Search Forum

Help, intermittent no start...

|

Hello,

1986 Bronco 5.0 (EFI), with 302 and AOD. The truck used to always start fine, until a few days ago where I dealt with corrosion on the battery positive. I would get a no-crank situation, cleaned up the battery post, replaced the terminal and everything went back to normal. At least I thought that was it... A couple days later went to crank and nothing again... Here's what I did: - bypass key start (connect S on relay to battery post): cranks. That is how I get by now when the issue manifests itself, until someone reports me to the cops for GTA. - traced continuity on starter trigger wire from ignition switch to S post: good. - continuity between start trigger wire and negative: no short (or so it seems). - ignition switch: it's old but springs back and continuity between battery and start wire is ok. - ignition switch adjustment, rods key tumbler etc.: all looks good and operate ok. - tested NSS: in P and N I get trigger wire continuity, any other nothing, looks ok. The thing is, sometimes it will just crank with the key, sometimes it won't, and I can't see anywhere the wire could short... Right now it's back to working fine. One thins I noticed when it wasn't working, connecting battery to start at the ignition switch connector would spark and heat up the jumper wire. Looks like a short to me, now where?? Besides running a new wire, anything else I could do? The wire is a bit hard to trace all the way... Thanks |

Re: Help, intermittent no start...

|

Administrator

|

Do you have a tilt steering wheel? Those have a known problem where a piece breaks internally and it won’t start from time to time. I had that on Big Blue.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

The flimsy mold-cast actuator? Yes I replaced it a couple years back after it broke on me at a gas station...

No shifting, could start by pushing the rod but was stuck in P. I do have tilt wheel BTW. My wife was holding the brake pedal while I shifted into D from underneath to make it 100 miles home :) Thanks for replying. I've inspected the NSS connection and it looks ok, and seems to work ok from what I can tell, but this AOD is different from the C6 I had before (where the NSS crapped out on me twice). |

|

only the tilt wheel has the cast zinc actuator. this is one of the reasons some of us prefer the non-tilt columns. as to whether or not it is related to the nss. next time this happens put the selector in n instead of p and see if it helps. if so then its either the shifter adjustment or the nss. another common issue is the shifter handle itself. how loose/tight is the handle where it connects to the collar of the column? it hinges on a roll pin and often the cast collar gets worn out.

|

|

Thanks, I'll check the shifter a the column.

Forgot to mention that I had tried P or N, no difference... Also I tried with a jumper at the NSS plug that goes into the transmission (pins 3 & 4) and that made no difference either. I hope I find it, I'll be sure to post up if/when I do. |

|

it seems as if you have covered most things. then the next suggestion I can make is to do a lamp test unfortunately this has been randomly happening so finding the cause starts with finding it in its failed state. having a test light in the truck is the key. or put together a bulb holder with bulb to be able to install at the solenoid trigger wire to ground. this way you can see from the drivers seat when turning the key.

|

|

Great idea!

It is annoying that it's intermittent. I almost want to install a temporary push button for when it happens at least it's not as embarrassing as hotwiring under the hood in a busy parking lot. |

Re: Help, intermittent no start...

|

Administrator

|

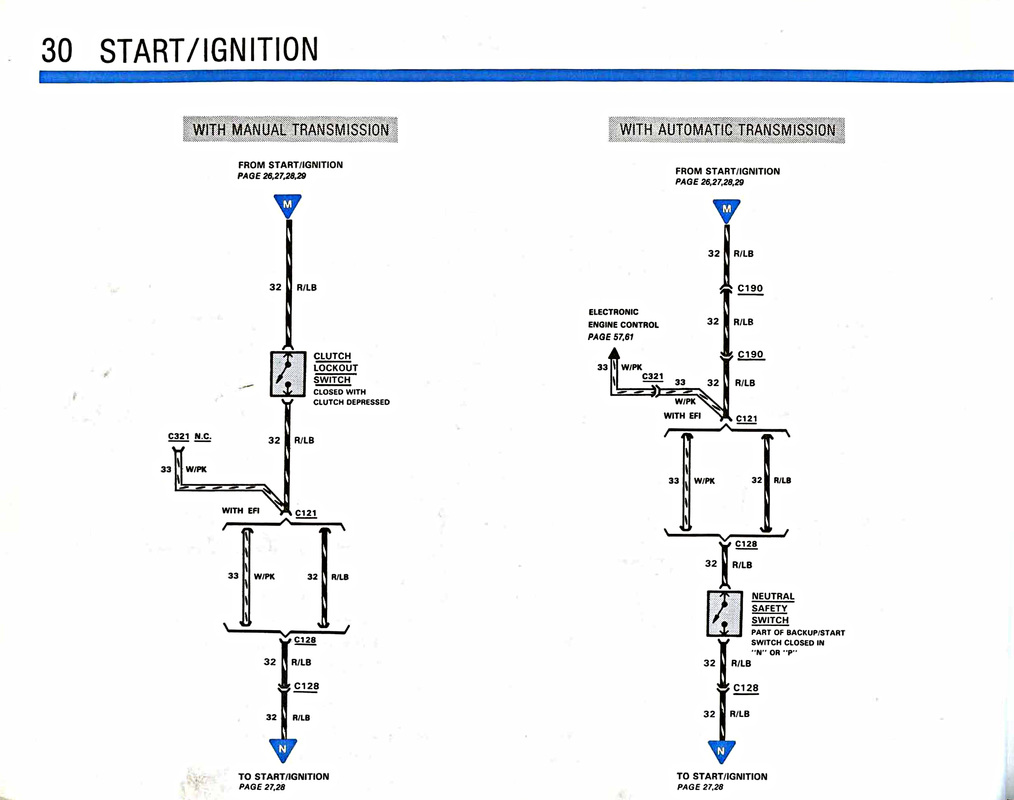

You should check the jumper in the harness where the clutch switch would be for corrosion.

It may be bad enough that not enough current can pass. (this is also a convenient place to 'inject' current if you use an "add a circuit" type fuse doubler to put your push button) When people swap to an automatic or the clutch safety goes out I always tell them to just take a spare fuse and stick it in that connector.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Help, intermittent no start...

|

Administrator

|

In reply to this post by Maurice

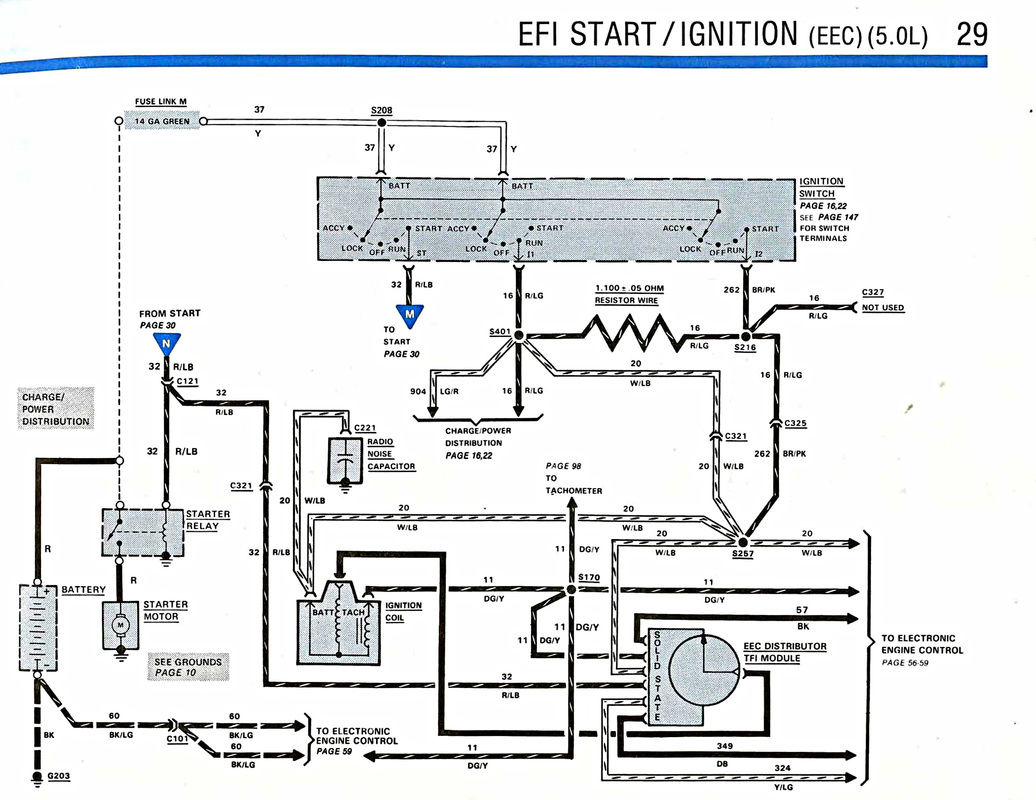

The clutch switch jumper is in C190 of this diagram.  In this diagram which connector are you putting the jumper wire thats heating up?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Thanks Jim.

I used the jumper to probe for continuity in the wire. Maybe poking it changed something? I'll take a closer look at that connector. What do you mean "inject current" there? I could try that but I'm concerned the short (or whatever is happening) could be downstream of that... I was connecting battery (37) directly to start (262) at the ignition switch connector. Initially sparked and wire got hot with ammeter needle dipping. After some digging and poking, things went to normal and doing that caused engine to crank over... |

Re: Help, intermittent no start...

|

Administrator

|

C262 is the ignition side, not 32, the red/blue starter wire.

You were sending power to the coil and ignition module.... You mentioned using a momentary switch to crank the starter. I'm saying that you wouldn't need to tap into any wiring if you used one of those piggyback fuseholders and ran your switch to above your left knee where the clutch safety is already jumpered.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Oh my bad, I read the diagram wrong. I was jumping to 32. Like I said it did eventually just crank (and not start since I didn't connect ignition).

I hear you, it's just that tapping into the existing wiring might produce the same result if the damaged part is on the reused path... But I guess that would be narrowing it down some so could be invaluable. Thanks |

Re: Help, intermittent no start...

|

Administrator

|

Narrowing it down would be pulling the jumper shown in the first diagram and seeing if it's a really tarnished.

I always like to apply Deoxit D5 and work the plug in and out, then give it a little flush with the same stuff.it works wonders on tuners and connectors.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Pulled the jumper out and things looked clean and without corrosion... Cleaned it anyway (I'll have to get some DeOxit), and actually put a fuse instead for now. Of course this is the "everything works fine" phase so I'll have to wait for it to start acting up to continue the chase. Or not, but I'd like to understand what went on.

Thanks all for the help. |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |