Old Blue - 1984 XL Flareside

|

Administrator

|

What I found here says:

Here’s another example of legacy term confusion. Sometimes it is necessary to use a tap with extended length. The added length may be used to add “reach” to the tool, or to allow tapping to a depth longer than the thread length of the standard blank. Maybe it’s necessary to accomplish both! The confusion lies in what to call that style of tap. “Pulley” taps were originally designed to tap threads in a pulley assembly. Length was extended, but shank diameter was approximately the same as the thread major diameter. The shank was used as an alignment guide to reach through the pulley hub. Thread depth could not exceed the thread length of the tap. Today, the term is rarely recognized by recent generations.

So, if you can't find a pulley tap then maybe you can find an extension tap? (I'd never heard of it, either.)

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Learned something new

One could also take a grinder and cut flutes in a bolt that is long enough. Essentially a long chase giving the crud somewhere to go. Oil, thread, remove, clean, repeat.

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

|

Administrator

|

That's a good idea, especially if you have a cutoff wheel so you can get a sharp edge on the cut.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

In reply to this post by Gary Lewis

I've never known that difference. 💡

But I've rarely encountered a situation where I needed to tap longer than the threads available on the tap. I have had situations where I needed a bottoming tap in a blind hole, but only *had* a taper tap. So I just tap as far as I can, back it out, blow it out, cut the tip off with a .045" disc and go until I bottom again. Then I back it out and cut more off, until I get threads close enough to the bottom. Scott's trick with an old bolt is pretty effective for chasing threads.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

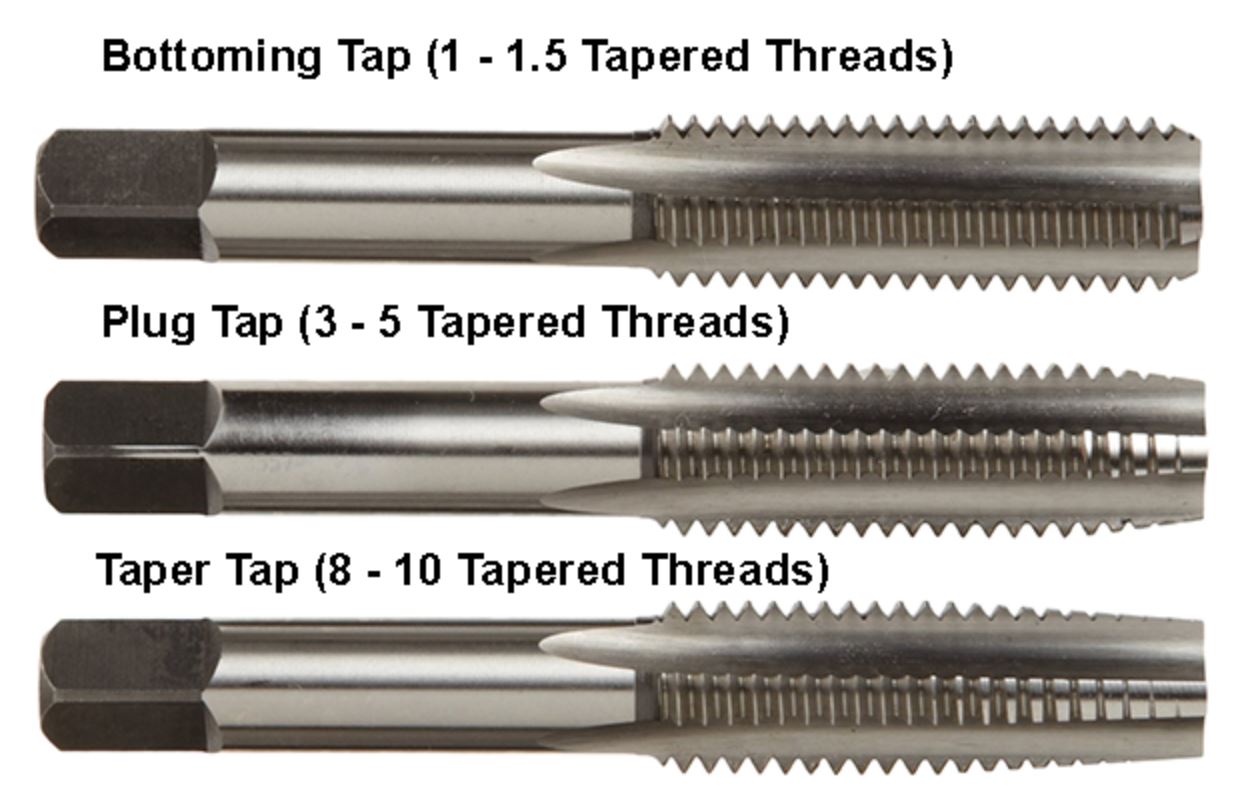

Until I took the course in machine work I didn't know there are different types of taps.

What I learned is: What I learned is:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

“Pulley tap” Never heard of them either, that I can remember. Heard of the three you showed. Cool!

Interesting!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

In reply to this post by Gary Lewis

I started doing what you suggested - going a few more turns, backing the bolt out and cleaning it off, and repeating. It’s getting there, I had to go back to tea life later in the day but I think I’m ready to install again soon.

Thanks for the advice - I try to not force things out of fear I’ll damage something that I’m not able to fix, but I’m learning they are sturdier than I give it credit for. And following Jim’s advice, I’ll use thread sealant on the ends.

Chris

'84 F-150 XL 2WD Flareside, 302 w/ AOD transmission, Motorcraft 2150 feedback carb w/ CA Emissions, EEC-IV w/TFI, factory A/C, Tilt Column, Borgeson/Bluetop Steering, Speed Control, 308,000+ miles - Info about me and my truck - My project thread |

|

Administrator

|

Keep on keeping on, slowly, carefully, and you'll get there.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Will do! PS - Dang autocorrect! I meant “real life” not “tea life” :) On Sun, Jan 31, 2021 at 6:42 PM Gary Lewis [via Bullnose Enthusiasts Forum] <[hidden email]> wrote:

Chris

'84 F-150 XL 2WD Flareside, 302 w/ AOD transmission, Motorcraft 2150 feedback carb w/ CA Emissions, EEC-IV w/TFI, factory A/C, Tilt Column, Borgeson/Bluetop Steering, Speed Control, 308,000+ miles - Info about me and my truck - My project thread |

|

Administrator

|

I think you'll be fine if you continue slowly, or find another long bolt and slot it as Scott suggested.

Autocowrong, or auto-incorrect is amazingly frustrating!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I believe I do have an extra bolt, that is a good idea Scott had. I don’t have a grinder but perhaps a Dremel would work? I don’t know how a grinding disc would do against grade 5 steel - I’ll try to find a softer bolt lying around. On Sun, Jan 31, 2021 at 6:55 PM ArdWrknTrk [via Bullnose Enthusiasts Forum] <[hidden email]> wrote: I think you'll be fine if you continue slowly, or find another long bolt and slot it as Scott suggested.

Chris

'84 F-150 XL 2WD Flareside, 302 w/ AOD transmission, Motorcraft 2150 feedback carb w/ CA Emissions, EEC-IV w/TFI, factory A/C, Tilt Column, Borgeson/Bluetop Steering, Speed Control, 308,000+ miles - Info about me and my truck - My project thread |

|

Administrator

|

It would work but will likely go through a number of the discs and the slots will be smaller (not ideal).

Did the thickness of anything change? Can you stick a punch all the way through the hole to ensure they are going into the water jacket? If not, did these have acc brackets under them perhaps? Sorry, I don't know which are through holes or not so just trying to think of other causes.

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

|

Administrator

|

I knew "tea life" wasn't right, but couldn't come up with what it should have been.

On the bolt, if you are careful you could groove it with a hacksaw. The groove will be deepest at the end, but it won't take much. And a sharp edge will cut through the junk that's in there far better than just a nice smooth thread. Just don't cut all the way through as you want the bolt to be full-sized and not deflect in.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Gary Lewis

I think on the 302 motors that is just an inslated cable holder to keep it from the exhaust pipe. On the 300 six there is the same holder for the power to starter but there is also a ground cable with a tab bolted to the same frame bolts to ground the frame. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

In reply to this post by kramttocs

Yup, that's a handy trick. I used to do it every now and then if I didn't have a tap or a thread chaser. I use a zipcut disk and cut it on an angle so that I end up with a sharper cutter (as opposed to cutting perpendicular to the threads). Another handy tip is to buy a Refrigeration Ratchet Wrench to keep in your tap and die set. I have used mine for tapping threads many times. It has 4 different square hole sizes, and while it doesn't fit every tap size, it fits most of them. Great for tight spaces where you can't fit the big tap handle or get a good turn on it.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

Administrator

|

Cory - Thanks for the tip on the angle to cut the bolt. That makes sense.

But thanks even more for the suggestion of the refrigeration wrench. Someone has recommended that before, probably you, but I didn't follow up on it then. But I did today 'cause I've recently had a need for that as the tap handle was a pain where I needed to use it. So I bought this Klein Tools ratchet from Amazon for $17.50 inc tax.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Yes, I've mentioned before. You'll be surprised how often you'll reach for it once you have it. Like I said, it doesn't fit every size tap, but it's fits often enough that it's worth having imho. I find a lot of times you need a little more leverage than the small fit in your palm tap handle, and the large tap handle is just too big to use in a lot of areas on a vehicle.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

Administrator

|

In reply to this post by kramttocs

Yep, there are brackets that need to go on (alternator, AC/idler puller, and PS), but the bolts started getting hard to turn before I got near. Good point. But you're right, there will be less travel needed for the bolts when I put the brackets on.

It's been so long since I had stuff assembled, I spent a good chunk of time going through old pictures on my phone so I could refresh myself where stuff went. I always think I take enough pictures and then without fail I later wish I had take more!

Chris

'84 F-150 XL 2WD Flareside, 302 w/ AOD transmission, Motorcraft 2150 feedback carb w/ CA Emissions, EEC-IV w/TFI, factory A/C, Tilt Column, Borgeson/Bluetop Steering, Speed Control, 308,000+ miles - Info about me and my truck - My project thread |

|

Administrator

|

So, I got some time and put the water pump on! I worked the bolts over the past few weeks (probably about 10 mins of real work really), and I got lots of gunk out and I'm happy with the fit now. Everything went well... almost.

I did hit one snag though, and I'm not sure if it's a big deal or not. I mentioned awhile back that when I removed the water pump, I noticed some bolts were only hand tight... All the bolts went in nicely, I put the pump on (with gasket and a little insurance Permatex around the sides of the pump where the water circulates in and out) and let it sit hand tight for an hour then torqued the bolts to 15 ft/lb. All went well, except for one bolt (of course) Pics below. Thankfully it's an "upper bolt", I'd assume the lower bolts near the inlet/outlet are the most important. Essentially, I can get that one bolt past hand tight, but only about one revolution past, then the bolts "pops" for lack of a better word and it loses grip. If I back out the bolt and hand tighten again, I can feel it grip the threads and I cannot pull the bolt out, but if I go past that point where it "pops", I can't pull it out but it doesn't tighten anymore. If I put my finger on the back side of the timing cover, I can't feel anything odd, or metal filings etc. (No bolt either, but I wouldn't have expected that anyway) I have a feeling this damage was done in the past, but I'm not sure what could have caused it. I'm guessing the advice is to tap a new hole for this bolt or getting a new timing cover? Or since it was like this before (although I was unaware of this behavior of this bolt) is it worth seeing if it's ok?

Chris

'84 F-150 XL 2WD Flareside, 302 w/ AOD transmission, Motorcraft 2150 feedback carb w/ CA Emissions, EEC-IV w/TFI, factory A/C, Tilt Column, Borgeson/Bluetop Steering, Speed Control, 308,000+ miles - Info about me and my truck - My project thread |

|

Administrator

|

I've always chased all holes when replacing a water pump, but that's mostly because I use Loctite PST on all the bolts and bee a a clean and primed surface.

You could throw a Helicoil in there. I'm sure the new stainless threads would hold the water pump on. I'm just not familiar with Windsors having bolts that are way out beyond the block like that I guess.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

| Edit this page |