Big Blue's Transformation

|

Administrator

|

Sorry for being pedantic.

It's part of this whole autism thing.  And just minutes ago I was questioning myself, thinking 'maybe this is like the zinc chromate primers of old'.... that would be a coating. So, I wasn't doubting you. Just trying to get a better understanding of what kind of process you would use under PC, and how it would hold up in the oven without off gassing.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I didn't take it as pedantic at all. More informative. In fact, I've recently re-read the guidance on phosphate coatings due to our conversations. I've not found any mention of out-gassing problems with powder coating an iron phosphate surface, but I was concerned about that as well.

When I first started powder coating I phosphated everything. But later learned that a media-blasted surface provides adequate tooth for adhesion w/o phosphating, so have switched to that for most things. However, phosphating does provides an even better surface texture and also gives some additional corrosion protection, so it would be a good choice for brake calipers.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Oh, and the process will be to spray the chemical on the calipers and keep them wet for at least 20 minutes. I've tried heating the part before spraying it, but that usually creates a layer that has to be washed off, so just keeping it wet works well.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

Thanks Gary.

I didn't think FePO4 would off gas, but I did think something like the ZnCr primer would, and would probably get soft at elevated temperatures. This is why I asked. Thanks for sharing your powder coating knowledge and experience as well.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I'm not sure "experience" is the same as "knowledge". I've PC'd hundreds, if not thousands, of parts. But to say I have knowledge might be a stretch. However, I've had some serious failures and those have been the times when I've learned more than on the successes. Here are some of those failures:

Lack of grease removal: My original thinking was that media-blasting would remove grease, so I blasted dirty parts. But all that did was to contaminate the media and embed dirt and grease in the part. Then, when in the oven, the grease turns liquid and runs out of the pores and seriously messes up the powder. The only thing that works for me is to make the part CLEAN before blasting, then rinse it with brake cleaner after blasting.Out-gassing: Aluminum is bad about harboring crud on the surface. Whether that's in pores or cracks or whatever, it is there and unless it is removed when the part gets up to temp it'll out-gas and blow the powder off. So aluminum parts have to be brought up to temp, ~400 degrees, and held there for at least 20 minutes to burn off the crud. I have an air cleaner cover that has fish eyes all over it.2nd Coat: Many of the powders are supposed to have a 2nd coat on them to protect them, like primers and metallic powders. But since powder is applied via electrostatic attraction and the 1st coat insulates the part, getting a second coat on is difficult. However, if you put the 2nd coat on when the part is hot, like when you pull the part from the oven on the 1st pass, the powder will stick to the hot part very well. But, it is then very easy to get too much powder.Orientation: If the part has cavities that can hold powder you might want to orient the cavities down when applying the powder. Ask Brandon/Bruno2 what his timing cover looked like.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

I mentioned both. Not trying to say one = the other.

You have, and share, both Kind of reminds me of the epoxy encapsulation learning process. A) Always coat at the end of the day (as solar heating is tapering off) B) Do not use a 'fast' hardener that creates a lot of exotherm. C) Keep coating thickness to a minimum. Not only to limit heating, but to more easily allow bubbles to burst through. Air in the pores of wood will expand and make the epoxy a froth in really bad cases. Another workaround is to wrap your workpiece in an electric blanket and get it really warm before application. That not only lowers the viscosity of the epoxy as it's applied, but tends to draw it in as the wood cools.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Jim - What were you epoxy coating? Looks like a learning process.

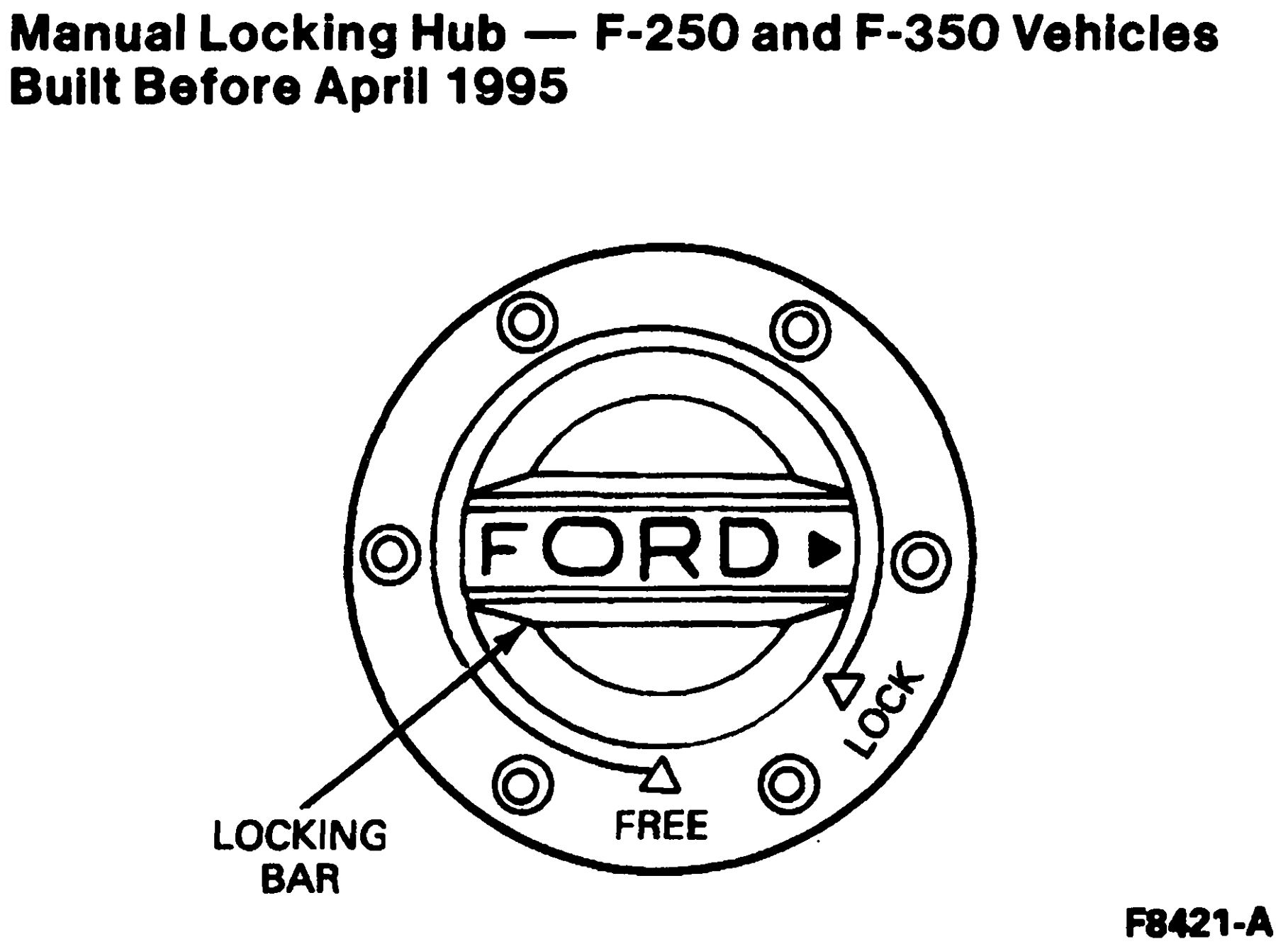

All - I think I've figured out what the deal is with the locking hubs. I bought the 1995 factory shop manual so I'd have the illustrations, torque values, etc as I'm re-installing things. And, in doing so I ran across these two illustrations that 'splain what the deal is with the hubs. Looks like I "lucked out" as I have the later ones.  Notice that the early hubs have 6 screws and the later hubs, like mine, have 3 screws. And the early hubs have a 7/8 turn engagement where the later hubs have 1/3 turn engagement. And the latter has me a bit concerned as just turning the lockout dials with the hubs off is tough to do, much less with them installed. I've sprayed silicone on one of them and it didn't help. Perhaps if I pull it apart, clean and lube it it'll get better.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

Lots of things Gary.

Boats -13' kayak to a 36' sloop. Bent laminations - bows, skis, snowshoes, fishing nets. Exterior architecture - like column caps and fenestration (palladian & arch window casings, jambs, muntins and mullions) Pretty much any time you need natures composite material (wood) to be completely water and rot proof. * stupid auto correct *

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Big Blue's Transformation

|

In reply to this post by Gary Lewis

Did Warn make the factory manual hubs? I've always thought they look much the same, and I think Warn made a design change in their "standard" hub at some point. That might have coincided with the March 1995 change at Ford. I know that currently the Warn Premium hubs take almost one full turn to move from "lock" to "free" (or the other way) and there's no real spring bias trying to move the dial to any particular position. On the other hand, currently the Warn Standard hub takes about 1/4 turn from "lock" to "free", and there is a spring that tries to hold it in the "lock" position, with a detent holding it in the "free" position. If you move the dial just barely out of that detent it will snap to the "lock" position if you let go of it. I had a set of Warn Standard hubs on my current F-250 for a month or two. One of them kept locking itself. Apparently the detent was too weak (or the spring too strong) but it was not at all uncommon for me to find it in the "lock" position when I had unlocked it a day or three earlier. I was able to return them to the vendor I had bought them from and get Warn Premiums in their place. No trouble since with the hubs moving on their own. I say that I think Warn changed their design because I have it in my head that their Standard hubs used to have the almost 1 full turn with no spring or detent. But saying that, I don't know why I think that. I've never owned any Warn Standards other than that one set. So it could just have been a bad assumption on my part. But anyway, that's definitely a difference between the Warn Standard and Premium hubs now (or at least about 5 years ago when I was going through that on my F-250) Oh, and generally you are not supposed to put grease on manual hubs. Over-lubing them seems to generally cause more problems than under-lubing. So if you do clean and re-lube them, keep the lube on the light side.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

Maybe something like the Teflon dry lube from PB Blaster would remove stiction without turning dust into the clay like lapping compound that causes these hubs to seize?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Nothing Special

I agree. Some folks don’t like the Auto Hubs, I’ve been told “they’re not going to work when it’s cold.” If you put too much grease in there they will be troublesome. The FSM for my Bronco says to soak them in ATF and let them drip. I did that and have had no problems.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

In reply to this post by ArdWrknTrk

Bob - I think that if I want to go with the earlier lockouts I'll have to change everything, meaning the hubs. But there's something I read that said the later style hub, with the rounded hex lock nut, requires a different lockout. Hmmm....

Jim - Dry Teflon might be the way to go. I'm catching an hour here and an hour there while the grandtwins are here, but I might get one of the lockouts cleaned and lubed in a day or two to see if it'll rotate easily. I think I have some Teflon lube for bicycle chains that flows in and then dries, leaving the Teflon, so I'll try it. All - Speaking of catching time when I can, I've been thinking about the switches on the dash. The OX locker comes with a lighted switch, and I'll also want switches for the air compressor, battery parallel, fast idle for winching, etc. And in order to have a place to put them I asked David if he could find me an F600 radio bezel since those came with the switch positions. However, I've never seen one with more then two positions, so would need to graft others in. But, he came up with what I think is "the" answer - Dennis Carpenter has a repop F600 bezel, as shown below, for $60.  Assuming that it is very similar to the Bullnose bezels there's ~8 1/2" side-to-side and 2 1/4" up/down for the switches. And, it has a continuous slot of maybe 1" into which I can put a readout from the Arduino to give info on battery voltage, air pressure, driving lights, camping lights, etc. So that got me to thinking about what switches to use, and I asked the guy at OX what theirs is. He said it is a Carling. Below the OX switch is shown on the left and what I think is the right Carling is on the right, and it is a V1D1B60B-ARC00-000 Contura II. But they have many different lenses for them, including one that shows a light. The dimensions are 1.950" vertical and .940" wide, so I think that six will fit easily. In fact, seven should fit and eight might fit. So once I get the D60 back from Boom's Garage I'll have one of those switches and can play with how/if that switch would fit on a Bullnose bezel. But, if someone has an F600 bezel and can measure things for me that would really help. Thoughts?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by grumpin

Hmmm

I didn't realize it was a viscosity issue that caused the hub lockouts to seize up. Mine always had a lot of crud packed between dial and ring. I don't think switching to a fluid over grease would change that. If it happens because of cold perhaps '00' corn picker grease like I use in the snowblower would work? Gary, I use that TDL on the rack and worm of my tablesaws. (height and tilt adjustment) You can't imagine a more dusty environment than up inside the cabinet of one of those.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

I can’t speak on seizing up. But as Nothing Special said light grease. The FSM also mentions an Automatic Hub Lock Grease for the brake band and drag sleeve. E1TZ-19590-A. I would imagine lightly coating everything with that should be good.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

Re: Big Blue's Transformation

|

In reply to this post by Gary Lewis

Automatic hubs require different spindle nuts than manual hubs (or at least, than most manual hubs). The auto hubs need to have a "ground," somehing that doesn't turn with either the axle or the wheel hub. The spindle nut is the closest thing to the auto hub that isn't moving, so they used that. But the spindle nuts for auto hubs gets in the way of (at least most) manual hubs. So if you have the auto hub spindle nuts you need to replace them with standard spindle nuts to put (at least most) manual hubs on. Warn sells a "conversion kit" to do this, but it's just normal Spicer spindle nuts on a piece of cardboard that has a big red "W" on it. You can go to your favorite auto parts store and get the same things cheaper. And I keep saying "at least most" manual hubs. As far as I know, all manual hubs work with the standard spindle nuts and none work with the special ones required for auto hubs. Which would mean if you took any manual hub off you could put any other manual hub on. However, I wouldn't put it past Ford to get a special manual hub that can be used with the automatic hub spindle nuts so they don't have to stock two different types of spindle nuts. If that's what they did you would need the normal spindle nuts to put any other manual hubs on it. Still, Ford doesn't generally seem like the kind of company to use a slightly more expensive part when they could use a cheaper one, even if that would mean stocking fewer parts. And I also don't think they make their own hubs, so that's another reason I think their manual hubs would require the same spindle nuts as all the others. So while I can't say for sure, my bet is that any manual hubs will work on that axle with the spindle nuts you have.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

First, I think I've confused things. I have no idea if the hubs themselves work. What I'm having trouble turning are the knobs in the caps. They are not terribly dirty, and one's been lubed with silicone spray, and yet both of them are just about all I want to turn when they are off the axle in my hands. I'll clean them, hopefully soon, and then lube them to see if they can be made to turn reasonably easily.

Ok, and now for the puzzler. I got the '95 FSM and have looked at the illustrations therein, and mine doesn't match any of them. I've put the illustrations below, but mine matches the one from Torque King 4x4 in the lower right. And in it I have parts 13 & 14. So I'm quite confused. Bob - You said: However, I wouldn't put it past Ford to get a special manual hub that can be used with the automatic hub spindle nuts so they don't have to stock two different types of spindle nuts. If that's what they did you would need the normal spindle nuts to put any other manual hubs on it.I think you are right - I think these manual caps & hubs work with the rounded-hex nut, but I won't know that for sure for some time. However, the hubs themselves have six screw positions, so in theory I could go for the earlier caps that use six screws. And, if the hubs work properly with the rounded-hex nut and the existing caps then why wouldn't they work with the rounded-hex nuts and six-screw caps? All the cap does is push the hub in, right?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I have the six screw lockouts on mine, so maybe tomorrow if it isn't pouring I'll pull them off and see what I have inside the hub since it's obviously been converted at some point to Warn standards.

|

|

Administrator

|

Thanks! Your axle is a '90?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by ArdWrknTrk

AFAIK, Warn has always made all factory hub locks for all 3 US makes (actually for Dana, which sells axles to all 3 US makers). The guts of the locks need airspace so the mechanisms can move. Filling them with grease effectively hydraulics (hydrolocks) them; manual OR auto. Mine work fine in all weather. I'm more-familiar with 1/2-ton axles, but I don't think Dana designed a different hub based on what type of lock goes in. I wouldn't use it inside the lock. Maybe outside the cap, under the knob. I think it can be very confusing have 7~8 identical switches in a row. Especially if you need to hit THE RIGHT one quickly; either in the dark, or when you can't take your eyes off where you're going. That's why I used several very-different switches on my dash - it's impossible to confuse them (even though I still haven't labelled them).  That space is designed to be dry, so rain can keep it clean. I'd disassemble the plastic knob from the metal cap, clean & polish both, and see how it works without lube. Dana makes the hubs; Warn makes the locks. |

|

Administrator

|

I have Warn premiums now, and while they are stiff they don't seize up and they don't lock themselves on the passenger side like the plastic ones were doing.

It got to the point that I seriously considered someone was pranking me.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

| Edit this page |