Dad's Truck Build

|

Administrator

|

Ray - That's basically the game plan I came to a few minutes ago. Then I got an email from David suggesting the same plan.

So, here's where I am, but I'll update after a bit.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Now to go try it:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Ok, we are now up to maybe 1/32" clearance, but I don't have the bottom nuts on the cab mounts, much less tightened down. But, with poly they won't squish much. However, more clearance is needed or there will be thumps and bumps.

So, I'm looking into what can be done with the tranny's mount. But, I could put 1/4" spacers on everything. Would that be enough, or does it require 1/2"? Another option would be a spacer on the rear cab mounts and not the fronts. That will then require two different spacers on the bed. Thoughts?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Could the head of the bolt be turned to a smaller diameter and the housing trimmed?

|

|

Administrator

|

David - Yes, it probably could, but the head of the bolt is already smaller the the boss it is going into. So trimming the boss would be the first move in that area. However, I don't know how much can be taken off and still have adequate strength, so I'm reluctant to do that.

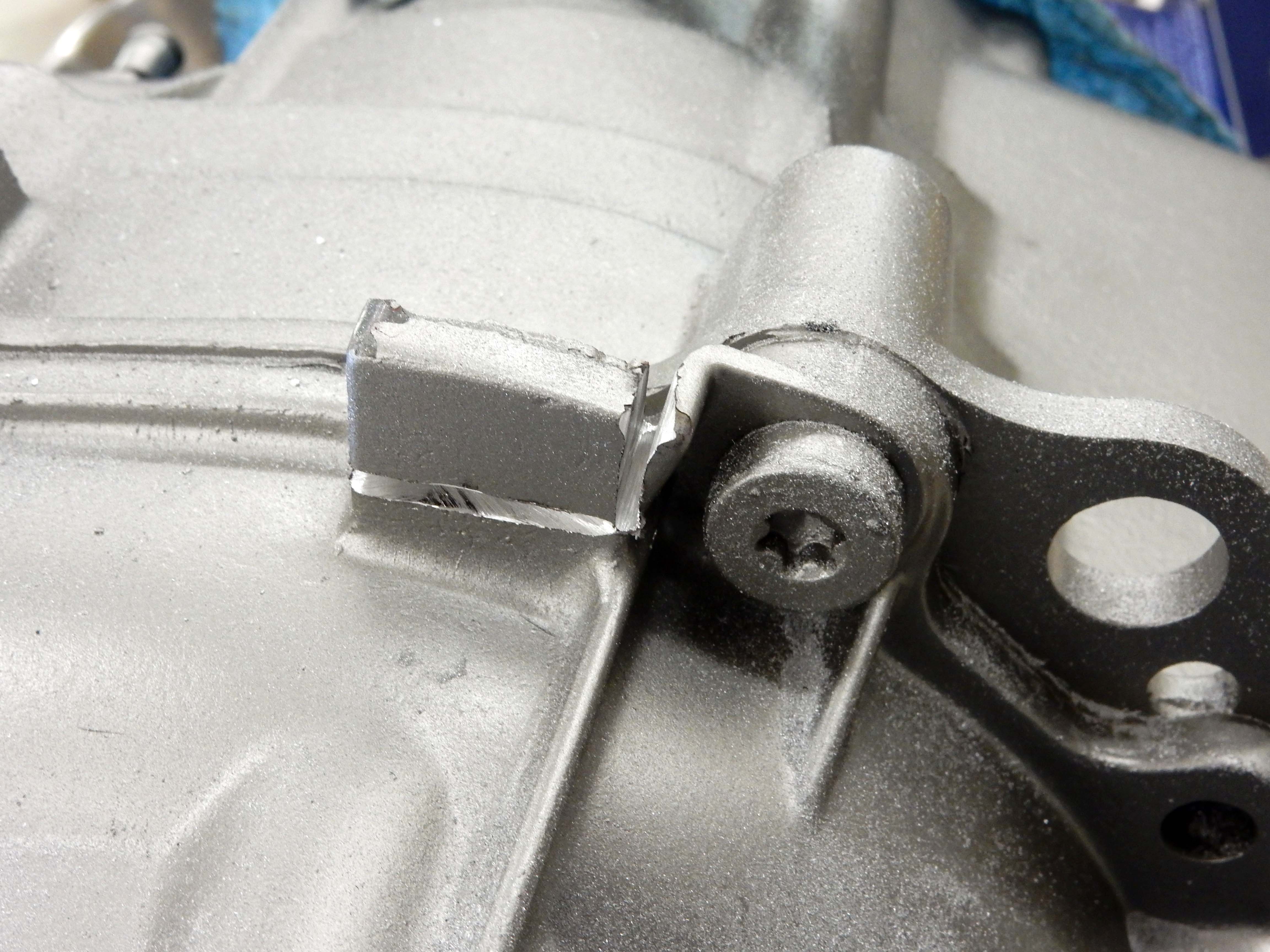

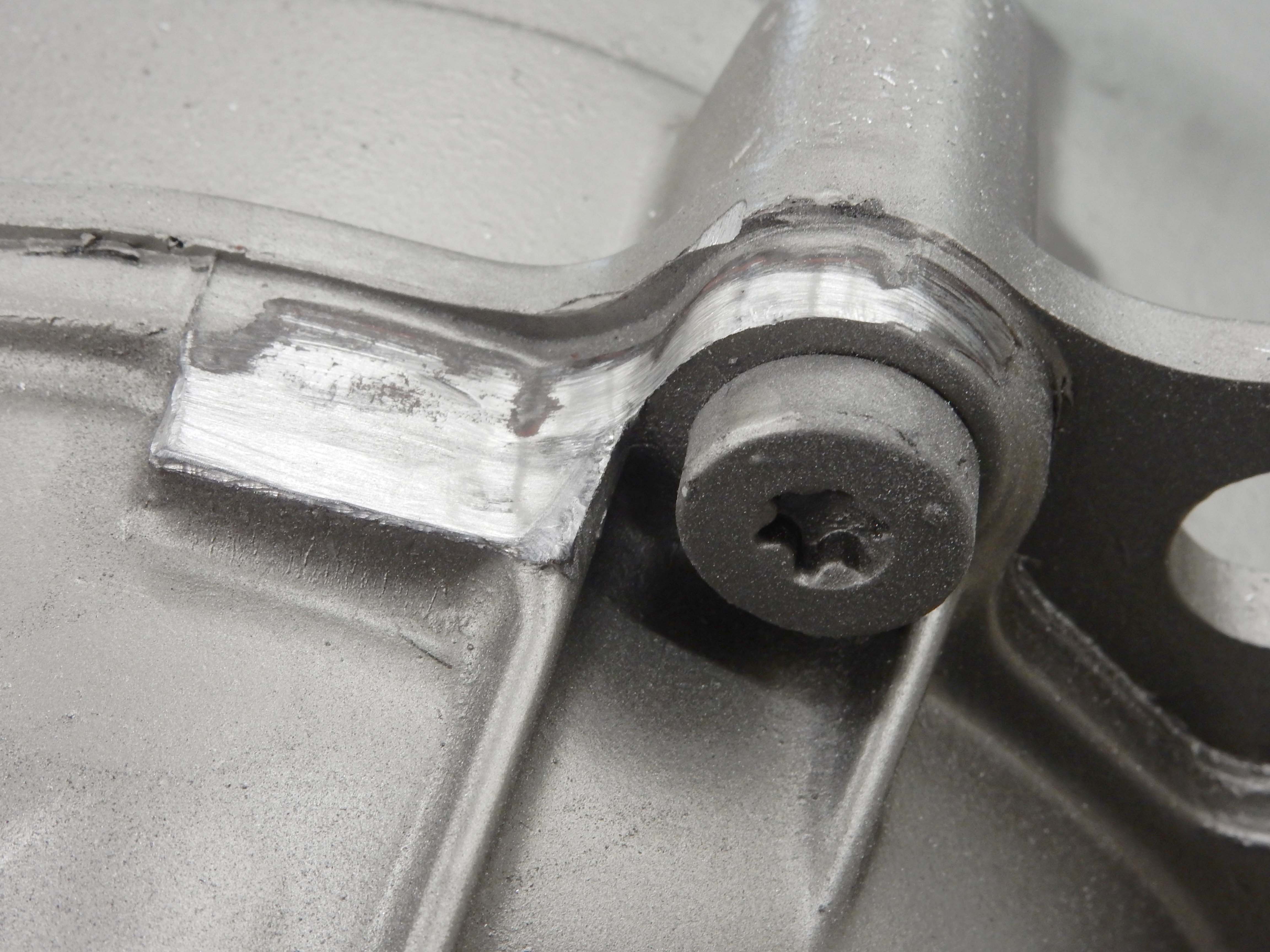

Having said that, I did get some clearance today. After cutting off the tab I re-installed the 1356 and lowered the cab and had maybe 1/32" of clearance, as shown on the left. Then I cut 3/8" plywood spacers and installed them, just for testing purposes, and got the 3/8"+ shown on the right. After that I torqued three of the four mounts down to 30 lb-ft, but ran out of time to get the fourth, the right front. Anyway, with those three down to 30, when the specs call for 40 - 50, I still have 1/4" of clearance. But, by the time I get them to 40 lb-ft I'll bet I'm down to 1/8". So I'm not sure that 3/8" is enough spacer. How much of an issue with the bumpers will 1/2" of lift be?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

I certainly wouldn't attempt to "tilt" the body in relation to the frame; keep all the lift pucks the same thickness. The bumpers should have 1/2" of adjustment from the factory, but I don't think anyone including you will notice if they're 1/2" lower (relative to the body) than original. I think 1/4" is plenty with poly mounts, but it won't hurt to drive a few miles on wood pucks until you choose the thickness you want, and buy/make permanent ones.

|

|

Administrator

|

In reply to this post by Gary Lewis

Gary, there is quite a bit of adjustment in the front bumper’s slotted mounting holes. I needed to raise mine to accommodate the home-made front hitch that I found in the junkyard. When I went all the way to the top of the slots, it tilted the bumper out at the bottom. I didn’t end up needing all of that clearance, but I could have spaced the bumper out at the top if I needed to. I did not leave it like this, I just had it at maximum travel while I mounted the cross member/receiver piece:

Edit: by chance have you checked the tunnel cover clearance over the E4OD? Would shims give you enough clearance to use the Bullnose tunnel cover?

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

In reply to this post by Gary Lewis

Gary...you are over thinking, over engineering. The solution is a minimal spacer on the body mounts, and a BFH on the floorboard. No one will care if you "clearance" the floor pan with a hammer.

Just take some time and make your clearance dimple as straight and clean as possible. I suggest start the dimple by striking a small diameter rod. The work your way slowly to larger and larger diameter rods until you get the clearance you need. Maybe turn down the ends of your striking rods to be spherical so you dont get sharp edges cutting the steel instead of shaping it. Perhaps you have multiple ball peen hammers. Trying holding the peening/round side to the floorboard, then strike the flat side with another, larger hammer.

1988 F250 Supercab Longbed 7.3 IDI, C6, 1356, GEARVENDORS, 4.10 Sterling with autolocker

1986 F150 302, C6, 9" 2.75, Wood Flatbed |

|

Administrator

|

Ok guys, thanks. I think the plan is shaping up. I won't get to it today as we have other things going on, and maybe not tomorrow, but I'll tighten the bolts down to 40 lb-ft and see if I'm right that there's ~1/8" of clearance. If so, then 1/2" spacers would do the trick. And, there's probably that much adjustment available in the bumper brackets.

But, there's Ray's, and Janey's, suggestion of using a hammer to get clearance. In the pic below the one in question is the closer of the two white marks, the one just this side of the tape's end. I'm not opposed to dimpling the floor there as it will never be seen. And, if I can get 1/4" of movement that would cut the spacer size to 1/4". If it is ever to be done, now is the time as once it is bolted down there's no way to get to it w/a hammer. So I'm going to ask my paint/body man to stop by on Thursday or Friday and we will see if he can dimple it. We might want to strap the thing to the lift arms to ensure it won't move, but that should be easy enough. With your help I think it'll get there. And I'm feeling much better about it. Thanks!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

An air hammer with a large face is probably a good way to work that sheet metal. Especially if you can put a large anvil (any chunk of steel or cast iron) on top to limit the bulge. But it should be easy to control the depth just by holding the tool back; even at full power. And being a faster impact, it's less-likely to push the body on the lift (which can be limited with ratchet straps).

|

|

Administrator

|

I sent a text to John and hope he'll come Thursday or Friday. I don't know what tools he will have or want to use, but he is a wizard on metal working.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Put the BW1356 t-case back on today. Cleaned the gasket surfaces, coated another gasket with Ultra Black, put the gasket and the t-case on, and snugged up the bolts. Tomorrow, after the RTV sets up, I'll torque the bolts down and touch them up.

And, speaking of touching things up, I also touched up the t-case where I cut the tab off. Can't really tell where it was now. Also, I installed the new spark plugs. Haven't gapped plugs in years, but the NGK's came at .030" and I set them to .040". Then a little anti-seize and in they went. Boy, this was the easiest plug change I've done since the Briggs & Stratton Model N on my go-kart! Still haven't heard from John, the paint/body man, so I don't know if he's coming tomorrow or Friday. Hope so as I'd like to have a pro put the dent in the floor.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

Wind up pull cord?  https://www.bing.com/videos/search?q=Briggs+and+Stratton+Model+N&view=detail&mid=7B67B25E1CCF7E5B16137B67B25E1CCF7E5B1613&FORM=VIRE |

|

Administrator

|

That's the guy!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Man! Has it really been 5 days since I posted here? Oh well....

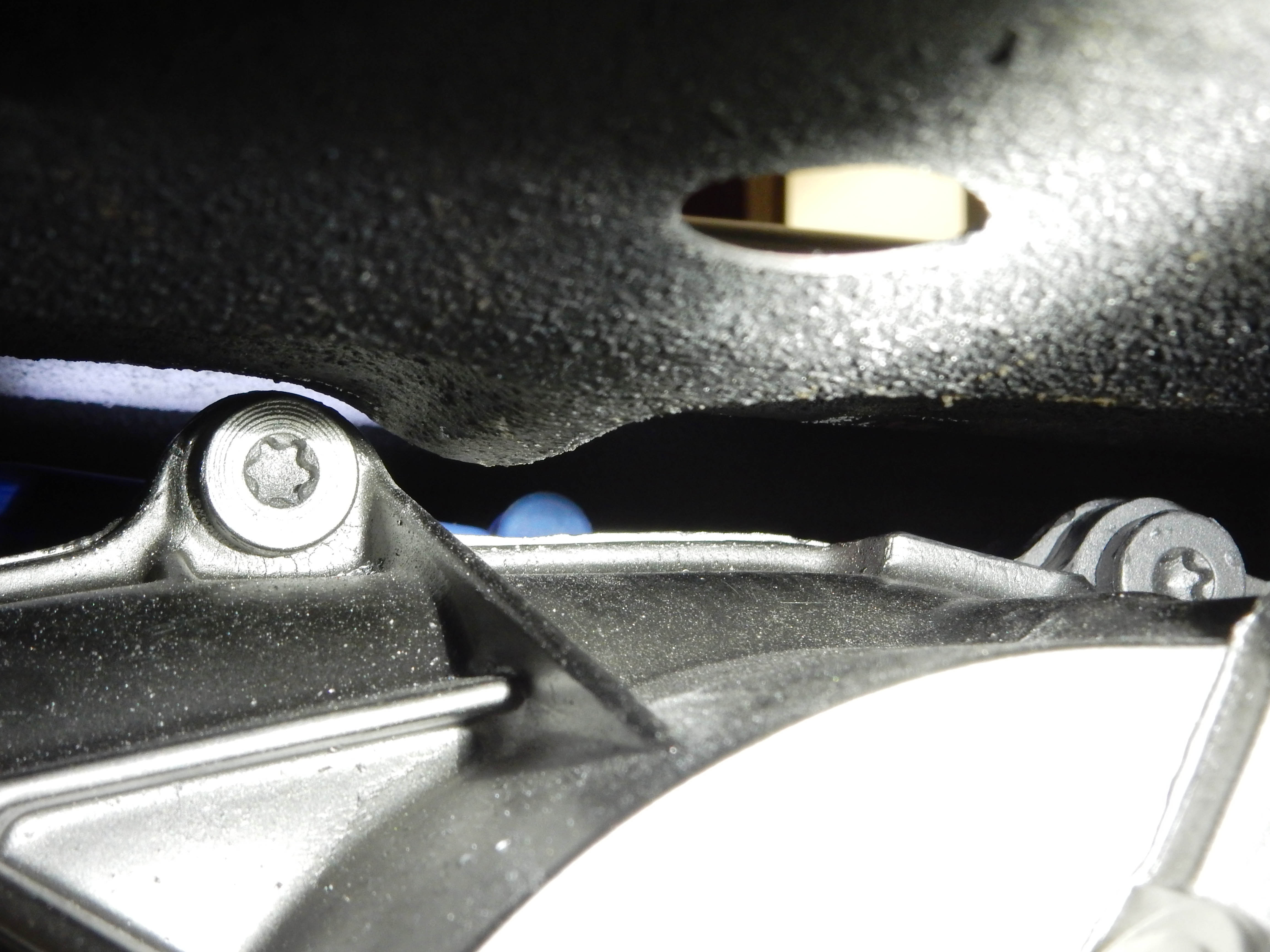

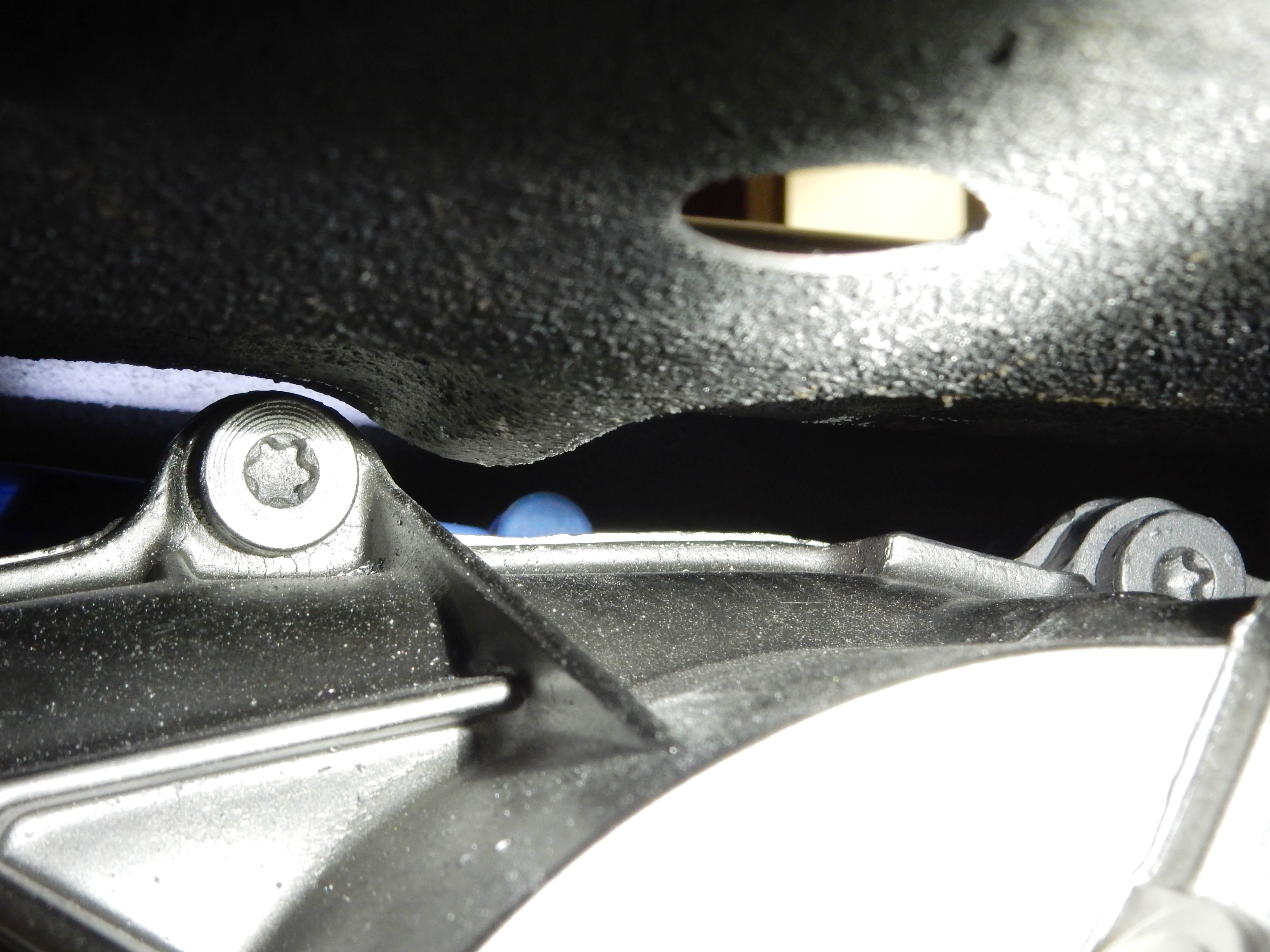

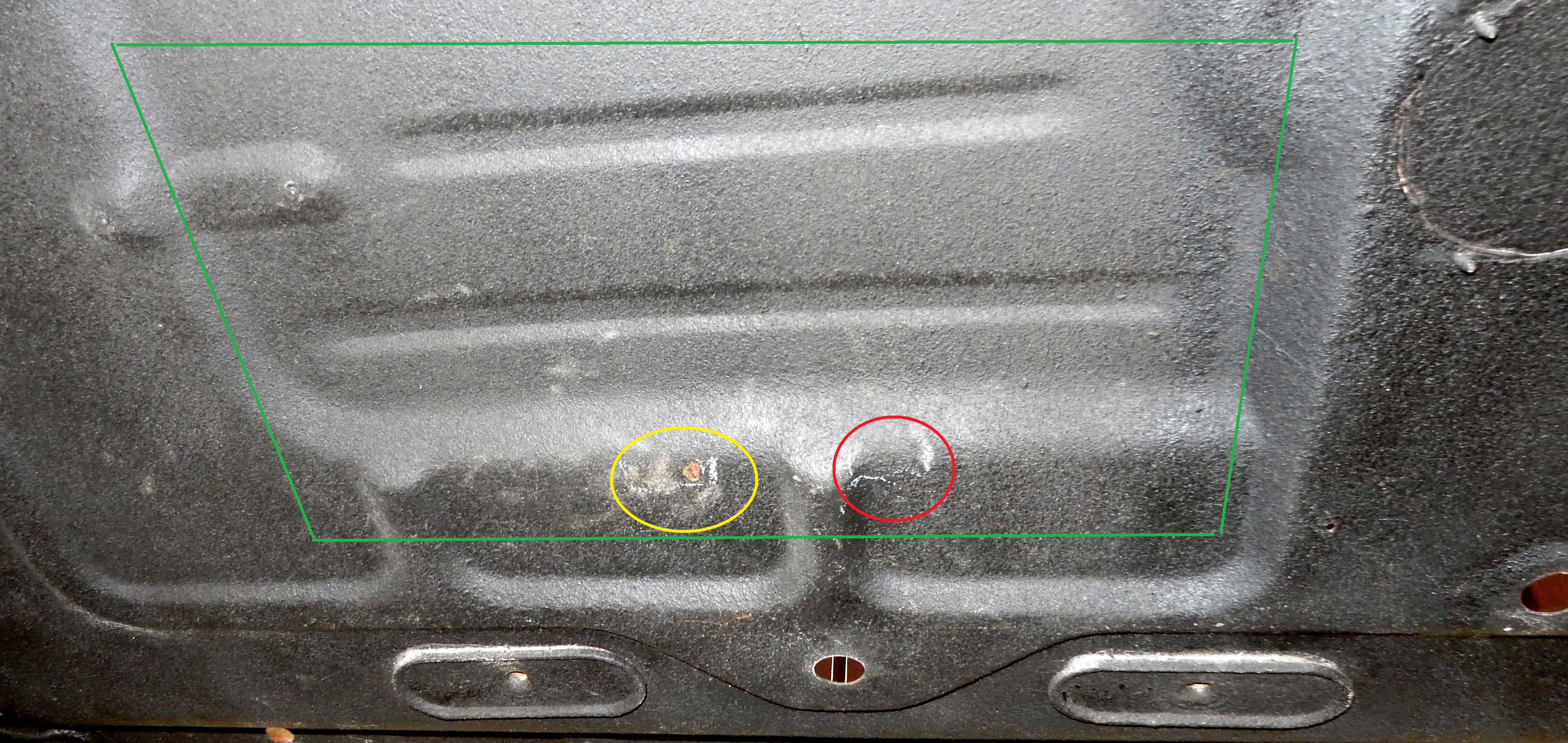

Anyway John, the paint and body man, came down today to look at the situation with the floor of the cab. He doesn't want to start banging on it, and doesn't want to weld. But, he did recommend that I get a piece out of another cab and we graft it in. If it is just like this one we should be able to overlap them, use the structural adhesive as well as pop rivets, and make it every bit as strong. Plus, with undercoating on the bottom and Dynamat on the top, plus carpet, no one is going to see it. Below is a pic of the underside. The yellow oval shows where the tab was hitting - before it was exorcised. The red oval shows where the center bolt boss will hit after the mounts are tightened down unless something is done. And the green lines show where I think I'll trim a donor's floor. But, I'm now wishing I hadn't gotten rid of Huck. As a '90 would his floor have the raised spot extended? Or, would there be other differences that would make it difficult to fit it in? Anyway, anyone have a cab to cut up? John said he's headed to the salvage soon and will be on the look out for one. And Brandon/Bruno2 was just here and said many of the yards no longer allow cutoff wheels, so I need to check that out.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Called North Yale Auto Salvage, which is maybe 10 miles away, and they think they have the right truck. And they'll let me cut it out. Further, they do allow battery-powered cutoff wheels, which Brandon tells me that some do not.

I'm not going to be available until next week, so hope get over there then. And, in the interim I have a good excuse to buy this:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

That's great! You always need more tools!

I'll have to ask our pick and pull next time I'm there about cutting stuff. They won't let you in without long pants and shoes.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Banned User

|

In reply to this post by Gary Lewis

A jigsaw is probably more-efficient (burns through its battery slower, for the distance it cuts), but I was surprised at how clean a cut I got from the slitting chisels, and how fast they cut through sheet metal. A hammer drill that can be set to hammer-only would drive it. |

|

Administrator

|

Grumpin - It is all in the way the information is presented. I explained that the yard has the part but that it will be less expensive if I pull it. But, my battery-powered reciprocating saw won't work as there's still a transmission down below that it would hit. So, I need a right-angle grinder, but it has to be battery-powered as there's no 110v in the yard.

Ridgid has one that uses my considerable complement of batteries, but from Home Depot it only comes in kits with other tools - for $300 or $700. And I already have most of those tools. However, Direct Tool has the grinder by itself for $99, and we are going to be there anyway on Friday. On top of that, the Ridgid vacuum that we'd already agreed I'd buy when there isn't available in anything but a kit with a blower, which I don't need. So, this is less money all the way around.  Steve - I've not been impressed with how long metal-cutting jigsaw blades last. I've tried several different ones in my little 110V saw and they tend to die pretty quickly. But I've had good luck with cutoff wheels on a right-angle grinder, so will be going that way. And I'm not worried about the power situation. I have 4 batteries and that video says the batteries lasted a long time. So I should have plenty of power.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

That'll be fun! Making sparks at the junk yard!

Plus, and I like this, you'll still have your original floor!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

| Edit this page |