Restore of my 1986 Bronco XLT

|

It's definitely smooth. But maybe ist a sign That there is much heat, cause of the play..

I'll see more tomorrow when I'll open the bearings.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

Re: Restore of my 1986 Bronco XLT

|

Administrator

|

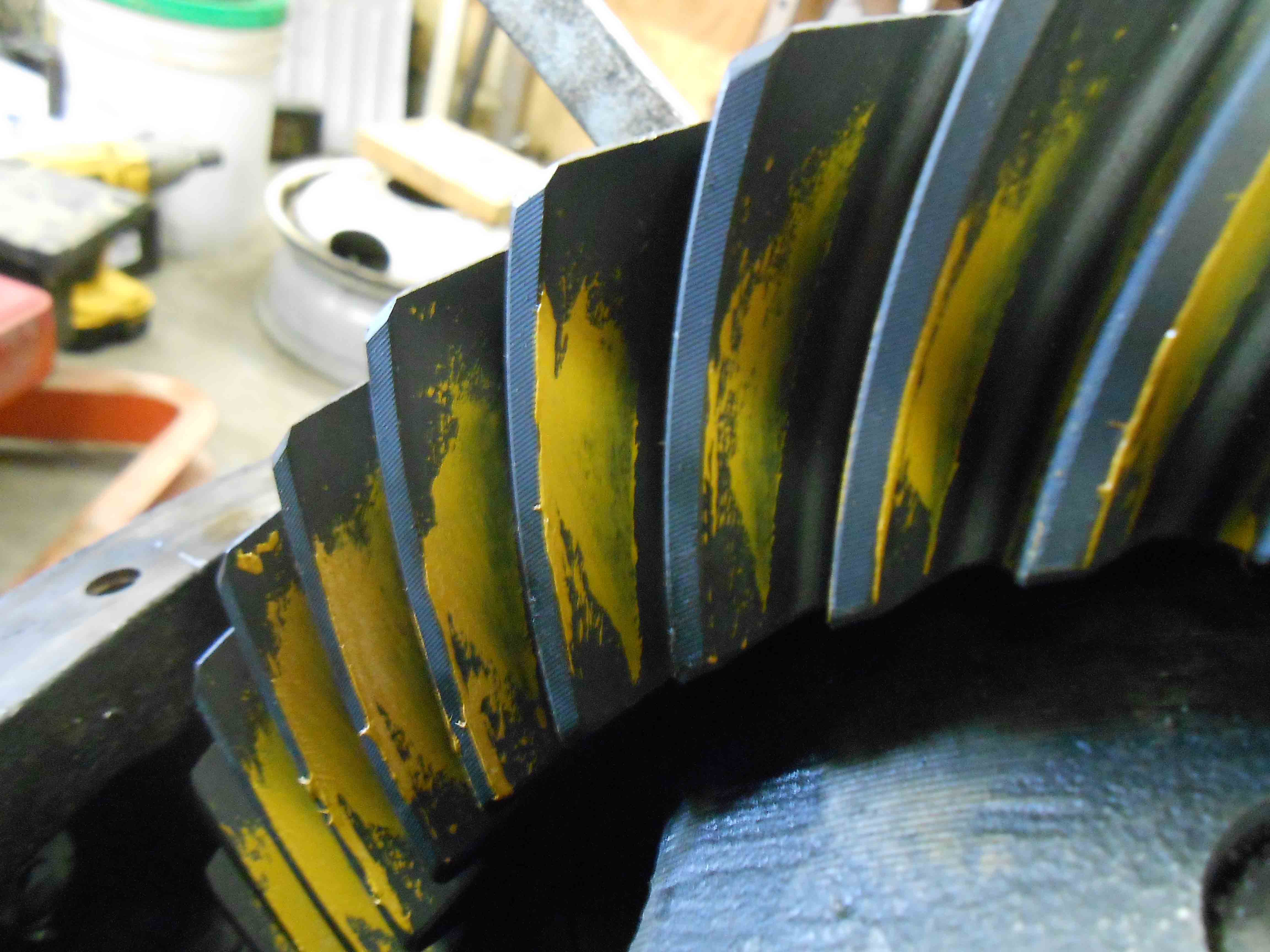

Rene' here are two pictures of a pattern that is from a Ford 10.25" full floating rear axle. It was done with yellow paint mixed with oil so it wouldn't dry quickly if I remember how I did it (it was done September 2019). I did it for my best friend as the axle he had gotten to set up with a rear disc conversion had a water damaged gear set.

This is the drive side, the portion of the ring gear teeth that are loaded by the pinion as it drives the ring gear around.  This is the coast side, where the ring gear is driving the pinion during coasting or deceleration.  The idea is to try to get both the drive and coast sides where the contact (wiped area) is near the root of the ring gear teeth, but not so far down that the pinion is driving with the tip of the teeth, or being driven by the tips of it's teeth in coast.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Hi Bill, Ok...that's also a way to go.

In the shop manual are the tolerances for the 8.8 written down. Currently the differential is still mounted, so I can't see the wear of the shims or the bearings. Today I will unmount everything and I'll see the status of all parts. I also plan to replace the universal joints, cause I have to unplugg the drive shaft for replacing the pinion bearing and seal.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

Re: Restore of my 1986 Bronco XLT

|

Administrator

|

Rene' this was after setting the basic adjustments up. The people I ordered the parts from provided a "set up" bearing with the inner cone and roller honed to be a snug slip fit on the pinion shaft. That allowed it to be assembled and disassembled in order to make the needed adjustments for the correct mesh.

On your ring and pinion sets (front and rear), Ford has three different types of hypoid gear sets, they call them "hunting", "non hunting" and "partial non hunting". These refer to the way the sets mesh, a hunting set of which I had in my Shelby was the 3.89:1 which when the ring gear tooth count was divided by the pinion tooth count came out to 3.8888888.... to 1 so every tooth on the pinion would hit every tooth on the ring gear so the set "hunts" for the wear pattern. A non-hunting set would be like a 3.00:1 where the ratio becomes a simple 1 or 2 place decimal, 30 tooth ring gear and 10 tooth pinion. Every pinion tooth hits 3 ring gear teeth, these sets have to be timed to each other and a replacement set comes marked for the timing. When disassembling one of these, the gears need to be marked for reassembly. The set in the pictures is a 3.73:1 set, which was a hunting set, 41 tooth ring and 11 tooth pinion if I remember correctly, it actually calculates to 3.2727272727.... to 1.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

This post was updated on .

Hi Bill, that's interesting. Never thought about this.

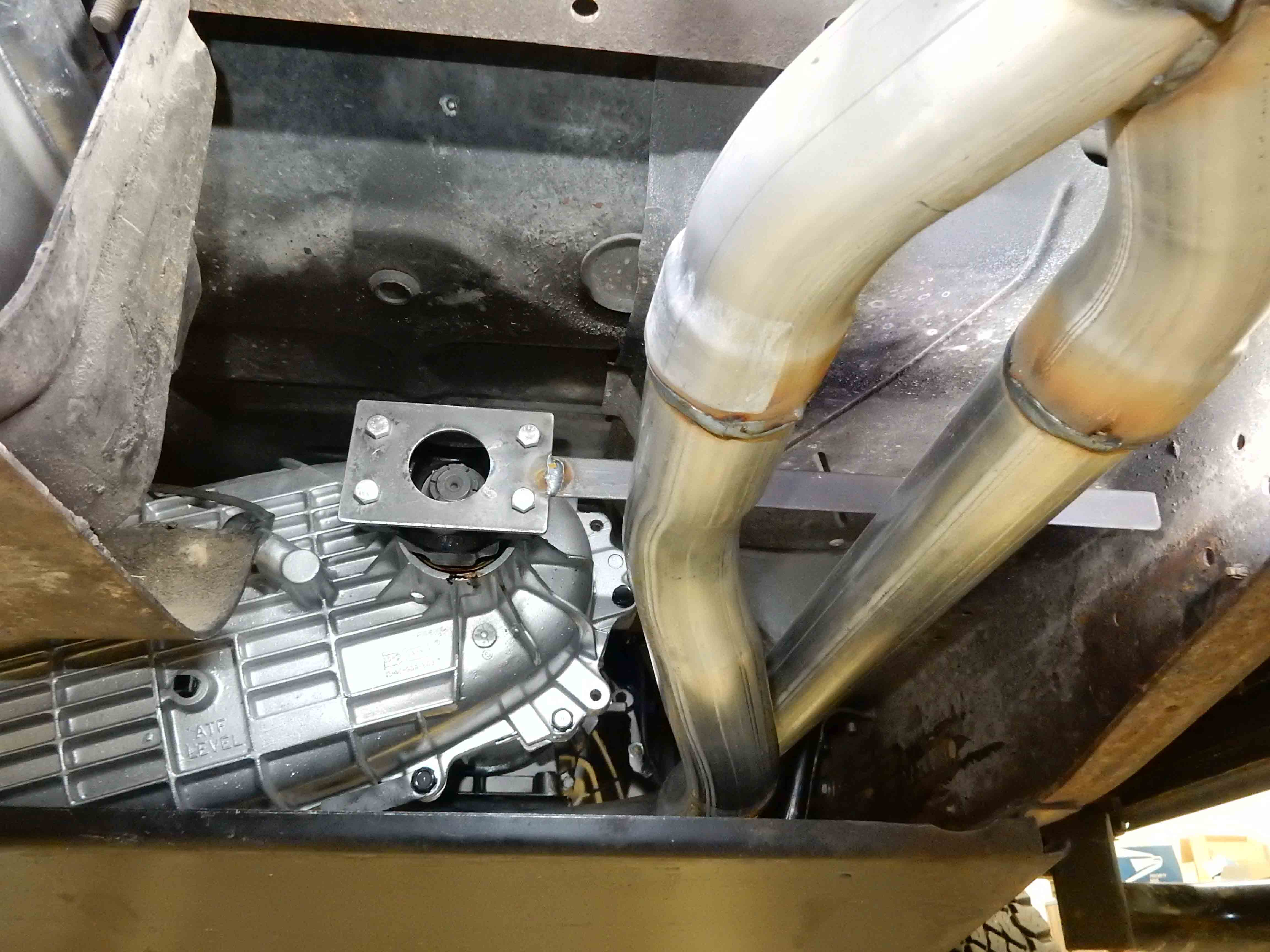

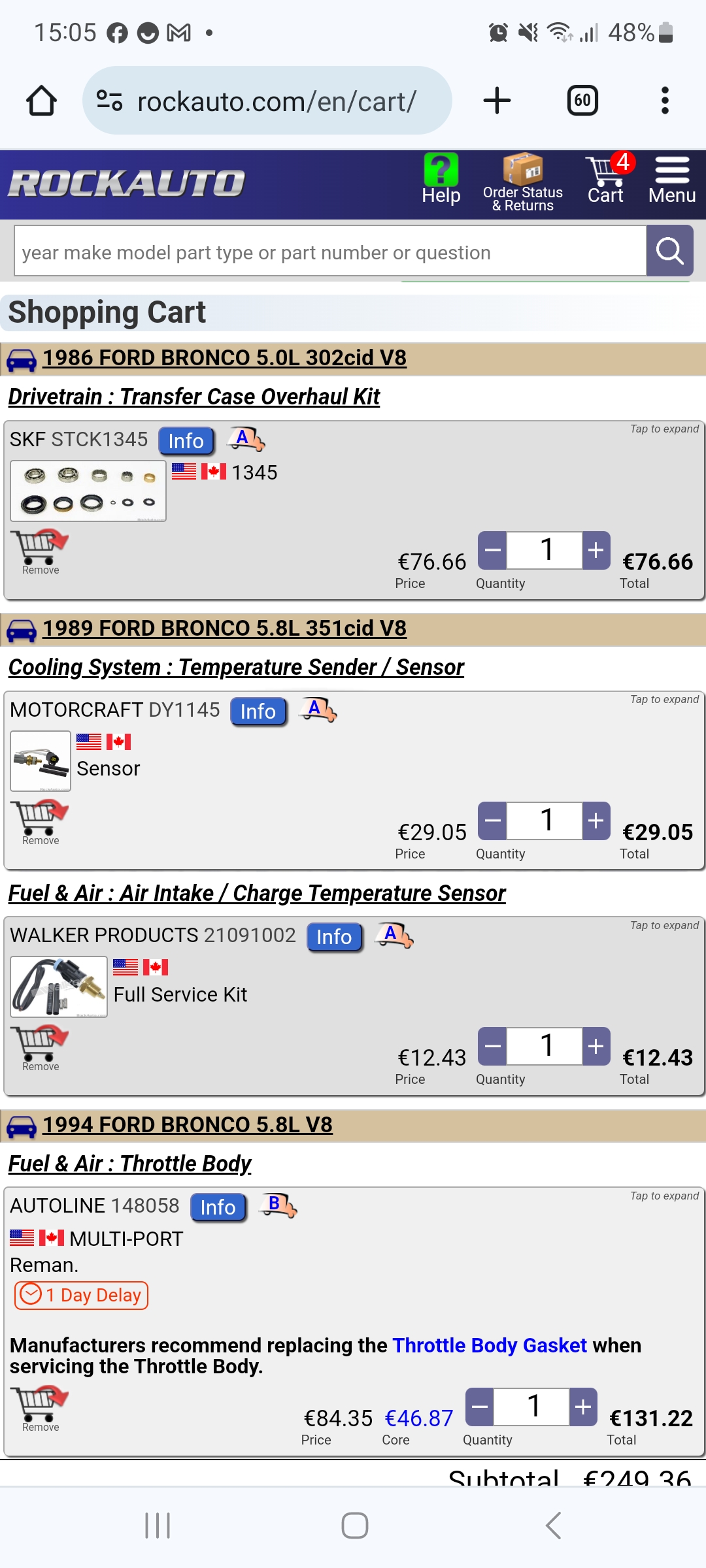

Yesterday...or even more this morning at 2am I have finished my differential and drive shaft rebuild. As expected the pinion bearings have had much play. Also both differential bearings. To change this, especially the pinion bearings, was as Gary said some month ago...pain in the ass...  So yesterday's lesson was again not to work too long, especially when you are tired...I have torn one grease pin of a U-joint and mounted all in a way that I can't access the grease pins...  I will change it again, when opening the transfer case... As having the drive shaft unmount, I saw that also the bearing of the output shaft from the transfer case seems to have play. I can move the shaft with the yoke up and down by hand. Is there anything to mention, when opening the transfer case? Is it possible to change the rear shaft bearing without unmounting the transfer case or is it easier when it's unmounting it? Will this kit work? Rockauto.com

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

Re: Restore of my 1986 Bronco XLT

|

Administrator

|

If your transfer case uses a fixed universal with a slip joint in the drive shaft then you could have ball bearings (not owning a 4WD, I am assuming the style). If it has a one piece drive shaft that slips into the rear of the transfer case, then it will have a bushing like a 2WD transmission.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Ok...I will cross-check the parts with the manual on this site here. I only flew over the shop manual, so today I'll take a closer look, if there are special tools needed.

As for the pinion of the axle I have had to fix the nut to about 280 mm to get the desired preload to the both bearings...holding the yoke without a special tool is not possible. As I haven't had one, I've to build one that resists this amount of force. In the end, I've got it. But as looking some videos on YouTube about the axle rebuild, I've found out, that there is a replacement with shims available to set the preload...much easier to set...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

Re: Restore of my 1986 Bronco XLT

|

Administrator

|

Rene' I used a pipe wrench and a long (around a meter) piece of exhaust pipe as the reaction bar. I used a C-clamp to hold the wrench on the yoke when tightening. Removing the yoke was also interesting, it is a press fit on the pinion.

Removing the yoke:  Closeup of the wrench on the yoke:  Ford tool for removing the pinion from it's press fit outer bearing:  Same basic design as your 8.8" just bigger and has full floating axles. Give me a Ford 9" any day to work on, very easy compared to these. I actually have a spreader for the smaller axles.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

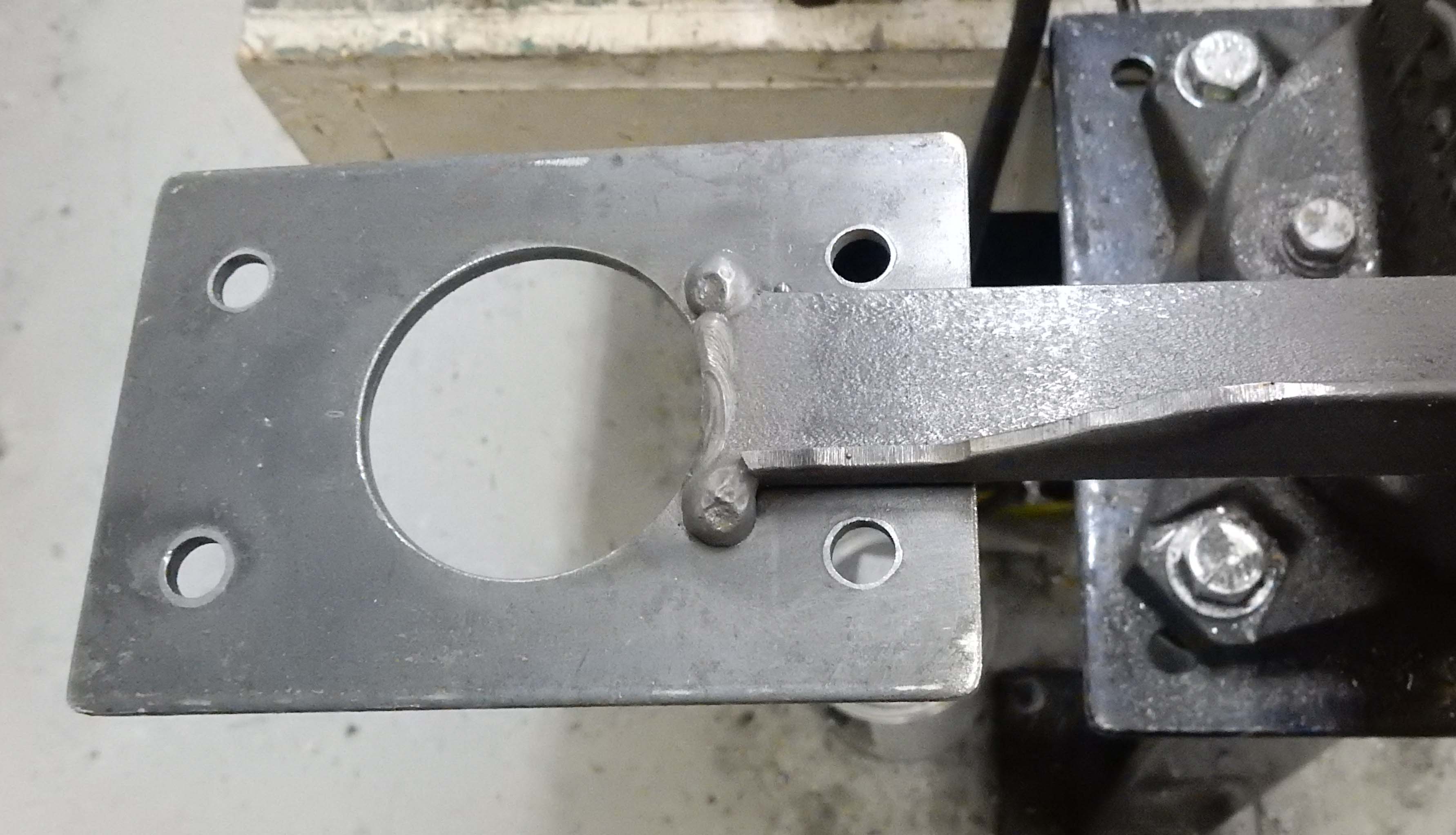

I made this tool to hold the u-joint flange on the transfer case while I torqued the nut on the shaft:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

So, as I see, both of you also have build their own tools...

Mine looks like the small brother of Gary's one... First I have to get my CJ7 ready again. My HEI distributor had loosen a screw of the finger and damaged the cap. After getting a replacement also the HAL sensor was down. Also replaced...now it won't fire on every revolution at one output...I've decided to get back to the stock distributor... After finishing this, I'll get out the transfer case of the Bronco for overhaul. So, I may also find the part on my C6 that leaks a bit, when there is more space.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

Administrator

|

There is always something that needs this or that, and many times there's no tool available to fix it. But if you have the tools with which to make tools, you win. The lathe, mill, welder, and grinder come in very handy.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

You're right!

It's like the former owner of my bronco.... He realized that he has two bent connection rods, bit no new rods in stock... so he grinded the pistons that they can pass the counterweights of the crankshaft...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

Yesterday I've parked the Bronco outside at about 8 degrees Celsius for over 10 hours...as I want to start, the engine won't start at all. Only pressing the pedal and hold the rpm at about 1,500 for a minute, I've got it to start and idle.

I definitely have to solve this problem...winter is coming...  Does anyone have an idea where to start searching?

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

Administrator

|

Sorry, I missed this.

I'd guess that either your air charge temp (ACT) or engine coolant temp (ECT) sensor is bad. That would mean that the ECU doesn't know how cold it is and that it isn't adding enough fuel to the mix to get the engine to run.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

That's also my thought.

I have added some to my next basket. I also have added a throttle body...what do you think? Does this make sense?  I'm also not sure, if I need additional parts for the overhaul of my transfer case... I plan to change the plenum in the next years to a Holly Hi-RAM...I think this could work better with SEFI, cause of the geometry and the position of the injectors...but I don't know if I want to spent such an amount of money within the next two years...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

Administrator

|

I think that makes sense, except for the transfer case. First, do you know what brand and model transfer case those parts are for? I ask because both the BW1345 and the N208 were used in '86. And they take different parts.

Also, you might consider replacing the chain in your transfer case. They can stretch and while you are there would be a good time to do it. But I'm still not sure I understand your desire to replace the throttle body. Is this due to the noise you are hearing?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Oh...good objection...I haven't checked in real, what transfer case I have...only from an image compared with my memory.

I will also take care of the chain, when I know my TC model... About the throttle body, the noise is one point...another is the still sawing rpm...but maybe it's also caused by one of the sensors...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

Re: Restore of my 1986 Bronco XLT

|

Administrator

|

Rene' a couple of items, first, if you are ordering the 351 throttle body, it should have more bypass air flow than the 302 one. This should help with the surging idle. The other is the sensors, I have found that the Ford EFI system occasionally has issues with aftermarket sensors (my son had a real problem with a Standard brand throttle position sensor) his was a 1986 F150.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Hi Bill.

Ok...good tip. I already use the 1994 IAC on my TB. Regarding the TB of the 351, you mean that I should change mine, also when I plan to change the whole intake set in some years? For the price at Rockauto.com, I think it's applicable for the remaining time. Regarding the sensors...can you recommend a brand? I have bought three different TPS as restoring the engine. For only one, I was able to set it into the correct range on my TB. So maybe this is what you mean...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

Re: Restore of my 1986 Bronco XLT

|

Administrator

|

I will only use Motorcraft sensors on my Fords, even ordered O2 sensors for my wife's 2011 Flex from Motorcraft.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

| Edit this page |