3-D printer Fog light bezel has been made and shipped!

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

My father was director of engineering for a number of acrylic companies (Polycast, Ever Kleer (?), and Cast Optics)

Acrylic has good hardness and takes a good polish. (can be solvent, flame, or mechanical polish) It is also brittle, subject to notch sensitivity, UV, ozone and chemical attack.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

In reply to this post by ArdWrknTrk

No, the letters are not distinct from each other. I could put spaces between the letters, but then the overall string would be too long unless I scrunch it up some.

As for sanding and polishing, how 'bout I try to sand it on sandpaper held on a hard surface, and then put the whole thing in my vibrating polisher? The only issue is what media to put in the polisher. Thoughts?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

I guess the question is how aggressive a media, and what size?

How do you feel about the background texture? How 'soft' a corner do you want on the letters and border? I use carbide paper on my surface plate for sharpening chisels and plane blades but for cleaning a surface (where I don't want razor sharp edges) I will put down one of those sheets of orange gasket rubber you can find in the plumbing supply. It seems to have just enough give that I don't cut myself.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

In reply to this post by ArdWrknTrk

What is notch sensitivity? Does that mean it is easily broken at a notch? Concentration of forces?

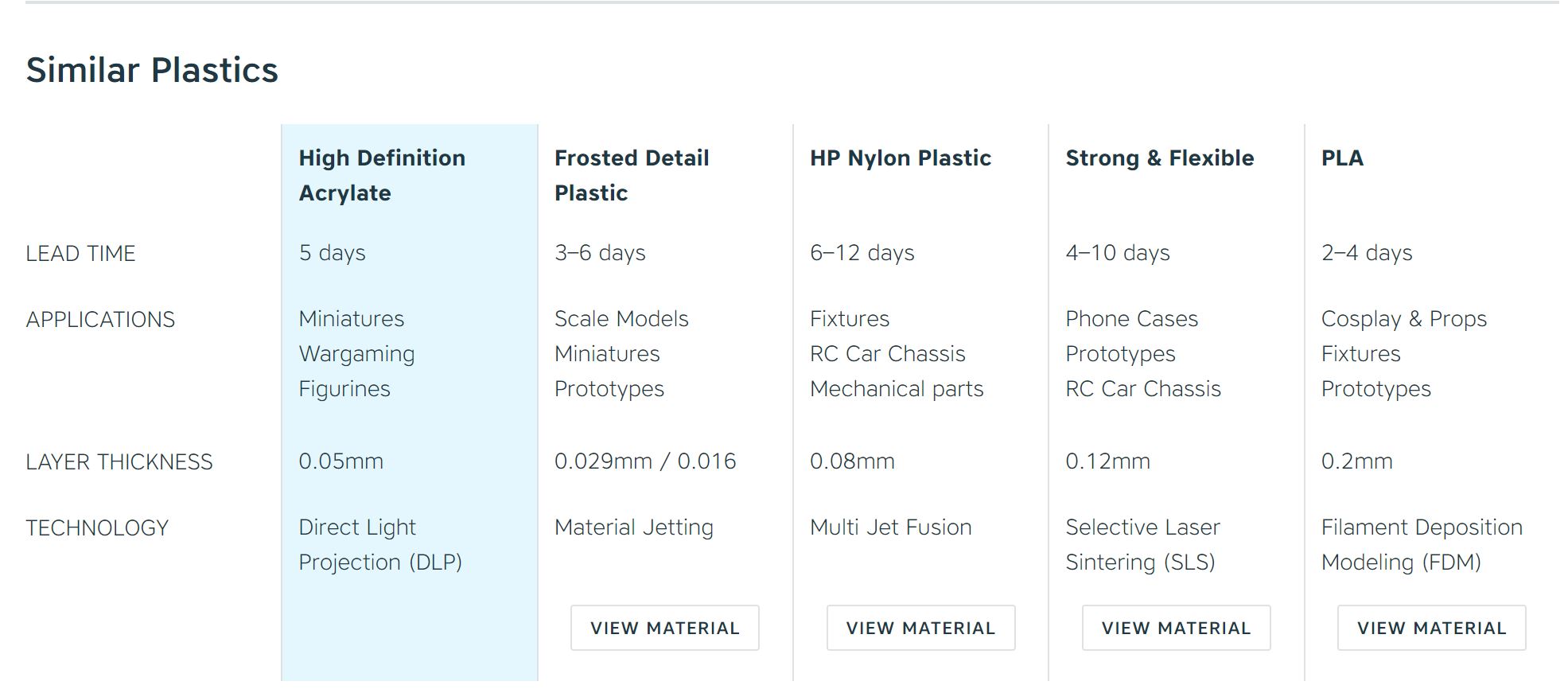

There's a discussion of how the acrylate parts are made here. And one statement looks encouraging: High Definition Acrylate is made of a photo-reactive resin. It is printed using Direct Light Projection (DLP) technology which provides excellent resolution and accuracy. It is capable of fine details and is therefore ideal for miniatures and models trains. Additionally, the DLP process produces a smooth surface, making it well suited for painting. The material is heat resistant up to 120°C and is printed at 50 micron layer thickness.

Further, here's a comparison of plastic materials, and the one I used was Strong & Flexible:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

In reply to this post by ArdWrknTrk

For the polisher I only have the plastic pyramids, which are much too large and aggressive, and a nut hull media with polishing compound embedded. I'm afraid the polishing compound would embed in the plastic and be impossible to wash or scrub out.

I wonder about using walnut hulls from the blast cabinet? Or, glass bead?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

In reply to this post by Gary Lewis

If acrylic is scratched or exposed to some chemicals (like anerobic thread lockers) these tiny fissures are places for cracks to start.

And acrylic does like to crack!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Gary Lewis

By their own definitions and descriptions it would seem that the high definition acrylate would be the highest resolution material and give the best resolution on the lettering. Plus acetone smoothing would at least be an option. It also sounds to be the most fragile choice, but this bezel is cosmetic and does not need strength except to hold itself on by the mounting posts. I would think it would be worth trying to see if the overall resolution and surface detail is cleaner or if it would at least clean up easier/nicer...

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

In reply to this post by Gary Lewis

Yeah, I would stay away from media with compound mixed in.

If you just want to burnish it maybe BB's or steel shot would be an inexpensive solution

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

This post was updated on .

In reply to this post by ArdWrknTrk

Actually the Shapways lettering is Horrible.

The letters seemed to "melt together" and the lettering from the one I got was "altered" to get them to resolve...

1986 F-150 Flareside 4x4, 351, 4-v, ZF5 speed. AC, Cruise, Tilt, Slider, Digital clock, Radio, Lariat seat, Pwr doors/locks

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

You're going to come back and paint the silver right? Polishing isn't needed. You only need to sand with some 600 wet, on a flat surface like glass, then paint the surfaces that your smoothed. If you find the surfaces too flat after sanding, then a buffer will soften the edges. Some white or blue buffing compound on a pedestal buffer would do it.

Pete's Ponies

Mustang RUSToration & Performance 1982 F100 Flareside 1983 Bronco |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

In reply to this post by reamer

I did some sanding using 600 on a glass plate. Didn't take too long to get down to the letters, and as you can see below they cleaned up a bit. But, as Ron points out, they aren't nearly as crisp as those on his printed version nor on his original.

Here's his pic with the original and his printed version. Note the crisp lettering in both cases:  Now here's my Shapeways #1 with some sanding. Note that the letters run together - although they appear to be in the correct places. I think the running-together is a result of Shapeways tweaking the lettering. So, maybe with some help from Shapeways?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

I'd be tempted to just pull a mold off the NOS one and cast them rather than trying to have one created from scratch.

3D printing is great for realizing imagined things. (Prototyping or one offs) But if you have an object *already* and want to make a few more just like it.... The studs on the back are perfect sprues and the cost of those materials is trivial compared to design time, production, shipping, etc.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

Where would be the fun in that?

Actually, that might be a good way to do it. But, I'm well into this so want to keep going. It is my first 3D printing project, at least the first that I've printed, and I'd like to see it work out. Having said that, the one that I have is usable, and might find its way onto Big Blue. No, it isn't "right", but tucked up under the steering wheel it will be hard to see that it isn't.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

I have made several items for cars by molding. I even sold a few. Making a mold is fun, at least when they turn out right :)

Pete's Ponies

Mustang RUSToration & Performance 1982 F100 Flareside 1983 Bronco |

|

Administrator

|

In reply to this post by Gary Lewis

I am a little confused about what is going on here... Gary and Ron, you each created a shape file and had it printed by the same company (shapeways) is that correct? Did you both choose the same material? Gary's is definitely more like the original but Ron's came out much cleaner and crisper and appears to have less of a texture problem. The letters running together is going to make it very hard with painting the faces. I think if you revise the file it would be worth separating them even if it is at the sacrifice of size/space accuracy. As much as I like the correctness I don't think your eye would see it unless side by side with the original.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

Yes, and no. I created the .stl file and Ron submitted it to one place for printing and I submitted it to Shapeways. Both companies had problems with the letters, and took different approaches to resolving the problems. Shapeways made the letters thicker, and Ron's company did something else - which resulted in crisper letters but in different places.

Mine was printed via "selective laser sintering nylon powder layer by layer." But there are 59 other materials, each with their own production method, to choose from. And, each has differing tolerances for things like the letters - which they call extrusions. I'm not sure what material or process Ron's was printed with, but it is smoother and the letters much more crisp. So, I'm planning to contact Shapeways to see if they can help me figure out how to do the same.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

The acrylic would be a much better material to deal with your problems.

Even given its shortcomings in this application..... Interesting to read that Shapeways does this with visible light and then does some post process curing with UV. Looking at the Formlabs printer you can draw some conclusions about what wavelengths affect their resins.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

I just sent this to Shapeways:

First, let me say that this isn't a complaint. This was my very first 3D print and I'm stoked. But, I think the results can be better with your help.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Well explained Gary, and a good test of Shapeways customer service. I did not realize that there were so many options for materials and processes.

Do you think the UV part is a big issue? I imagined the part being painted before use. Is it just me or is Ron's example much smaller than the original? Did yours come out the correct size? This is exciting stuff, and I hope Shapeways can help improve on it.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: 3-D printer Fog light bezel has been made and shipped!

|

Administrator

|

Ron said his printed part is the same size as his NOS one. And mine was an absolutely perfect fit in the holes in the instrument bezel, so I know it is the correct size - or at least the studs are in the right places.

But I don't think the UV is an issue, so suspect we will go acrylic. And, while I was hoping to use the piece w/o painting the black part, that could easily be done. Speaking of painting, is there any way you can think to easily dip the part in a tray of silver to paint the bead evenly, and then put it down on something with the white paint to get the tops of the letters? And, this is exciting. I think it is way cool to draw something up on the computer and have it come to you in the mail. The only thing that would be better would be to have your own printer, and I'm not yet ready for that. However, Bill has one, so.......

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |