1981 Ford F100 Revival (Parked for 12 years)

|

I tried to look for the specs of how hard the bolt is but I couldn't find anything other then heat treated.

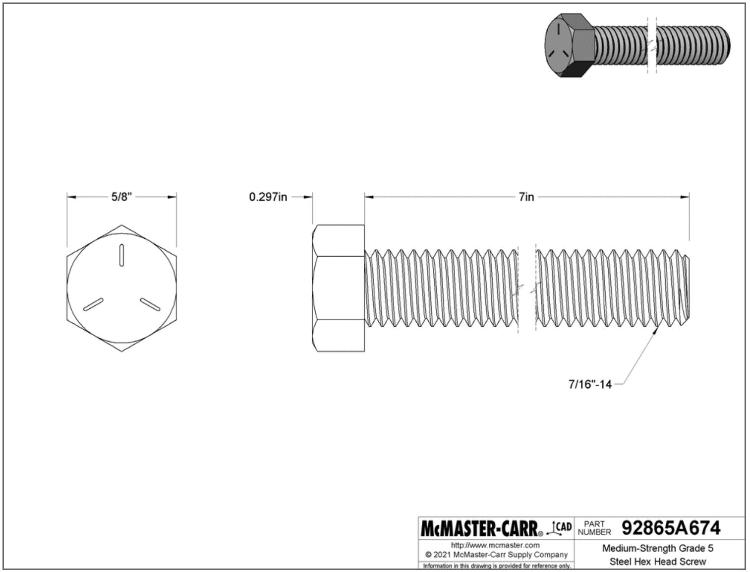

When using the nut that came with the bolt it wouldn't go down all the way. But when using the OEM bolt it went on better probably because it is old and used. It checked out the OEM bolt at 1.75 pitch when I tested it with my thread finder. The new bolt did seem very hard. Maybe I didn't spend enough on my tap and die set. https://www.northerntool.com/shop/tools/product_200631758_200631758

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Threads are cold rolled onto screws and bolts. This has a burnishing effect and makes them much smoother than cut threads.

I can't really say why you are having trouble, or even give an opinion without being there. I'm sure your truck will be better than the day it rolled off the line when you are done. 🤯

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I even tried using my thread restore kit to smooth it out. It helped but not enough. After two hours I called it and moved on. That bolt was not meant to be installed.

Thanks, I hope I can improve it in some ways. My goal is a reliable classic but I will see how far that takes it.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jonathan

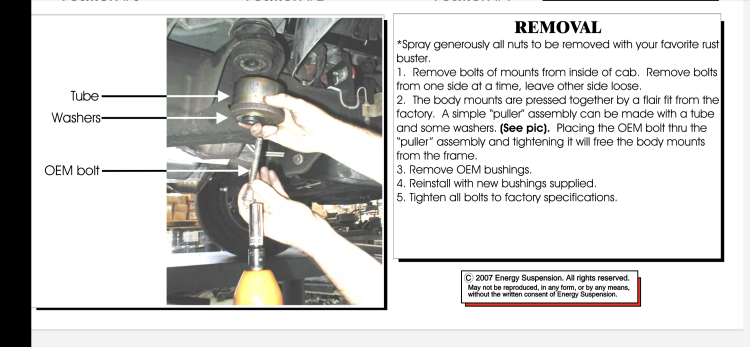

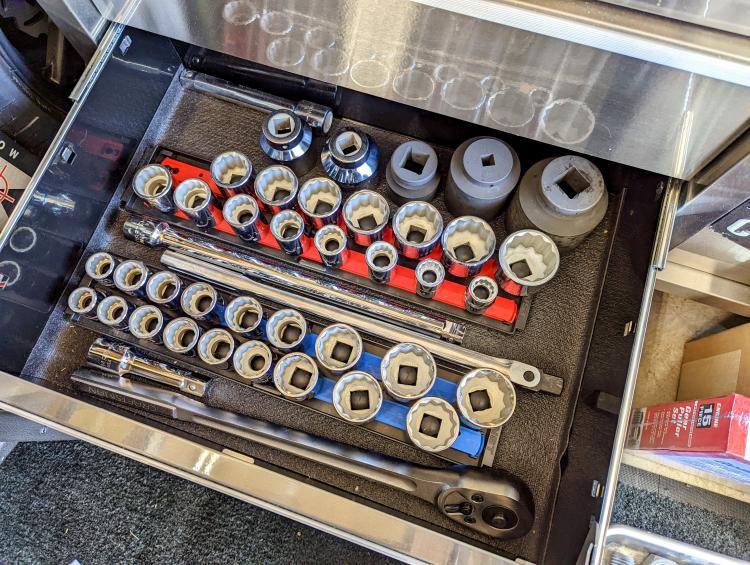

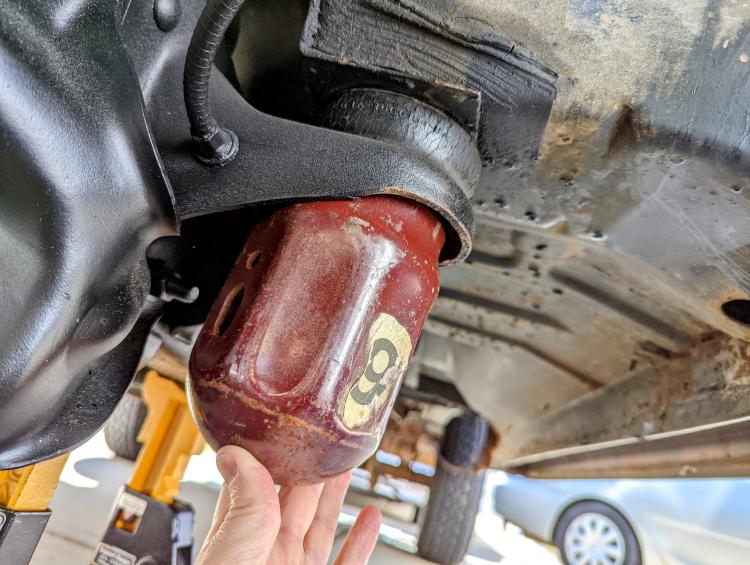

Yesterday after work the search went on for something I could use as a puller like shown in the bushing instructions. I thought for sure my bushing removal kit or the extension kit would have something that was big enough but it did not. I even looked for my largest socket and it was not big enough either. I did find a hole saw that was wide enough but it was not deep enough. In the end the only thing that I found would work was my 40CU nitrogen tank bottle cap. It is too deep to use the OEM bolt so I had to order a 7/16"-14 7" bolt from McMaster-Carr. This time it is fully threaded! It was either that or cut down the cap shorter which I didn't want to do. It would take me forever with a hacksaw by hand. The bolt should arrive tomorrow. I determined the length by inserting my thread cleaner until it went past the threads and moved free, then added that to the length of the cap.

I drilled a hole in the top for the bolt but in the process broke my drill press on the last drill bit step larger. The vibration was too much and it came out. I tried to hammer it back in but it will not go and finished with my largest hand drill. I put the chuck and spindle in the freezer and will try again. Does anyone know much about this? How can I keep it from falling out? Also my Craftsman ratchet broke. Can I still get a new paw for it? I didn't take it apart yet, hopefully it just needs some lube. Use caution with the bushing removal extension kit from Harbor Freight. It has one piece that is super sharp that will cut you deep at the slightest touch! I have no idea why this one adapter is made razor sharp.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I'm not sure I understand. What broke? Was it the chuck? What I see in the picture is a chuck attached to a taper. It looks like a Morse taper with a tang to me. Some Morse tapers have threads and a draw bar pulls the make taper into the female taper. But usually a drill press has a tang and a slot, like yours and mine. So, what is the problem?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

In reply to this post by Jonathan

I don't think you have to pull the sleeve too far to get it to disengage. Just look at the depth of the poly bushing tool.

Once it's free the body mount should come apart. Morse taper should just slam in and grip. Perhaps you've raised a burr in the socket that's keeping it from seating? Make sure you're lining the tang up when inserting. Made in USA Craftsman would have a lifetime warranty. Good luck finding a Sears! I do think Craftsman hand tools can be exchanged at Lowe's. (and now I'm chafing at the thought of Ed Lampert and what the divestiture of Craftsman to SBD has done to another icon) ... yes, I'm a boomer. 👴

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Gary Lewis

The taper slipped out and I couldn't get it back in. The last time I inserted it I don't remember lining anything up. I just hammered it in. I have it in the freezer now to aid insertion due to shrinkage as that is what I was told to do last time from the nice gentleman that gave me the chuck. I will try and see if there is a slot for it to slide into.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by ArdWrknTrk

The nitrogen tank cap is a little overkill in how deep it is but the hole saw was way too short. I had nothing in between. I don't have much metal cutting tools to help me make is shorter so I will try and make it work.

I will check if there is something to line up to. I don't remember doing that at all before which may be my problem with the chuck falling out. But I was in all the way before so it either does not have a slot or I don't remember lining it up. My ratchet is Made in USA. I would hate to replace it with something from China. I wonder if I buy a new one from Lowes if the parts are the same inside for me to swap out. My Sears closed last year.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I'm just saying that you only need to get the bushing sleeve to release from the top washer. Once the crimp (flare?) pulls free the body mount should come apart.

Perhaps your hole saw is too shallow. This is why I like the yellow Starret extra deep ones from Amazon. I have a 17" Jet drill press that's 30+ years old. Never had an issue getting the Morse taper to seat. But if the guy you got yours from offered advice it's probably best to follow it. Things have changed with Craftsman. There have been many different models and revisions of late. IDK if you can get just the guts in a kit under warranty. Last time I tried my only option was exchange. I hope this all works for you! 🙂 I know how frustrating it is when my plans and tools let me down.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Jonathan

At the suggestion of the bushing manufacture I wiped off the silicone and put on wheel bearing grease which they said would work better to prevent noises. Here is a website link to someone that went through a lot of trouble to compare. I just used what I had though.

https://www.suspension.com/blog/the-best-grease-for-polyurethane-bushings/ I put in a stainless steel bolt and nut. The old bolt rusted half way though and I did not want to use that again. Anyway I got one done and five more to go!

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by ArdWrknTrk

I can't wait to see the crimp or flare and document how it is holding on so secure. Its all a mystery

to me right now. Tomorrow I should have time to get it out if the bolt arrives on time. Thanks for the tip on the Starret extra deep hole saws. I will check that out. I wish I had a Jet drill press. Mine is a cheap Craftsman. Maybe someday I will upgrade. Yeah I remember the days of the work bench in the back of the Sears store with all the hardware to rebuild ratchets. And the box under the counter with all the old ratchets people traded in. They would let me go though the box and exchange for a vintage broken Made in USA ratchet. Good times.... Usually I let my tools down not the other way around.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I have to thank an ex-girl friend for the dp.

Melissa was always very thoughtful! 🥰 I posted some pictures of the trashed bushings when I cut the cab mounts off my truck. (that would have been when I replaced the rockers and parts of the floor) Not sure how to find them in the whydtytt... The top of the sleeve flares out when you cinch the radius under the bolt head down into it.This then captures the top washer.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

What a great girlfriend. That was a very nice gift.

Thanks for the details on how the bushings locks in. That makes sense now and I can see how that would work. Talking about how the bushings locked together made me think if there anyone in the forums that worked at a Ford Truck Plant? That would make some interesting discussions. I knew a guy that worked at a plant in Louisville, Kentucky years ago in the 80's. He is probably dead by now as he was much older then me. But I even got to see the paint booth which was off limits to regular tours. This was a one on one tour. I also had a friend that worked at the GE plant that died last year. He taught me a lot about cars when I was younger. I guess I need to find someone to pass down things to also.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Good job on the bushings! And I agree that silicone is not the lube to use on polyurethane bushings. In my case I couldn't reach the torque that Ford specified for the cab mounts w/o the bushings being mushroomed waaaaay out. The silicone grease was way too slick.

And I guess you got the chuck and taper back in? Yes, the tang has to align with the recess in the spindle, and then a light tap should seat it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

You bring up a very good point on the bushings Gary. How do you torque something that compresses? What is the torque spec? I can try but don't see how it is possible without crushing the bushing to the point it won't work as designed to have a little give. Polyurethane is much harder then rubber though so it may be more likely to reach the torque spec over rubber but I have never done this before.

I have not worked on the drill press yet. The chuck is just chilling in the freezer.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

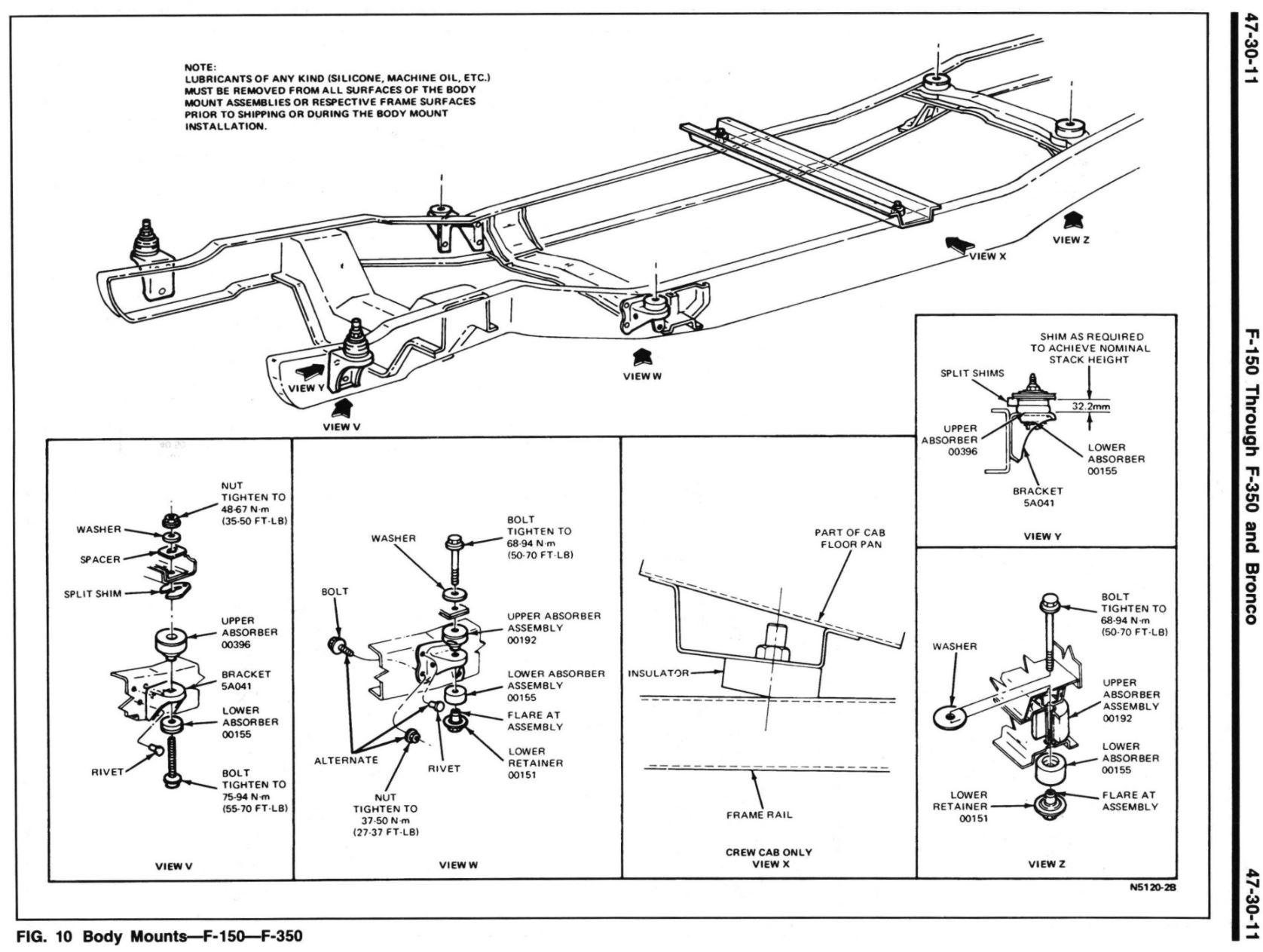

Actually, according to the page below (Documentation/Body/BODY SHELL, EXTERIOR TRIM, FRAME & UNDERBODY) there is not supposed to be any lubricant on the surfaces of the body mounts, as said in the note in the upper left. And, thinking back on it, that's how I finally got the bolts torqued properly, with the torque values also shown. With the silicone lube the poly bushing just kept squeezing out from under the mount.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Thanks for the great picture with the specs. I will give it a shot.

As for the recommendation of no lubricate I think that applies to the original OEM rubber bushings. Poly bushings may get noisy with no lubrication. Here is a link talking about it. https://moviecultists.com/do-polyurethane-bushings-need-grease Polyurethane bushing manufacturers advise to never use a petroleum based grease for poly bushing lubrication. Polyurethane should only be lubricated with one specific type of grease to insure long bushing life, and squeak-free performance, Silicone based synthetic water-proof grease. How often do you grease polyurethane bushings? Maintenance: Unlike rubber suspension bushings, poly ones need to be greased every three to five years. Feel of the Road: Polyurethane bushings help the vehicle feel like an extension of the driver. The bumps and potholes become more pronounced. Do polyurethane bushings squeak? Rubber makes no noticeable sound while polyurethane has the possibility of squeaking (if not properly lubricated). Historically, one of the most common complaints about poly bushings is that they squeak where rubber bushings do not. ... The sound is easily avoided by applying grease to the bushing during install. Can you use lithium grease on polyurethane bushings? Lithium based grease adheres to metal very well, has a high heat tolerance, and is water resistant making it another possibility for use with polyurethane bushings. These lubricating agents are basically oil mixed with lithium soap, usually with several additives. How often should you grease bushings? All poly bushings will have to be re-greased. Every 5-10k. I usually do mine every ~10k miles. Use a synthetic grease.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I think you’ll have a hard time reaching that torque with grease on it. But let us know what find.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I asked the bushing manufacture about the issues previously mentioned. Here were their responses. Interesting that they are mentioning not to use grease unless needed now. But it is a pain to have to go back later to grease them later.

"The bushings shouldn’t be compressing that much unless they are over torqued, if they are something is missing or wrong with the installation. We also typically don’t use grease on body mounts unless there is noticeable squeaking or creaking coming from chassis/ cab after installation so I couldn’t chime in regarding grease getting pushed out... They should be able to be torqued to spec without issue." "If its compressing that much I would also check the bolt, some Fords used what’s called a torque to yield bolt on the cabs so they are only good for one use before needing to be replaced. It shouldn’t be the case for yours, but make sure the bolt isn’t flexing when torqueing it down. And as noted in the service manual the cab should be at minimum of 50ft/lbs which should be reachable." Please let me know if you are still having issues or concerns.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Maybe I put it together incorrectly, but I used that diagram and those torque specs and the bushing just kept squishing out with grease on it. Not the grease itself, but the bushing. And it felt like I would be able to just keep squishing it.

But by cleaning the silicone grease off very, very well it went together nicely and torqued down perfectly.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |