Don't Use Grease On Body Bushings!

Don't Use Grease On Body Bushings!

|

Administrator

|

Just an FYI, apparently you aren't supposed to use the gooey grease they send with the polyurethane suspension bushings on polyurethane body bushings. I did. What a mess!

So, what happens if you do use the grease? You can tighten the body mounts down seemingly forever. And the bushings either slip over to the side and try to get out from under the cab or ooze around the mount on all sides. And, what do you do to correct this? Use lots of isopropyl alcohol. LOTS. And then Dawn detergent. Then more isopropyl alcohol. And then a hot shower to try to get it off of you. I'm not sure that I got it all, but I got most of it and will have to use something stronger to get the last of it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Rubber or poly bushings? Something sounds off. Poly bushings are rather hard and shouldnt compress much. I always use the clearish/whitish grease that usually comes with poly bushings to prevent squeaks. I didnt use the grease on my chevelle and they squeaked so bad. Was very annoying.

1988 F250 Supercab Longbed 7.3 IDI, C6, 1356, GEARVENDORS, 4.10 Sterling with autolocker

1986 F150 302, C6, 9" 2.75, Wood Flatbed |

|

In reply to this post by Gary Lewis

Reminds me of the time I put Murray's Superior Pomade in my hair. I was going to a '50's themed party so I slicked my hair back with that stuff. When I got home I found out that shampoo wouldn't touch it. Then I found out that Dawn wouldn't get it out either. Finally, after spending a few minutes on google, it took two applications of vegetable oil to break down the pomade, and then Dawn to get the oil out.

-Chad

1986 F150 currently undergoing body reassignment |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

In reply to this post by Gary Lewis

Works great on Chrysler suspension bushings and on my homemade bumper mount repair.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

In reply to this post by Operator1

Ray - They are polyurethane. And they didn't really compress. They just moved out of the way for the most part.

I checked with Energy Suspensions and their page for body bushings gives these steps: 1. Remove bolts of mounts from inside of cab. Remove bolts from one side at a time, leave other side loose.

|

|

In reply to this post by 85lebaront2

Pomade?

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

LOL!!!!!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Gary Lewis

-Chad

1986 F150 currently undergoing body reassignment |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

Hmmmm, that might work. But I'm tempted to run the bushing through the dishwasher. Yes, I have a dishwasher in the shop. Surely the temp wouldn't hurt the bushings if I didn't put it on the HD Pan cycle?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I would scrub it with gasoline before I went to all that trouble. Surely it wouldn't hurt poly.

-Chad

1986 F150 currently undergoing body reassignment |

|

Banned User

|

Gasoline does NOT dissolve silicone grease - that's why the grease should never be used on the fuel system; it can clog jets & injectors.

But I do recommend using grease on the body mounts, though it's not required on Energy black because of the self-lubricating effect of the graphite in that poly (and no other color or brand). It only takes a little, though - just a thin film everywhere it touches metal. If your bushings stretched enough to slide out of place, it sounds like you severely over-torqued the bolts. Poly is harder than vulcanized rubber, so I'd expect it to break the bolts. I'd also expect it to bottom-out the factory steel sleeves, or the steel reinforcements inside the bushings. |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

No, I didn't over-torque the bolts. I got to 20 lb-ft when the spec is 30 if I remember correctly, and by then the bushings were doing their best to escape.

However, I did use a lot of the grease, so maybe that's the issue. But it doesn't come off completely with the cleaners I've used, so I'm sure there's still a film of it left on the metal, if not the bushings. We will find out how it goes when I get to torque the bolts down again, hopefully mid-week.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

I'd use lots of absorbent paper towels (Brawny), and then (if necessary) throw them in a tub of hot water & Dawn with PurplePower/SimpleGreen for a few hours. If you need them really-dry of grease, maybe try something like this: https://www.amazon.com/dp/B004UQQVJY https://www.amazon.com/dp/B00397L0DC |

|

In reply to this post by Gary Lewis

20-30 ft lbs is not near enough force to squish a poly bushing, even if it has grease on it. The bolt going through the center should keep it in place. I guess I am missing something. Ive always used a thin layer of grease on poly bushings and never had an issue. Maybe the cab mount flange and the flange on the frame arent in parallel planes, causing the pucks to try to squeeze out? I dunno.

1988 F250 Supercab Longbed 7.3 IDI, C6, 1356, GEARVENDORS, 4.10 Sterling with autolocker

1986 F150 302, C6, 9" 2.75, Wood Flatbed |

Re: Don't Use Grease On Body Bushings!

|

In reply to this post by Gary Lewis

Lacquer thinner will removed the silicon.

Pete's Ponies

Mustang RUSToration & Performance 1982 F100 Flareside 1983 Bronco |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

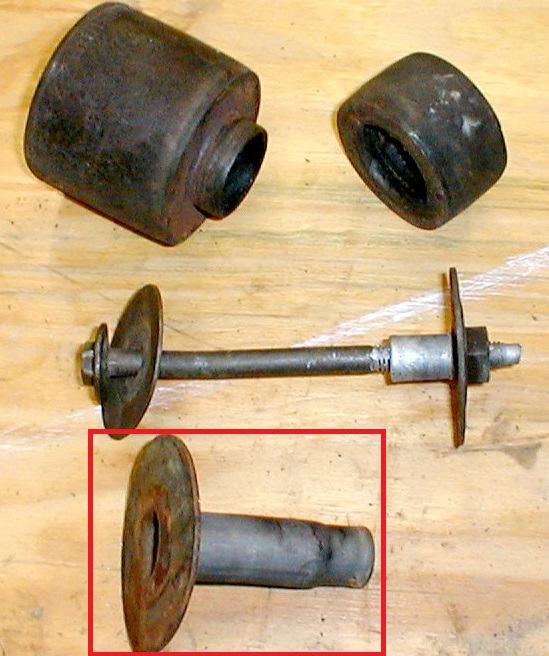

Steve - I'll bet that either of those would work. And if what I've done/will do doesn't get them clean enough then I'll get some of the prep. Thanks.

Ray - It isn't so much that it squishes the bushing vertically, but that the top or bottom of the bushing moves laterally so much that the angle that creates parallelograms the bushing. The worst was at the back of the cab where the bushing must be ~4" tall. While the bottom of it is captured in the mount the top is free to slide laterally up against the bolt and then try to ooze around the bolt. That caused a situation where I could just keep tightening the bolt w/o the torque coming up very much, and when I looked I could see the bushings at an angle. In front the bushings aren't nearly as tall, but the bottom bushing was trying to come out from between the cab and the bottom nut/keeper. In fact, it moved so far that there are rings in the bushing where the edge of the keeper dug into the bushing. I'll take a pic and post it later. Pete - I might try brake cleaner, in small amounts, to see if it'll cut the last of the grease that's on there. That's easier than lacquer thinner as that's in a 5 gallon can. But I can do that if needed. However, I don't want to damage the bushings either.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

Hmmmm, maybe that's what I'm doing wrong! I'll check, but I don't remember these:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I knew something wasnt right Gary.

1988 F250 Supercab Longbed 7.3 IDI, C6, 1356, GEARVENDORS, 4.10 Sterling with autolocker

1986 F150 302, C6, 9" 2.75, Wood Flatbed |

Re: Don't Use Grease On Body Bushings!

|

Administrator

|

Well, they say confession is good for the soul, so here 'tis: I did forget the inner piece on the rear. And that's going to make a big difference in how that tightens down as those bushings will be captive, meaning they can't go anywhere.

But, that's not the case in the front. I've checked and I have all of the right pieces there and from the pic below you can see that the bushing slid to the side. These are the lower bushings for the front cab mounts, and what was happening was that the bottoms of the bushings were slipping to the side due to the grease and the top was going the other way. Anyway, when things go together for good I'll have the inner piece in the rear, properly powder coated and with plenty of anti-seize. But, no more silicon grease!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |