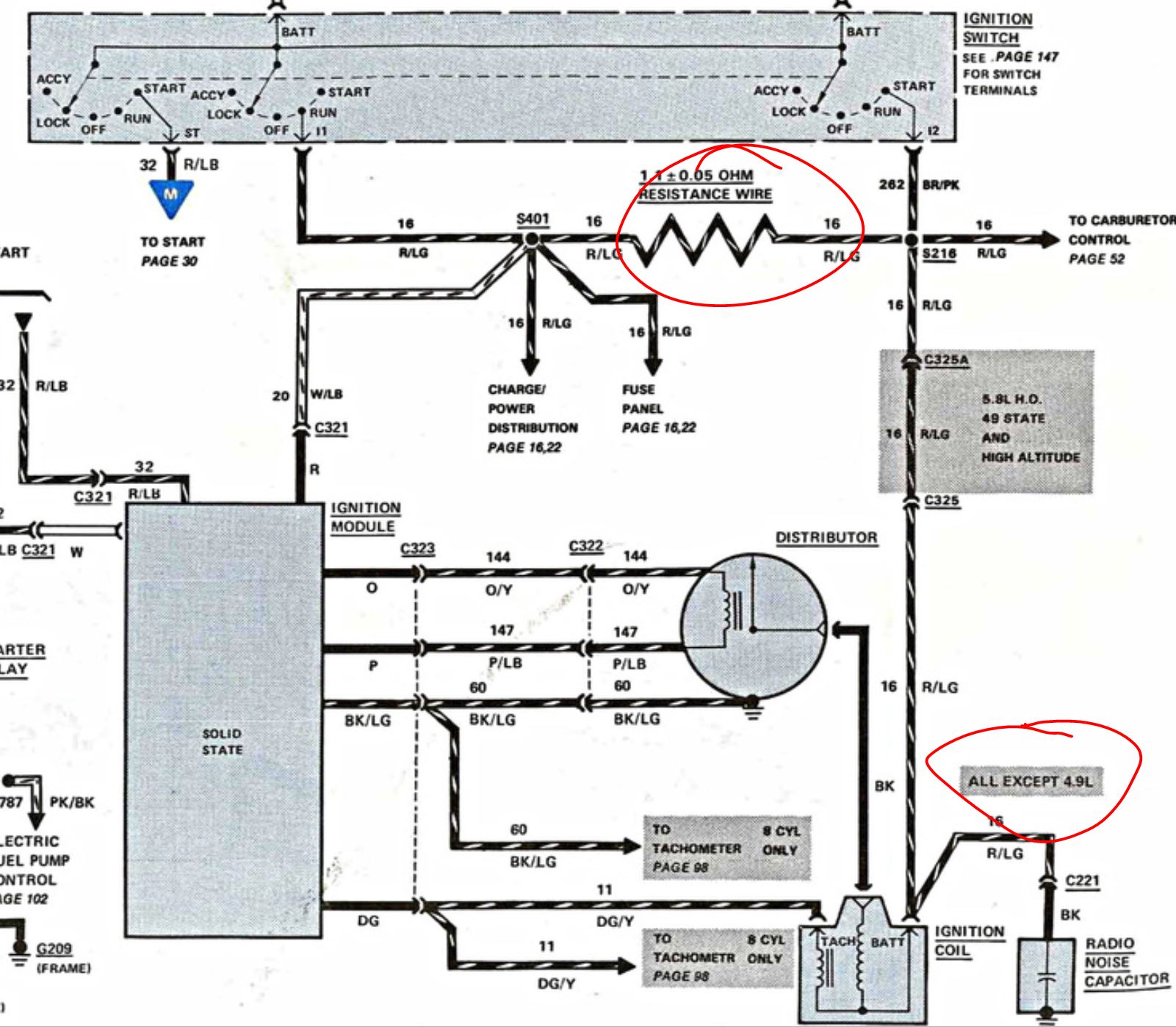

I wouldn't recommend using the coil power to run the choke as that comes through the ballast resistor, circled below, when the key is in Run. So the coil isn't getting 12v, usually more like 7 volts, and by running the choke on there you'd be getting even less voltage as with more current you'd have more voltage drop - which would reduce the spark voltage. In fact, it might be less voltage than using the stator for the choke.

That's why I recommend using the white/light blue wire going to the ignition module as it comes off ahead of the resistor and would have full battery voltage in Run. As for the condensor/capacitor, I've also circled the "All Except 4.9L" that shows in all the EVTM's I have. This one is from the '86 EVTM on Page 26 for Duraspark, but I've also checked the '81 and '85 that I have on the site.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

This says it was only some early '84 300s that lacked the capacitor:

https://drive.google.com/open?id=18eMI8GebF3VZQR0qDUWyksvAgIJt8JhO That implies that older & later 300s were built with it. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

That is interesting! I'd missed that. But, you are right, that sure implies that only early '84 4.9's didn't get it.

That would explain why others I've seen had it. And, I'd guess that the statement in the EVTM just got carried over from year to year. Easy to see that done in such a big organization as Ford.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

Yep. There are MANY errors in the Ford EVTMs; even the later ones. I find one nearly every time I study a new cell. And Haynes carried (probably STILL carries) the error about the IMS through several editions. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

Yes, and the trouble always is which Ford publication to believe. I think the more specific one is the best bet. In this case the TSB is more specific to a given year, so it would win.

But there's also the publication type to consider. I think brochures, which were on the leading edge, are the least reliable, possibly because the folks doing the manufacturing changed their minds after the brochure was printed. So, with that theory I'd say TSB's are the most accurate as they were written last, well after the fact, to correct a known problem.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by Gary Lewis

In the short time I worked at the dealership, I made 2 corrections for the service manuals, and 1 to a recall. What does that tell you about how often there are published mistakes?

I forgot to reply to this earlier... Good catch - I never think about that because I got rid of that wiring harness so long ago. So if you're using a 6V heater, and you don't want to use the alternator "S" (for whatever reason), you could use the coil positive/capacitor circuit. It would get ~12V during cranking (actually closer to 11 typically), but I doubt that's long enough to fry the element. |

|

In reply to this post by Ferdinand

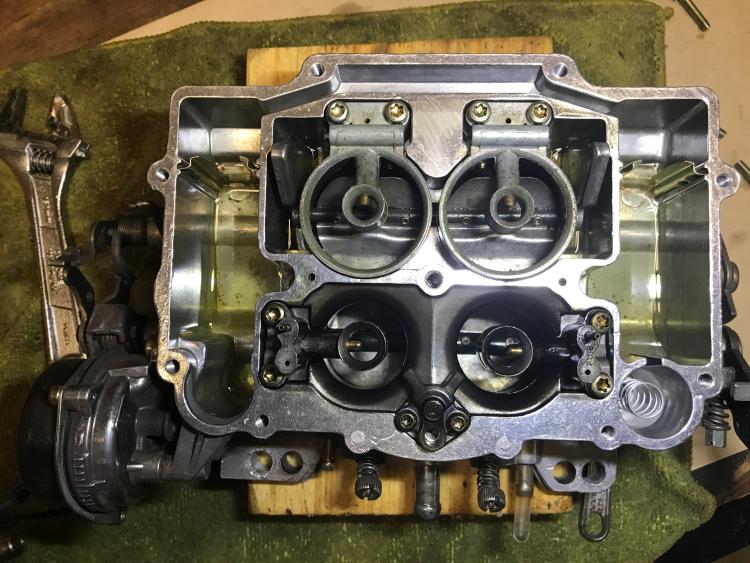

Sorry guys. I thought this post went through the other day but I don't see it in the thread...

So this is where I am stuck: I pulled the carb apart again thinking I may have had a float issue or some sediment come through.    Evertyhing looked pretty clean and good. (Especially for a carb that was on fire 🙃) Since I can't seem to get anywhere with vacuum or timing, I started trying to think of other options. Fuel was one variable. Also my cousin called in some help and thought of checking my vacuum booster for a leak which I will do later tonight. As far as the fuel goes, I found this:  This hard bend may be restricting enough fuel to make me run rough. I'll be checking it here very soon! (Thinking of either making a loop with more soft line, or bending steel tubing into a "U" shape and just connecting it with 2 little sections of hose.) I have to admit, I am curious why Ford has a design that puts two hard lines pointing up to be connected for fuel. It has me thinking I may be missing something? Thoughts?

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

In reply to this post by Ferdinand

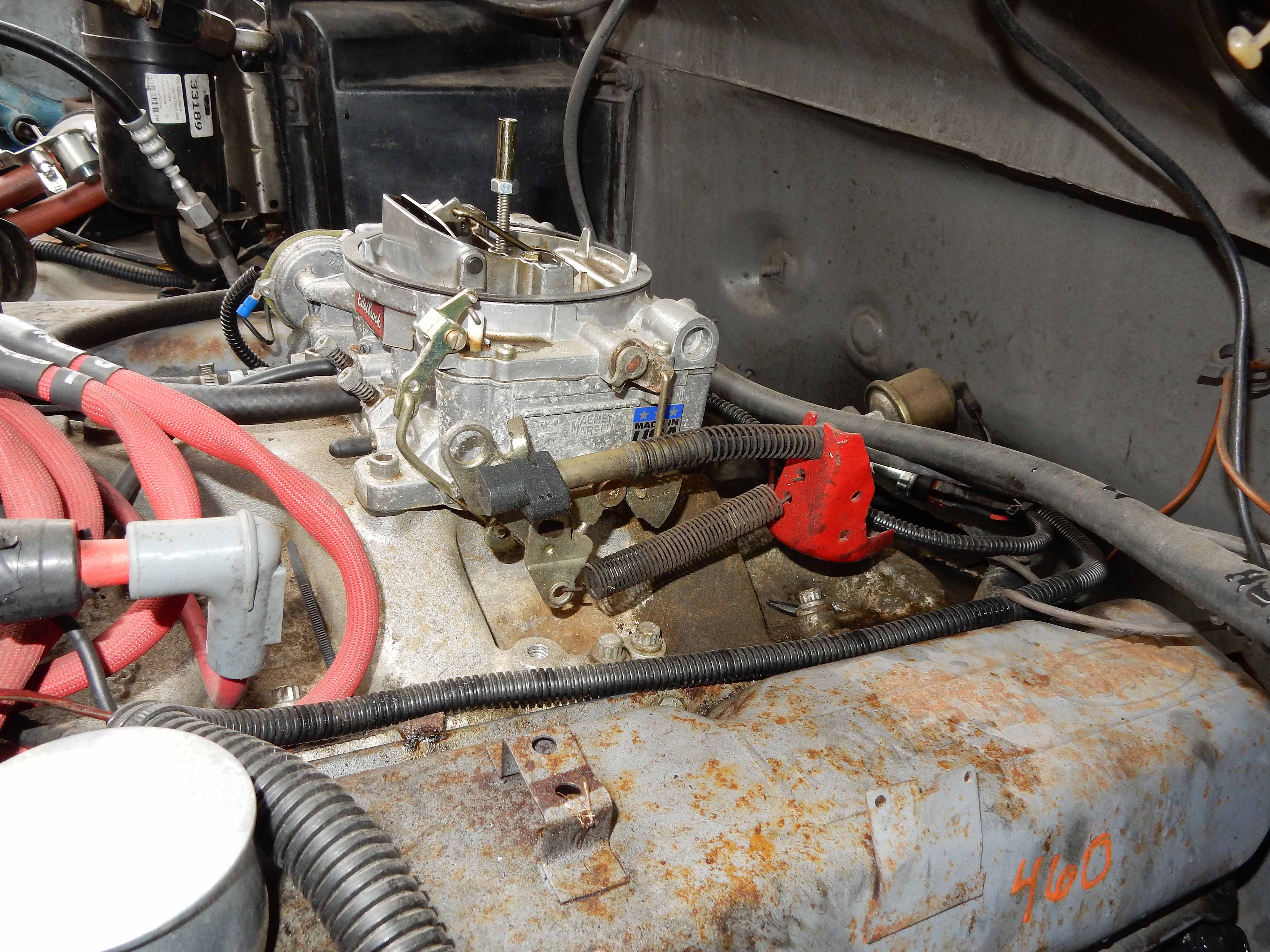

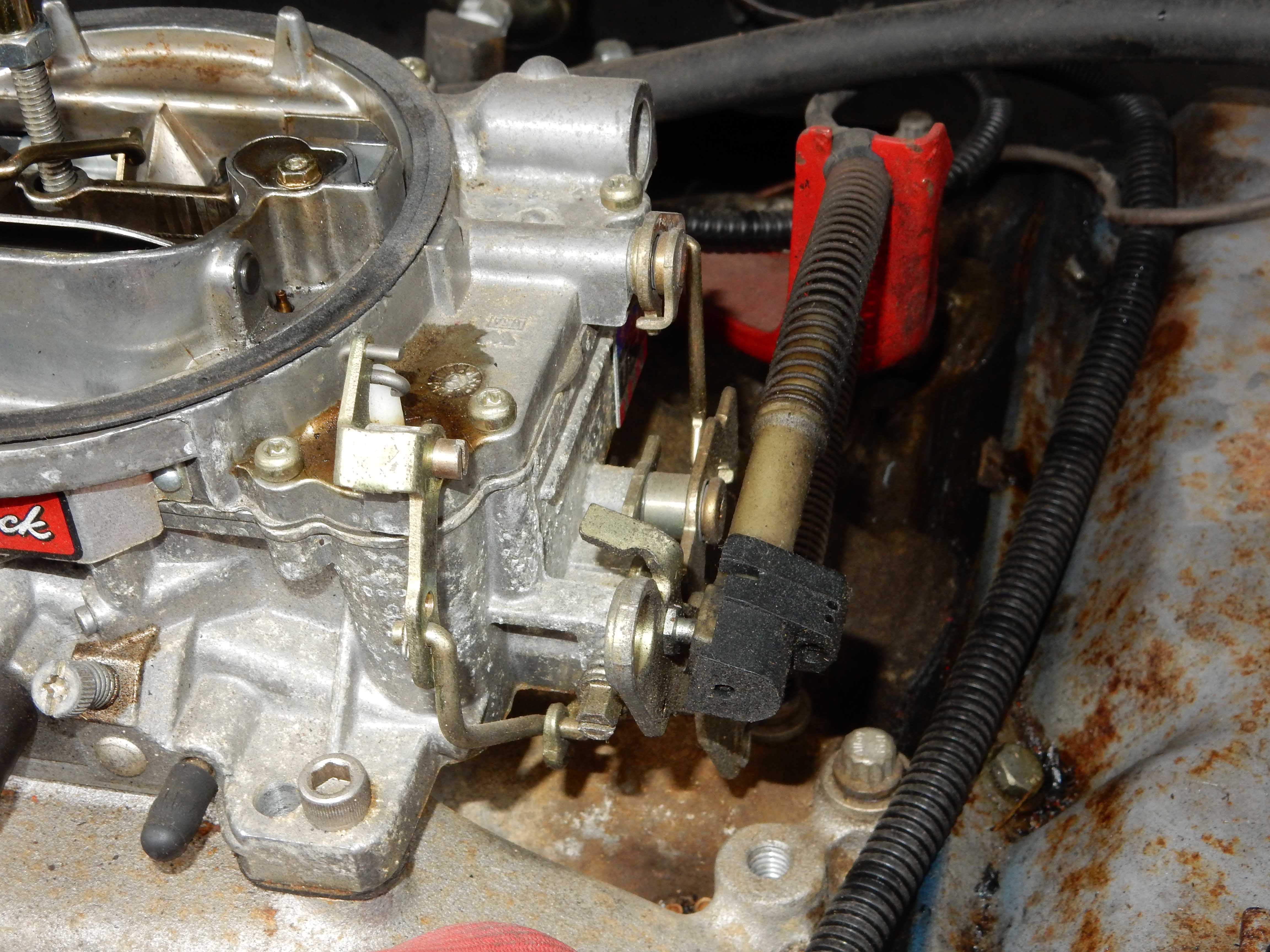

Also, if anyone is running an Edelbrock carb, can you please take or share some pictures of your throttle linkage?

The linkage was charred quite badly so by the time I chem-dipped and sand blasted it(I do not recommend sand blasting your linkage) It was hard for me to tell exactly how it all went back together. I looked at the info from Edelbrock and I tried searching the web for some clear photos of something similar to my application but haven't really found much that I could easily see. Thanks everyone!! P.S. I am still looking for a good tap for my choke. I hope to get it connected tonight as well. I will pick something from the fuse block since what is out under the hood sounds like it may be an issue using that. Thanks for weighing in on that issue guys!

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

Those bends aren't too hard to restrict fuel for the kind of load you have. Maybe, remotely at 6000 RPM in 3rd gear. So I don't think that is your problem.

As for the linkage, I'll take a pic tomorrow - if it stops raining. In the interim I'll look my pics over for one that shows the linkage.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by Ferdinand

Possibly the fact that, if the nipples pointed straight at each other, the hose would have to go straight from one to the other. And if the engine mounts broke (as they commonly do), the hose would be so short that it would be ripped apart, causing a fuel leak right there in front of the hot manifold, probably resulting in a fire. So pointing both nipples up forces the line into an arch, which allows for the movement between the engine-mounted pump & the frame-mounted tube. Forward (into the belts), backward (into the manifold), & down (into the frame) aren't really options, so it had to be up. That's my first guess... But I think you're right that a longer arch or loop in the hose would do you some good. I certainly wouldn't replace the hose with a hard tube U & 2 shorter hoses. |

|

In reply to this post by Ferdinand

Any one see anything wrong with this picture? And no I don't think that bend is that bad to cause the issue you have. My bad I see "not for fuel ...." is that "injection systems"? Ok if under load you are off the idle side of the carb so you need to look at every other part of that carb. Did you rebuild it or just pulled it apart to give a look see? How far down did you go? Does it use a power valve? Any plastic parts inside it that could have melted? If you have not I would pull it all the way apart and do a good cleaning then a look over for melted or warped parts. I would run thin wire thru all ports being careful not to gouge the ports to hurt air / fuel flow to make sure they are all open. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

In reply to this post by Ferdinand

Let's see if these help. (Please disregard the red bracket.)

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Thanks Gary!

This is very helpful.

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

|

This post was updated on .

In reply to this post by Ferdinand

Nearing my limit...

Still having same problems  (Opening comments were due to realizing I left a map light on and drained the battery 🙃) So in battling the issue I have leaned out the idle screws, still no good. (thought it sounded and smelled like it was running rich) Tried pulling the vacuum advance from the distributor and time it, no better. Put it in reverse and let off brake, no real change. (checking for vacuum leak in brake booster) Hooked up electric choke now I am having a few more issues (but I’m guessing I just need to adjust the choke.) I’m about to roll this thing down into the pond. I am completely stuck at this point.  If anyone has thoughts, I am all ears...

Jamie Helmick

'85 Bronco 351W HO, C6, 4X4, Full rebuild @ 51k original miles (fire), Edelbrock air gap intake & 600 cfm carb. w/elec. choke. 4" RC lift w/35's. Check the Projects Page if you're interested. |

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

DON'T ROLL IT IN THE POND! I'LL BE THERE WITH MY TRAILER!!!!!!

Seriously, you are right on the cusp of getting it sorted. I'll go back and re-watch your video, but whatever you did around the 5 minute mark made a big difference. So, can you tell us what you did at various points in time? Again, don't give up. Please! (But, if you do let me know and I'll come get it.  ) )

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Ferdinand - '85 Bronco 351W XLT "Phoenix" rebuild project...

|

Administrator

|

Ok, what's the status? How's your mood? Hang in there buddy, there's light at the end of the tunnel.

And, I meant it when I asked for a bit of explanation as to what you did when in that long video. It might help us understand why the tone changed and, therefore, what the issue(s) is/are.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |