1981 Ford F100 Revival (Parked for 12 years)

|

not exactly. when you see a pinhole, you think " I can tack that" then you hit it and it becomes a 3/8" gap. this happens often because as usual these rust from the inside out. poor sealing from the factory due to the inability to paint well on the inside. there is barely anything in there. that said, when you see a pin hole its most likely a dime sized on the inside. its best to cut out an area larger enough to assess the steel. Then make a small metal patch slightly smaller and hold it in place with a magnet or two. then tack it in place. do this slowly while tacking against the last tack building as you go but moving around to allow the steel to draw out the heat and not just creating one super-hot spot. too much heat will cause warpage. be patient! I cannot emphasize that enough. sheet metal welding is much more challenging than heavier stock.

the one I consider a repair as an example, is fairly perforated at the bottom. it required a section or two to be cut out and reconstructed. it will be nice when I'm done but it is taking a lot more work. one minor plus is that by cutting out a larger window I can spray a much better coat of "weld through" primer inside and on the filler, piece too then weld it in. I know may will just say get a new one but good parts are not cheap and cheap parts are not good. on another personal note. I love these trucks! restoring an all American truck with cheap imported parts just feels wrong. when I'm standing beside something I built, i want to be as proud as forrest gump on his wedding day

|

|

Thanks for the tips and detailed description. Where do you usually purchase the sheet metal from and do you replace with thicker sheet metal then was there originally or use the same gauge?

I am with you on restoring the original parts if possible. It makes the truck more original and special then a half Chinese made truck. I would like to form a patch for the passenger side fender to replace the rotted out lower corner. The challenge is it is curved and I never did sheet metal work or forming before. But I guess what a better time to learn?

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

if you are referring to the lower area in front of the front wheel then there is nothing but curves. however, the smaller of a patch that you can get by with, the easier it is to form. there will be fewer compound angles to make. sometimes it's even worth it to get a damaged fender in a junk yard to cut patches from if you can.

all that's really necessary is that the metal that you need is good. who cares if there is a dent or rust in an area that you don't need? the real benefit is that you know it's good steel and the same gauge. make clean cuts. you really want a little gap to fill when seaming them together. don't try to make them too tight before welding. there should be a hairline gap to fill as you stitch them together |

|

Thanks for getting back to me with further details. I will try to source a original fender from the salvage yard to use.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

If I found a truck at the salvage yard with speed control what items do I need to remove from the truck to get it working in my truck? My list so far is the steering wheel pad and speed control servo.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

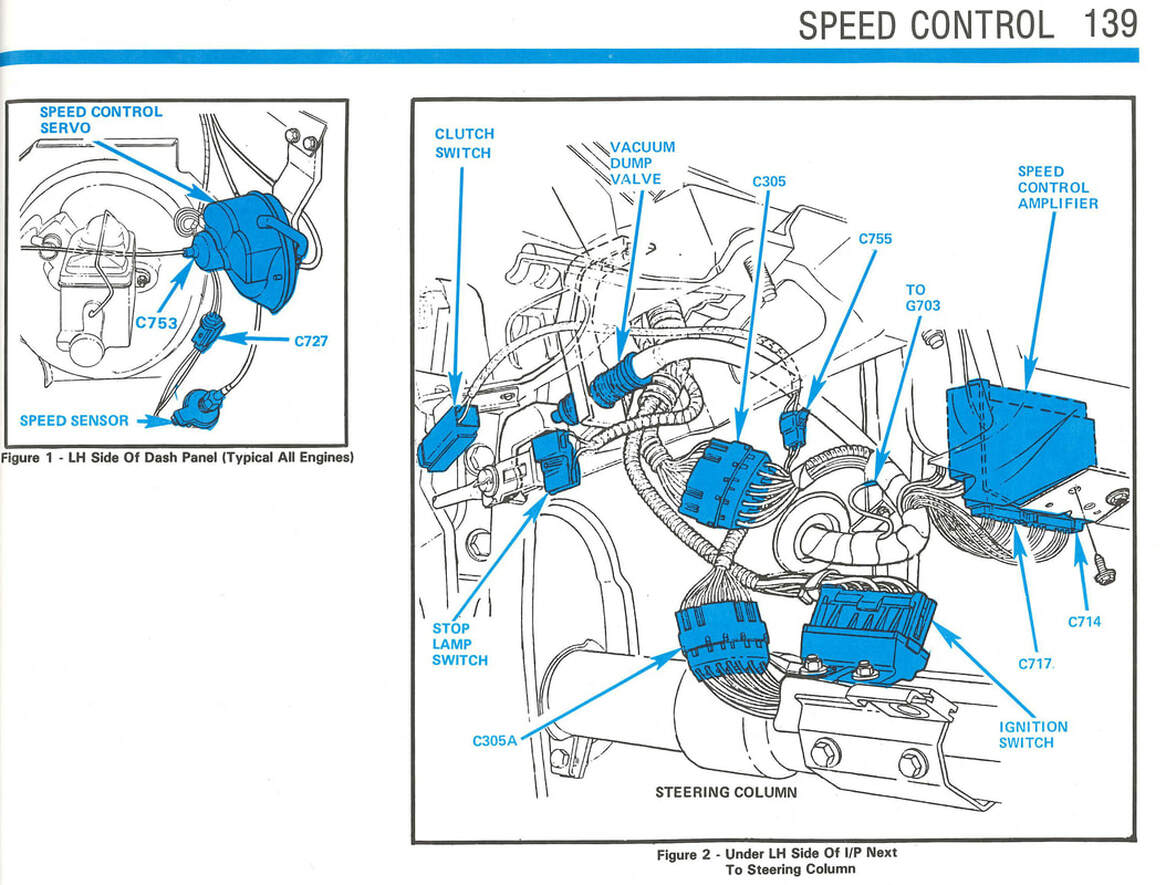

You also need the amplifier that is under the dash left of the ash tray as well as the wiring. And the wiring includes an add-on jumper that connects to the curved connectors on the steering column. Plus you need the horn relay that is on the bracket for the amplifier, the vacuum dump valve, the clutch switch, and the speed sensor.

You can see most of that stuff in this page from the 1985 EVTM:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Thank you for your help Gary. Is the wiring I need with the vacuum hose going through the firewall? Do I just pull out that whole thing going through the firewall with the wiring attached? Is only the hose going through the firewall or is there wiring connected in the engine bay also? I can't tell for sure looking at the picture.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I think there's wiring taped to the hose, and both go through the grommet. So you should be able to push the grommet through the firewall and get everything in one go.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Will these parts be universal among all the Ford truck makes from 80-86 including the Bronco?

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

All of the parts are universal save for the bracket. The servo was mounted in different positions depending on the engine. Go to Documentation/Electrical/Speed Control and then the Instructions tab to see the factory shop manual section that will probably answer your questions.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Jonathan

As you identify parts, we'll try to see if some of those are on my truck. We'll work that out if you can use them.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

Thanks Randy, I will try to acquire the most I can from the salvage yards and other sources first. I will let you know if there is something I can't find if you are not using speed control. There is no rush for this since I am still working on so many other things on the truck.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

In reply to this post by Gary Lewis

Thanks Gary, I will check the documentation out.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

i too have many of these parts on hand. im in the middle of moving my shop and am realizing how many "bits" i have squirreled away. no clue as to what box holds what just yet and as i restock the shelves i "should be far better organized. i will see as i go if there is a part that you need.

|

|

Thanks Mat, let me know what you happen to find.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

Cleaning the engine bay damaged the very thin paint on the brake vacuum booster. It was also starting to rust in some spots. So I pulled it off to paint. While I am at it I am going to repaint that part of the firewall and I want to fix or replace the steering shaft firewall boot. Does anyone know a part number I can search to find this? I can't find it remanufactured anywhere. Also looking for tips on how to remove the steering shaft so I can get the boot out.

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

I don't know if you can find one, but that seal is base part number 3513, which you can see on the Illustrations tab on the page at Documentation/Interior/Steering Columns & Steering Wheels.

Then you go to the Part Numbers tab and find the rest of the part number, where you'll find that it is E0TZ 3513-A for all F & U-Series trucks from 1980 through at least 1989. And, by the way, I didn't have that part number in the part numbers list, but added it just for you.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Thanks for your help Gary. I created an eBay search alert for that part number. I will also look in the salvage yard for one better then mine. For now I will remove the steering column and take it out to try and fix it. Do you recall any threads where someone outlined the removal of the steering column?

1981 Ford F100 6 Cylinder 4.9 Litre 1 Barrel

3 Speed C6 Automatic |

|

I can help on the removal. first of all, you took some good pics so keep them handy and maybe take a few more. the "boot" that you are referring to is actually an egg-shaped plate which has a rubber layer molded onto it. the assembly is what you are looking at. it is held in place to the column by a clamp on the inside part. it takes a 1/2(13mm) . but to get to it you certainly need to remove the whole column.

step one. remove battery connections disconnect steering sector under hood disconnect shift down rod from column remove access panel under column at the dash remove plastic column cover between dash and shifter arm being very careful to open it up enough to clear all internals. remove the transmission selector indicator cable. 5/16 screw and then lift the cable off the stud and un clip it from the small white plastic anchor. secure it out of the way .IT IS FRAGILE!!!!!! remove two bolts holding column to dash brace disconnect steering column electric connections both from the crescent shape connector and the main from the ignition switch then remove the five 3/8 hex screws holding the boot/plate to the fire wall and walk the column out and carry it to a bench (many of us consider the tailgate sufficient) |

Re: 1981 Ford F100 Revival (Parked for 12 years)

|

Administrator

|

Jonathan - Welcome, happy to help. As for instructions, Matt's should be what you need. But if you want more go to the Instructions tab at Documentation/Interior, Steering Columns & Wheels. There you will find both the section from the factory service manual as well as a document that Scott wrote up on the column itself.

Matt - Thanks!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |