Fuel Injection upgrade

|

This post was updated on .

Well thats what I was thinking but I was looking at Holley and Edelbrock fuel pumps those mechanical fuel pumps have screws that hold them together to allow you the ability to clock the pump how you want it for your application. This would allow for ease of disassembly and I guess during disassembly I could gut pretty much everything including the lever and plate off the back side where the lever would normally go this would keep any kind of failure from possibly filling the crank case up with fuel. Weep hole could be plugged as well. Pull the check valves out and it would be a giant pot that fuel would flow through. I just wonder if that could pose a problem since it would be such a large cavity allowing for fuel to settle leaving deposits away from the fuel flow. I also question about the pressure, Im sure the pump itself wouldnt fail at 60 PSI but the gaskets is another thing. This is the type of pump I keep looking at if I would do it. Id probably go with the summit brand one cause the Holley is over $100 and the summit brand one is under $90.  I wouldnt use a OE Ford one how ever Id be concerned that the smaller 5/16" fuel line inlet/outlet would be too restrictive when everything else is 3/8". Only 5/16" I have will be the quick disconnect I have for the return at the fuel tank which is a -6AN to 5/16" quick disconnect where its some 2 feet max of 5/16" hardline back into the tank. I dont believe that short of a run of 5/16" line would create enough of a back pressure on the return system to overwhelm the regulator but if it did I could always do a -6AN bulkhead fitting and bend my own hardline for the inside of the tank and make my return connection to the bulkhead fitting. ~Update~ Just came across this when looking up dummy mechanical fuel pumps. This is on a Corvair but same idea would still stand. The Holley pump above appears to have 3/8 pipe threaded through and through which I couldnt thread a 3/8 npt on the inside to make the same hardline connection I would have to do something like a bulkhead fitting.  I think I can come up with something but hope it can be with a cheapie mechanical fuel pump with 3/8" npt fittings and not hose barbs.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

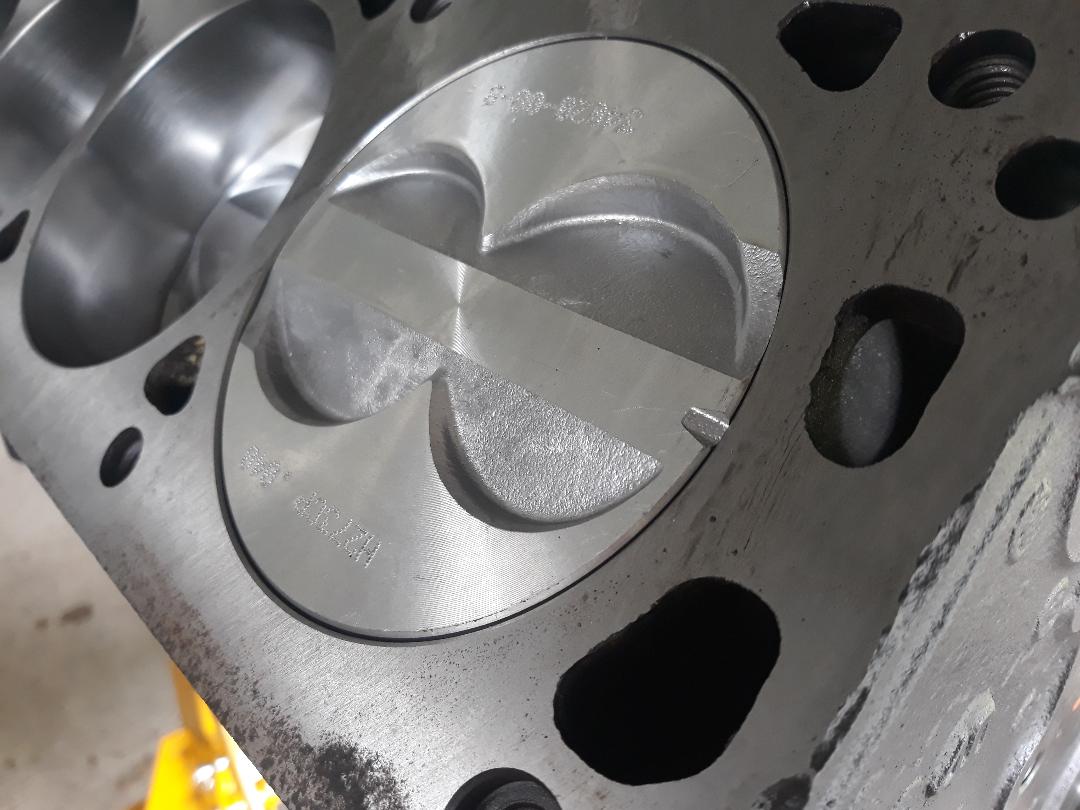

Little update on my project, Today during lunch I got two photos of my short block which I believe is getting close to being shipped out.

Instead of building a 306 I am closer to 307 cid now as the short block had to be bored 0.040" over instead of 0.030" over. I dont mind this long as my trust I placed in the builder is correct and that he actually made sure there will be no issues. I did request the block to be left bare if possible since I will be painting it, in the photos its hard to tell if the block is bare fully or if there is black paint on the sides and no paint on the front. I dont mind this as I can mask off the deck and the under side before I use my drill and a wire brush wheel to clean it all up and prep it for paint.   I was looking at 9.1:1 compression but that was based off a 0.030" bore and a guestimated 0.011" deck clearance. With a 0.040" bore and the same guestimated 0.011" deck clearance I am seeing 9.17:1 which may very well be 9.2:1 as looking at the photos it appears the deck clearance is closer than 0.011" which is great for me cause I have the Recommended Felpro 10-111 headgasket for my AFR heads which is 4.100" bore and 0.041" compressed thickness. I will also double check piston to valve clearance just to be sure but I dont believe I should have a problem with 1.90"/1.60" valves. Especially when taking into account the valve timing from my cam card which states the intake opens at 1* btdc, closes at 35* btdc and the exhaust opens at 49* bbdc and closest at 5* btdc. Long as installing the cam straight up puts the cam on the money when degreeing the cam I shouldnt have a problem with piston to valve interference. So far it looks like the work was done quite well and it doesnt look like there is any defects or cut corners that I can see. I cant tell if any heavy metal was added to the crank, I was informed the hyper pistons for this build it should have the rotating assembly rebalanced due to the pistons being a bit heavier than stock. But I am not the builder I am just the assembler that will be putting it all together and checking specs here and there. Im thinking I am going to have to order my 2K urethane engine paint from eastwood, the stuff I have now is about 3 years old and shelf life unactivated is listed as 2 years and I dont want to take the risk. id rather spend another $80 on the paint and do it right than cause myself a headache.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Looks good, Rusty.

But on the balancing, did you ask for that to be done? They can do that w/o fully assembling the engine. And I agree on the paint. I wouldn't chance it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I asked him back on April 6th when I heard about that from the engine builder we use at work that I wont use cause of mistakes he has made in assembly. But the engine builder replied back with "we balance everything we build so this isn’t a issue at all for us". The engine builder we use at work he said you can tell if its been balanced as he will have to add heavy metal to the counter weights to offset the heavier hyper pistons that is being used. I trust that it has been balanced as he did state that they balance everything they build and he has been in business since 1968 so he has to be doing something right to be in business that long. The crank is a reconditioned OE 50oz imbalance crank and the rods are reconditioned OE as well. Thats why I went with him cause his price was reasonable and the fact that I am getting a OE crank and rods that puts my mind at ease for not having to worry about any issues that could come up with an aftermarket unit.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Decided to give summit a second chance after they wasted a weeks worth of my time when I was trying to order a pair of custom AFR heads with the upgraded valve spring package to match my cam closely as well as the 3/8" to 7/16" rocker arm stud upgrade. They told me they had to get the pricing with upgrades from this other store that is the only one that can take on that kind of order and they would call me the next day back with pricing to finalize the order. A week later never got a call back I called 3 times trying to find out whats going on kept getting told they will call back tomorrow once taking the information again. I eventually ordered the $2,200 cylinder heads from Jegs and got the order placed in one go and havent bought anything from Summit since 2019 after that head incident.

Well I got one part of my order today which was the cylinder head dowel kit and the timing cover dowel. Part number PIO-S-1112 was the head dowel pin kit for $6.99 that stated in the quantity section that it was a kit of 4 pins. That was fine. Part number DUR-AD-967 was the timing cover dowel pin and this is the problem, the quantity section stated it was sold in pairs. What I received was a lone timing cover dowel pin in a baggie. I emailed summit to try and get this resolved cause I only ordered one as their site stated they were sold in pairs not individually. The second half of my order is the Ford Racing timing cover set that I will be using instead of the cheaper dorman one I purchased has me too worried about the crank seal not lining up perfectly from what I have been hearing about the dorman timing covers for sbfs. Hopefully summit can resolve this and not try to pin this on me due to a website error where it should have said each instead of pair. But this is the kind of thing that has me not wanting to do business with summit because if I was waiting on this to come in to finish my engine build I would be screwed cause it took this four days to come in from ordering and I would have to wait till Monday for them to resolve this meaning I would lose basically another week of building my engine all due to this screw up on their part. I was going to buy a blueprint 306 short block from Summit, they were going to cut me a deal on it after they heard about the cylinder head issue but when I asked the manager in a email 1 day after he replied to me with that offer asking if the shipping would include lift gate service or if I would have to pay extra for that as I wanted to know to not be surprised he never replied to me again. I love summit cause they have quick shipping especially with a new warehouse being in dallas I can get parts in 1 - 2 days but this kind of stuff is becoming too much for me with how horrible they are getting with handling orders. I know the virus had some effect but this bad service goes back to 2019 before this virus even was known.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Another step closer. I went to the UPS Freight yard to pick up my short block which arrived yesterday at 11:55am. I wasnt able to make it yesterday as they close at 12:30 for pick ups and drop offs so I scheduled to pick up today.

I have to say Creb Engineering really packaged the short block nicely, the block was mounted upside down with two 2x4s at a angle fitting the cylinder head deck surface with a strap over a piece of cardboard holding the short block to the pallet. There was no damage to the block and only very minimal rust that I will have to clean up. The rust is mainly regulated to the bellhousing area and on the hump cutout for clearing the starter. There is also a little surface rust on one of the crank throws at the back. I believe this to be the WD40 being washed away as that area was a little exposed than the rest. But no where else in the block was there rust out side of some pitting on the block deck surface but the pitting is located on the outside edge away from where the head/gasket seals so its of no concern for the reliability of the build. He also ran a tap in every threaded hole so everything is properly clean and looking through the cooling ports it appears that there is no rust inside the block what so ever. Brass core plugs were used which is a plus in my book as they do not rot out like steel plugs do. All oil galley plugs were replaced with pipe plugs which is a huge plus in my book as well. Another thing that I did not expect was inside the crate was a box of rocker arm studs but it wasnt studs in the box but a can of brake cleaner. He told me spray the block down with brake clean to flush out the WD40 before I paint the engine assembly. I didnt expect him to do that but that right there along with the quality of the crating and the quality of the short block I received I feel I will be doing business with him again for any Ford short blocks I need in the future. Below are some photos of the short block installed on my engine stand. I did not do any work today but I did take note of pieces I need to source that are not with the short block. I need to source a pair of bell housing dowels but I am going to look up the OE Ford part number and get OE Ford dowels and I need to get the threaded adapter that threads into the block for the oil filter. I will be sourcing this via OE Ford as well. I believe this was left off to allow your original to be reused. I also need to find where my dial indicator is as I need to check my deck clearance cause looking in person I honestly think the deck clearance is tighter than 0.011" Running my finger over it to me it feels more like 0.005" but I need to verify this to check quench as well as to calculate compression ratio. I want to provide as much accurate information as I can to Parkland Auto Machine to have my Distributor recurved. This front view shows the oil galley pipe plugs installed. It also shows how clean the block is which is just as clean inside the water jackets.  This photo here shows the corrosion on the outside edge which if memory serves right would not be covered by the cylinder head but any case I will be going over it with some light machine oil and a wire brush wheel on my battery operated drill when I get to the exterior rust on the bell housing area. I do not believe that will effect the sealing of the block. It is not in the area of the fire ring sealing surface for the cylinders nor is it near the printoseal areas of the coolant passages.  This is a close up it shows the pitting a little better which is not really deep pitting but it is mainly showing the piston to deck clearance. If anyone wants to make a guess on how far that is down from the deck surface I will entertain the answers. I think its pretty close to zero deck I dont think its 0.011" like I was calculating. You can also see through the coolant passage the cylinder and see how it is void of any rust. Im really going to have to flush my radiator core and radiator out. Im going to replace the hoses just to be safe anyways. I also need to check piston to valve clearance as well with some clay. I should be good how ever with 1.94"/1.60" valves but I still want to double check just to make sure.  This photo here shows some surface rust around cylinder 8 that I will be wire brushing. I dont think its really in the metal its just a flash type rust or could just be some discolored WD40 that is staining the surface. I have not washed anything on the block yet as I am not doing assembly yet and I dont want it to rust with the humidity we have along with all the rain we've been having the last few days.  This photo of the under side shows the missing oil filter adapter piece but it mainly shows the surface rust in the cast iron back by the bell housing. This is where I will be wirebrushing mainly as some of it is on the pan rail as well but not in any place where the the gasket will seal. It also shows on the crank throw where it appears fresh drilling was done to adjust the balance for the Hyper pistons which I was informed all rotating assemblies are reconditioned OE and they are balanced as well. I dont see any heavy metal slugs for adding weight so it appears that a little weight had to be removed to bring it back into spec.  So my goal for tonight is to source the OE number for the oil filter adapter piece and the bell housing locating dowels and to hopefully find them on ebay for sale. This will allow me to have the block prepped for assembly starting this Saturday if its not too humid. My goal for saturday is to grease/lube up the cam shaft and the timing set and get them installed so I can at least degree the camshaft make sure it matches the timing card and verify what length pushrods I need to order. Im hopeful the length is close enough that I can run the same length pushrod for both intake and exhaust. I am going to do the half lift method of figuring the proper length of pushrod. For those that dont know the half lift method is where you adjust your rocker arm down till the center of the rocker trunion and the center of the roller tip pin is horizontally level to the valve spring. From there you take the lift of your cam divide it in half and turn the nut that many number of turns to set the rocker arm at half lift. This when done properly will result in the rocker arm being horizontal to valve at half lift placing the roller tip as close to ideally close to the center of the valve as possible. This will give me a easier starting point to figure out what length I ideally need. Then I will contact AFR cause AFR recommends 0.120" thick wall pushrods and when looking at OE length push rods I could not find anything 0.120" thick. When searching for 0.120" thick there is no pushrod close to being the length I will most likely need. I need to confer with AFR and see if I can run anything else. Cause for a OE Roller length pushrod which is 6.250" length for use with guideplates summit lists 3 wall thicknesses, 0.080", 0.105" and 0.135" and AFR states they do not recommend larger pushrods as they will require clearance done to the heads which they dont recommend thats where the 0.120" recommendation comes in from. I am wondering if 0.080" would be enough or if I should go with 0.105". There just isnt any 0.120" in these lengths.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Found the Dowels and the Oil Filter adapter piece.

EAD-6397-B for the block to bellhousing dowels they come in packs of 4. D7AZ-6890-B is the old part number for the oil filter adapter piece but it appears to have no clear cut way to install it without using a jam nut on the oil filter threaded end. These are sold in pairs by Ford F1AZ-6890-B is the replacement for D7AZ-6890-B and it appears identical to the one above except it has a large torx interior on the filter side for installation and removal. I how ever can not locate a NOS Ford one of this one but did find them listed by this part number online, cheapest one I found is $34 as it is a pack of 10. I dont need 10 of them so I am seriously thinking about spending $20 for the old style which would be correct for our trucks and just figure out a source for a pair of nuts to thread onto the oil filter side to install it.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

In reply to this post by Rusty_S85

Looks great! They did you a good job!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

It is, I am really impressed by the quality of work he did. I know I will be recommending him for anyone else in the future. The engine builder we use at work I have to go behind him and run my taps through every bolt hole in the block that he rebuilt. I shouldnt have to do that, part of the rebuild process is checking the bolt holes and ensuring the threads are good. I mainly didnt want to use him for my build cause when ever we ask him what compression the engine is he always comes back with "oh about...." which doesnt sit too well with me, there is no about when it comes to compression you take the measurements and calculate it and you round it up or down.

Like my compression when I recalculated it for 0.040" over from the 0.030" I calculated last time it moved the compression ratio from 9.1:1 to 9.17:1 which I am rounding up to 9.2:1 but I think it may be closer to 9.5:1 as that deck clearance looks a lot closer to zero than it does to 0.011". I will know this weekend if I can find my old magnetic dial indicator to verify absolute TDC before I take my measurements

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Rusty_S85

Hey Rusty, Just reading through your thread here trying to gain some info for myself. So you would install an '85-'86 fuel tank, and then install the Mustang Walbro fuel pump in the '85-'86 F150 sending unit? Do I have this correct? If yes, is the F150 stock pump not capable of the job? Or is this so that you don't have to use two pumps? The AC Delco Corvette filter would just mount on the frame somewhere under the cab? And you would run one single fuel line from it to the Sniper throttle body? Do I have this correct?

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

The fuel tank will be a '85-'86 fuel tank with the large sending unit. The Sending Unit itself will also be a 85/86 unit as well. The fuel pump will be discarded as the factory fuel pump in the tank is a lift pump to a fuel reservior that the high pressure pump on the frame pulls fuel from. The use of a Walbro style in tank high pressure pump similar to one that can be used on a foxbody mustang will take the place of the frame mounted high pressure pump reducing the fuel system to just one fuel pump vs two fuel pumps. The stock pump on the frame if you had one would provide the pressure needed to run the sniper, but out of personal preference I prefer a in tank pump as they not only run quieter they also run cooler with the fuel acting as a coolant. This helps the pump to last considerably longer than a simple frame mounted pump. The Corvette style fuel filter will be mounted on the frame under the truck. Preferably just in front of the fuel tank itself to limit the length of return hose to the tank. This will result in just a single line running to the sniper vs a dual line for feed and return. In my case with the Sniper Stealth there is no built in pressure regulator so you will have to mount your own. In the case of the traditional sniper there is a pressure regulator built in and a good number of people bypass this regulator due to it failing and needing to be cleaned to get the sniper to run the engine again. In my case I prefer the Corvette style fuel filter as every time you replace the fuel filter you are also replacing the pressure regulator. Holley makes a similar unit themselves but it has a replaceable filter element and the regulator you can rebuild but have to buy a rebuild kit from holley. The pressure regulator assembly itself from Holley is $120 last time I looked with the filters being $15 and the rebuild kit some $25. The Corvette filter how ever I can buy AC Delco from any autoparts store for under $95 so for me it is preferable as I dont have to order special filters and rebuild kits for the Holley assembly and the OE assembly is considerably cheaper than the Holley one. Another benefit is since I am going to be running metal hardlines now from the regulator forward I can rent a male quick disconnect flare tool to flare the hardline and use it to connect directly to the Corvette filter. The Holley filter has -6AN fittings and will require the use of adapters. I do have to use -6AN quick disconnects on the male side of the filter which is the inlet as there is no way to flare hardline to a female quick disconnect. I have not decided if I want to bend hardline from the fuel tank to the regulator, I may do that if I can secure the hardline and coil up some hose ontop of the tank for installation and removal.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Installed the oil pump and pickup today, got the cam installed but had to pull it out again cause the cam dowel pin doesnt slide in with slight pressure like I been reading it should. I tried hammering it in with a soft blow hammer after freezing for 2 hours it got halfways in and stopped. Still too far out for use with a 2 piece cam eccentric and too far out to even be used without a eccentric. Tried using a metal hammer with light taps and that soft metal pin just mushroomed.

Tried to get it out claming the pin in the vice I have but wasnt able to get it to budge. Going to be taking the cam monday to drop off at the engine builder next doors to where I work see if he can get the pin out and install it for me cause for some reason Crane uses severe press fit pins over slight friction fit. I hope he can get the pin out cause if he cant and the cam is truly trash, then I will have to start my researching over again cause this cam and Crane doesnt exist anymore. Comp I read absorbed a lot of Crane when Comp got bought out and the Crane brand went bye bye for good. Comp dont even have a cam close to the specs of this one off the shelf so I have to try and salvage this cam as there is nothing wrong with it. I just dont know what to do if the pin can be removed I dont know if the hole in the cam should be drilled slightly larger or if I should try and find a thinner pin. Maybe try and find a OE Ford pin and hope that works.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

That's a bummer! I hope you can get the pin out and a new one in with no problem.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Same here. Im thinking about trying to get the pin out again tomorrow but my vice just doesnt grab too good and I refuse to clamp the cam itself in the vice. If I can get it out I am seriously contemplating using the spare pin I have and chucking it up in a drill and run sand paper over it to reduce the OD of the pin as the pin I tried using was a closer fit than the one that came with the cam but the one that came with the cam is excessively over sized. Only other idea I had was possibly drilling the hole in the cam slightly larger. The pin doesnt have to fit tight as I am installing the two piece fuel pump eccentric anyways and the tab that locates the eccentric on the cam gear will retain the cam pin from falling out.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

How about heating the cam a bit and using vise grips on the pin?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Thats what I thought about, I just dont know how I could hold the cam outside of clamping the cam in the vise itself. I thought about grabbing the pin with a vise grip while holding the cam and trying to turn the pin but I know I wouldnt be able to hold the cam from turning by hand. I also thought about cutting the pin off flush and using my center punch to mark the softer pin and then just drilling the pin out. Its just everything I come up with requires the cam to be clamped in a vise some way to hold it.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

How about strapping the cam to a table or workbench? In my case I could put a towel down on the work table, put another towel on the cam and a 2x4 on top of that, and wrap a ratchet strap around the table and cam over the 2x4.

But I sure wouldn't cut it off flush.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

I found a video on youtube its for a LS3 but the pin broke off and what he ended up doing was using thick foam padding to clamp the cam just enough in the vise to hold it then he drilled the pin in the center and threaded a long bolt in using a brake flare nut that had a larger ID than the OD of the pin then used a nut to thread down on the bolt to be used as a puller. Might be something I could do. I got some foam pads I saved I could try using that to just hold the cam to keep it from moving then instead of cutting the pin maybe try and drill down the middle. But the pin is quite pointed now from slipping off the vise. Another idea I had was drill through and through then use a zerk fitting and try and pump grease in the back side of the pin that would create a force to push the pin out kind of like using grease to push out a standard transmission pilot bushing. But then if I were to drill through and through I could use a long bolt and just keep threading it in till it hits the bottom of the pin bore and keep turning to pull the pin up on the threads and out. I have a few ideas of getting it out. Only thing is how do I fit the pin I have seeing as its a larger OD than the one I tried using that couldnt fit. I dont know how well I could shrink the OD down with sandpaper and the pin chucked in my drill. I also dont know if I sourced some NOS Ford pins if they would be a smaller OD or not. ~Update~ I got a idea to try first, I read a forum post just now for a 408W, the guy said clamp the pin in a vise and hit the snout of the cam with a brass hammer. I am going to do that first tomorrow but instead of using a brass hammer I will use my plastic/rubber soft blow hammer which is what I used to start the pin till it stopped so it should be enough with some force to jar it out. I think this will be my best choice and first option to try as it reduces the amount of damage to the cam itself. The next step would be figuring out the pin issue and if I should try to source a thinner OD pin or try to thin this pin to fit. I really hate to try and find a NOS one to buy off ebay cause I want to get my cam installed so I can check the degreeing of it and continue on with my build. I dont want to get my oil pan on till after the timing cover is installed and I cant install the timing cover till I get the cam installed. ~Update 2~ In looking in the parts and illustration guide the cam pin is 73328-S or 378189-S. Looking it up under the 302 it only lists 378189-S for the 302 and its listed as 80/ and the specs are 5/16" x 1 3/8". I bought a pack of 10 NOS off ebay for $30 just now, in looking it up Comp states this length is for the 1 piece fuel pump eccentric but the reading Ive done indicated the two piece eccentric replaced the one piece in 1973. Like wise I saw a bunch of posts stating with a 1 piece you need 1 1/2" long pin so I suspect comp is wrong on their lengths unless comp is not drilling the pin as deep. Im hopeful this pin being NOS ford will simply fit with no problem, if not I know its listed as 5/16" I will take a 5/16" drill bit to drill the cam pin out I dont care long as the pin doesnt have lateral play. The pin isnt what locks the cam gear in place, its just for alignment of the cam gear the bolt that holds the fuel pump eccentric and cam gear on is what locks the cam and gear together. So it looks like I will be pulling the pin out tomorrow I am fairly confident the use of the plastic/rubber hammer on the south of the cam with the pin clamped in the vise will get it out. Once I get it out I guess I will spray it down with brake clean to hose off the assembly lube as I already had it installed before I found the pin wasnt a smooth fit. I think I will relube the cam up and install it and the thrust plate and just wait till next weekend when these pins come in. At least the cam will be in the block ready to go.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Got the pin out. I tried using my soft blow rubber/plastic hammer which I used to drive the pin in to drive the pin out by clamping the pin tightly in the vise and smacking as hard as I could the snout of the cam. That didnt work, then I tried heating the cam up around the pin with my propane torch then hitting the cam that didnt work either. Finally I tried heating the cam and tweaking the cam back and fork wiggling the pin to try and deform the soft pin and wiggle it out, this I thought was working as it looked like the whole pin was moving in the cam but I guess it wasnt as the soft pin snapped off almost flush with the cam.

Last option was to drill it out, I started with a 5/76" drill bit for my pilot and I off set it just slightly from center. I then went up to a 3/16" drill bit then finally a 1/4" drill bit. This resulted in the 1/4" drill bit slightly touching the side of the bore drilled in the cam which released the tension on the pin. Drill bit grabbed the pin and spun it out of the cam. As of now the cam is installed back in the block for the time being till my NOS Ford cam dowel pins come in to see if they fit a bit better. Hopefully I dont have to pull the cam out again and attempt drilling the hole in the cam with a 5/16" drill bit. Im hopeful that the pin is just over sized compared to the OE ford pins but my gut says that the pins are all the right size, just that crane didnt drill the hole big enough. But then I think about how the pins I got from the engine builder I know were slightly thinner in OD than the ones supplied by Crane so maybe there are various sizes out there.  Once I get the pin in, I can then install my cam plate, dig out my magnetic dial indicator and check for camshaft thrust make sure it is with in spec as I bought a NOS standard plate and there is two other thicknesses of plates listed in the Ford catalog. Then I can throw my degree wheel on and verify installing the Comp Cams magnum true double roller timing set is on the money when installed straight up. Otherwise I will have to see if I need to advance or retard the crank key way to get the cam to match the cam specs. I need low/mid range power so I want the cam installed straight up like the cam card says. I also need to do some reading cause the paperwork with my cam states do not use moly grease I think it said on the cam lobes. I used Lucas Assembly lube on the whole cam but it has among all the components zinc and moly. I am a little concerned if that is going to be a problem but I dont think it will as I have never seen a assembly lube without moly I think they just dont want the thick moly grease. I will have to re-read the paperwork with the cam make sure it said grease as I think thats what it said when I read it yesterday. So as of now I have the cam just installed in place, got a few discolorations on the cam bearing where the cam journals slid slightly across the bearings, its not a gouge just a discoloration so I am going to let that ride and hope it doesnt cause a issue with wear. I tried to be as careful as I could and only way to have been more careful would be disassembly of the bottom end to reach my hand and support the cam on the inside which I wasnt about to do. Ive installed many cams this way at work and never had one have a problem. I got the oil pump installed, was able to torque one of the ARP fastners to the recommended 45ft lbs but the other one I could not as the oil pump body is in the way. Im going to bring my crowsfeet wrench set from work and see if I can get enough of a bite to get that bolt to 45ft lbs as well. I know it states 30-40ft lbs for the bolt but ARP stresses to use their torque spec as it provides maximum clamping force and is something like 25% of the yield strength of the bolt. I didnt like having the torque that hight but that is what ARP stated and I did use their washer and their grease on the threads and on the washer between the head of the bolt and washer. I also did the oil pump pickup the same way but I bought studs for those and I hope I didnt damage the pickup tube as I had to tap the pick up tube down on the studs. I think its because melling didnt account for most people using ARP bolts and the main cap bolts on mine are ARP and that washer raises the pick up slightly giving it a twist. I dont think the brazed joint was damaged but I will be finding out when I spin the oil pump up with my drill before I put the timing cover on. Last thing I want is to be sucking air around a join on the pickup. Also I am anxious to see how this oil pump performs. I havent primed it with oil yet before I throw the oil pan on I will be pouring some 10w30 or straight 30W driven break in oil down the screen of the melling pickup tube which will flow into the pump itself. This will help prevent me making a mess from oil dripping out of the pickup before I put the pan on. This pump is not the standard Melling pump this is their high pressure pump which it looks like they dont offer anymore. Looks like my engine is going to be the last of its design. Crane was closed down so my Crane roller cam cant be bought anymore unless you have someone custom grind these specs. The Melling oil pump I have is no longer offered anymore either. This high pressure pump which I dont know why they call it a high pressure pump, it has a bypass spring of 80 or 90 psi. Looking in my paperwork the spec on 302/351W engines for oil pressure in the 70s - 80s is 65 psi hot @ 2,000 rpm. The standard replacement melling pump has a 55or 60 psi bypass spring. There is no way the standard replacement melling oil pump would ever hit factory specs of oil pressure and could be why my oil pressure gauge on my truck rides around the low end of normal on the N and O. They probably used the standard oil pump instead of the proper high pressure pump which the engine came with from Ford. My 351W in my 78 Mercury is all original and the OE gauge which reads 0 to 90 psi with a normal range with 10w30 oil rides on the A and L when cold and the M and A when hot at idle. Based off the scale I estimate cold the pressure is around 70 psi and hot at idle its around 55 psi. I will be checking pressure with a mechanical gauge when I spin the oil pump up with my drill but I dont believe I can spin the pump fast enough with my drill to emulate idle speed to see what kind of pressure I will have. It will be one of those things I will have to do my 30 minute run in with a mechanical oil pressure gauge installed then switch to my OE gauge sending unit. I need to get my pan to the engine builder next doors to where I work to see if he can throw it in his blaster and blast the oil pan to bare metal. I dont like the thought of grey engine paint on the inside of the oil pan. It probably wouldnt come off but its not a perfect coating as around the hooks that held the pan it is just a over spray in that area and I need to clean the rust off there.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

Yippee! Glad you got the pin out.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |