Electric issues

|

I was referring to the manufacturer's finances. as in dimes multiplied by thousands means more to the bean counters then to the man diagnosing his truck in the cold rain halfway between anywhere and nowhere.

|

|

In reply to this post by mat in tn

I misread that, my apologizes! You are extremely helpful and I have appreciated your valuable helping me through this. Feeling like I’m close to getting this thing running just need to figure out why it’s still not starting could it be that the non clicking relay has something to do with it. Also gonna check the fuel line at injector rail etc, and check fuel there.

Thx

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

In reply to this post by Gary Lewis

Do you know what/where the part number would be for the fuel injector wiring harness. mine is in bad shape and needs replacement having a hard time locating one. Are these still available if not what’s the solution

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

Administrator

|

Check out our page at Documentation/Electrical/Wiring Harnesses. It happens to have the harness, which I think is 12A581 for the base number. But there are several of them so you'll have to chose which one.

However, I don't think they are still available. But you may find that I'm wrong.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by El Chapo

Oops, I forgot the solution bit. If your connectors are good you might be able to splice wire in to fix the harness. If not you might be able to make your own as most of Ford's connectors are available individually - see the page at Documentation/Electrical/Connectors. Or, maybe Painless makes one?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Thank you much appreciated

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

I tried to find a new harness about 3 years ago (a full one) as my wiring was very brittle.

There were no new Ford harnesses and the only kits were generic and used their own (non ford) connectors so would have been even more complicated. I ended up pulling harness out of 2 other trucks I found then, opening up the harnesses (including my original) and cherry picking the best of the 3 wires for each circuit.  I was able to free the wires from most of the plastic multi-pin connectors using an eye-glass repair screw driver to depress the little tab inside the plastic connector that holds the metal connector (crimped on the wire) in place. The new, better wire then just snaps back into the plastic connector. The metal connectors on the wires are available, but I only found them in combination multi packs, which isn't an easy way to get what you want. I opted not to use new wires because I needed more than 7 colors to keep from confusing myself about what wire was which circuit. There are some connectors, especially outside the firewall (i think the ignition circuits) that are molded so the wires cannot be detached. I used new non-ford waterproof connectors to replace those.

1984 F250 4x4 351W ZF5-42

|

Wow that’s an impressive project you took on there, Thanks for sharing I’m starting with the fuel injector harness, since I can find a new one. Wow that’s an impressive project you took on there, Thanks for sharing I’m starting with the fuel injector harness, since I can find a new one.

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

I feel your pain.

I'm sure you'll have no problem once you get rolling

1984 F250 4x4 351W ZF5-42

|

|

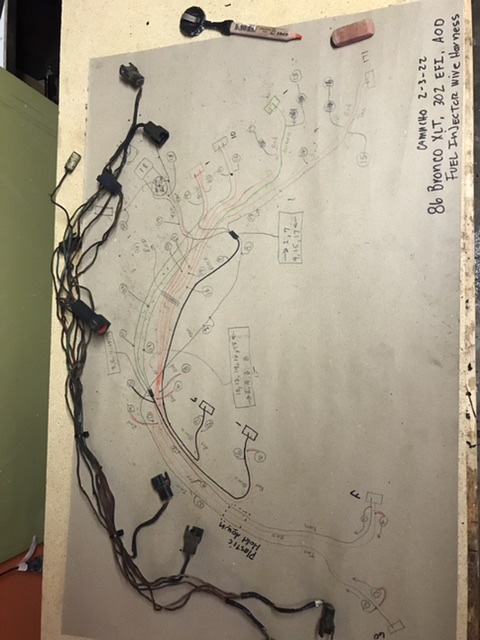

Here’s what I have so far

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

excellent way to do it! one step at a time and you will be done soon enough

|

|

Administrator

|

In reply to this post by El Chapo

I like that approach.

By the way, I'm doing something similar and I'm using velcro cable wraps to hold the wires together as I create bundles. They let me open things back up to add a wire when I discover that I missed one, but keep things organized. You can see them here:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Yup I like that, good job. Thx for the feedback and comments guy’s. I guess I’ll need a noid light once I put everything back together just to make sure it’s all in order. Maybe local parts store rents/loans them out?

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

In reply to this post by mat in tn

Morning… can I get a recommendation on the type of wire I should be using for the harness. All I know I think it’s 18 gage?

Should it automotive grade to withstand high temperatures, etc?

Thx

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

|

Administrator

|

Yes, something that says "automotive" should be good. But I'm sure there's a rating that's on the jacket of most wires that is best, although I don't know what it would be.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Great also what kind of electrical tape and wrap is best

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

That's an opinionated question. So I'll share my opinion.  I'm personally a huge fan of "loom harness tape". It's only slightly more expensive than electrical tape - single rolls can be $5-6 but you can get 5-packs for $10-12 if you buy it that way (like https://www.amazon.com/gp/product/B07RHM81PV). I've had the best luck with Tesa so far but tbh every brand I've tried has seemed pretty much the same. This stuff is MUCH more abrasion resistant than electrical tape. All tapes can dry out and crack, but this seems to last longer IMO (time will tell, I've never had it on something for decades). And it's much more compact and easier to get a nice appearance than plastic loom tubes. One suggestion if you're going to try it. Don't try it to apply it the same way as electrical tape or you'll get frustrated. With electrical tape you usually want to "stretch" the tape a bit as you apply it, so usually you pull out some length of it and pull it firmly as you wrap it. You sort of apply this the same way but it doesn't stretch, so don't pull out a length of it. Just keep the roll very close to your loom as you wrap it around.

--

1981 F-250 Custom. 6.6L V8, 4 barrel Holley carb, ARA aftermarket A/C. |

|

Administrator

|

I have been going back to what my dad used years ago, cloth friction tape. It seems to be what a lot of the harnesses I have worked on used originally. If I use the vinyl electrical tape, I will put a couple of passes of the friction tape at the ends as it seems to help keep it in place when I finish the run.

I have a bunch of the tie wraps with release tabs I use for working on a harness as, like the Velcro, I can loosen them to add a wire I missed. A few things I have learned in rewiring several vehicles. First, when laying out a harness run, it is highly advisable to have a pattern to lay it on, both corners and up and down portions because once taped up, it can be nearly impossible to get it to fit correctly. Second, any place it runs where it needs to be able to move, whether bend or twist (power wiring into doors) the factory wiring is usually just a loose bundle secured at one or both ends allowing the wires freedom of movement. Wiring to and from the engine, needs to allow for engine movement, you would be amazed how far a large torquey engine can move against what can seem like nearly ridged mounts.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

In reply to this post by taskswap

I'd thought of going with friction tape, but just ordered that loom tape. Thanks!

However, I agree with Bill that I don't want things nailed down so tightly that I can't shape it as needed. So my plan is to run the loom tape around a run of wires with spaces between the tape, and then cover that with split-loom. And, I'll tape the ends of the split-loom so it doesn't move the the wires inside can flex a bit.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

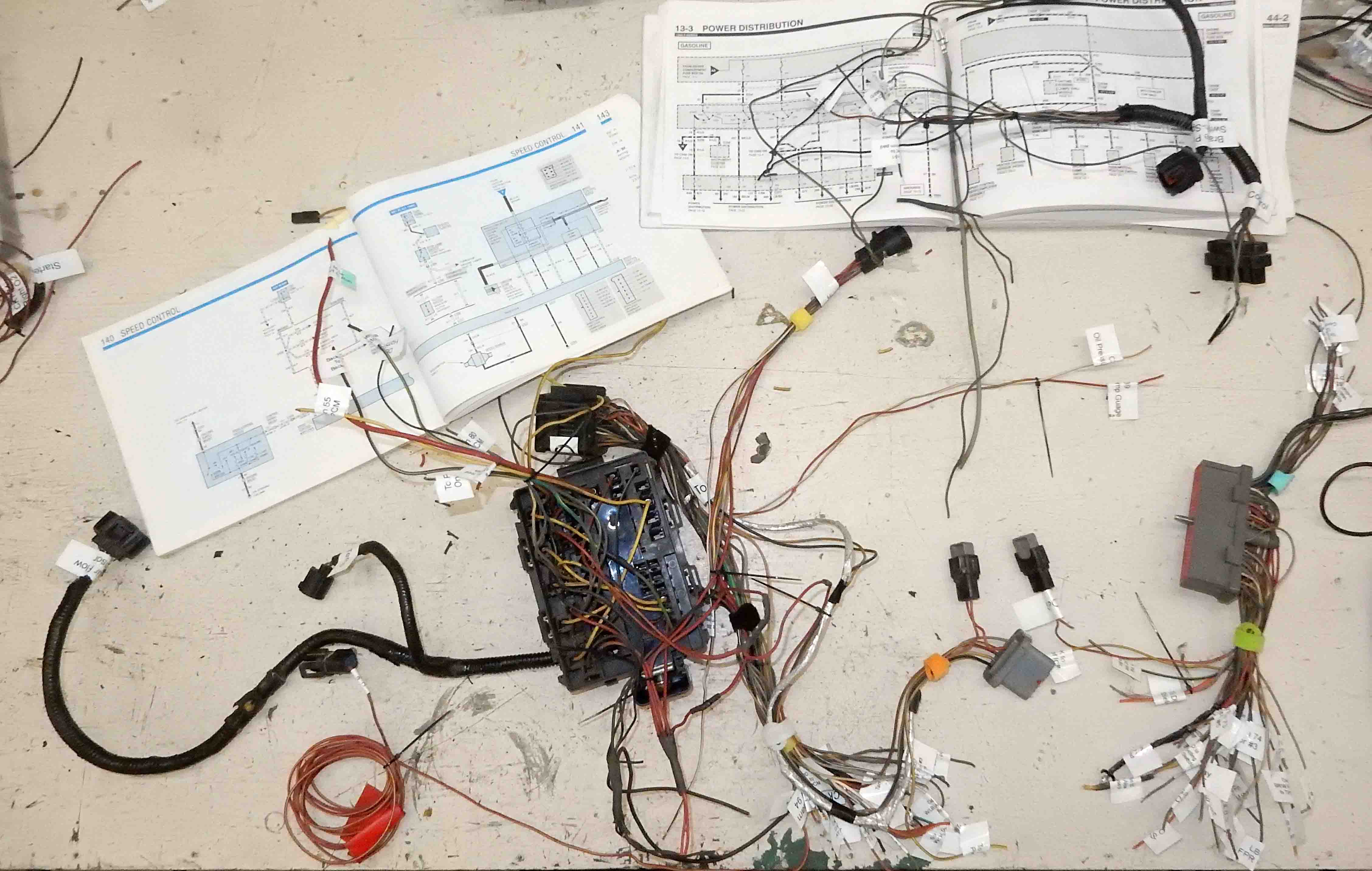

Took me a minute but feel I’ve made progress, tested for continuity and all checks out. Obviously haven’t done my final wrap yet I will use my fuel rail when I do that for a guide making sure it’s shaped much like the original. Not perfect by no means just hopefully it all comes together in the end and of course that it was successful!

Btw: got the fuel pumps to turn on at ignition. Had the manifold professionally cleaned and installed new fuel pressure regulator the Throttle body control sensor seemed fine upon inspection so taking my chances there.

The new Amazon (50$) injector set didn’t exactly match the originals as the pins/leads were shorter and felt like it wasn’t making the best of connection, will test and refurbish the originals. More fun with that I’m sure.

86 Bronco XLT “La Bronkita” Tow/light pkg. 302/EFI, BW1345

|

| Edit this page |