Shop Crane With Engine Stand

|

Administrator

|

Some of you will remember my problems trying to move an engine from the engine stand to the shop crane, or vice versa. For those that don't, the legs hit each other and it is a HUGE pain to make the transfer.

Today I got the new Summit catalog and found the combo unit shown below. So before I go chop up my engine stand to fit on the shop crane's legs, please tell me why I shouldn't. Yes, I realize that it'll be much more awkward/bigger. But it may well be worth it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Looks like a good idea!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

In reply to this post by Gary Lewis

Clever!

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

|

Administrator

|

In reply to this post by Gary Lewis

Well since (a) my shop crane folds and (b) my antique Lakewood engine stand will fit between the legs with the flywheel end away from the crane, I can't see an advantage for me, your mileage may vary though.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

In reply to this post by Gary Lewis

Looking at their combo vs my engine stand it looks like I'd just have to make the "H" that theirs sits on and bolt my upright to it.

I can see that their "H" is adjustable width-wise to allow placing it at various places down the legs, which would somewhat be determined by how long the engine is as well as how far you have the boom out. And I see that the "C's" that fit down over the legs of the shop crane are canted to account for the angle of the legs. Plus, the rear "C's" have a pin on their skirts to hold them to the legs. What am I missing? What improvements do you see?   Gary, AKA "Gary fellow": Profile

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by 85lebaront2

Yeah, the legs of my crane are too close together. Neither of my engine stands will fit between them. And I designed the crane as well as the engine stand I built.

So, I could rebuild either the crane or the engine stand, neither of which would be fun, or build the new "H". I think that would be easier, and if I don't like it I'll go back to the existing base.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

Gary, the pins are so the engine stand portion can't tilt with the engine on it. BTW, one of the features I like on the Lakewood stand, the pivot for the engine is a hefty piece of pipe (stand is rated for 1500 lbs) and is infinitely adjustable with a hefty Allen head bolt to lock it. I grease the inner pipe when I have the stand empty so it can actually be rotated fairly easily even with a 460 on it.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Mine isn't rated as I designed and built it. But it is actually copied from a heavy duty stand a neighbor had which had metric-sized material. I used inch-sized material so upped everything to the next size and it became rather beefy.

It has grease fitting for the head also, which allows rotating even a 460 fairly easily - if you center the mass. But if you don't get it centered it can be a bear to rotate.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

The stand part the H where it rest on the crane are angled a little.

Now you pull the motor with the fly wheel away from the crane & stand so now you have to set the motor on something or floor and turn it around so you can bolt it to the stand. My crane also folds to get it out of the way. I have 2 may be 3, don't remember now, stands and IIRC only 1 is a 3 wheel the others are 4 wheel. 1 also has a pipe to get lavage for turning the motors because grabbing the motor does not always work for turning it. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

Dave - You have an excellent point. Usually the way I pull an engine is with two chains, and each chain goes from one head to the other. That lets me adjust the angle of the engine w/o using the load balancer, which adds too much space. But that means there's no chance of swiveling the engine once it is pulled.

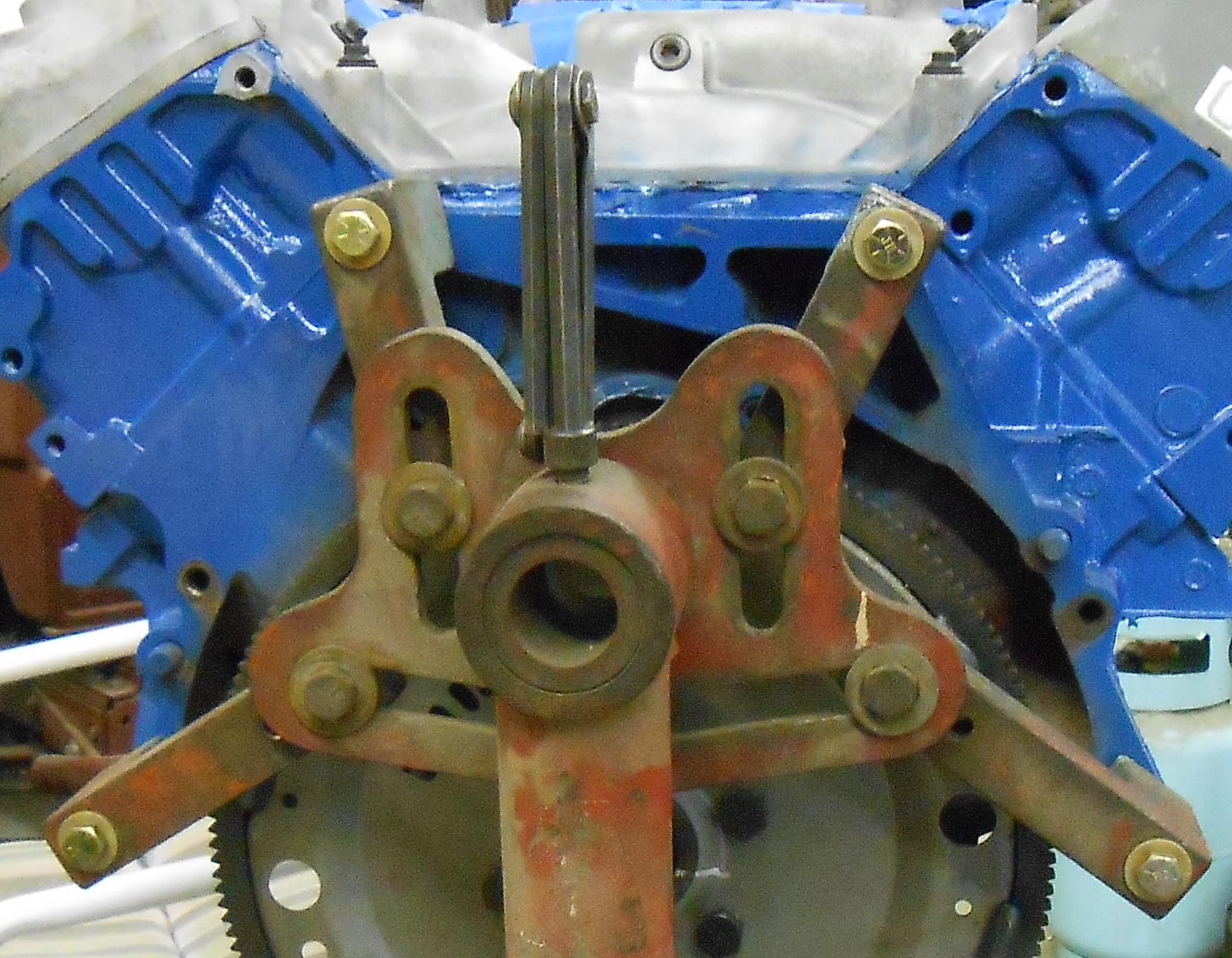

So, why not put the engine stand on the shop crane the other way 'round? Meaning point the flywheel toward the front of the shop crane. That way you don't have to set it down nor turn it around. Any problem with that? As for folding, both my shop crane and engine stand fold up fairly small. You can see that in this pic of the engine stand, but the crane folds up the same way, with the legs going over center and angling back a bit and the boom going almost straight down.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Shop Crane With Engine Stand

|

I'm glad to see I'm not the only one that has to stack washers on the mounting bolt to the block to get the correct length. I have bought the correct length several times it seems like but by the time I need them they have been used for something else.

Turning it around would work as long as the legs of the hoist aren't in the way building the engine where you would trip over them.

Bruce aka Moose--1978 F250 LWB Flareside, Dana 60's w/ 4:10's, 460, c6

|

|

Administrator

|

LOL! Yes, I had to use washers. This is a one-size-sorta-fits-all thing, and those never fit anything well.

As for length, you are right that the legs are going to be in the way. But that may be preferable to the pain of having to dream up ways to get the legs to miss each other. That's been a major issue every time I pulled an engine.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Shop Crane With Engine Stand

|

In reply to this post by Gary Lewis

I haven't used a shop crane much (I've shown my redneck engine hoist before). But would that mean bringing the crane in from the rear of the truck? Unless I'm not getting what you are asking that seems like it would require a pretty big shop crane! (my redneck engine hoist)

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

Bob - No, the crane comes in from the front. Then the engine stand is placed on the legs and the engine lowered down and bolted to the stand. Then the boom can be retracted and lowered so it is out of the way.

The advantage is that there's no problem with the legs of the crane hitting the stand. Just lower the engine, slide the stand up to it, and bolt them together. The disadvantage is that the overall combo will be quite long.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Nothing Special

Now that's a true "shade tree mechanic"!

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: Shop Crane With Engine Stand

|

Did you think about getting a swivel hook on the end of the hoist chain?

Bruce aka Moose--1978 F250 LWB Flareside, Dana 60's w/ 4:10's, 460, c6

|

|

Administrator

|

I thought about a swivel hook, but then I decided there wasn't any reason not to reverse the engine stand. And I like having the engine fairly well constrained so it won't swing and hit the vehicle.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Shop Crane With Engine Stand

|

In reply to this post by Gary Lewis

Ya know, if you read ALL the words it makes a lot more sense! I had read "why not put the engine on the shop crane the other way 'round?" I couldn't make that work out for me. So to give you my answer to the question you ACTUALLY asked... I haven't use an engine stand any more than I've used a shop crane. But it seems to me that I'd want to be working on the front of the engine more often than the back, and the crane would be more in the way like that. Of course it would make it easier to get at the back of the engine for attaching it or removing it from the stand. And it would be a wash for working on the sides, top or bottom, which are more common locations to work than the front. So it probably wouldn't be much worse, and the convenience of being able to go directly from the truck to the hoist might make it a better option overall.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

LOL! That explains the question.

I'll see if I can take some measurements today, but I don't think there will be an issue with getting to the front of the engine. I say that because I'm sure the boom will be extended to at least the 2nd if not the 3rd notch, which puts the engine, and engine stand, out quite a ways. So when the engine is on the stand the boom can be retracted and dropped almost straight down, giving a lot of room. But that also means the whole contraption will be that much longer in the shop as the legs can't be pulled in, much less folded, while the engine is sitting on them. So it isn't a good solution for long-term storage, but may not be too bad for R&R work.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I have one of these stand combos. And yes swivel the engine 180 degrees and mount to the stand part. Works fine. It also folds up when not being used...

1986 F-150 Flareside 4x4, 351, 4-v, ZF5 speed. AC, Cruise, Tilt, Slider, Digital clock, Radio, Lariat seat, Pwr doors/locks

|

| Edit this page |