Search Forum

460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

1 ...

678910111213

1 ...

678910111213

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

You can't fix stupid....

It was painful to watch the 15 seconds I did. He has the cam gear off one tooth.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Lol. Yes I don't understand how he got the gears on and didn't realize. Basically no point installing that set as it was still retarded like the original set.

All i'm planning to do is get the cam and crank lined up straight up (which won't be the case at TDC in the old set). I will rotate the crank back as needed to get them to line up, then install the new timing gears.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

No, that's a straight up set.

It's double roller with a single keyway. (not Hy-Vo, no bonded nylon..) If it had multiple keyways you could install it advanced or retarded (there are usually a mark next to each of the keyways, ∆ is O IIRC) He needed to pull it back off and move the cam gear over one tooth on the chain. He would have been fine. (IDK what eventually happens in the video)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Wouldn’t it be easier to bring the cam where it needed to be and then move the crank gear? I have always done that even on DOHC as the crank is easier to move. I’ve always worried about valve train spring tensions and so forth making cam gear movement erratic.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

It doesn't work that way.

With DOHC you can usually pin the phasers or gears themselves. In a pushrod V-8 you bring it to where TDC #1 has both valves closed. The cam and crank are keyed. You just slip both sprockets on together. But that guy had the cam sprocket off by one link...

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

This post was updated on .

I was saying with the chain taken off, the link between cam and crank is absent, so it should be possible to make small adjustments in either cam or crank or both to ensure everything is at TDC and then install the chain back on. It’s hard to mess that up.

Oh I did peek in on the cam sprocket, i may be wrong but I don’t think I saw any fuel pump eccentric.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

And yet.... here we are. 🙄 The guy needs to shift the cam gear one tooth in the chain! The keyways point directly at each other. If he couldn't get the sprockets started, he should have just slipped the cam gear in the chain and tried again. Instead, he managed to get it all the way on, but with the cam retarded one whole tooth.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Ok I think I get what you are saying about his mistake, finally

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

|

While laying low until more supplies arrive, I figured I would look at factory manual procedure for intake

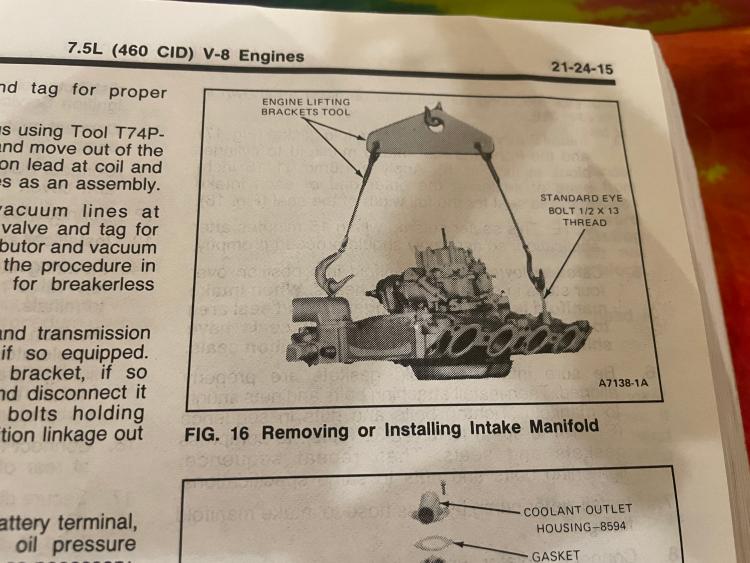

Intake gasket - 9D440 or 9C484 Clean mating surfaces using spot remover - B7A-19521-A (not sure what the equivalent is) Rubber sealer - D6AZ-19562-B (maps exactly to ultra black in the Permatex chart) Factory manual wants gasket maker only to be applied at the block mating surfaces on either side of the gaskets at the front and rear ends. No mention of use around the coolant ports, but I think i'll use it for insurance as there is definitely noticeable pitting on the manifold side. My favorite recommendation from the manual is the handling procedure where they want to use a jig with a couple of eyebolts

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

This post was updated on .

The only problem with a shop crane/engine hoist is that it lowers in an arc, and not straight down.

With a pan you only really have to seal the lifter valley. The manifold itself doesn't matter at the china walls, only at the ports. You also realize that their chemical recommendation reflects only wat was widely* available when it was written. I know that when "TRS" came out in GM dealers, it was immediately viewed a a problem solver by all mechanics, across the industry.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

This post was updated on .

Yes. This lifting method would work well with the stud approach previously discussed wherein the vertical descent would be controlled. Anyways, I think with 2 of us, I don't believe we would need it. If we use it, it would be to maybe do some last minute repositioning, etc.

I think the method is certainly great to remove a cast iron manifold in-situ. I would not even attempt to install cast iron reaching over the fenders  I was also thinking that the oil seal would be only below the pan. The valley pan metal "gasket" appears to have a crush design where it is protruding on both the head/intake side. Once torqued down it should flatten and form a good seal, minus areas with pits where a gasket would seal. Just hope I get good vacuum. I have inherited in the past a couple of intake jobs where the base vacuum was poor. Good point on recommendations being outdated.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

Yes, crushing the little bead around each port is key.

But, like only using graphite grease to seal the exhaust manifolds, it wasn't great, with factory fresh parts... I understand heat transfer. 💡 I also understand why these engines had such a bad reputation for leaks and cracked manifolds, even back in the day. Retortuing procedures, after X heat cycles are pretty critical.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Intake is still coming along, waiting on bolts but I decided to use the one of the plugs to maybe add a coolant bleeder or maybe a water temp gauge. I have the worst luck with internal hex head plugs. I always strip them. Had to use a 5/8-18 tap (needed for 3/8 MIP) with a special 37/64 drill bit ! Good luck finding that at the local hardware store. One of the times I don’t miss Amazon.

I will be using PST going forward on all these fittings!! Thanks Jim!

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

You do realize that 5/8 tap is a straight and the NPT tap is tapered? So if you run the straight tap all the way through you'll take out the taper and the pipe fittings won't seal very well.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Gary Lewis

Dang, well I need to stick to pipe fittings here with sealant.

For some reason I thought the taper comes on the fitting itself and not the thread, but a lesson learnt. I did try a plug, and it does bottom out as expected after going 4-5 threads so maybe I didn't screw up too bad. Got lucky.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

|

This post was updated on .

In reply to this post by Gary Lewis

Also I've realized why i got lucky. 3/8-18 NPT tap's diameter is larger than 5/8-18, now it makes sense why my tap didn't need to do much at all.

Most of the clean-up was done by the 37/64 bit which removed the leftover threads, Phew.  Was confused big time because 3/8 is not >0.6 inches which is what I was measuring and I measured 18 threads so I pivoted to a 5/8-18 tap. Now I know the NPT chart is in its own realm. New thing learned today.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

That PST will be doing yeoman's work in this case, but I'm pretty sure I will hold.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I think it will hold well. I got very lucky since I used a smaller tap than was needed!! PST is still my goto from here.

It looks like PST would need a primer to cure, unless the mating surface is reactive like iron or brass.. Would like to know sometime how that works, the chemistry.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 460 Smog Delete and Oil Cooler Delete for a 78 Bronco Swap

|

Administrator

|

It's anerobic.

It cures because there is no air. (The plastic tube or bottle is inhibited) You can use primer P or T, but it's not really necessary.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |