1981 Ford F100 Revival (Parked for 12 years)

|

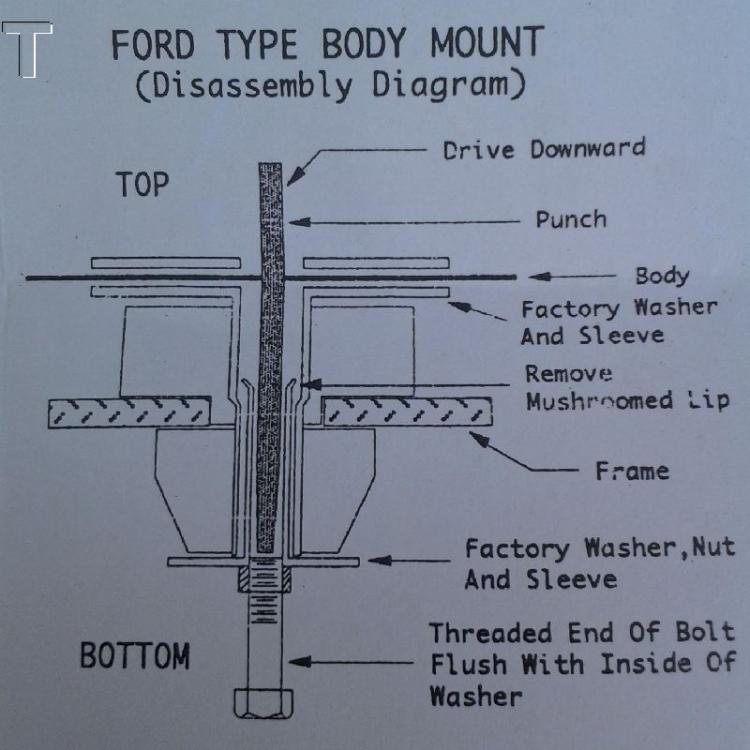

The long bolt arrived from McMaster-Carr. The homemade puller assembly worked for the drivers side front cab mount. It was making me nervous because it just kept compressing and the crimp would not release inside. Finally it popped free after reaching the compression limit. Good thing this one was not rusted out and it came out without much hassle.

The new lower bushing on the underside is thinner then the factory bushing but it does not matter much because it is not on the side that will affect the height of the cab.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

Now onto the real challenge. The rear cab mounts which one is hidden by the fuel tank that will need to be moved out of the way. It started off bad already with the passenger side bolt head rusted away. That was after identifying it. I thought the bolt was under the rubber cover but nothing is there. It was the bolt next to it under the carpet. The design is different then the front cab mounts so my homemade puller would not fit. I ordered a Front Wheel Drive Bearing Adapters Press Kit to get the size cup I needed to just fit in the gap. The stripped bolt head I was able to remove using my old Craftsman damaged bolt nut remover set. I am glad I purchased so many tools when Sears was still open. Some of the tools I never use but when I need it I am glad it is there. The price of tools have went up so much over the years also.

There is a really good bushing set made by SBFilters that is made of a much better material and comes with the pullers. Looking back I would just buy it to get the pullers and better quality bushings. "They are MADE FROM A PREMIUM SILICONE RUBBER These bushings offer great vibration isolation and will not crack or breakdown like the OEM foam or rubber bushings. Also comes with corrosion resistant coated steel cups and bolts." Related links: https://www.sbfilters.com/body-mounts/ford/1980-1996-obs https://amzn.to/3x6OutK

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Glad you got it apart. And you are right, some tools aren't needed very often, but when they are they are worth their weight in gold.

Kinda rusty on that floor. What are you going to treat it with to stop the rust?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I will probably just sand the rust away and paint. I plan to put some sound isolation over it after that. I need to order new door seals. Water keeps getting inside. I already rusted some new parts I was storing in the truck because water got in. When it sat for years I think water pooled on the passenger side and rusted the bolt out.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I would hit it with POR-15. Since you are going to cover it you don't need to topcoat it the way you would if it was open to UV, which turns it white. But POR-15 will seal it and even if you get water on it again it won't rust.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Jonathan

Back to work on the passenger side of the cab bushings. The front radiator mount was hard to get off so I kept it from moving with a strap. About a pound of rust came out from under the radiator mount.

For the rear cab mount I tried a hammer method that I saw on YouTube. It didn't work despite banging at if for a long time. I think it may of worked if it wasn't so rusted inside. The front cab mount on the passenger side came out easy. Got lucky on both of those. But the floor was very wet and the strange diaper thing under the carpet was a soggy mess.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

I thought for sure after getting a cup that would fit inside that I could get the bushing out but it was far too rusted. The cup I thought wouldn't fit at first but I found I could slip it from the side and then up. But it won't fit from the front like the other front cab mounts. I kept blasting away with the impact and the only thing it did was strip out the bolt head. It started to worry me so I stopped, removed the bolt while I still could and then plugged the hole with a different bolt and let Deep Creep sit inside it overnight.

I ordered a bunch of new hardware from McMaster-Carr and things to help remove the bushing. This time I ordered a very strong bolt for the puller that hopefully won't strip the head.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Gary Lewis

Thanks for the tip. I will look into getting some.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jonathan

Another day and another failed attempt to remove the rear cab bushing. I am trying to remove the passenger side first because the driver side is covered by the fuel tank. I would rather work out the details before moving to the other side. I got some new hardware from McMaster-Carr. This very pretty grinder bit that is 7" long. And some very strong hardware made for heavy machinery with a 12 point head. I also ordered a 12 point socket since I don't have any. I was surprised that the socket was a good quality Proto socket made in the US. The bolt had a very nice finish too. I also got this very thick washer that was slotted so I can take up some more space since the bolt I got was not threaded all the way. I also slowly started to add pressure using a breaker bar seeing if that would help. After that I got frustrated and just hammering on it with the impact. Despite all this and even trying to remove the rust and buildup inside the bushing I could not get it to release. I left tension on it hoping it would come loose during the night or at least help loosen it up.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

Another day again... This time I had half success. The passenger side I got removed after using a slide hammer puller I fashioned up from a 2ft long threaded rod from my McMaster-Carr order that I cut down to fit under the truck. I ordered a bunch if different crap to handle all kinds of methods of removal. The final winning method was more slide hammering and grinding out the crimp. I left the weight of the slide hammer resting whilst I grinded away. Finally it broke free! It damaged the threads a little but I cleaned it up with a tap and filed the damage on the outside of the bushing so it will slide back in easy. As for the drivers side I moved the fuel tank out of the way by disconnecting the filler neck from the door area to slide it over. Then tried the "correct" method first and all I ended up doing was strip out the threads after switching out my battery to the biggest one I had. Between the strong battery and the super strong bolt it took the threads right off. So I went back to the grinding method to remove the crimp and hammered down from the top with a brass drift. It finally came out! Now I need to order a Heli Coil kit to replace the threads. For extra safety I will double nut it since there is enough bolt sticking out to accommodate an extra nut. I would just weld on a new nut but I don't have a welder and don't know how to weld yet.

I also got some new bolts and washers. I couldn't find a washer thick enough for the front cab mount so I will just double them up.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

I prepped the truck for lifting. All the bushing bolts are loose or removed. I also removed the radiator fan shroud since the body will lift but the fan blade won't. Here you can see the stripped out bushing end and the Heli Coil kit I got to fix it. I dug the broken threads out of the bolt to show the damage. The drill press is back together again since I need it to drill out the large hole for the thread replacement.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Man, you are having LOTS of "fun" on this quest. But you seem to be getting right along with it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

It is a big learning experience. I am savoring every moment of the project. It is like eating a delicious desert slowly.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jonathan

Okay, lets get some new mounts in. Lifting the body makes me nervous. And I found being on a hill does not help. The whole cab slides back and was scraping on the truck bed on the way back down. After it was back down the bolt holes do not line up with the cab. I ordered some inflatable air bags to help me line up the cab by inflating them in the gap between the cab and the truck bed. I tried using a piece of wood but it kept deforming the metal. So I think a large air bag will be more gentle. So I lowered it back down with the new bushings but the bolts are not in it yet. Getting everything line up right will be interesting and a dance going back and forth. I may try to find a wood rod that fits the complete front cab mount hole all the way so it stays lined up while I get the rear cab bolts in.

One bushing was very bent so I fixed it with my vise and a hammer before installing it again. I asked the manufacture why it is shorter and this is what they said. "The factory rubber is designed to allow more compression. The polyurethane will not compress the same so its compensating for that." One thing I can't figure out is why the power steering pump started leaking after lifting the cab? It made a big mess and wouldn't stop leaking. I can't tell exactly where it is coming from. The frame of the truck didn't move so it does not make sense to me.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Did you take all 4 body mount bolts out at the same time? I'd leave one side in and do like you show in one pic - raise one side up with a 4x4 under it. That way it is less likely to shift.

Anyway, glad you are having fun. I get frustrated when things don't unbolt and bolt back on nicely.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I left one side of the bolts in and loose. And completely removed the side I am working on. I guess it shifted so much because my driveway has a slight incline. There is a lot of play in the bolt holes also.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Yep, that's how I would have done it. And I'll bet you are right that the driveway's slant caused it to shift.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Jonathan

The air bag shims arrived and worked good. I was able to gently nudge the cab forward to line up the holes to insert a place card consisting of 1/2" ratchet extensions. After test fitting I covered them in grease so they can slide easy when I lift up the other side. After I install the other side bushings what is the best way to line up the cab? Is there a body repair manual someone has with how to line up? The whole thing moves around a lot in the bolt holes so I need some kind of reference. I never really did body work before so I don't know what is the best method.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

I figured out why my chuck came out last time. I turned up the speed for a different project and forgot to change it back down. I had it running at the fastest speed which I guess won't work on a big bit in metal. Before I drilled out the bushing hardware I turned down the speed.

I purchased an adjustable spring tensioned tap guide to help get it in straight but my drill press vice kept slipping so I finished it up on my bench vise. It was my first time using a heli coil but it went well and seems okay. There should be enough bolt sticking out to add an extra nut after I tighten it down to be safe.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Glad the air bag worked.

As for alignment, I've been told that you work from the back to the front. The bed is bolted to the frame so is the reference and you align the cab to it. Get the gap the same on both sides and when you tighten the mount bolts down you use them to get the creases aligned so that when you sight down them they continue from the front of the cab to the rear of the bed. Then you adjust the fenders to the cab, aligning the creases there. As for the helicoil, did you stake it or put it in with red Loctite? That makes sure it won't turn w/in the washer.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |