Clocking A 3G? Help!

|

Administrator

|

I'm trying to re-clock the 3G alternator on Big Blue, and I need HELP!

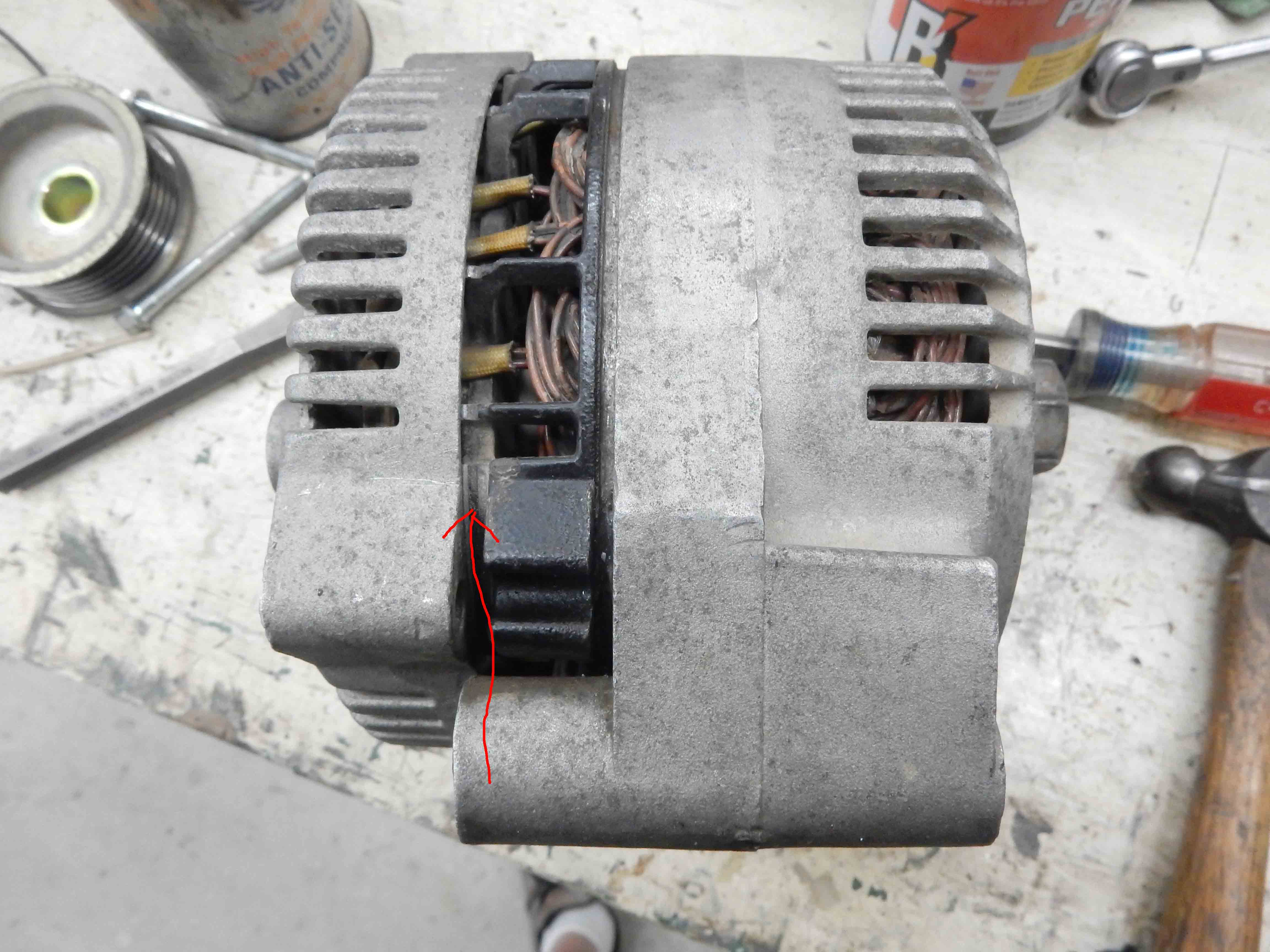

Our page on the 3G points to Steve83's page, which says: Various applications will have the rear case clocked differently, so if your wiring doesn't reach, FIRST loosen the front nut and take the pulley off. Then remove the 3 case bolts, flip it, lift the front case while pushing the shaft into the rear case slightly, rotate the front, set it down, and reassemble itI take that to mean the front case needs to come up off the windings, as shown by the red arrow in the pic below. Right? I'm not getting the case to come up more than about the 3/16" shown, and it doesn't want to rotate. What am I doing wrong?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

What's going on ?!?

Looks so easy for this guy:

Jeff / 1984 F350 Crew Cab 4x4/5.8L w351 4V/ T18/ D50 4.10 front/ 8' bed.

Restored 2019-2022. Nicknamed «Big Brother 1984», due to its soooo-looong shape & nod to George Orwell's 1984 famous novel. |

|

Administrator

|

Yes, it sure looks easy - for him. But my case isn't wanting to separate from the windings.

I put just a bit of penetrating oil on the winding/case joint and I'm hoping that will let the two part ways.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

Gary, it is hard to tell from your picture, but the stator windings have to stay with the side the diodes. I have run into ones with enough corrosion that the steel doesn't want to leave the aluminum.

I have seen the laminations start to seperate where the case went over them. Maybe a heat gun on the aluminum case while applying pressure might help as aluminum expands at roughly twice the rate of iron.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Yes, I'm keeping the windings with the diodes in the back half of the alternator. But even with heat there is one spot where the steel isn't letting go of the aluminum. I've pried, heated, lubricated, tapped on it, etc and it doesn't want to let go. I even put the screws back in and pulled it all together again and then tried to pull the front half up, but it goes so far and stops.

I put a bit more penetrating oil on it and will let it sit overnight. Perhaps that will persuade it, but if not I may just leave it clocked the way it is.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Loosen the three bolts, spray it with PB Blaster and smack it hard on the side with a dead blow hammer.

Just like a pitman arm. Be careful WHERE you hit it, so you don't mangle the casting.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I'll give that a try, Jim. Thanks.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

If you want a less drastic approach you can try tapping your way around. (Me? YOLO!

) )

Just don't ever completely undo the bolts or you're gonna have to pull the brush holder and pin them back, in order to get it together. There should be plenty of room to turn the halves.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

my oldest friend loves to fix things with hammers. you sound a lot like him. he laughs that I have rubber hammers. I probably own fifty hammers from oz to lbs. and three are rubber mallets. we hit stuff here!

|

|

Administrator

|

I have dozens of hammers from tiny chasing hammers for engraving to a #24 beast of a rock splitting maul!

(more than a few rubber mallets and dead blows)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I had a 20 lb. sledge, but I only used it as a novelty door stop. I gave it to my sil when i moved here.

|

|

Administrator

|

I bet he has big shoulders and a strong back!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Gary Lewis

If I remember correctly, you’re trying to clock the wrong half. The casing that has the mounting ears is the half that rotates. And yes, they can be quite a challenge. Imagine how it was mounted, and the bottom of the circle is where condensation will collect and form rust. That’s going to be the problem area although the entire windings assembly is a very tight fit, even when new. Took me 3-4 days of Seafoam Deep Creep and a little tap tap every time I walked by.

Kurt K

'85 XLT Lariat, ‘95 4.9L, Sniper 2300 on an Offy C, ‘97 4R70W w/ Quick 4, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

|

Administrator

|

Thanks, Kurt. I am trying to turn the casing with the mounting ears, but you are exactly right - the point in the casing that is down when mounted is where it is binding. I'd not thought about that being where the water gathers, but it makes sense.

So I'll do as you did - hit it again with PB Blaster and a deadblow hammer each time I walk by and eventually it'll come loose. Thanks!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Patience is a virtue!

And maybe try a very small metal hammer to “tap” with. Metal to metal will transfer better shock waves than rubber to metal. Very light taps over however many days it takes. It’ll come loose.

Kurt K

'85 XLT Lariat, ‘95 4.9L, Sniper 2300 on an Offy C, ‘97 4R70W w/ Quick 4, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

|

Administrator

|

My father was wont to say "Patience is my one long suit" with a wry smile that meant "I know that's not true". I can't say that he passed much patience on to me, maybe 'cause he didn't have much to spare after I came along. But I have a can of PB Blaster and a small ball pein hammer and I'll give the thing a squirt and a whack each time I pass by.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

My father had a cartoon on the wall of his workshop with two buzzards sitting on a branch.

One buzzard was turned to the other saying "Patience my a**, I'm gonna kill something!" I wish I had it today! ❤️

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I re-read your opening post and it confuses me when you ask about the 3/16” and the red arrow. You don’t want, nor need, separation there. You want to separate the casing on the right from the black center section. The black winding portion stays with the back casing. The front casing has a bearing that is held in by a retainer w/ 3 screws which you can’t get to until the case has been pulled off of the armature, so the armature needs to slide out of the inner race of that bearing in order to get the case to separate from the winnings. This is an additional point of friction that is adding to the friction of potential rust within the front case.

Sounds confusing, I’ll try to post a pic. of a disassembled 3G

Kurt K

'85 XLT Lariat, ‘95 4.9L, Sniper 2300 on an Offy C, ‘97 4R70W w/ Quick 4, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

|

Also, I’d go ahead and remove the regulator now so that you don’t screw up the brushes should the back bearing be the one that frees up before the front bearing.

Kurt K

'85 XLT Lariat, ‘95 4.9L, Sniper 2300 on an Offy C, ‘97 4R70W w/ Quick 4, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

|

Administrator

|

Just pull the pulley and whack the shaft.

It will push the rear bearing into the back case and separate the halves as far as the bolts allow

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

| Edit this page |