Search Forum

1981 Ford F100 Revival (Parked for 12 years)

1 ...

34353637383940

... 53

1 ...

34353637383940

... 53

Yeah that was before. You are the only one with priority early access.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jonathan

It only took me about 5 hours to get the axel pivot bushing out. Good thing I picked up this picnic blanket from Costco. I should of stepped back and researched it more before going hog wild on it. Later I found out they have kits for ball joint kits that can probably press it out easier. The slide hammer for bearings was not working good because all the rubber absorbing the impacts. I also tried a bearing puller but there was nothing to push against so that didn't work. So I drilled holes in the rubber and cut out the middle. Which didn't help much because turned out it has a sleeve around it that also needed to be removed. Finally I had to remove the whole axel thing out from under the truck so I can get at it with a hammer and punch easier without holding a 5 pound drilling hammer over my face laying on my back. Trying to do that without damaging the arm was challenging. For the drinkers side I will be better prepared. Did I mention that I am an idiot? Oh well, live and learn. I am just an amateur that likes to fix his own stuff.

See pictures of kit from Harbor Freight and let me know your thoughts or better ideas. I really don't have room for a shop press right now.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

Thanks for the early access? Lol. It's still looks scary to me. You will be an expert on Bullnose restoration when done. This is really going from a revival to a restoration. Good work.

I put a new little tree in my truck this week.  . Didn't take photos. . Didn't take photos.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

Yeah when I get time I should start reading other threads to see if I can help with something I already learned. After I get it on the road I can slow down and breath easier.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

Now back to the bushing. I really hope there is some metal machinist on here or somebody that can help me understand tolerances for interference fit. I had to order so many different models of Moog bushings because they have so many matches for the truck. The K8300 I got one Made in Mexico and one Made in Turkey. The one from Turkey looks so much better quality and seems may fit okay but I can't find another one. I have ordered 6 more from Amazon already hoping to get another Made in Turkey with no luck! So I am not sure what to do. I called Moog and they said the one from Turkey is the newer one but I think they may be wrong because the copyright on the box was 2011 and the Mexico one was 2019.

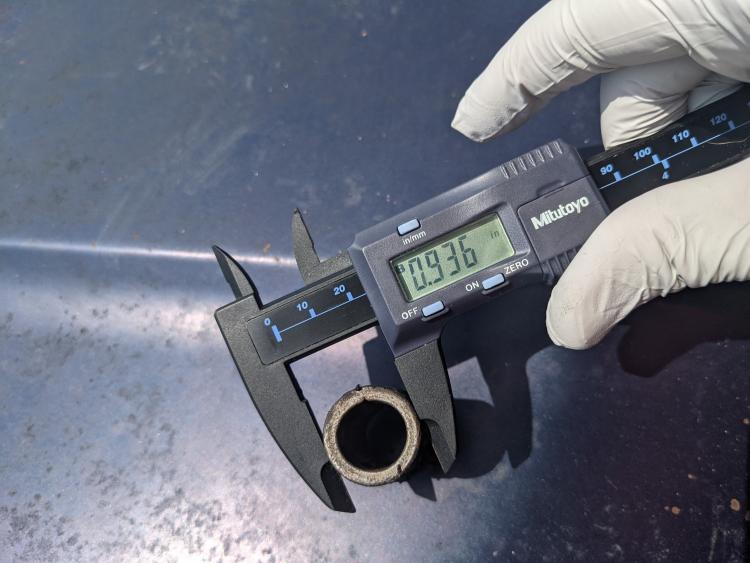

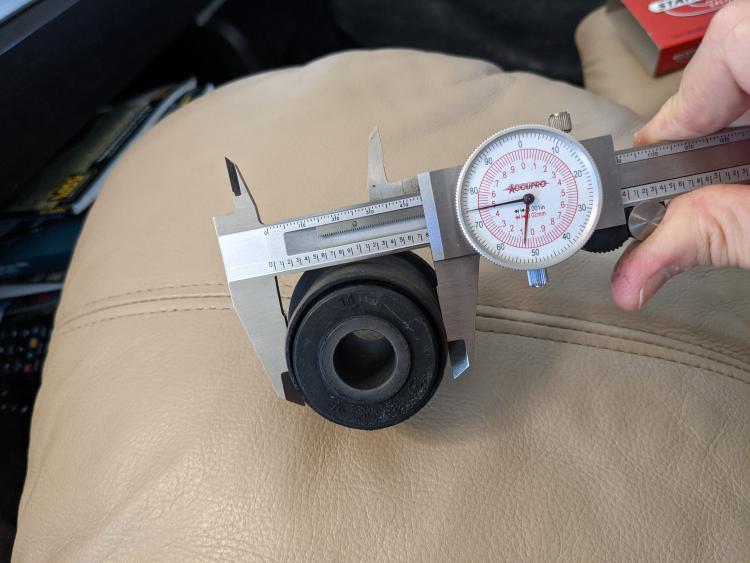

The other question is the interference fit. Is .025 inches or .6 millimeters too tight of a fit? The Mexico one is smaller at 44.6mm and the Turkey one is 45mm but both the same K8300. The two pack K8621 is 44.8mm. The internal diameter on the arm is 44.3mm or so. It is hard to get a good measurement. I still have more Moog models on the way. I really wish they would publish all the specs and not only a few. None of them say the outside diameter. I also wish there were not so many choices and hits when you search for this part.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Yes, this thread is EPIC! And you are learning a lot.

I'm not a machinist, but I do machine work. And .025" is way beyond an interference fit. More like .0025". But you aren't working with the types of parts that are typically thought to have interference fits. They are usually solid so there's no compression to speak of. But you have a tube that can compress, and there's rubber inside of it that'll give. So it isn't unusual for bushings to be that much larger than the component they are going into. And with that HF press, and a bit of lube, that bushing should go right in. I have the same kit and have done several of the bushings, and they have all gone in. But I use a small wire wheel to clean the inside of the radius arm and a round file to smooth any gouges.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Jonathan

Jonathan, come back - would love more updates and documentation on your truck.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

Administrator

|

In reply to this post by Gary Lewis

Agree with Gary, in that .025 is wayyyy beyond interference fit. But, that is metal to metal, not a rubber bushing to metal. Typically, depending on materials, .002" is a good press fit for metal to metal. Also, and just fyi, when working on tight tolerances measurements need to be taken with a micrometer, not a set of vernier calipers. There is also a procedure for properly using those telescopic bore gauges, so you might want to look into that. Great post, looking forward to how it all plays out for you.

John

"Blackie" - 1986 F150 4x4 - Mildly warmed over 351W HO - Original owner |

|

In reply to this post by rcarlisle

i put new stock height coils on my truck and it raised it at least two inches. If you have king pins make sure there is a shop that has tooling to bend axles for alignment. I would also replace leaf springs prior to alignment. If they are sagging then expect a couple inches to be raised in the back as well.

RedBull

1981 F100, 73' 351W, C6, 9" 3.00L |

|

I bet mine would raise that much as well.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

In reply to this post by Gary Lewis

Thank you for the feedback Gary. I was worried about the fit. I guess I will find out when I install the bushing how tight it is. Using your recommendation I will clean the inside of the bushing hole and use some lube. Should I use anti-seize or another type of lubricant?

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by rcarlisle

Thanks Randy, I have been making slow progress. It didn't feel update worthy so I will do more updates at once. My free time has been more limited also.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Machspeed

Thanks for your feedback and tips John. I hope to get better at machining type work and always looking for recommendations.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Jesse3877

I have king pins. Thank you for the tip. I just assumed that the alignment was limited, I didn't know you can bend axles. I will look into that. When I start to work on the rears I will probably replace the leaf springs. I live in NC and don't want to be associated with those strange looking Carolina squat trucks that look like they are about to take off.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

I guess there is someone in NC that can bend those axles - I've read an old street rodder magazine articlae about bending the old front beam axles. Not a job for the faint hearted or unexperienced. And requires a dang heavy press.

When I took the coilover helper shoncks off the back, my rear lowered to where I have maybe an inch higher rake in the back. But my springs are probably weak. The instant drop when I removed the coilovers while laying under the truck was a bit disconcerting. My wife thought I was crushed by truck. I did save those, "Just in case" Glad you are back. Hope to see more progress soon.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

In reply to this post by Jonathan

I think anti-seize would be my choice of lube.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by rcarlisle

I finally found a Made in Turkey bushing after calling around to local auto parts stores. I sent back all the failed attempts on getting one from Amazon.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

wow. just wow at your dedication.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

In reply to this post by Jonathan

I started to clean up the frame in just the wheel well area to get ready for paint. (A month long process) I also removed the old rubber bumper. The new rubber bumper I got from Lots of Mismatching Crap (LMC) is not tapped out with threads for some reason. So I will need to tap it before installing. It was held on by a T-40 head screw which was hard to identify because it was full of dirt and I couldn't get a good look at it.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

A little more slow progress in removing years of mostly surface rust. There is some mild pitting but the frame is very thick so has some metal to spare I think. The rubber isolators are all very bad looking like this one.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Bullnose Enthusiasts Forum

›

Projects

|

1 view|%1 views

| Edit this page |