Dad's Truck Build

|

Administrator

|

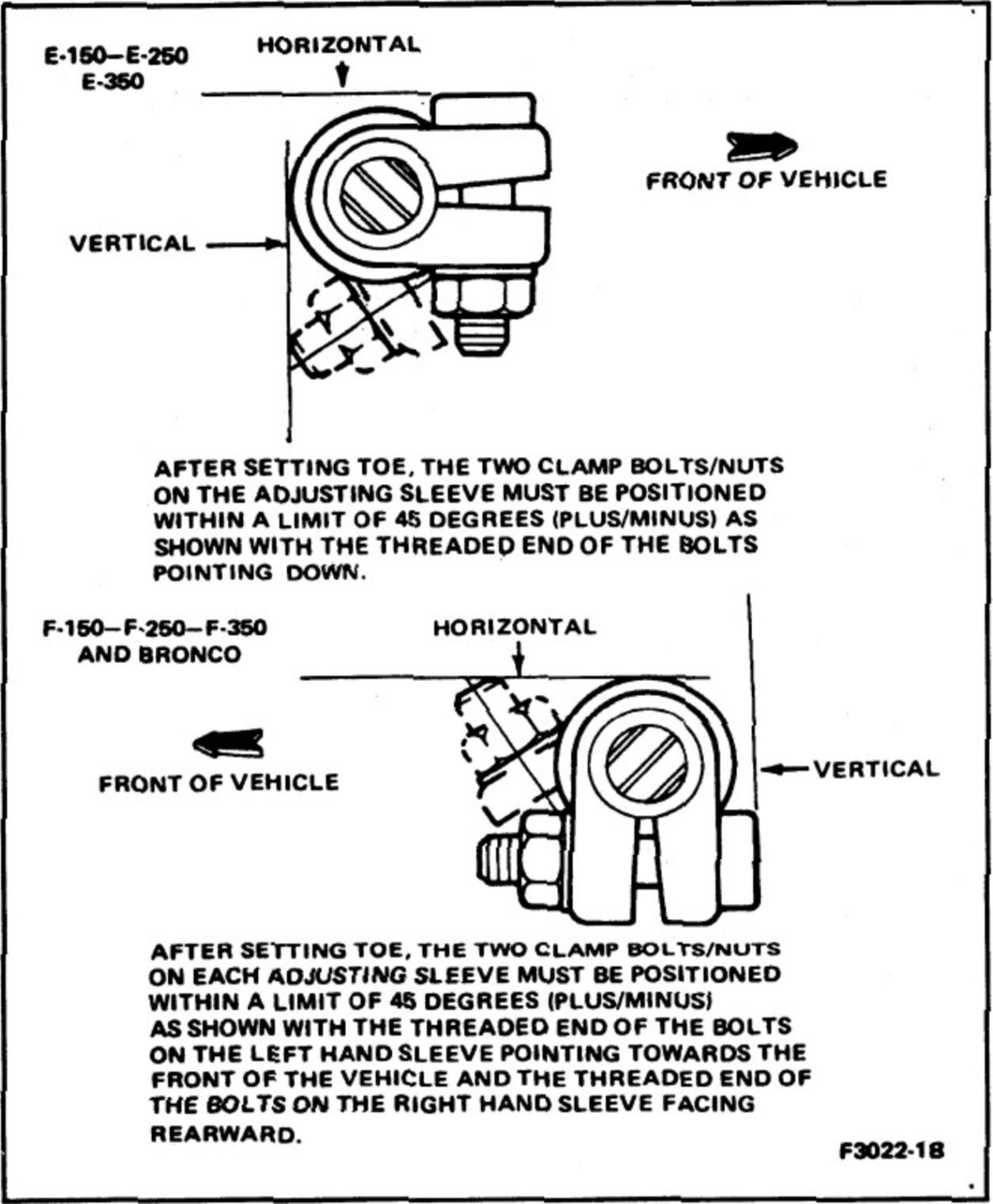

Interesting, the ones on Darth have the bolt heads on the front side and nuts on the back. If I remember correctly, the right side can only be assembled that way due to the strange design of the crew cab steering linkage.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

I'm just going from this on Page 13 here: Steering & Suspension/Front Suspension and then the Instructions and the General Suspension Service tabs.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by 85lebaront2

The PO dragged the truck around with his tractor by that tie rod. Come to think of it; I guess that tie rod is still on the truck. How is it different from the X-cab, std. cab, or Bronco linkage? |

|

Administrator

|

Steve, it has to do with the steering angle, my inside front, in whichever direction I am turning gets very close to 90° to the frame. The right side inner tie rod is unique to the crew cab and uses a stepped adjusting sleeve as the inner rod threaded end is bigger than the outer threaded end. The left side is more normal.

FWIW, the right inner is one expensive piece. Last time I had to replace it I was all set to order a Motorcraft with a lifetime warranty, and just when I put the order in at the local dealer, it came up as NLA.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

This post was updated on .

Got some testing done using the shop crane today. First, here's the engine in position, although the stands are still on. And, by the way, the flexplate is on and torqued down, and the engine plate is ahead of it.

Then the question was if I could somehow get the shop crane's legs past those of the engine stand and get in position to pick up the tranny. The answer is yes, as shown below. But instead of using the load leveler I'm going to use ratchet straps, although we'll add a couple more than those shown for safety on Monday. The issue is clearance. Looks like with the straps in the configuration shown I can get the boom 15" from the vent on top of the tranny and that will give 4" of clearance between the bottom of the tranny and the top of the engine and 4" from the boom to the firewall. Oh, note that the rear mount is installed and torqued down/up.

So, what does the to-do list look like now? Green is done, and red is to-do.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

|

Administrator

|

I don't think changing out the stands for the mounts will be a problem, Steve. We'll just dangle the engine from the shop crane, use the battery-powered impact to remove the stands, and then install the mounts. And with one of us holding the engine it should be easy enough for the other to torque the bolts to 50-70 lb-ft.

But thanks for the suggestion.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Must remember: Two steps forward and one back is still progress. Two steps forward and one back is still progress. Two steps forward and one back is still progress..........

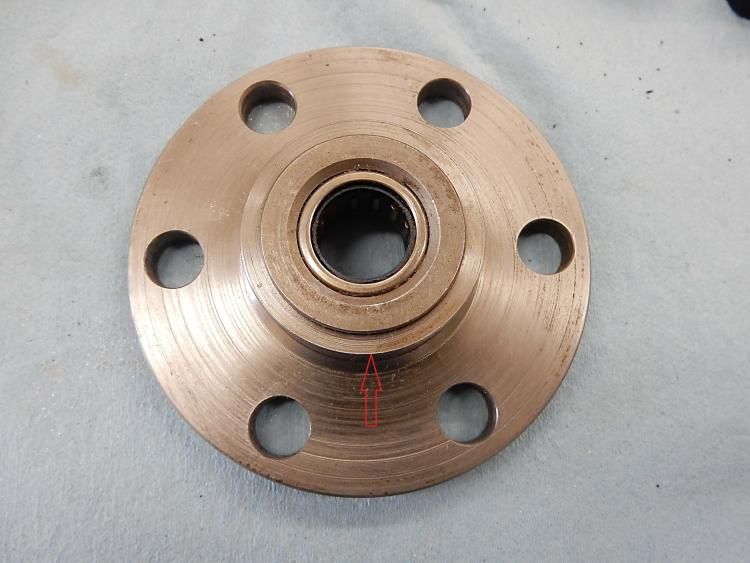

Ok, so the best laid plans of mice and men. Things didn't go exactly as they were planned. Close, but no cigar. As you know, today was a big day. My brother came down to help me install the engine, transmission, and transfer case and then put the cab back on the truck. Well, we got the engine installed, and here he is guiding it home:  And, here he is doing the same on the tranny:  Then the "fun" started. We got the transmission lined up and connected to the engine, but it wouldn't pull up tight to the engine w/o binding such that you couldn't turn the engine over. After installing 6" G5 bolts as guides, and a jack stand on a skate, as shown below, we were able to pull the tranny back and inspect things, slide it forward to test, slide it back, ...... We did that drill multiple times until we proved that the adapter is the problem.  And, the issue with the adapter is twofold. First, on the front side of it the recess that goes over the rear of the crank wasn't machined cleanly enough. In the pic below you can see that there is a bit of a ledge at the end of the arrow, and that was keeping the front face of the adapter from mating fully with the rear face of the crank. So we put the adapter in the lathe and bored it slightly deeper and cleaner, which allowed it to mate correctly with the back of the crank.  But, that still didn't allow the tranny to mate with the engine. So we took more measurements and determined that the projection on the rear of the adapter is at least .175" too long. In other words, we were pushing the torque converter to the rear and into the transmission, therefore binding things.  So tomorrow I'm going to spend time accurately measuring the 460 and its flexplate as well as the 400 and its flexplate, and determine what the dimensions of an adapter should be to put everything in its proper position. Then I can modify this adapter to match those dimensions.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, didn't the 351M/400 engines come with a C6? The E4OD converter attaches to a 460 C6 flex plate with no problems. I doubt Ford used either and adapter or special torque converter for those applications. I would research those numbers, probably in car applications. FWIW, my boss at NNS had a 1979 Lincoln with a 400 and C6.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

In reply to this post by Gary Lewis

I'm no expert on this, but I think it's pretty easy to damage a torque converter doing that. I know it's a risk if you don't get it to make the 3 "steps" going onto the trans. I don't know what I'd recommend, but if the torque converter is damaged I'm thinking you'll want to know that before you get the trans installed.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

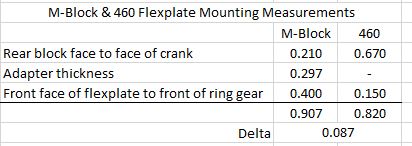

Bill - Yes, the M-block used a C6. But the issue is that the M-block's crank ends about 1/4" closer to the block than the 460's. So if you put everything together w/o a spacer to move the flexplate back, there's 1/4" of slop in the system.

I want the flexplate to be exactly where the 460's flexplate would have been. That way a 460's starter is a perfect fit. And I want the pilot for the torque converter to end at the same spot as a 460's so there's no slop in the system. Bob - We didn't tighten the bolts any where near enough to damage anything. We were very careful to check that we could turn the engine over, and when we sensed that there was a bind we stopped tightening the bolts.

I'll draw it up tomorrow and I think it will be easy to see what I'm talking about.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, my question is what did Ford do on the 351M/400 with a C6? was it a different "dished" flex plate? I thought I remembered the starters were the same as the 429/460 ones as far as depth and the weird one bolt each way design.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Yes, the flexplates are quite different. Here's the table from several days ago and you can see that the flexplate is .250" different between the two engines. And the end of the crank is .460" different in relationship with the back of the block.

Anyway, drawings with measurements will be coming tomorrow.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, no one likes a set back... especially after as much planning and preparation as you’ve done. However I think you are doing really well. Snags come up even with bone stock parts, and modifications/adaptations up that probability by at least 10x. Even commonly done swaps and mods don’t document every possible glitch, and a E4OD behind a 400 is likely an all time first no? I say bravo and carry on! Everything else looks really good, and you should have some very useful data for the next guy... is this one of Tim’s ZF adapters that you are working with or an entirely different part?

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

Thanks, Jonathan. I appreciate the support. And, in the almost light of day, we did make good progress yesterday. Just not as much as I'd planned or hoped for.

The adapter is the prototype to Tim's. I drew it up, with the help of many others, and machined it. The fit was perfect and I told Tim about it. He was interested so I sent him the drawings and he made several. I wonder how many he's sold? But it obviously isn't quite right for an E4OD swap. As for how many E4OD's there are behind 400's, I haven't read about any others. So this is may be another first-of-its-kind, and little glitches like this are to be expected. I just didn't see it coming. Hopefully later today I can figure out what the issue is and fix it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

For your information, when I switched the E4OD into Darth, with the converter fully seated as far into the front pump as it would go, when I "married" the transmission to the engine the converter studs just penetrated the flex plate. I had enough thread protruding through the flex plate to verify a correct installation, roughly 1/8", just enough to get a new TC nut started to seat the converter.

Since the E4OD was intended as a reasonably fitted update to a C6, even though they were not used on the 400s it would seem that a 400 set up for a C6 with the original parts should accept an E4OD with no problems. The recess in the crank. or adapter has to be the correct diameter for the C6/E4OD converter snout. The actual location of the TC with the nuts tightened is approximately 3/8" forward of the full seated position, you need to allow for that. If it was mine, I would try an installation with no adapter, just the 400 flex plate and thin headed bolts attaching it. If the TC studs just enter the flex plate like this, you have the correct assembly. Unfortunately I no longer have access to the starter nose drawings, so can't do a dimensional comparison there. I used Rock Auto's catalog, according to them, using the Motorcraft Remanufactured PNs, the 351M and the 460 take the same starter for the automatic transmissions, this tells me that there should be no need for the adapter if a C6 was to be used and since the E4OD is designed to bolt up the same as the C6 then it should not need an adapter and the later 460 PMGR starter should bolt on perfectly. One of the notes in the 1981 351 listings specifically states one threaded and one unthreaded hole.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Bill - I think what you are saying is that when you tighten the torque converter's retaining nuts it pulls the converter forward from the fully-seated position approximately 3/8". And that's valuable info as we noticed that the converter's studs were just coming through the flexplate, so wondered about that.

As I think about this, there are two things the spacer needs to do:

The thickness of the flange on the spacer determines where the flexplate is relative to the back of the block/front of the tranny. And the length of the nose of the spacer determines how far forward the torque converter can be pulled. Thinking through it this way has helped. Thanks. As for needing a spacer or not, let me draw it up and let's see what we think.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

What you might do, if you have an original M block starter and a 460 automatic starter, they don't need to be the PMGR, in fact the old movable pole piece might be easier to use. Attach the block plate to the block using short 7/16-14 bolts, probably only need 2 or 3, right above the starter and maybe one opposite for stability.

Then to use proper English terms, offer up the starter to it's proper mounting, using a temporary bolt and nut and short bolt, snug it with the proper spanner. After that, with the flex plate to be used stroke the starter drive into it's proper position for cranking the motor and see if the meshing of the gears is correct. Basically do this with and without the spacer to see if you have the proper gear mesh and clearance, then work on the TC position.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

I do have M-block and a 460 starter. And the 460 one came off Huck with an E4OD. But, is there a 460 auto and a 460 manual starter? I don't see that in the MPC, but maybe I'm missing something?

Do you think the block plate is stiff enough to hold the starter w/o the tranny?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Gary Lewis

WOW Gary, can't wait to see it in person later this Month!!! I am getting excited!

1988 F250 Supercab Longbed 7.3 IDI, C6, 1356, GEARVENDORS, 4.10 Sterling with autolocker

1986 F150 302, C6, 9" 2.75, Wood Flatbed |

| Edit this page |