Rear Bumper/Spare Tire Mount Thoughts

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

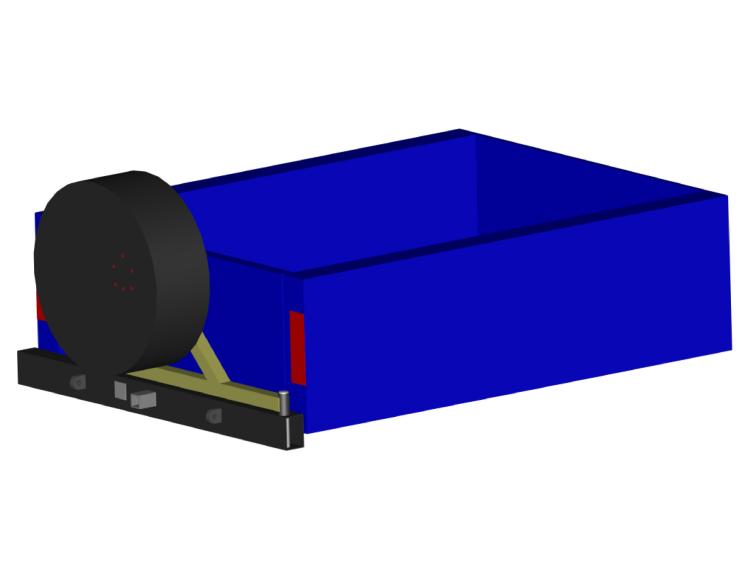

I've been slowly re-drawing the bumper and spare tire carrier in 3D. It isn't done but I thought I'd share with you where it is and invite (beg for?) your comments.

Here's an overall view, so let me point out some of the design details as well as things that need to be added or resolved: I had planned to design it to carry a 44" tire, even though BB currently runs 31's. But that puts the top of a 31" tire 12" above the top of the tailgate, blocking the vision. So, I might drop the carrier 4", which will mean that a 35" tire will just about be the max.The tire carrier is 2 1/2 x 1/4" square tubing. The pivot is a 1 3/4" OD tube that is inserted through the bumper and welded top and bottom. The swivel is a piece of 2" tubing w/a .120 wall, which will give .010" clearance. The square tubing is fish-mouthed to fit the swivel tightly and give as much room for welding as possible. I'll need to put a washer between the swivel and the bumper for wear, and I'll add a grease fitting as well as a retaining bolt and washer at the top.The left end of the tire carrier will ride on a little ramp on the bumper, perhaps made of nylon, and be held to the bumper w/a clamp like this one.In addition, there will be a tab on the arm close to the left end that will catch the bumper so it can't swing too far and hit the tailgate. Further, I want to put a little catch on the bumper that will pass through a hole in that tab and automatically hold it to the bumper. I cannot find a description or picture of what I have in mind, but there are some on my boat. It's a pin that's split on the end with an unequal length arm pivoted in the split. Normally the long arm is down, and when you swing the tire carrier against the bumper the pin will go through the hole in the tab and then the long end of the arm swings down, capturing the carrier. I know that sounds like a belt and braces approach, but that's me.

|

Re: Rear Bumper/Spare Tire Mount Thoughts

|

The factory tire carrier on my early Bronco swings around and hits on the side of the vehicle. It's not that big of a deal because it's the tire that hits. There is a dent in the trim from it swinging in pretty hard once or twice, but with a little care it's not that bad (certainly less damage than I've done rock crawling!).

But originally it didn't swing that far. From thy factory it had an "allsyagotta". As in "alls ya gotta do to keep that from swinging around and hitting the side is put a cable on it." There was a cable hooked to the swinging carrier that would pull tight when it was opened about 100 degrees (I don't recall what the other end was anchored to). It worked OK, but was a little hokey, and didn't seem necessary, so when I took it apart for paint I never bothered to put it back on.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

I looks like I can put a tab on the front of the bumper's right end that will catch the arm before it hits the body. Obviously it'll have to be solid, but that would be better than a chain.

I reviewed my plans with my nephew today. He's a mechanical engineer as well as a tremendous mechanic. He liked the plans, although he did seem to think that a ball or roller bearing arrangement for the swing arm would be better than my plans to use the tubing for the bearing. But I think the tubing will be adequate for the limited number of times it'll be used. Thoughts?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Rear Bumper/Spare Tire Mount Thoughts

|

On the stop, keep in mind that anything near the pivot has a big mechanical disadvantage. For instance, if it's 1" from the pivot point and you lean with 10 lbs of force against the other end of the carrier, say 40" from the pivot, you have a 40:1 advantage, and the stop (and pivot) see 400 lbs of force from your little 10 lb lean. Not saying it can't work, just realize that the forces can really skyrocket.

On the bearings, I'd be a little leery of the unfinished ID of steel tubing as a bearing surface. It'll work for the little motion and very low speeds it'll have to deal with, but it'll probably feel rough and it will wear. Rolling-element bearings would be best,but are way overkill (and we all know how much you hate overkill  ). I'd maybe try to get a smaller ID tube that I could bore out to get a smoother surface. Or maybe a larger ID that I could press some plastic or sintered bronze bearings into. But again, I do think your idea will work. ). I'd maybe try to get a smaller ID tube that I could bore out to get a smoother surface. Or maybe a larger ID that I could press some plastic or sintered bronze bearings into. But again, I do think your idea will work.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

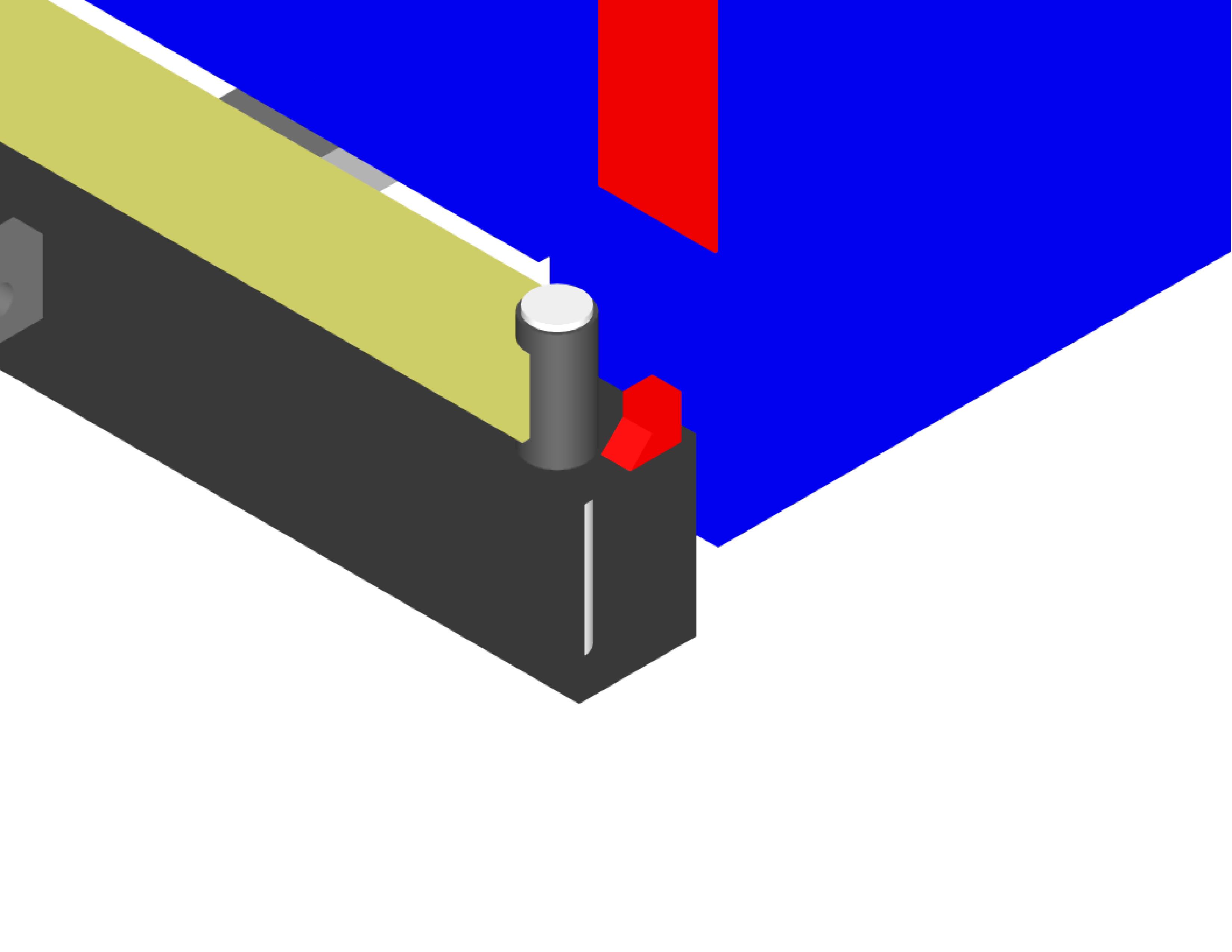

I agree with your math on the force on the swing arm. But I don't have a lot of choices - at least few I'm aware of. Here's the one I've got drawn, which is a 1" thick by 1" wide stop with a 45 degree ramp on the front. And, while the ramp won't really be used as the arm should be at the same height as the top of the ramp, it does give more leverage to the weld.

The inside edge of the stop is 1" from the center of the pivot, and the outside is 2". So the force will average a bit less than you calculated, but will be spread over a larger area.  As for the pivot, Ben said his company has several and he'll see what he thinks is best. But I've looked at trailer spindles and there's one which uses 1" bearings and is good for 1250 lbs. The large end of the spindle is 1 1/4" and it is, obviously, steel so can be welded. However, all the hubs I've seen are cast, so welding to them is questionable. So Ben will see if he can find one that is steel and not cast. I could turn it down in the lathe to get a reasonable diameter. Anyway, please keep those cards and letters coming in!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

I fear y'all have tired of this subject. But I haven't, and have done some more work on it.

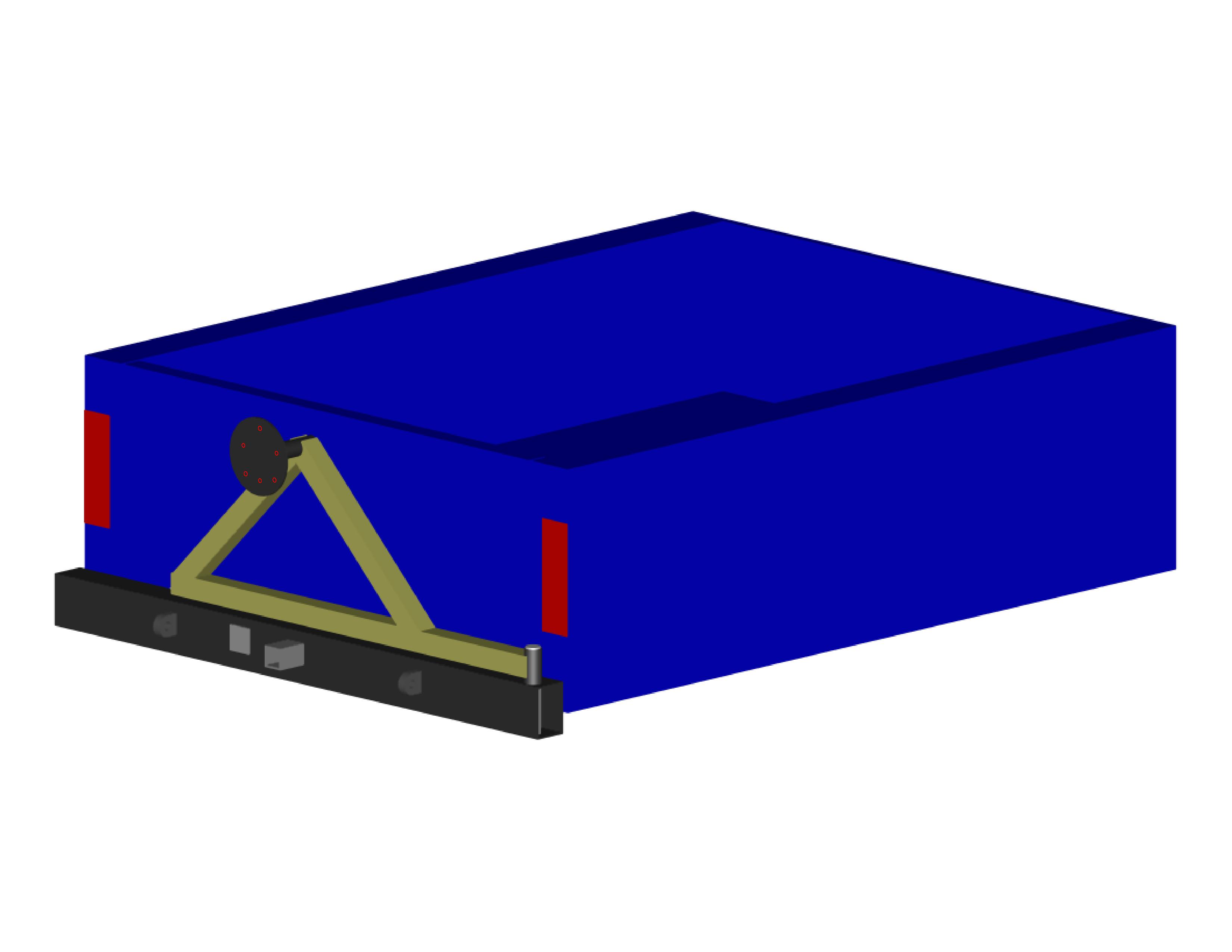

But first, I've created a page for this project on the website: About Me-Contact Me/Projects/Rear Bumper and Spare Tire. And, I created a "project" called Rear Bumper And Spare Tire Carrier in the Project section here in the forum. My reason for creating the two is to test how well they work. The one on the website gets the pictures automagically updated as I work on the project and "print" new pics. And, the viewer can zoom in and pan around on them, which you can't do in the pics in the Project section of the forum. So, please tell me your thoughts as I can't keep two different places up to snuff. (I like the webpage best, so....) Now, for the updates and questions: - I've added a license tag holder and a 3rd brake/license tag light/backup light in the middle of the spare tire. But I'm not happy with the lights I've found as most are too tall - it shouldn't be more than about 3". So, if you have some to suggest.... - I've added a filler panel to the top front of the bumper to keep the yuk from being kicked up and getting onto the bumper - I made the swing arm go all the way across and the angled spare tire support arms go basically to the ends of the arm. There are two reasons for that. First, by making it a full triangle the thing can't sag. Second, it makes each arm almost 38" long and I think I can get a hi-lift jack mounted on the arm.  Thoughts? Please? I'm hoping to have this made for my Christmas present, and need to get it right.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I don't have much to contribute, but I'm looking forward to watching it progress.

Sonoma County,CA

1982 F150 Flareside XLS NP435 4x4 351W Motorcraft 2150 |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

Do you like the pics on the webpage or in the Projects section? I could, as I think about it, keep the pics on the webpage updated and have a discussion on the Projects section. The pics on the webpage let you zoom in, scroll around, etc.

Boy, it sure would be nice for y'all to be able to pan and tilt. Meaning for me to have a full 3D model and you be able to view it from any angle. I wonder how that could be done?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

Well, there have been some significant changes on the bumper design, as explained on the Projects page. But, here's the Reader's Digest version:

Hinge: I found what I think is the right arrangement as it it very solid, with tapered-roller bearings, very strong spindle, seals, etc. And, it just tucks in below the active tail light - look at the pic. |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

Turns out I can type, albeit slowly. But I can TurboCAD almost as well as w/o burned fingers. And today I got the trail jack drawn up and properly placed. Turns out that there is just enough room between the tire and the tailgate.

And, with some testing I got it where it doesn't obscure the tail light and doesn't hit it when the swing arm is fully open. But that wasn't the case initially.  It fits pretty well just ahead of the spare. And, by removing the top end of the jack it doesn't stick up in the air - although I don't have a pic to prove that. Anyway, check it out in Projects, or even better on the webpage.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Very cool!

And the front end should be on the ground when you sit in it...

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

The 4 x 6" bumper was going to be something like 96 lbs by itself, so a 4 x 5" should be 80 lbs. The swing arm, including the angled pieces, is going to be pushing 100 lbs. I think the tire and wheel will go 85 lbs as the tire alone is 62 lbs. And the jack is 26 lbs. That's almost 300 lbs and doesn't include several things.

And all of that weight is well behind the rear axle, so the rear may be down a bit and the front up.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

All kidding aside, I think that's good for the lighter end of the truck, especially off roading.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

I agree. The tire was already there, and the jack had to go somewhere, and the old bumper and brackets come off. So maybe 1/2 of the weight is additional. And with the weight of the 460, aux battery, winch & winch bumper up front, it isn't all bad to hang this off the rear.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

This post was updated on .

In reply to this post by Gary Lewis

It doesn't take much to make the wheel mounting points adjustable. Either several holes so you can move the lug studs; or a sliding plate for the studs to raise/lower the spare; or several places to bolt the studs' plate to the arm. That's VERY overbuilt. The tube doesn't need to be nearly as wide (horizontally) as it is tall (vertically) because there's not nearly as much force applied horizontally. And the wall doesn't need to be 1/8"; with the right design, 1/16" would be enough. I don't think 1/100" is enough to ensure the tube will fit over the mount. With 1/4" clearance (total), you could wrap a 1/8" sheet of teflon between them, which would be much more-durable, without collecting dirt or staining the back of the truck like grease will. Another common hinge (the precursor to the RockStomper hinge) is a spindle & hub that fit the truck (so they can be used as spares in an emergency). If it's a 4WD truck, the hub can have a manual hub lock that also fits the truck as the only catch for the swing arm. If you put a block at the end of the ramp, the arm won't be able to go past. But the hard plastic lubrication is a good idea that you should continue throughout the design. I used it on my grinder stand:  I still think you should make the automatic catch your MAIN catch, and the difficult one (wing bolt, or whatever) your backup (only for when you know you won't need to get in the t/g for a while). Then put all the catch mechanisms on the arm, going into the bumper. Limit cable, or a boss sticking up from the bumper that interferes with the arm near the taillight; or both. Your design has a lot of extra weight on it. The arm going along the bumper to the other side, and the angle going back up to the spare are redundant. If you use a rectangular tube more like the bumper (e.g., 1 x 3 x 1/16"), it will bear the weight as a simple angled arm coming up from the pivot. The only reason to have anything parallel to the bumper is to mount the catch, and that doesn't need to be as heavy since it will only receive torque - no weight. If you don't like that look, you could run a short piece horizontally along the bumper about to where it will be hidden by the spare, then turn it up to the mounting lugs. It was designed to. There was an optional bracket so it could be bolted to the side of the truck (with the spare mount flipped over the top bar) allowing the t/g to be left open while driving (particularly at low speeds, as on a farm). You could also turn the inside of any common Sch.40 steel tube so the bearings would fit into it, and not use the trailer hub. That's essentially what the RockStomper hinge is. Flexible LED strips are inexpensive on eBay, and can be mounted to a simple flat horizontal lip above the license plate, glowing down onto it. Then you can put any lights that fit between the top & bottom of the plate, and the inside of the wheel. But I wouldn't wire those up to the normal reverse lights because they'll blind other drivers. I'd make them off-road-only. For bright reverse lights that work on- & off-road, mount them under the bumper so they can't possibly shine or glare upward at vehicles behind you.  I wouldn't do that, even though I know it's common. The only reason the spare is going on the swing arm is because it takes up too much of the bed, and you don't want it hanging down. Neither of those limitations applies to a high-lift because it's so skinny. Put it in the bed, or inside the bumper, or jacked into a locking position on the bumper. It doesn't need to swing, so I wouldn't add that weight. |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

In reply to this post by Gary Lewis

Steve - I see I have a response from you, but will address it in my next post.

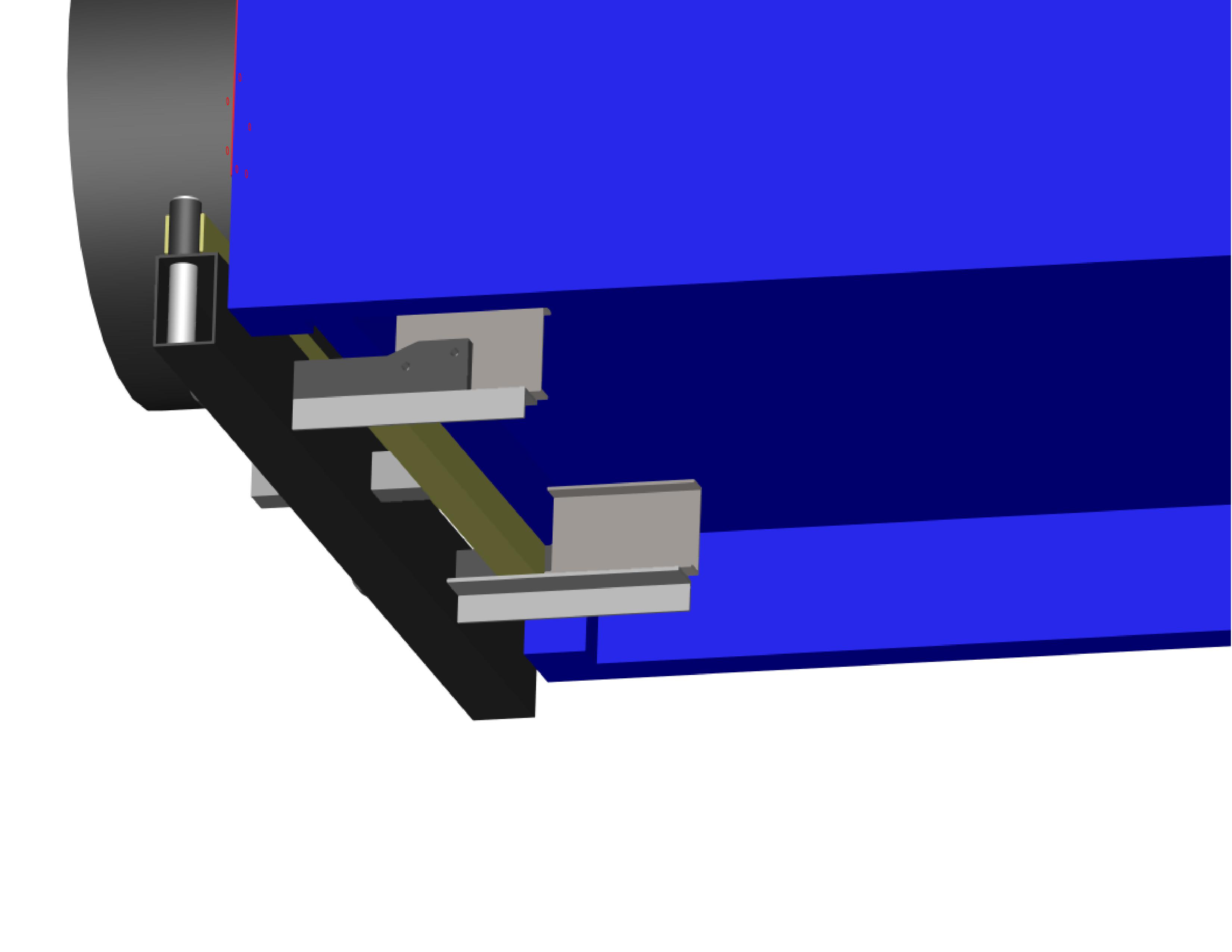

Bill - Thanks for the measurements. I've added your info to the spreadsheet, shown below, and I think we can make these conclusions: The factory bumper holes are a given distance from the top and rear of the frame, although exactly where remains to be seen.Given the differences between frames (see below), it isn't going to be possible for one attachment method to fit all frames if you have it attach to the bottom of the frame as well as the normal bumper attachment holes.There aren't any "stock" holes in the bottom of the frame. Darth's don't match BB's, even though they appear to be from a very similar hitch that attaches at three points per side. And the receiver that was on Dad's truck attached with only two bolts per side, and in very different locations.Given that, the only way to make the bumper universal is for it to only attach to the bumper attachment holes. So I called my nephew, who is mechanical engineer, and he says that those 4 bolts are adequate. However, it isn't enough overkill for me so I'm going to have a piece of 1/2" thick by 2 1/2" wide strap welded to the bottom of the tow eyes and drilled to match the holes in BB's frame - as shown in the latest drawings on the Project page. That way the bottom of the frame takes the up/down forces and the side of the frame takes the sideways forces. But, that arrangement will only work for RCLB F250HD's or 350's, as they share a frame. And the frame on other trucks will either be too tall or too short for these tow eyes to end flush with the bottom. So, if this design were to be made commercially there would either have to be different tow eyes for each frame or we would have to dispense with the strap at the bottom. Anyway, I think my overall design is done. But I still have some details to work out. For instance, the latches, plural. And how to mount the Rigid Chase light, which I'm pretty sure I want as it'll give me a strong backup light, which these trucks badly need, without embedding trailer lights in the bumper - which I don't want to do.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

A couple of items, first Darth is a CCLB (not that I think they made any CCSB models in the Bullnose models) and also a DRW model if that made a difference in the frames. Second the 4 3/8" dimension is as close as I could measure since the bumper is attached right now.

On the bolts, they are some big Metric bolts on Darth, on the pre 1985 models they may be SAE bolts.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

In reply to this post by Steve83

Steve - Thanks foe the detailed response. I'll try to address each one, but I'm sure to miss something. And, let me say from the outset that you may be two or three revisions back on the design.

I have the tire carrier drilled and tapped for 3 bolts of both the 5-lug and 8-lug Ford pattern, so shouldn't that be enough? The bumper is specific to these trucks.As for the swing arm, the final plan has the horizontal piece as a 3 1/2 vertical x 2 1/2 horizontal tube with 3/16" walls. The extra height significantly increases the torsional rigidity, which is needed as the jack is only 1/4" from the tailgate, albeit down close to the swivel/hinge.The new swivel is a Mega Spindle with tapered roller bearings.I have blocks at the end of the swing arm on the left, and on the right end of the bumper to ensure the thing can't hit the body. Both blocks are 1" wide by 1 1/2" deep steel welded to the bumper, so should be sufficient. But I would like to incorporate some Teflon to prevent the powder coat from being rubbed off and rust starting.I agree on the latches. And I'm still looking for the right ones, plural, there. I want something automatic and then something that pulls the arm down so it cannot bounce.Yes, the whole thing is overbuilt. But that's the way I like to build. That way I have the peace of mind that the receiver is more solid than the current one. That the swing arm won't flex. The frame won't bend, etc. It'll weigh more than it needs to weigh, but I'm ok with that.On the lighting, I think I've settled on the Rigid Chase. It is expensive, but it ticks all the boxes in one go. However, I'll have to see if the backup light part is too bright, as you suggested. If so I can add a switch to disable that part until it is needed.Jack: I like that it just fits on the arm. And with the new spindle and the design of the arm it won't be too much weight there. But, I do need to provide a way of locking it on.Anyway, I really do appreciate your input - even if it doesn't look like it. You've helped significantly in this quest, but I think I'm happy with the design at this point - even though it is overbuilt. However, I'm still looking for latch ideas. And, I'm seriously considering a backup camera as an option to this.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Rear Bumper/Spare Tire Mount Thoughts

|

Administrator

|

In reply to this post by 85lebaront2

Yeah, I thought about the CCLB, but they didn't make a short bed - although Jonathan is.

And I understand the problem of measuring with a bumper in place. I think I'll pull the one off BB soon and make SURE I have the dimensions correct. I don't think this new bumper is going to flex very easily. BB's bolts are SAE. I know 'cause I put new ones on. But the original ones may have been metric. I'll check the bolt hole sizes.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by Gary Lewis

I was only talking about adjusting the mounting height for different spare sizes. I don't think it'll be as twisty as you seem to think. Particularly if you make it LIGHTER instead of heavier, and SHORTER instead of longer (across the back of the truck).  A simple bullet-shaped pin that stabs into a socket in the bumper face will accomplish that, without much weight, complexity, or wear. I like building things overstrength, but building them overweight makes them weaker (at the mounting points, where the weight has to attach to the truck); and puts more wear on the truck; and reduces braking/accelerating/steering performance; and costs more for no more benefit. So there are many good reasons to keep it as light as it can be, without losing any strength. As long as you keep replying to my posts in this thread, I'll assume you're at least considering the points I'm raising.  If you stop replying to me, I'll quit posting in this thread, but I won't be offended. If you stop replying to me, I'll quit posting in this thread, but I won't be offended.  They're remarkably cheap & effective. I just put one in the '04 CV I swapped my mother into. It's wired into the big touch-screen radio I put in it.   Finding a place for the camera will take some effort, but it'll probably be easier than finding room for the display. |

| Edit this page |