Dad's Truck Build

|

Administrator

|

Yes, the automatic and manual 460 starters are different, ask Jim with his issues discussed on FTE. I actually did post the drawings of the nose pieces on there for Matt. They are probably still there under Jim's starter problem, or issues, or woes. I don't remember the exact thread title.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Ray - I can't wait to show it to you.

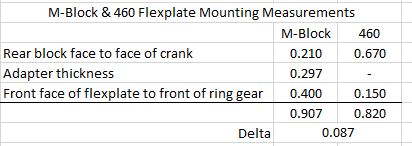

Bill - I'll go look on FTE for them. You posted them? All - I got some measuring and CAD work done today, but then the call came to rescue a friend, as explained on WHYDTYTT, and I spent the rest of the day doing that. And now I'm exhausted. But I can already see that the spacer I used for the ZF5 isn't going to work for the E4OD as it holds the torque converter too far rearward and that causes a bind as well as doesn't all it to mate properly with the flexplate. So, after Janey's checkup tomorrow I'll get back to measuring and drawing. But I put the E4OD's flexplate back on the 460 on the engine stand, so instead of calculating dimensions I can now directly measure them - on both the 460 as well as the M-block. Like the position of the ring gear with respect to the rear of the block. Like the position of the part of the flexplate where the torque converter mates with respect to the block. So that will simplify as well as make things more accurate.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

I'd think 4 measurements would be enough to get the "working" length of the spacer... 1) bellhousing face (block mounting surface) to TC stud base face (flexplate mounting surface) with the TC pushed all the way back into the trans pump; 2) block face (bellhousing mounting surface) to flexplate's TC hole surface (TC mounting surface); possibly measured using a straightedge spaced the same distance off the block at each end so that it passes across the flexplate; 3) length of the TC stud (tip to base face) 4) thickness of flexplate at TC hole #1-#2-#3+#4+ 1/16" (or roughly 2 threads on the TC stud) That should put the tips of the studs just far enough through the flexplate to start the nuts. Then the nuts will pull the TC out of the pump the remaining length of the studs, less the thickness of the flexplate. IME, that's how most Ford TCs fit. If you want, I can take those 4 measurements from my spare 5.8L & its original E4OD tomorrow. If my math is right, it should come out to ~0 (since that's the thickness of the factory spacer). |

|

Administrator

|

In reply to this post by Gary Lewis

Gary, I almost hate to bother you with this (explaining it to me) but I’m trying to wrap my head around the spacer... in the matrix below, are all dimensions “positive” distance relative to the block/bellhousing mounting plane in the aft direction? When you say front of the flex plate are you referring to the front of the vehicle? Like I said, sorry to bother you with this... just trying to understand...

From a logic standpoint, the 460 flexplate is the same for both the C6 and the E4OD... so if that same C6 fit the 400 one would think the E4OD would also fit? 🤷♂️

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

Guys - I'm back from Janey's checkup and it went well.

And, after trying to catch up on various things I'm now working the measuring/drawing thing, and have these responses: Steve - Thanks. I think you've answered a question I've been wrestling with, which is how to measure the space between the TC and the flexplate on Dad's truck. There's a bulge on the flexplate just outside where the TC mates, and it makes in next to impossible to measure. But, your idea of measuring the studs is the key - subtract what's poking through from the full stud measurement and you have the space.  Jonathan - You have figured out my thinking. But, I'll have to be better with explanations in future. Better yet, the drawings should make it easier to understand.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

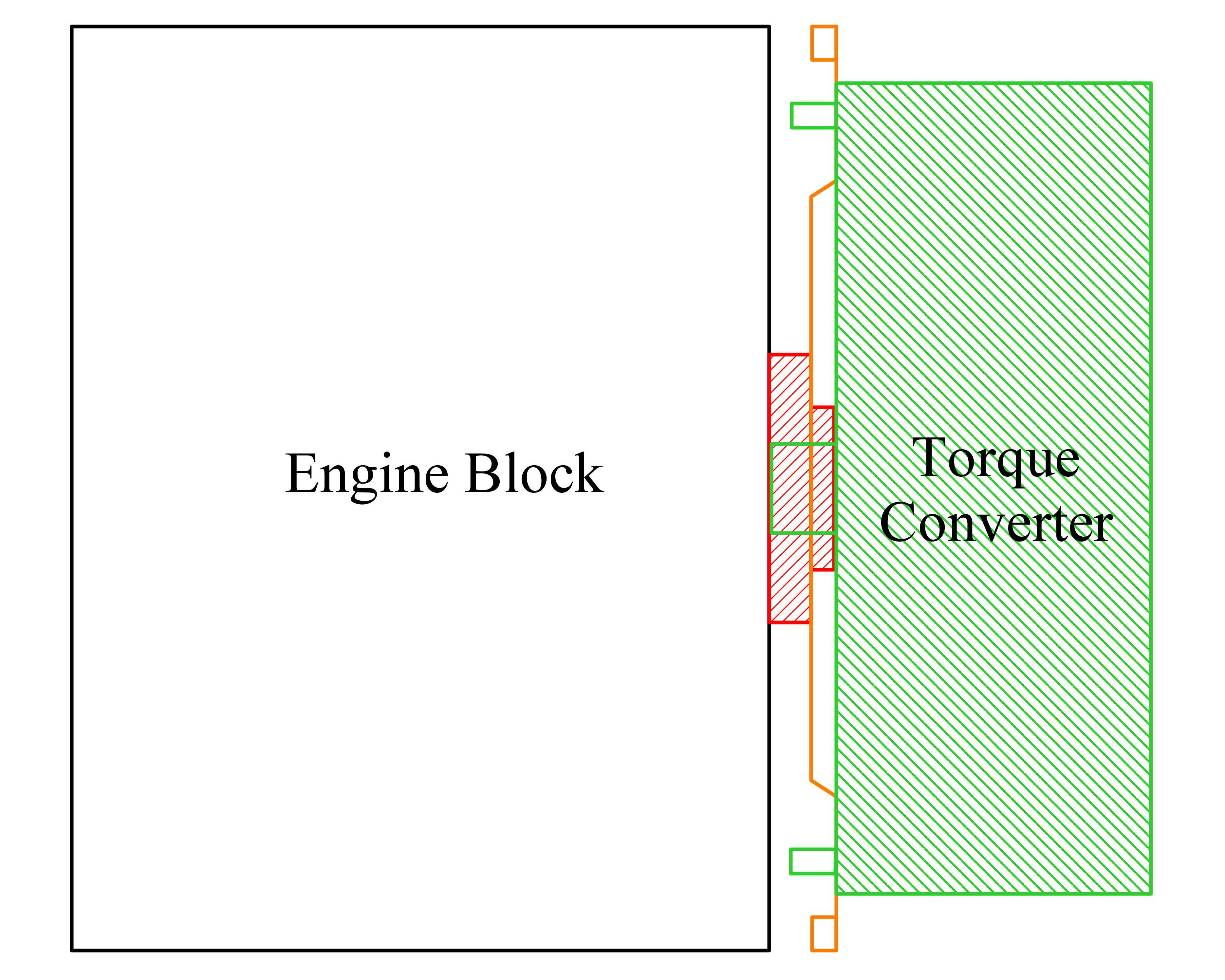

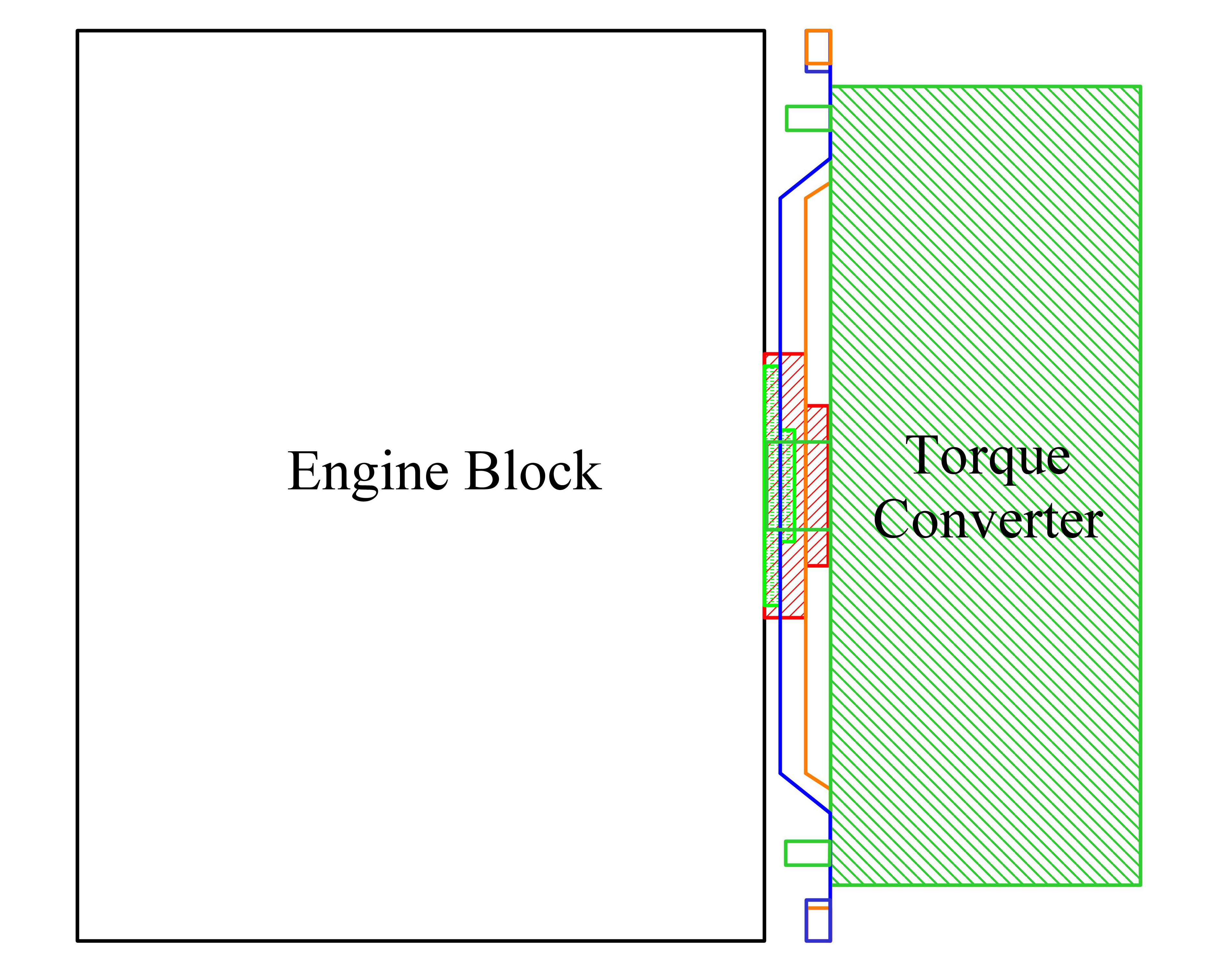

Well, where do I start? Will this suffice?

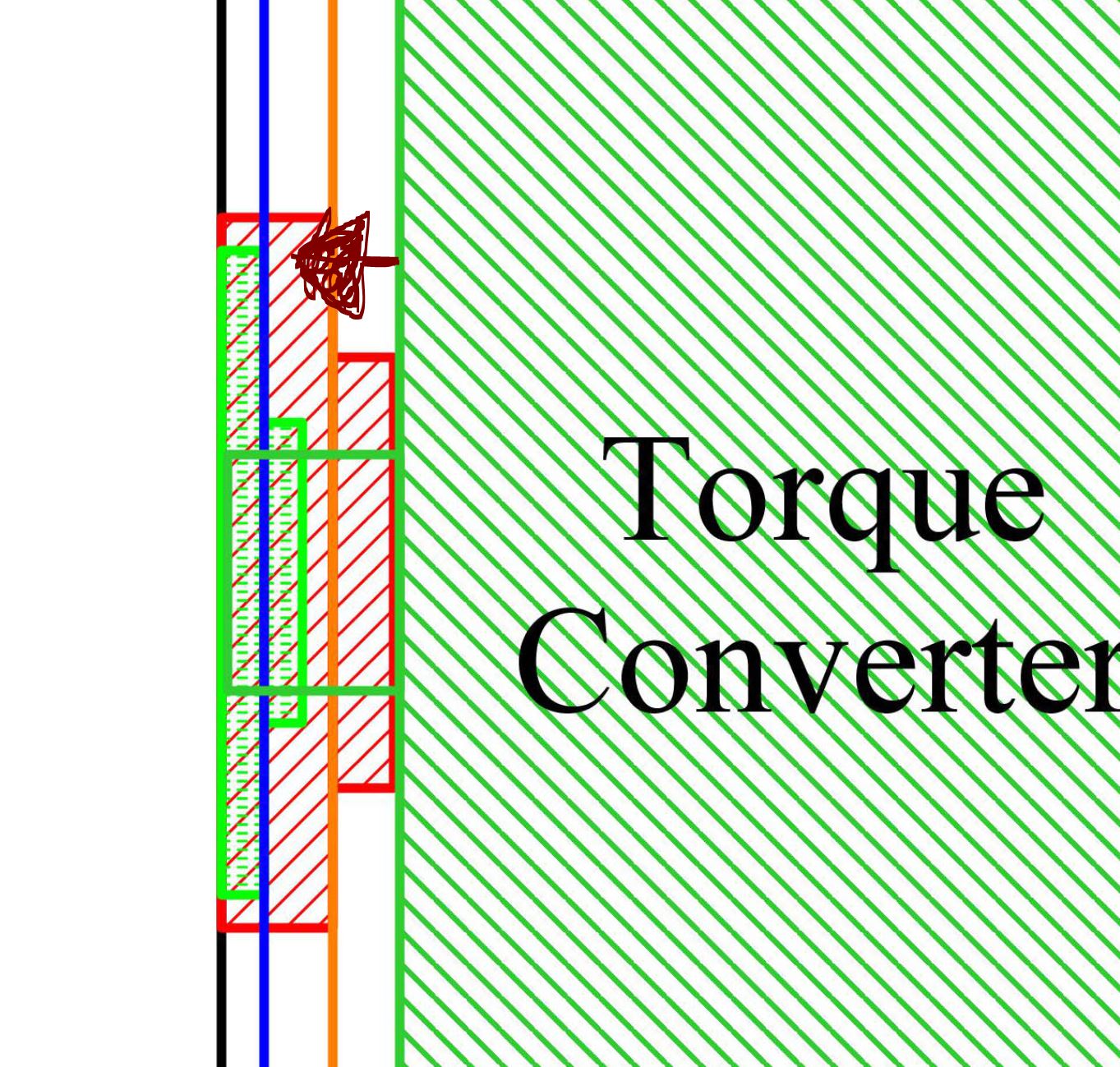

No? So, you want a slightly longer explanation? Well, on the left you have a block w/a 460's crank sticking out, the red bit, then a 460's flexplate (orange), and an E4OD's torque converter (green). On the right you have the same with an M-Block's crank (blue) and flexplate (blue) added. Note that the ring gears and flexplates are in essentially the same exact position, with the M-Block's being .006" forward of the 460's. Big deal. And, what you can't tell is that the pilot on the torque converter is engaging the M-Block's crank by .332", which is probably adequate. However, the pilot engages the 460's crank .862". (NB: These dimensions are after subtracting .100" for the engine plate's thickness.)   So, if that is the case then why not torque the flexplate down, slide the tranny forward and engage the flexplate, slip the nuts on the studs, torque them down, and then torque the tranny/engine bolts down? Done, and the engine turns over easily by hand.  Here's where I'm stopping for today so I can get cleaned up for church. But tomorrow I'll do the rear mount and crossmember. Then it'll be about time to put the cab back on.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

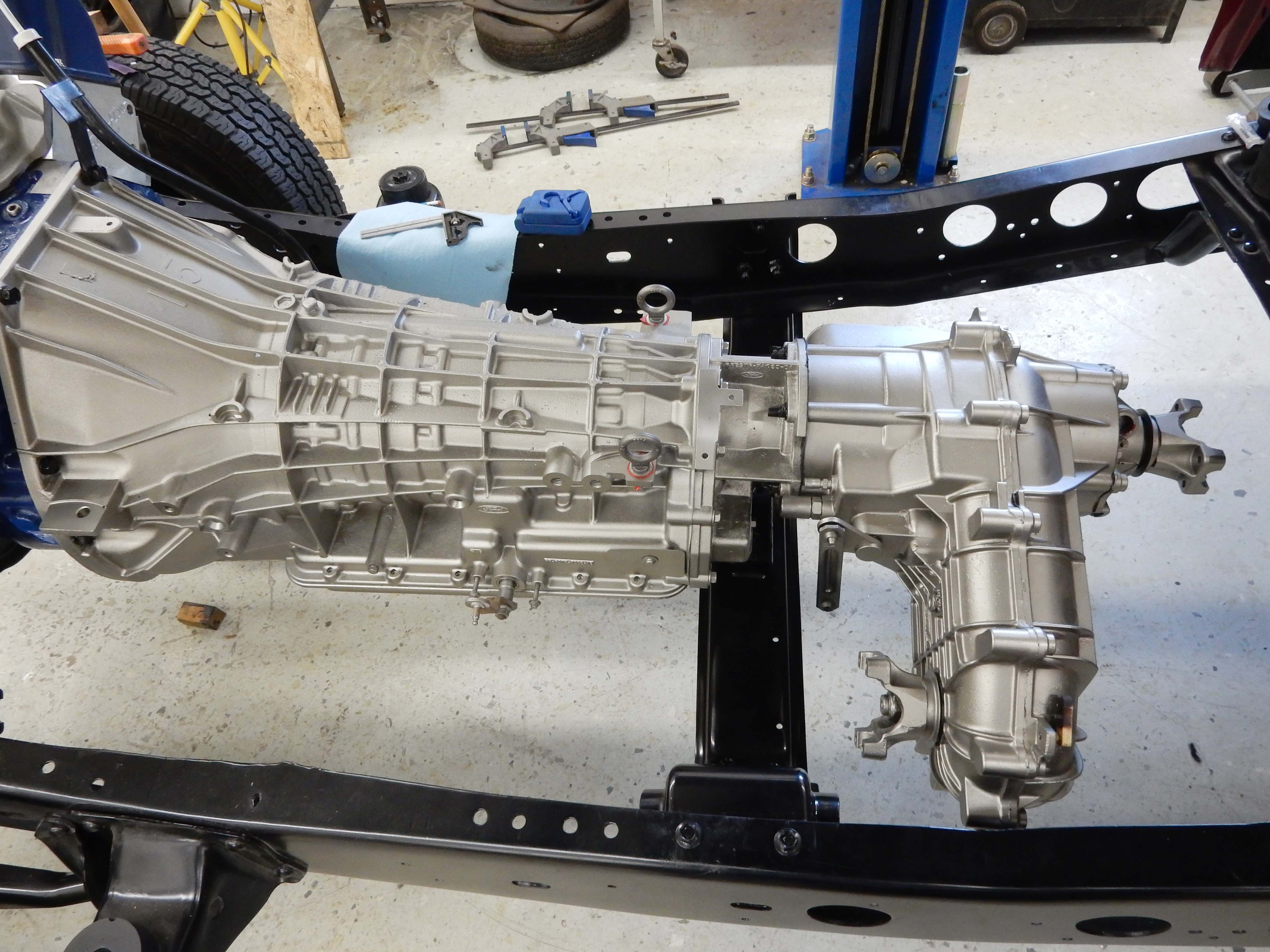

Fantastic Gary! Wow that looks good bolted together and set into place!

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

When I get the crossmember in I'll add the transfer case and it'll look like a mile-long drive train.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

FIFY!  It appears that there's no chance of the Xmbr meeting the factory frame holes.

|

|

Administrator

|

No, not a chance. The crossmember will be ~6" aft of the factory holes. But I'll measure and report on exactly where they are as I do it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, looks great! I gather I was correct on the not needing an adapter if the correct flex plate is used. Only concern I see might be the lack of a solid piece around the TC center. The reason I say this, the converter clutch is applied by essentially reversing the oil flow in the converter, oil flow is normally in the outer portion at the back of the converter and returned through the input shaft. When the converter is in lockup, oil comes in the hollow shaft to the front of the converter forcing the converter clutch piston to the rear engaging the clutch. I would be concerned that the converter may "balloon" without a solid piece at the hub.

I also gather that the 460 PMGR starter is going to work on it. FWIW, Darth's E4OD mount is 7" back from the C6.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Yes, Bill, you were right. And I was wrong. Boy, was I wrong!

Re the "solid piece around the TC center", are you talking about the lack of anything supporting the front of the TC? You are thinking it might balloon forward since it doesn't butt up against the 460's crank, like shown in the snag below? I could machine a sleeve that would be a slip fit over the hub and just be contained by the crank on the front and TC on the rear and provide some extra strength to the hub. But, do you really think it is going to expand enough to cause problems? At this point I'm loathe to do that as I feel like I'm "there". But, if it is ever to be done now would be the time. I think I'll call the people that built the torque converter and get their thoughts, but would like yours as well.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Ok Houston, there is no problem!

I talked to the owner, Dale, of B&I Torque Converters in OKC, who are the ones that built this unit. He said that my unit (TF59 LS HD) has a billet back and welded turbine and impellor. And with the billet back there's no chance that it is going to expand. (And, by the way, the "LS" means "low stall", which is exactly what he'd recommend for this application.) However, had I not opted for the "HD", which gets the billet back, then there could have been a problem with ballooning. So, Bill, you were right once again.  Also, I asked him about the 3/8" of pilot engagement with the crank on the 400 and he said that's quite adequate to center it. Bottom Line: No worries!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Great news Gary! On to the cross member and transfer case!!!

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

In reply to this post by Gary Lewis

That is great news, Gary!

|

|

Administrator

|

Well, today this happened today:

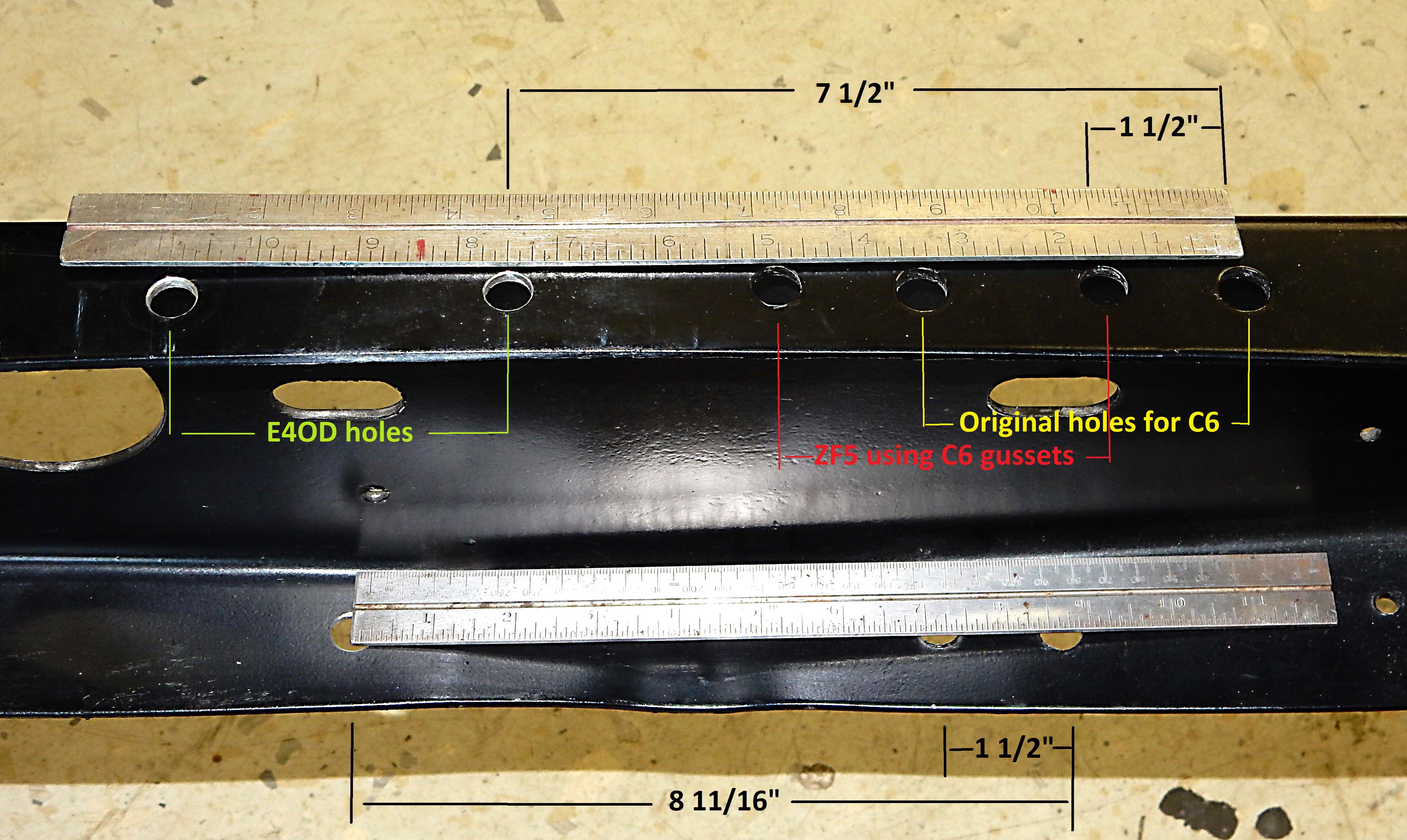

Yep, the crossmember is in place as is the BW1356 transfer case. Here's another view:  Along the way I took lots of pics and made many notes regarding where the holes went in the frame. I think I'll revive the E4OD For Dad's Truck thread to get into the nitty gritty detail that have been uncovered in the last few days, including: Several drawings of the crankshafts, flexplates, and the torque converter as well as dimensionsThe discussion about the possibility of the torque converter bulging/ballooning under pressure that we had todayPics and dimensions for where I drilled the holes in the frame to accommodate the E4OD's massive lengthDoes that seem like a reasonable approach? Use the E4OD thread for the detail? And then summarize it in a page on the website? But, since we talked about the length of the E4OD in this thread, here's a shot of the left side frame showing all the holes in it. As you can see, the E4OD holes are 7 1/2" behind the original holes, and the ZF5 holes are 1 1/2" behind the original holes - assuming you use the C6 gussets. But, with the ZF5 gussets you can use the original holes. Also, I'm thinking about placing 1/2" G8 bolts with washers top & bottom in the unused holes to put some strength back in the top and bottom flanges of the frame. Obviously that's not as strong as w/o the holes, but is better than nothing. Thoughts?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

Sounds good sir, I mentioned the ballooning because it is a known issue with the E4OD converters. Looks real good in there, seems a shame to hide it under the floor, maybe a glass floor?

Question, were those holes in the 4R100 case threaded or did you Tap them or use nuts?

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

I'm glad you did mention it! I would have hated to have the question come up later and not know if it was going to bite me.

Glass floor! Good idea! My brother said something similar - that it is going to be a shame to bury that engine under the EFI stuff. So we talked a bit about adding a stand-alone controller for the tranny and staying with a carb and that dual-snorkel air cleaner. Edit: I missed the question. Which holes?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

This post was updated on .

In reply to this post by 85lebaront2

Older 4R70W TCs (around '98-05 IIRC) were known to balloon, but mainly in police Crown Vics that had higher shift points, or in other Panthers that were driven hard (allowed to upshift at WOT). The TC was redesigned to eliminate the problem. I've never heard of an E4OD TC ballooning, and I don't think a stock flexplate could stop it anyway. AFAIK, the TC pilot is never supposed to bottom in the crank - it always floats there. So I don't see the lack of material near it as a problem. As long as it's centered before the flexplate nuts are tightened, it should be fine. If it's offcenter, I think there would be an obvious vibration at idle, and possibly frothy ATF on the dipstick.  I don't see how they could, unless the washers were MASSIVE in every dimension, and the bolts cranked to the point of stretching. But I don't think the difference would ever be appreciable. The only time the frame flanges are ever really stressed across those holes is in a T-bone collision. That's why the flanges are so narrow to begin with. Normally, the stress is in the (tall) frame web. I assume he means the ones with eye bolts to lift the transmission. If so: the nut is visible in the passenger-side pic. |

|

Administrator

|

Yes, those are lifting eyes with nuts on the bottom. I'd purchased them when I thought I was going to make a dolly for the engine and wanted to be able to lift it with them. Shipped the engine to Tim instead.

On the nuts, bolts, and washers, thanks for the thoughts. Now, to think about the near future for Dad's truck. Rest! My goal for this spring has been to get it on all fours with steering and the engine, tranny, and t-case in. That way I can roll it onto the trailer and show it in the fall. And we are almost there. Here's what I need to do to get there, I think: Torque the t-case/tranny bolts as they are just snugged up to let the Ultra Black set upTorque the engine mount/frame nutsPowder coat another tranny mount/crossmember nut and install those and torque themTouch up all the fasteners installed recentlyLube the body mounts, lower the cab, and snug up the boltsRoll the truck to the other end of the shop to await its turn againAs for what I'll be doing twixt now and Dad's truck's next turn, it's Big Blue's turn. Recently I've noticed that the clunk in the front end has gotten worse and the steering has gotten less precise, so I fear the frame is cracked. And, I've smelled oil burning one too many times, so it is time to pull the engine and replace the seals - as well as a few other things, like heads, pan, intake(s), exhaust, fuel delivery, spark system, valve covers, etc. Plus, there's a ZF5 sitting in the corner taking up space, so it needs a turn to play. In other words, a new/different project. But this one won't include media blasting and powder coating everything. So, hopefully it'll go a bit faster.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |