1981 Ford F100 Revival (Parked for 12 years)

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I don't think it is critical at all. And with my toolbox mounted I can't accurately measure at the top, but I'd bet mine is more like 1 3/4".

Anyway, hope you get those bolts in. You are doing a great job and I think you are going to be very happy with the results.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Thank you for your encouragement Gary. I worked on it after work yesterday for a few hours with little progress. This time I put one floor jack on each side and lifted the cab up enough to relieve the pressure so I can move it easier but it was binding on the front passenger side radiator bushing. I need to purchase another jack so I can lift at three points. I currently only have two working floor jacks and the 2nd one is very small and could hardly reach even with a 4x4. Today I will go to Harbor Freight and pick up another jack.

Last night before I slept I reviewed the issue and had an idea. I am going to take a long 2x4 which should be just about right at 1.5" width and lay it down between the cab and the truck bed. That way I won't need to keep fighting the gap. I will just push it back to the 2x4. Then my main concern will be side to side.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I think the 2x4 is an excellent idea. That should get you really close and let you worry about getting the bolts in w/o hitting the bed w/the cab.

I'm really surprised that you are having this much trouble. The two cabs I've done dropped down on the frame nicely. So I'm wondering if you don't have a bend somewhere in the frame - or the cab. I found that Big Blue had apparently been in an accident and the front of the frame had been bent. It took a come-along and several HD ratchet straps to get it back where it should be. So in your case I think I would see which bolts go in nicely and then figure out how to move the frame enough to get the other bolt(s) in. If you have to pull the frame rails together then you'll need some way to do that. If you need to move the rails apart, then maybe a hydraulic ram like you can get at HF. But you may want to take the frame past the point where things align to get it into alignment when released. And this can take considerable force. Be careful!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

In reply to this post by Jonathan

I get a chuckle out of you using an internal bore gauge to check the distance between cab and bed.

But you're doing great work and I'm sure the truck is thankful for the attention!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I thought "Now, why didn't I think of that???" The bore gauges are far easier to use than bending my tape to fit in there. Which didn't work at all.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Gary Lewis

I did find a strange bend in part of the frame that I am not sure is normal or not. I will get a picture of it and post for you to examine.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by ArdWrknTrk

You should see what I use screwdrivers for.

Thanks, hopefully all the hard work will pay off soon. I really need to learn to weld to replace the cab corners.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jonathan

I tried using a 2x4 as a cab to bed spacer but it was too thick and the rear cab mount holes were not lining up. I sadly also managed to dent in the back of the cab with the 2x4 which is not something I needed considering all the other dents. I switched to a slimmer deck board from repairing my rear deck. I purchased a floor jack that Ugly Puppy picked out but it was not enough to help me get the cab over. I had trouble moving the cab toward the passenger side. I even used my lawn tractor as an anchor point and kicking the heck out of the drivers side door jam to push it over and it still would not move over enough. The only thing it did was hurt my back which is still recovering. It is just is fighting me the whole way. I reached out to Randy feeling frustrated and he gave me some good advice to lock it down and move on. So that is what I did. I will need to try again when I can drive it to a flat surface or take it to a body shop. I also think I will need some shims. The drivers side is too low and the passenger side is too high which I don't understand because the mount is shorter and I tightened down as much as I could. I can't shorten it any more unless I modify the bushing. I also ordered some new washers for the rear cab bolts because the other was too thin and started to bend before reaching the torque spec.

See the last pictures of the radiator bushing bolts. It has to slide all the way to one side for the other cab bolts to line up. Something seems twisted.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

Since the drivers side suspension is almost ready to go back together I needed to clean up all the years of crude on the mount for the bushing side of the control arm or whatever it is called. I didn't do a full paint restore but just removed the crude and put a protective coating on it.

I also picked up some rust remover to try. I tried it on a brake shield that I already polished off most of the rust already but for some reason it seemed to expose rust that I didn't know was there.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

The plan was to finish cleaning the hardware for the suspension and paint or treat most of the parts but my back was hurting too bad from the cab moving and had to put the painting on hold.

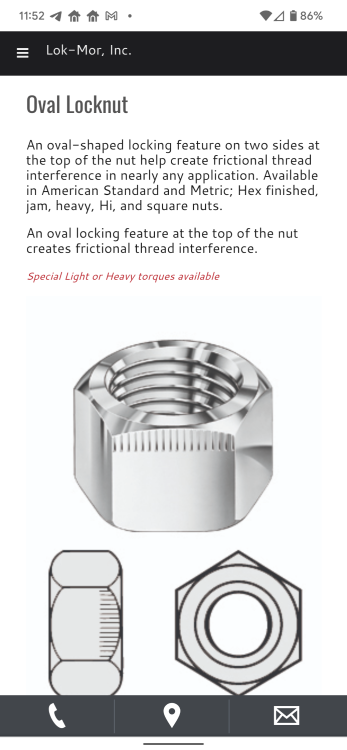

I thought I had some bad nuts at first for the suspension spring mount but from looking into it I believe the bolts are made like this on purpose. They are oblong and not a perfect circle. Based on the line on each side of the bolt it looks like it was squeezed with some sort of press when it was manufactured. So I will reuse the bolts because I think it is made like that.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

In reply to this post by Jonathan

Most chassis and suspension use distorted locking nuts to make sure they can't back off due to vibration.

The crappy nylon insert nuts are too easily damaged by heat or hydrocarbons. You don't need to learn to weld in order to replace a cab corner. Panel bonding epoxies work quite well, especially in situations where access is limited or extreme heat would cause you to remove lots of other components unnecessarily. Gary used adhesive to extend the floor clearance of his Dad's Truck for the E4OD. Of course in typical Gary fashion he went full belt and suspenders with a lot dimpling and flush rivets as well.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Yes, I'd lock it down and then move to a different location.

And yes, those are locknuts. I think they are called "prevailing torque" locknuts. Last, yes I do wear a belt and braces.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Haven't heard that term in a while... Braces

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

We have some Brits on here and I've lived there, so try to remember their terminology from time to time.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by ArdWrknTrk

That makes sense. It does seem to grab well. And it is not exactly in an area you want your nut to come loose.

Thanks for the tip on panel bonding epoxy. I will look into that. Gary's project sounds cool. I will look for that post.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Gary Lewis

This project is teaching me all kinds of new things. I never saw a locknut like that before.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jonathan

The new thicker washers arrived from McMaster-Carr. You can see in the picture the large washers I purchased to use was too thin and started to bend in. I even tried to reinforce with another washer on the top and bottom and that didn't work. I couldn't even reach 50 ft lbs of torque before because the washer would just give out. The new thick washer worked good and I was able to torque to 50 ft lbs which is where I will leave it for now because I need to revisit this later. Next step will be to move the fuel tank back.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

The fuel tank is back mounted in again. I noticed that the top of the bushing hardware is not making solid contact with the cab body so I tightened another 5 ft lbs to 55 ft lbs. The bushing hardware was at an angle when I took it out which I straightened. It may need to find its level again to match the cab. I will just keep going back again to step it up to 60 ft pounds after it settles for another day or so.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

This post was updated on .

Yesterday I discovered a light behind the bumper on the drivers side. I was going to ask on here but did a search online for what it was for. Turns out that a lot of trucks on the dealers lot did not come with a rear bumper. The license plate mounted to the back under the bed. So the light was the original license plate light. After the truck was purchased it seems many put on an aftermarket bumper or paid the Ford dealer to install one that may of been aftermarket also. I would prefer a regular chrome rear bumper and a hitch under it. What hardware will I need other then the bumper to attach it to the frame? The current bumper I don't like but it seems strong.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

My next step is to install this bushing and paint the control arm (correct name?). From the research I did they said to put the bushing in the freezer to make it easier to install. I think I want to install it before I paint it so I won't damage the paint pushing it on. I just hope that it won't rust under it and leak rust juice on the paint where the paint won't reach after it is pressed on. My question is about install lubricant. Many say not to use lube because you don't want it to spin. It needs to be a pressed fit. So from what I understand these are my best options that don't leave a residue which could cause it to spin. Let me know your thoughts.

Windex Soapy Water Ru-Glyde Tire Mounting and Rubber Lubricant Also do I need to install immediately after pressing on? Does the bushing need weight applied in the correct position to settle correctly?

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

| Edit this page |