Search Forum

Flare Side Bed - Let's Take One Apart!

1234

1234

|

Truck: 1980 F-150

This truck is originally from Arizona and I don't think it spent much, if any, time on the road here in Illinois. So, it's going to come apart pretty easily and I'm not going to have to deal with severe corrosion. If you're suffering/dealing with oxidation, I feel your pain as I've been there. Apologies, I've already removed the tailgate. That was simple; unbolt four metric fasteners from the hinge pivots and done. However, those bolts have captured nuts in the bed sides that would be VERY difficult to access as they're inside the rear boxed section of the bed side. I was able to remove all thirteen fasteners that hold the left/driver's side flare to the bed box. Additionally, the two flare stays came off but both are broken. I also removed the step (five carriage bolts) that's between the front of the flare and the rear of the cab (the support remains bolted to the bed, for now). I did come across something odd; what appears to be a stake post support. However, it doesn't like up with any stake post holes in the bed (it's not in the first image, below). I used some PB Blaster a few days ago on all the fasteners. I think that stuff works well. You can see how far it 'creeps' on metal surfaces.  Here are the flare stays. The top one is the one that goes between the bed floor and the side step. It's beefier because it's supposed to stabilize the step when weight is placed on it. The broken tab is at the end where the stay fastens to the bed floor. I was thinking of having it fixed/welded but these stays are kind of flimsy. I think I can fabricate something a little more substantial out of some metal angle. As for the rear one, it was broken at the end that connects to the flare. And, the self-tapping fastener was loose. I guess I was lucky it didn't fall out. I may fix and re-use this one.  Both stays are fastened to the underside of the bed floor with the same carriage bolts that hold the bed side to the wooden bed floor. This is the "stake pocket" that I am a little confused about. Like the stays, there are two carriage bolts that fasten this to the underside of the bed floor. There is no stake post hole, in the bed side, that's directly above it. I guess it's a nice place to collect road debris thrown up by the tires. You can see it's been there a while, as there's a wear mark in the bed side that's starting to oxidize. Anyone have any ideas? I'm inclined not to re-install it, it's heavy.

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

gotta love the homemade wheel dollies.

|

Thanks, too much left-over wood and casters...

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

In reply to this post by Bronco638

I'm here to tell you that you will remain confused about what the "stake pocket" is for. It has been discussed and talked about many times over the years. It IS a factory piece, installed when the truck was built. As for what it's purpose is? I don't think anybody has ever confirmed. I always assumed it was a registration jig for the assembly line...but some people are adamant that's there to protect the fuel filler neck from getting pinched up against the side of the bed in the even of a side impact. I think some people said it was a leftover part from the previous generation(s) of Flaresides that was somehow part of a side mount for a spare tire, back when they still did that. In any case, all anybody can do is guess...unless one of us happens to find somebody that worked on the assembly line back then;). I'm as confused about it's purpose as I was years ago. In any case, everybody usually throws that part away and just puts new bolts in the empty holes. That's what I did, as did many others. Good luck! PS: Be careful with the fuel filler neck and the vent line inside it...neither are available in the aftermarket. I cleaned them up and re-used them on the Falresides I rebuilt. That bed looks like it's in nice condition! Congrats. I'll be following along.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Well, isn't that fun... I guess I could see that it might prevent the filler neck from being crushed in a side impact. But, that seems like an odd way to do that, given its shape. Huh, I guess I'll put it aside for now. I'm hoping they're in decent enough shape that I can clean and re-use them. At first glance, they look OK. The fuel that's in that tank is going to be good for cleaning parts....maybe... The whole truck is in nice condition, with respect to corrosion. And, the old engine and trans (351M & C6) had the courtesy to leak some so the frame, forward of the cab, has been nicely preserved. Front suspension, too. The only rot is in the cab corners and I think it's because the rear window was replaced with a louvered plexiglass unit a while ago. I'm thinking that the weatherstrip seal isn't good and it leaks. The cab drip rails seem to be good. But, when I get to removing the interior, I'm hoping to see some sort of evidence of a leak. I'll keep posting as things progress (with the bed).

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

Time for that left/driver's side bedside to come off. After removing all of the fasteners, I discovered that the rear corner of the bed had been welded in two areas. I was able to use a 4" grinder (using both cut-off and grinding wheels), cold chisels and a hack saw blade to cut thru the welds and the bedside came loose. Here it is sitting in the bed of the truck, leaning against the right/passenger side of the bed (which is still bolted in-place). That's a complete dash out of an '85 (I think) Bronco laying in the bed, nearest the camera. That, the cardboard box and the black plastic crate need to go to storage. The rest of the items on the bed floor are pieces of the bed (the flare and tailgate are sitting in the bed of my Ranger). It's interesting, the wood bed floor is in really good shape in a few small areas. In other places, it barely exists.

A view of that lower, rear extension panel of the bedside. In the yellow rectangles, you can clearly see the remnants of the weld beads. In the lower left corner of the right rectangle is a blob of weld which is shiny from being cut, not a hole in the panel.  And, why were those panels welded in the first place? I'm guessing an accident/fender bender as I found some body filler in the rear bed panel, just above where the license plate bracket bolts (look closely, just to the right of the black arrowhead).  Another view of that same area but before dis-assembly. You can clearly see the cracks in the thin sheet metal. The sheet metal captured by the fastener in the upper right is actually broken off. I have that piece and will figure out how to put it back where it belongs. I can see why it was welded; it's an easier fix. But, this won't be the way it's put back together.

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

I will be following the build.

At one time you could buy that rear sill panel dont know if you still can as I have not looked in a while. On the broken braces they are for the front & rear lower of the fenders. The step should have it's own support bracket. It uses 2 carriage bolts thru the step to the bracket and IIRC the bracket bolted to the front sill. I did a different floor than wood so the front sill and rear sill I had to make changes to work. Also my bed was so bad I dont know how the factory had the step brackets to the sill? I also would never use the steps to access the bed as I would mark them up  Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

This post was updated on .

I will look into this but I think I'd rather fix what I have as opposed to using something new. I have no idea how I would manage to match the (faded) paint. The rear 'panel' has a double set of braces whereas the front only has one. But, yes, you're right. If you look closely at this image, you can see one of the bracket holes just above the band clamp on the fuel filler hose. So, yes, the step bracket is bolted the front of the bed and there's also a support bracket that's bolted to the under side the bed floor (which is fastened to the middle bolt of the three that hold the step to the flare).  I think it's pretty cool that you used a metal bed, from a style side, in your flare side. I do think the wood floor is kinda cool though. Since I won't be using my truck like you do, using wood will be just fine. My steps are sun burned paint and I won't have any issue putting my dirty boots on them. That said, they'll probably see little use. Your truck is nice and I'd be leery of using those steps, too! Anyone have any suggestions on bed flooring suppliers (I do not need hardware, just wood)? I'm considering something other than Pine or Red Oak as long as it's affordable. I will not be selecting Pine unless it's old-growth Southern Pine (which has been sitting for the last 50 years). That stuff is like rock unlike the current stuff, which is like foam-board. Ash, Maple, Poplar or Cypress would be my other considerations. TIA.

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

On the last one I did, my 1980 F150 4x4, I believe it was red oak that I used. It was the cheapest oak I could buy locally, and it worked just fine. I had the shop cut them to the correct length, and then I cut the slots in them with a table saw. I stained them with Minwax Provincial, and then put three coats are marine spar varnish or whatever it's called, sanding in between coats (except for the last coat). The wood cost me about $300 (Canadian) locally, so it should be even less in the US.

You'll notice that my bedsides do not have the inner fender tubs. I made these sides from scratch, and installing tubs was going to be way too much work on top of something I already had way too much work in lol.     I had so many hours into that bad you have no idea...lol. AS for the rear sill, the one I used in this bed was a used one from down south, and while it was relatively rust free, it was cracked in several places just like yours, and somebody had drilled about 20 holes in it screwing down new bed wood. I betcha I had a week of evenings just welding up that rear sill. You can buy new ones from Mar-K in Oklahoma and the fit and finish is A1, really. When I built my 1984 F150 Flareside, I used all new steel in the bed, except for the tailgate and the steps. I had to fab and weld new stake pockets on to the new steel side panels, but all the crossmembers and sills, head board, etc were all new.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

To back up a little when I took my truck to work today the rear lights do have the side markers.

Again they are aftermarket but were a bolt on to the factory brackets. Cory they were some pretty trucks even that older Ford you had for a little bit. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Yes, geez, I wish I had fab skills like that. Who cares that the bed sides don't have the little inner 'tub'. That's some nice work! What ever became of the Firebird (or Camaro)?

Mar-K still sells the Grade B Red Oak wood kit for $290. Grade B has knots and checks/splits and is meant for a "work truck" (as opposed to a show truck, I guess). The Grade A Red Oak kit is $500. Prices for other woods go up from there. I haven't quite decided how to treat the wood but I do know that the end grain will need to be sealed and the under sides of the boards may be sealed with something different than what's visible in the bed. With the patina of the truck (kind of a rose-gold), I'm not sure what would look good. I'm pretty sure what's in the bed now is original and is Oak (not sure if red or white). I know Dave mentioned that some wood beds came painted (main truck color) and some may have been pine. Interestingly, Pine is more expensive than Red Oak (and I'd consider Red Oak more desirable). I thought something more water resistant would be better (i.e. Cypress or Poplar) but they're not as affordable as Red Oak. I really don't plan to drive the truck in the winter slop but I'm sure it'll be driven in the rain/wet (after the salt has been washed away). So, moisture abatement is a consideration. I will check Mar-K for the rear cross piece, that's had such a tough life. The right/passenger side has also been welded so I'll need to cut/grind that bead to remove the bed side.

Dave A

'80 F-150 '11 Ranger '17 Expedition |

No special fab skills really...just a home mechanic with a welder! The Trans Am was at the body shop that painted the bedsides for me. It was a long term project of the guy that worked there. I can weld, but I don't do body work...that part I farmed out;). Dave on the other hand does it all! I have my limitations;). I enjoy following along with anything Flareside related. They're very cool trucks;). Keep it up.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

This post was updated on .

Well, I went out to the garage to "putter" and clean up some items in the bed. The next thing I know, two hours have gone by and more parts have "fallen" off...

First thing, as with the opposite side, was the flare.  I discovered the first fastener with an "issue"; of the fifteen studs that secure the flare to the bed side, the rear-most stud was broken off (yellow circle). And, on the opposite side of the light green rectangle is another bead of weld. So, I'm trying to decide on what tools I own (or will own) that will facilitate its removal. I'm hoping to get the RotoZip in there with its smaller cut-off wheels (as opposed to the 4" grinder with its larger wheels).  On the forward bed extension, I discovered a bit of 'serious' oxidation, about the size of a quarter.  Nothing serious and no perforation. I will encapsulate that though. Here's where we stand with the bed:  I should have that bed side off soon and then we can address the badly deteriorated wood and get to the cross pieces. I did notice that the wood spacers, between the cross-bars and the frame, appear to be completely intact. I'm not sure if they're pressure treated or not (they kind of look like they are, I see a faint greenish tint) but I'm surprised at the condition, if they still are the factory units.

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

Your bed is cherry compared to what mine was like LOL

Everyone of the extensions had to have metal replaced as did the bolt lips at the front & rear of both side panels. For that weld bead, it is hard to see but you cant use a thin 4" cut off wheel to cut it apart? Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

There's a YT video of someone disassembling a flare side bed on a Bull Nose from Pennsylvania. What a nightmare. I think he had to drill out or cut off every single bedside fastener, just to get the flares off. No thanks, I've done plenty of projects where you lay on the ground and rust flakes and/or dirt falls in your eyes. I'm very particular now.  It's hard to see because it's on the opposite side of the panel. One of the brackets, from the rear cross member (below the tailgate), is welded to that lower extension on the bed side. I can get the 4" grinder in there, with a cut-off wheel but it's tight and I don't want to have the wheel cut into other areas of the bed side while I'm focused on cutting the weld. The RotoZip, with its smaller wheels, will fit/work better (I think/hope).

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

this may well be a case for a spot weld cutter

|

|

This post was updated on .

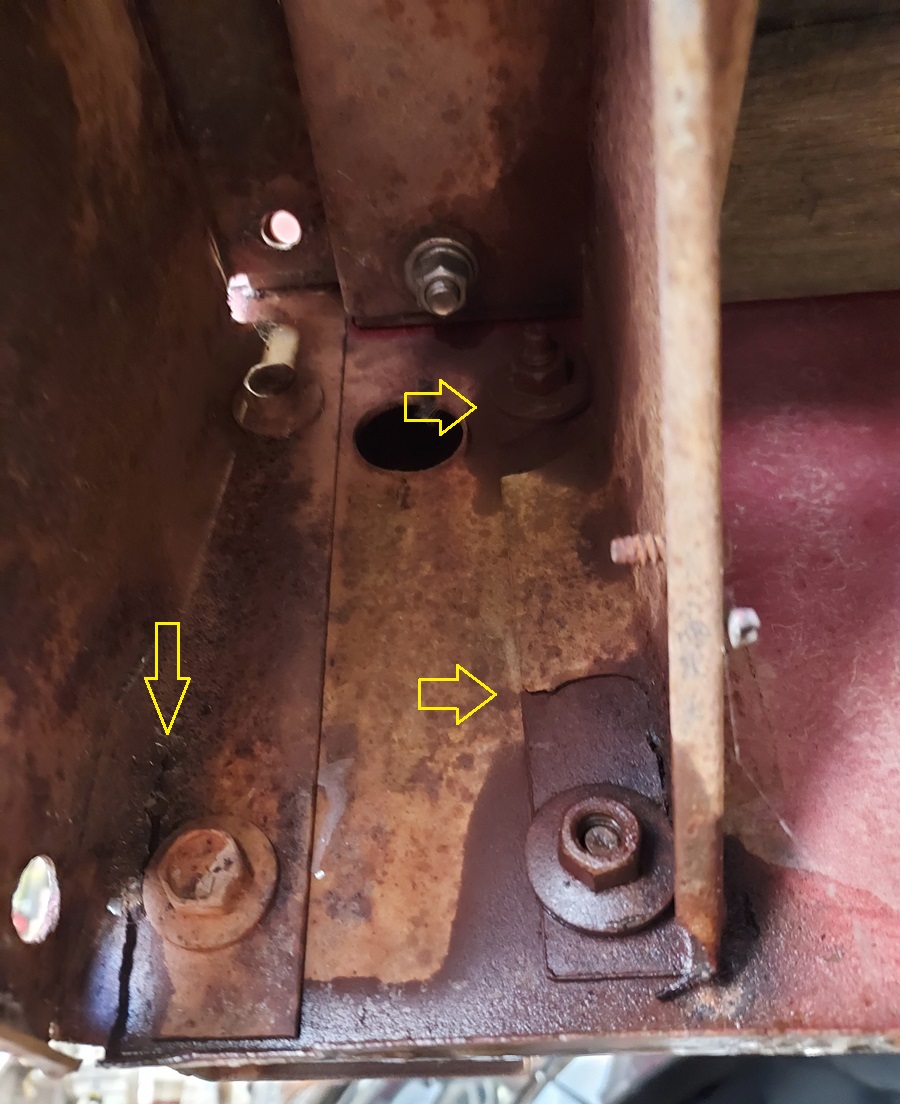

That would work great, if it were spot welds. But, it's a bead of weld about 2" long. I squeezed my camera into that area:  By the way, see that small hole, just to the right of the yellow rectangle? There's a corresponding hole on the opposite (left/driver's) side of the bed. That would be ground Point G1001 as noted in the wiring schematics. I think I may run a dedicated ground wire so as not to use the bed as a ground (which is pretty well insulated from the frame by the wooden mounting blocks, under the cross pieces).

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

Ok now I see it

Yea a Dremil with a small cut disc but they like to fly apart as they are not vary strong but I cant think of anything else to use? What shape is the rear sill in? I also dont think you can get the wood up with out removing the side panels. If the rear sil is bad and can get the wood up I would then take a cut off wheel or sawz all to cut the sill off and ground the weld down flat. I dont know why they would do that unless the bolts / nuts from the side panels to the sill were bad? I cant remember now is there 2 or 4 bolts per side on the sill / side panel? I do remember it being a bear to get them started and tight as I did not have a lot of room to work in back there with the metal ribbed floor. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

I couldn't get the RotoZip in there because it was too long to fit between the bed side and the rear frame horn. So, ended up using the 4" angle grinder with used cut-off wheels and used grinding wheels (smaller than 4"). I was able to cut thru about 3/4 of the weld bead, from top to bottom. The rest I was able to cut thru with a hack saw blade and cold chisels. It's not pretty.

This is what the left/driver's side of that rear cross member looks like, with respect to the angle bracing. They're pretty sad. I thought maybe it was due to an accident but the other side looks the same. I think vibration must beat them to death.  Here's the opposite (right/passenger) side. Similar story.  The more I look at that rear sill/x-member, the more I think I may replace it. It's no longer square or straight and I think it may have had a tough life (considering its location, I'm not surprised). However, up where the bed planks lay, it's in pretty nice shape.  The intermediate x-members are no different (going back to front).    And finally, the bed front which, no surprise, shows the most corrosion (very little, all things considered).  Here's the bed side now removed (in front of the other bed side).  And, the current state of the truck itself.  I cannot believe how easily the hardware comes off. I'm missing a nut or lock washer here and there but most everything is still there and still usable. Although, I think the blocks that go between the under-bed cross members and the frame might be 'after-market' as they have irregular shapes. But, I'll figure that out when they're removed.

Dave A

'80 F-150 '11 Ranger '17 Expedition |

|

it looks like the worst is behind you. so much easier to repair and clean up individual pieces. those rear crossmember ends look repaired already, not well but you can probably save them.

|

Bullnose Enthusiasts Forum

›

Projects

|

1 view|%1 views

| Edit this page |