New 3-D Printer

|

Not sure whether this should go here, in the 'Garage/Shop & Tools' sub-forum, or just as a random post in the general forum...but, I finally got a 3-D printer! I was supposed to have gotten it back in March as an anniversary present, but then Covid arrived and suddenly we had bigger things to worry about.

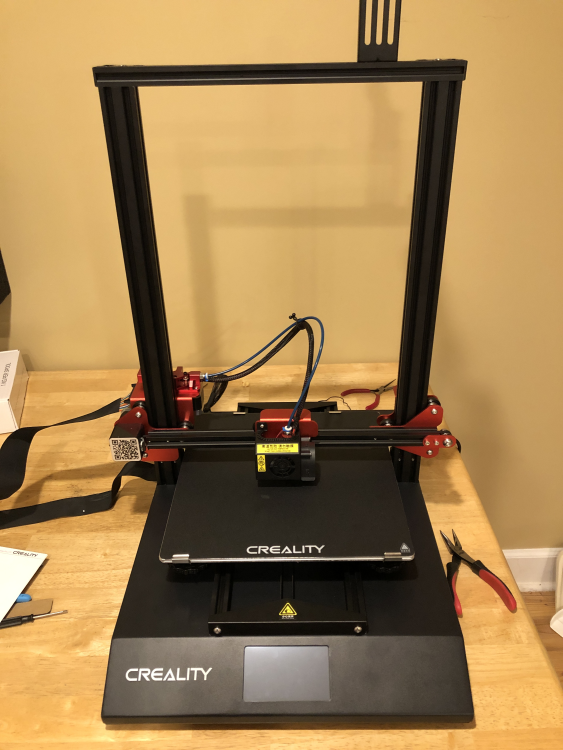

Now we're tired of worrying about that stuff, so we decided to spring for a Creality CR-10S Pro V2 (whew!) printer. Our son Dominic has expressed interest in 3-D printing ever since he joined the HS robotics team, and I have some ideas of my own for it - one of which is a speaker grille protector for those of us with mostly-intact dashboard speaker grilles who would like to keep them. I've also got an idea for an automated temperature control system for a Big Green Egg, but that's not really relevant to this forum.  The Post Orfice delivered it yesterday afternoon, and by early evening Dominic and I had gotten it assembled:  And by 11pm last night we had printed our first viable Calibration Cat:  Now it's printing a test object to see what temperature is optimal for the spool of filament that I'm using. After that...who knows? I'm certainly open to suggestions. |

|

Administrator

|

Nyan!

That's really cool Matthew. How large is the stage on that model? Or I should ask what's the print envelope?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

The base is 300mm x 300mm, and it can print up to 400mm tall. I can't imagine needing more than that, at least not in the short term. |

|

Administrator

|

That's some pretty amazing height!

What kinds of filament can you use? PLA, ABS, Nylon?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Dorsai

Love it, Matthew! I'm anxious to see what you do with it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by ArdWrknTrk

PLA and ABS, yes. Also some other types I’m not familiar with, like TPU and composite filament. Nylon is a no-go without modifying the printer first, apparently it needs a higher temperature than the printer is really good for. All of the above could be wrong, I am very new to this... |

|

Administrator

|

Yes, nylon is high temp.

But with the array of heads out there it may be possible, if the power demands are able to be met. I try to learn about these things even though I'll never have one. Try following CNC kitchen on YouTube. Very relatable and good at showing, as well as talking.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Dorsai

Very nice!

I have the Ender 3 Pro and it's amazing what you will find to print. Mines been working tonight printing a spacer for the Odyssey battery so the factory hold down bracket will fit it  Excited to see what you print with yours. Speaking of the speaker grill, for those that are too far gone I like the idea of a recessed tray for coins, sunglasses, etc.

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

|

In reply to this post by Dorsai

PETG is a great material to learn and utilize. It gives an alternative to PLA that doesn't soften in the summer heat.

1985 F-150 - RCLB, 2WD, 5.0(EFI), AOD, 8.8 rear with 3.55s.

Farm truck that had been sitting for many years. Lets see what I can make of it. :) |

|

Administrator

|

In reply to this post by Dorsai

I've just been watching ToT, as he uploaded that he got a Prusa.

https://youtu.be/xTn74yaqXeo Was totally thinking of you and the things you and Dominick(?) will make!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Random update here, for no particular reason. I mentioned in my other project thread that I’m helping my brother with his project, by building an Arduino-based transmission controller. You can’t have circuit boards just laying around in a vehicle, you need some kind of a case for them:

I’ve been printing various small items from the Internet since I got the printer, but this case is the first thing I’ve designed from scratch. It’s just a test item - that’s only the relay board - but it’s enough to prove the concept. The only problem is that the standoffs are larger in diameter than they need to be, but that’s easy to fix. Next step is to modify the design to have a fitted lid that can be screwed in place. I’m worried that warping might be an issue, but that’s why we test. |

|

Administrator

|

Cool! That's a really nice design, Matthew.

But on the standoffs, are you sure you want to make them smaller? If you get too small they could crack. And, assuming the Arduino has the same mounting points, what about a stud in the standoffs that would pass through the relay board and the Arduino, and then through the lid? And is the pattern on the lip there on purpose, like to hold a gasket? Will the lid have the opposite pattern? Just fyi, the project box I bought to put the fuel level sender relay in has a groove in the base and a ridge in the lid, and came with a piece of "o-ring" material that is cut to length and stuffed in the groove.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

The reason I want to make the standoffs smaller is that, as they are, one of the solder joins from the board is sitting on the surface of the standoff causing the board to want to sit at a slight angle. I don't think it's a huge problem, but it's still creating some stress from the screw pressing down that doesn't need to be there. Maybe a smaller standoff will crack (but I think not - the 'fill' inside the standoff is only 50%, so there should be some give), but again...testing.  That's a good idea for a standoff on the studs...unfortunately, the holes don't line up. I had considered a double-stack design with the top board rotated 90 degrees to the bottom and sitting on taller standoffs, but that doesn't work either - the holes on the top board won't clear the bottom. So it's going to be a side-by side layout. The pattern you see on the lip is just an artifact of the printing process, not intentional. My current thinking for the lid is to raise a lip vertically from the lower portion of the box on the inside perimeter, and then make a lid that is itself an (inverted) small box with a similar lip dropping vertically from the outside perimeter. If tolerances and warping aren't problematic the lid should come down over the base, like the top of a hatbox. As for gasketing, I did consider that...but the current thinking is that this will be mounted on the firewall in the cabin, so weatherproofing won't be an issue. Besides, the USB port on the Arduino will be exposed through the case to allow for tuning and troubleshooting, so it would be difficult to seal anyway. |

|

Administrator

|

You are way ahead of me. And I didn't know that you have control of the fill inside solids, but that makes sense. And it would give cushion so there's less chance of cracking. Plus, my CAD program allows you to print a thread in the standoffs, so there shouldn't be much pressure at all if you did that.

On the lid/box interface, that sounds like it should work well. And it should help prevent warping, or at least straighten things up if there is some warping.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I'm using SolidWorks (one of the perks of being a mentor for the HS robotics team - free SolidWorks, a $3,995 value) for CAD, so I can definitely design a thread into the standoffs. Given the small size of the screws in question (#4-40), I'm not sure the printer can print meaningful threads. Right now I'm using four random mismatched screws from my jar of loose screws, so I just let them tap themselves into the holes. I may put threads in there next time, just to see if the printer can do it. |

|

Administrator

|

Yep, that's a huge perk!

On the screw threads, 4-40 threads are tiny so I see the concern. But can you do other threads? Screwerk has self-tapping screws for plastic, and they have a large pitch.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Dorsai

Looking great!

Are you using Cura? The granularity it has is impressive - infill, line count/thickness, first layer settings, etc I haven't tried any other slicers. Do you have the magnetic or glass bed? Haven't kept up with the various v2 changes but my Ender 3 Pro came with a magnetic and the glass bed was hands down the best upgrade. Used to have lifting issues every now and then with the magnetic bed but I've gone through 3 rolls of PLA in the past 2 weeks on glass and no adhesion issues at all. Still trying to get the hang of ABS... I've found that using a tap works really well. I didn't have much luck with printing the threads and those weren't even as small as you were doing.

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

Coincidentally, I upgraded to Cura this morning. I had been using the Creality Slicer that came with the printer, but that's just a reskin of an older version of Cura. Straight Cura seems to expose a lot more options, so I'll be sticking with that going forward. As for the bed, I'm not entirely clear on what I have - it's the default bed that comes with the printer. You can see a good view of it at the top of this thread, it's black, slightly rough, and everything REALLY sticks to it. My biggest issue is getting things off of it without damaging the item or the bed. Three rolls seems like a lot of material, at least to me as a newbie. What do you do with your printer that you go through so much? |

| Edit this page |