Jim's 1982 300 Six Bronco Original Restoration

|

Okay it doesn't look like the linkage and shifter can be used on a "standard" transfer case adapter.

The shifter is pressed into the linkage and that part of it doesn't look like it can be reversed or anything. Curse Ford for using this transmission in a truck.

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

|

Is this the shifter and linkage I am looking for? My new trans is a T19 and xfer case is a NP208 Very expensive

https://www.ebay.com/itm/324992902502?hash=item4bab162566:g:YWYAAOSwd3thT4Md

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

|

On the driveshafts, my Bronco has that rear short double cardan u joint that it looks like you have.

I asked a mechanic I used to use to do the u joints in it and he said he doesn’t do them because when you get one changed in that double cardan you ruin it trying to do the next one. He suggested I get an assembly. They were around $300 when I was looking and there wasn’t any anywhere. I decided to take it to a local driveline specialist. And I’m glad I did. Took it in just after lunch and said I assume it’ll be done tomorrow. Girl behind the counter said it might be done today. She called around 3:30 saying it was done. $115.00, and they painted it! Been great. Now I don’t wrestle with u joints anymore. Take them there. Suburban rear was $65 with a balance, Jeep Liberty my son used to have $45. On the linkage, I don’t know looking at the pictures.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Yup after doing the front u-joints myself to save money I'm not messing with that anymore. The driveshafts on Bronco Graveyard appear to come with new u-joints but I have no idea what brand. I wanted to go with Spicer non-greasable all around but I guess that's out.

https://shop.broncograveyard.com/1980-82-Rear-Driveshaft-3-7_8-x-30-5_8-x-3-7_8/productinfo/32405/ https://shop.broncograveyard.com/1980-82-Front-Driveshaft-32-3_4/productinfo/32400/

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

|

Is this the floor cover I need for a T19 trans?

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Administrator

|

Hard to say looking straight down. That's 'cause there are two - the short one and the tall one. You need the short one but the tall one will work. ZF5's take the tall one.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Maybe the ujoints in the front end are more work, but I rebuilt both shafts at home and didnt think either were that bad. I rebuilt the double cardan too. I ended up buying 1330 series spicer forged sealed ujoints on amazon, it was the cheapest place. Tracking down the swivel ball hardware was the hardest part of building the double cardan. The ujoint press makes all the difference in the amount of work it takes.

I would say I spent well under 2 hours to do both with the double cardan. If you decide to try it out Ill dig through my amazon receipts and stuff to find part numbers.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, MSD ignition, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

1988 F250 "One Piece at a Time" - 460 ZF5 4x4 work truck project under construction |

|

I can't recall what gave me so much trouble, but I remember heavy use of my 4lb hammer and I'm still finding needle bearings under my work bench. The front driveshaft will not compress all the way. I'm definitely going to outsource this work or just replace em.

I bought this on a whim so I hope it's what I need for the T19 rebuild. It appears to have all the specialized tools required for reassembly as stated in Documentation, but the ad did not state the individual part numbers of each piece, just the suffix "A" part number. Here's hoping it also comes with suffix B, K, L, Q, R, and S. I suppose I'll know when it comes in, and I could probably turn it around for the same amount I bought it for...

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Administrator

|

Nice find!

The tool kits don't show in the master parts catalog. Given that I don't have a way of seeing what the individual part numbers are. But if that kit has the part number called for in the factory shop manual it should have all of the individual pieces you need.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

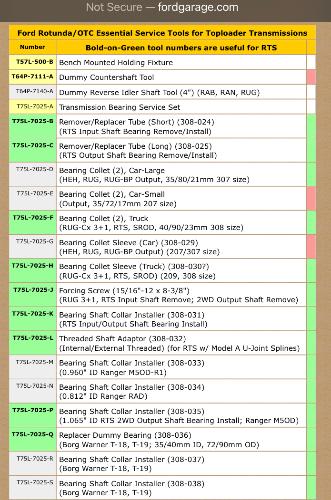

I found this on a page detailing TOD, RTS, and T170 conversions for Model Ts and As. It appears the "A" kit comes with all those other suffixes. Highlighted green are just the ones needed for "toploader" service.

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Administrator

|

Cool! You should be set.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by JimJam300

Yesterday I stayed up late drinking and removing the SROD transmission. I didn't really know if I could dismantle the weird 4x4 adapter-shifter housing so I left it in place and had to wrestle the crossmember out of the way.

Luckily this transmission is extremely light. I can easily pick up the whole thing by hand. I didn't even need to drain all the fluid or use a real transmission jack. I went through the scrapyard at work and cut the door off an old electrical panel, drilled a 1" hole in the center, bolted it to my floor jack, and ratchet strapped the transmission to the plate. It swivels too.  Earlier that day I went to a couple self service scrapyards to find a floor plate and a 4x4 shifter linkage. Ended up with a pair of EFI manifolds and a Y pipe ($50) that was conveniently lying in the engine bay of a stripped 90s F150. I figure I could probably use the Y pipe for an O2 sensor if I go with throttle body injection.  The floor plate and shifter linkage came out of a Bullnose 4x4 F150 with what looked like a NP435. I hope this works with a T19. I was lucky to find it. I accidentally cut the transmission shifter boot with my razor knife when pulling the dilapidated vinyl flooring back.... The shifter linkage I got is a splined shaft which is disappointing. But I might end up putting threads on it.  I really wish I could figure out why some of these pictures are right side up on my PC but are 90 degrees to the left when I post them. I tried using the image rotation code but it just ruins the rest of the post. I'm young, but I don't know computers to save my life.

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Administrator

|

You are making good progress. And the adapter to your floor jack is a good idea.

Good score at the salvage. Those EFI manifolds are said to flow a lot better. On the pics, the issue is that modern cameras embed an orientation code in the metadata of the picture and computers and mobile devices read that and orient the picture properly. This forum, and many other forums, doesn't read that code so doesn't re-orient the pic. So however you oriented the camera is how the picture displays. The way I fix that is to open the picture in some photo editing app and then save it. Sometimes the editing software doesn't rotate the image the way I want it and I have to rotate myself, but at least you can see it on the monitor and know which way up is. And that then works with the forum. At the same time I rotate the pic I downsize it to ~500kb. The max you can post on here is 1Mb, but there isn't any need for such a high res pic. So I shoot in whatever my camera shoots in natively and then downsize it and rotate it in one go.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Agreed, nice find on the efi manifolds. I did my exh manifilds, offy intake and carb upgrade all at once so it would be hard for me to say how much the exh manifolds themselves helped but lots of people who have a stock carb engine and those manifolds suggest a large change in felt bottom end.

Do be cautious, my efi manifolds melted parts of my alternator harness. Id keep an eye on that and either attempt to retain the factory heat shield or wrap the manifold.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, MSD ignition, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

1988 F250 "One Piece at a Time" - 460 ZF5 4x4 work truck project under construction |

|

I also run the EFI manifolds, Y pipe and stock carb but as most I did this as part of my truck rebuild so dont know what change it made as I did not drive the truck before that.

I got to say I am happy with the out come so far. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Since I've already got the transmission out I've been thinking of just pulling the engine and everything else out of the engine bay, painting the engine bay, and putting it back together. The crossroads of deleting the unreliable emissions control stuff and adding EFI is highly dependent on the answer I get back from Dirt Legal regarding registration in South Dakota under an LLC in New Mexico. The question was the legality of doing this in California in respect to a law that could slap me with a misdemeanor if I get pulled over. My lawyer friend seems to think that I should be fine.

I've decided to rip out the old wiring harness and put in a brand new one. I'm an electrical technician by trade, but automotive wiring is a bit different than what I deal with at work, and I feel very intimidated. I have built wiring harnesses with Molex-type connectors for electrical panels in the past, so I can't imagine the connectors would be very different, it's mostly the routing that scares me. The product I'm interested in is the American Auto Wire kit as it has comprehensive instructions specifically for our trucks. If there is a cheaper kit that's just as good, I'd like to know. And if anyone has advice I sure could use it.

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

|

That kit should be an absolute breeze for you. I got a universal kit from Painless(for about a 1/4 of the price) and I was surprised how easy it all was. And I'm not an electrical anything...

Rob

Eddy Myrtle '84 F150 300-6, Offenhauser C series intake, Edelbrock 1404(500cfm manual choke), EFI exhaust manifold, HEI dizzy, custom Painless harness, NP 435, NP 208, D44, 8.8"/3.08, 1.5" leveling coils, 265/75/16 tires. Toyopet (Daily driver) '86 Toyota Pickup |

|

Well I hit a brick wall on the T19 rebuild. Anyone got any tips on how to remove this lock ring? I've been trying for several hours and destroyed one of my snap ring pliers.

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

Re: Jim's 1982 300 Six Bronco Original Restoration

|

Administrator

|

I know they are expensive, but these Knipex snap ring pliers have done the job on things like that for me. I, too, broke several cheaper pliers until I got those.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Probably doesn't help you much but just in case... I was researching T-18 rebuilds, different thing but a lot of T-19 posts and videos come up when you do. I seem to recall this being a common problem-post and the advice being a combo of "try ratcheting snap ring pliers to pinch it then use a 90 degree hook tool to pry it out" and "just drill it every 3" and get a new one you'll destroy the teeth anyway". So... maybe?

--

1981 F-250 Custom. 6.6L V8, 4 barrel Holley carb, ARA aftermarket A/C. |

| Edit this page |