Search Forum

It is time to talk hydraulic clutch systems.

123456

123456

Here are the three styles of clutch forks. As you can see, it is angled differently and has a cut out for bellhousing clearance for the t-19 fork. Last image shows the forks, zf top, t-19 middle, and t-18 bottom.

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

|

Now for my actual issue...

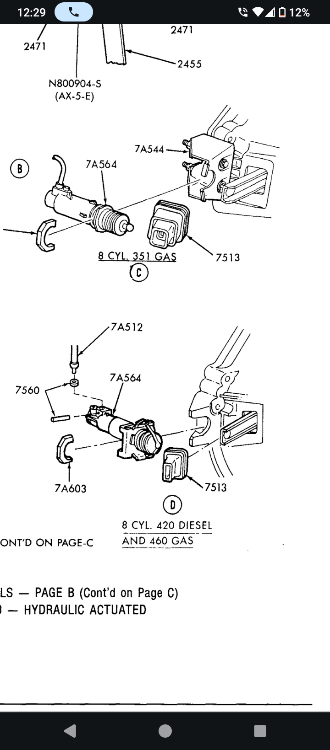

Put the clutch fork in, it fits, appears to be the right part. Now I need to figure out the hydraulics. The greedy style slave with the bleeder nipple has suddenly become available when ordered for a 5.8 t-18 transmission. No information on bore size.  However, looking at the diagrams  Obviously I have the lower 420/460 setup, not the 5.8 setup at the top. Now, if I run the greedy style slave, it does not use the metal clip? The part number is shown as the same slave in the Ford diagram, but there are several differences, and I do not have any plastic clip, and I am not sure where it could even go?

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

That's the one I use. (both T-19 & Zf5)

7A603 is just a plastic filler bushing. You use your existing metal clip, as shown for IDI & 460 Edit: I have that slave on my truck right now. If it weren't pouring I'd go outside and take a picture.....

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

In reply to this post by Haystack

The T-19 & T-18 use the SAME transmission 'butterfly" pattern, but T-18 is a Windsor block side bell while the T-19 only came behind IDI & 460's

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

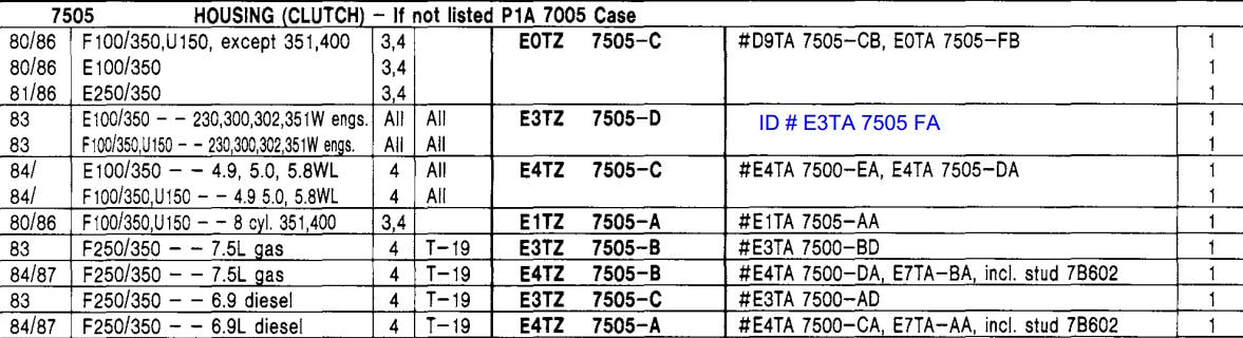

Here's the bellhousing page from the parts book.

You're looking at '84 on, as that's when hydraulic clutches took over from mechanical Z-bar design.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by ArdWrknTrk

No more hospital?

Knowing the slave is the same (or at least compatible l) between zf and t-19 bellhousing.... I may just order a pre bled setup for a newer truck, and just be done with it once and for all...

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

|

Nevermind, looks like all the pre bled ones are from 92 and newer and the master cylinder mount is different.

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

The mounting holes are diagonal, to help with firewall tearing, and the clutch safety mounts on the pushrod.

This doesn't preclude you from using one, if you're willing to drill the holes, and use the existing pedal block safety (not rewiring)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Haystack

I am ready to burn this truck to the ground.

3 months I've been messing with it on and off as I have had time. I have spent over $1k on parts, and still can't get anything to work. I am 100% sure it is a hydraulic issue, and I think there must still be air in the lines..I am at my breaking point. I ordered the nipple style slave cylinder, I bought a power bleeder, I reverse bled it, I bench bled it, I gravity bleed it. I'd bleed it in a bath full of brake fluid if I thought it would work. I am getting nowhere. I have taken the truck to 9 different shops, everyone one has either refused to work on it, or broken something that was already working. I have rebuilt the bushings in the pedal, I have replaced the arm on the end of the pedal shaft, I have even bought another transmission and swapped that in, just to make sure there wasn't something wrong with the other transmission. No matter what I do, I never get more then about half solid pedal and the pedal has never returned fully. Today, I spent 5 hours bench bleeding. I got a 5 gallon bucket, a giant c-clamp, submerged the line until no bubbles came out. I then connected it to the master cylinder and the slave. I bench bled it until my hands litterly started bleeding, and nothing is working. This isn't rocket science, I know that. But I am about ready to give up.

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

I wish I was there to help!

With my nipple bleeder slave I just run a clear hose up into the master reservoir and pump the fluid in a circle. Something is definitely going on if you can't get the over-center spring to bring the pedal back to the rubber stop with authority. It's extremely difficult to diagnose, and get your point across over the Internet, but I've got to say -like you- I'm about out of fresh ideas.  You've already gone way farther than I've ever had to. Usually you get it 60-65% and drive it, it fixes itself in just a mile or 2. The dealer service bay would only install a complete, pre bled system (slave, line & master) We used to joke that the factory assembled these in a swimming pool of brake fluid. Have you tried a sealed, complete unit yet? I'm sorry. 🙁 I'm usually on point with advice, but it seems you're doing EVERYTHING right and still can't get positive results.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

just reading in. does the pedal have a full return with the master cylinder disconnected?

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

It won't come back to center unless the master cylinder pushes it back, then the spring takes over.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

right. he is complaining that half back is all he is getting.

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

That only happens if the arm to the eye of the master pushrod is terribly sloppy.

But he said it's all new. So the yellow spring is out of place or missing. He can never bleed the clutch if the piston doesn't come back far enough to open the port to the reservoir. 💡

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

not sure how or why it would not be but that is something to verify

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

The over-center geometry is important.

But, again, he said he bench bled it. The pushrod can't be adjusted too long or the reservoir is isolated

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by mat in tn

The pedal has full travel, however, this was one of the fist things a shop broke.

I called around because I didn't want to pay $200 for a power bleeder, and I didn't have a nipple to bleed it. I called "matek" not realizing that was master muffler rebranded as "master auto tech". On the phone they said "yeah sure no problem, we bleed these all the time, the f series and rangers are notorious for this problem". Before I dropped it off, I fully assembled everything and got it as "good" as I could. At that point I had about 1/2 pedal, I could force it into gear with a clunk or grind. I dropped it off at 9am, right as they opened, the called me at 4:45 and said that the clutch was shot and needed replaced and that why it wasn't working. I replaced the clutch around 1500 miles and a week ago, because it was shot. When I got there, they already had all the doors locked and there was only my truck in the parking lot, sitting in the exact same place I left it. They let me in and explained that "as soon as they touched it, the pedal assembly popped and all the springs came out". Keep in mind, I drove it there, and they handed me the big yellow spring, a bunch of other random springs that didn't go to the truck, but didn't charge me. I walked out to the clutch, and the pedal was freely swinging, not hooked to anything. Pissed off, I drove it home without a clutch. Looking at it, they stripped the splines off the lever arm where it attached to the master cylinder, and then there were big giant pry bar marks where the yellow spring was. This was about the 6th shop I tried to take it to. I compressed the yellow spring in a vice and used zip ties to keep it compressed and it fell into place, then I cut the zip ties and it's been there since. Replacing that splines pedal arm took quite a few different junkyard runs, often I found one that were also stripped or mangled. I eventually found one that was solid, in almost new looking condition, minus the pivot arm and bushing. I took it home, ground off the welds to pop the pivot arm off, and installed a bolt. I very slightly enlarged the loop for the rod off the master cylinder to fit a brass bushing, it slides on an off with a very slight compression fit, but does not bind when the pedal travels. This was how I attempted to "fix" the bushings in a motel 6 parking lot when I was on the road in Oregon and the clutch first started giving me issues. I could not get bushings locally, and I was within walking distance (5ish miles) of a home depot. Looking over the hardware section, this seemed to be my best option, and it fits good without deflection. I have a washer on each side if the brass bushing which is slightly wider then the loop to the pushrod, and I used a lock but against the bolt to keep it from loosening up, and a second to hold the bushing. I could see them have bent the yellow spring mount when they pried it out. The pedal sort of snaps to the ground (without the pushrod attached) at about the half way point. It does still come up, but it seems to push down more then up. If this is the issue, I would gladly swap or replace the pedal assembly, but I still have never gotten a solid pedal from bleeding. I can see the pushrod fully compressing going into the master cylinder, and it is getting full travel with the pedal. If I adjust it any tighter, it bends the pushrod.

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

|

In reply to this post by mat in tn

The pedal does snap back to the floor about the half way point, however, if I manually pull up the pedal, it does go all the way up and stay there. If I crack the bleeder screw on the slave, it will gravity bleed out, draining the reservoir, so I believe that it is fully retracted in that position.

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

Re: It is time to talk hydraulic clutch systems.

|

Administrator

|

In reply to this post by Haystack

I used a 9mm shell casing epoxied over the stud with steel filled Devcon, and a snap ring in the extractor groove holding in a bronze 'top hat' Oilite bushing that I epoxied into the pushrod eye.

The shell lasts about 10 years depending on how much dust and grit is on your boots. To change it, just torch it off. 💡

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by ArdWrknTrk

The ford dealer rejected my truck after having it for a week. We have a "heavy duty truck center" where they work on dump trucks and the such (lots of f550 and up in the service bays).

I made an appointment, talked to the mechanic, he said they were really busy, but would get to it when they could. Called me a week later and said the "required parts are unavailable" and recommended another shop that does "good work". It ended up being an rv dealer, they gave me a weird look and said they don't work on stuff that old. The only pre bled system I have been able to source is for the 90-93 style trucks. I don't really want to redrill the firewall if I can help it, and I have like 3 complete replacement units at this point all new. The only thing that hasn't been replaced is the line.

1985 bull nose 460 cab and chassis bucket truck. T-19, hot fuel handling and more splices then an entire telephone infrastructure.

|

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |