1980 F350 4X4 C6 Project

|

Sorry, I am not familiar with the term TTY. Can you please define it for me?

Carl

1980 F-350 4X4; 400 C6; Dana 61 rear, Dana 50 TTB front 1984 F-250 4X4; 6.9L T19; Dana 70 rear, Dana 44 TTB front |

|

Administrator

|

TTY means torque to yield. In it you are torquing a bolt to a point where it stretches slightly, and then it should never be reused.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Atlas75

Torque To Yield

A fastener that is plastically deformed upon installation, and therefore one time use. This was never common in 1980, and is pretty rare today except in applications like piston rod and main journal caps. Some head bolts, usually for boosted engines.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Gary Lewis

Technically, you are always stretching a bolt.

That's why measuring length is a better indicator of clamping force than installation torque. But you don't want to permanently distort the bolt (in most cases)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Yes, your reply is more accurate than mine. It is the permanent deformation that is the issue that makes TTY bolts useful only one time.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Since I was tagged in this last night just before I shut everything down for the night, I will insert my $.02.

Torque to yield is a concept that stared appearing in the 80s, one excellent example is the head bolts and main cap bolts used in Chrysler's 2.2 and 2.5L engines. In these the specification calls for a setting torque (I will use 35 ft-lbs) then an angle of rotation, usually 90°. The setting torque is what the engineers decided is the value needed to clamp everything in place, the 90° spec is arrived at based on the number of threads per inch, or on Metric fasteners the thread pitch in millimeters. We had, at work a device that when it was scrapped, I tried to figure out a way it could be scrapped to a business I had a good relationship with. It was called a Raymond Bolt Master and it used an ultrasonic transducer to measure bolt stretch as you tightened the bolt. It was an amazing instrument and the basic system was reasonably portable. The company we bought it through sent a representative in to train us on it. While he was doing this, the subject of head bolt/gasket failure on the GM 5.7L Diesels came up, he owned one and had stuck the transducer on the outboard head bolt between cylinders 5 and 7 (they fire one after the other). Oldsmobile used 10 1/2-13 head bolts, like Ford does on some engines, 351W for one. He said the resulting stress on that bolt, and probably the inner one, pushed and sometimes exceeded the yield strength of the bolts. I had some used ones (GM said use only new on reassembly) and went by the Olds dealer and picked one new one. They were extremely strong, equivalent to FF-S-86 socket head cap screws. Ford 3.8L V6 engines have a special procedure for the non-reusable head bolts, they are torqued and relaxed a couple of times if I remember correctly, then taken up again and turned 90° to finish the job, these are also TTY bolts Danger of TTY, we had an in house manufactured accumulator, that had removable ends and they were held on with a ring of B7 studs. Engineer who had been my supervisor and I were brainstorming why we couldn't keep the O-rings that sealed the ends from blowing out at the pressure needed for a test. I mentioned "what is the load on the ends at XXXX pressure". Jeff Krohto, the engineer (a real good ME) got the light bulb over his head, looked at me and said "Bingo" did a quick calculation, called the technician assembling the accumulator and asked if he had torqued the ends yet, when he was told no, he gave him a much lower torque and there were no more problems after that. Normal, non bolt stretch torque is an interesting subject, it is very sensitive to the lubricant used and is generally arrived at by testing to reach around 80% of yield strength of the fastener. As for stretch measurements, ARP rod bolts for my turbocharged 2.2L Chrysler are tightened to a stretch measurement using a box wrench and a micrometer. When I was assembling it in 2004 my son and a friend of his were watching. When I was tightening the rod bolts his friend asked why I was doing it that way, Matt explained the process and told him, that was one of the reasons race engines cost so much. Sorry for the long involved post, hopefully it will help understand the usage of these type fasteners.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

But do you have any suggestions for replacing the Dana axle flange bolts?

What's up with these things that requires replacement?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

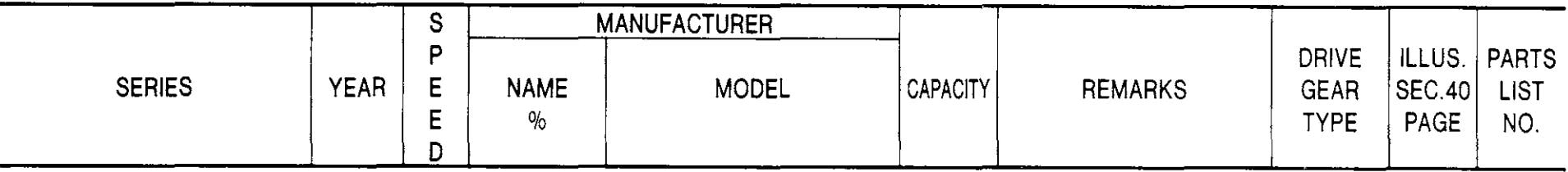

Good question, Jim! But someone please remind me, exactly what axle is this? I ask because, as you can see from the application list, there are several different parts lists.

As for "what's up", I don't know. Didn't think we had anything that needed to be on these trucks.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

It's a Dana 61 semi floating, locking axle.

I can't imagine having to replace 16 bolts any time I pulled the drums off for pads or brake service.  Looks like parts list 218 is correct.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I would have thought parts list 185 or 186.

Carl

1980 F-350 4X4; 400 C6; Dana 61 rear, Dana 50 TTB front 1984 F-250 4X4; 6.9L T19; Dana 70 rear, Dana 44 TTB front |

|

Administrator

|

Is yours a full floating axle, with flush hubs like that?

If so, again my apologies.  I'm not any athority on Dana 61 axles Maybe time to decode that BOM

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Atlas75

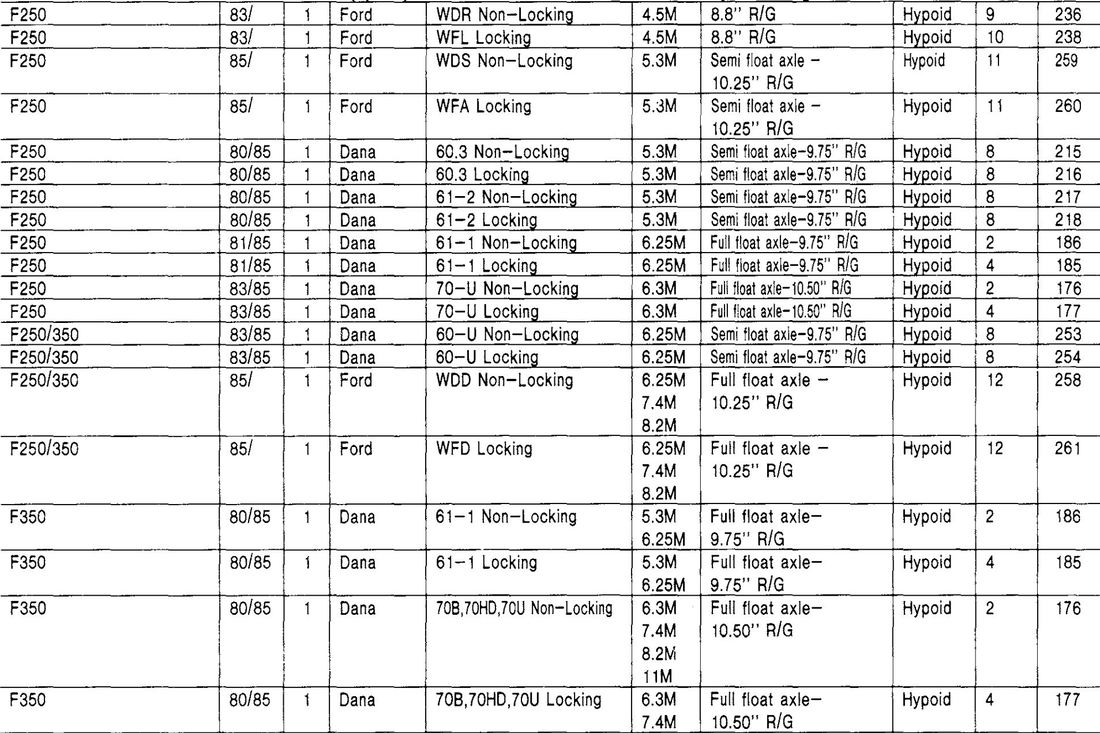

Well, looks like we might need more info. This suggests that there was a change at serial # F10,001. Do we know which it is? It is "after", right? Because it is a bolt and washer.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

You saw the Unbrako head stamp.

It's definitely not a stud and nut. But, even if it were, it could have been retrofitted to the newer standard.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Gary Lewis

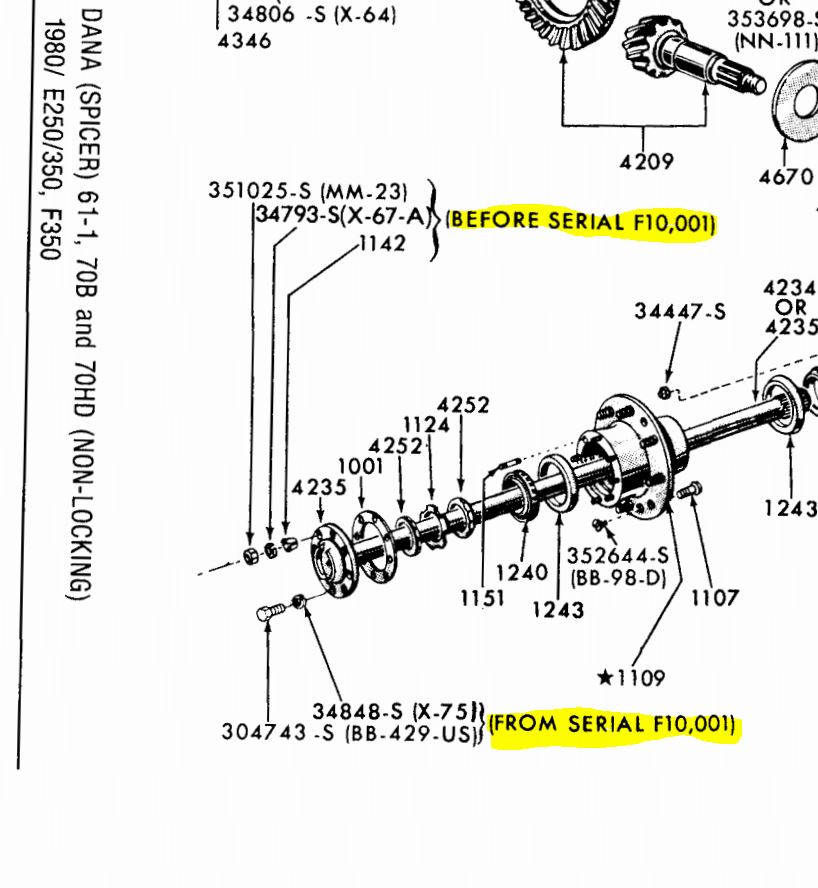

I'm confused?

The snippet above says the bolt is 304743, but there is no mention of that bolt in the whole of the text side of the MPC. Instead, the snippet below of PL # 185 seems to say it is 355765, but it only takes 4 of them. Is that the right part? What is the size of the bolts in question?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

1/2-13 ????

You are highlighting a bolt for the gear carrier in the pumpkin.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Ahh! My bad. So, what size is the bolt? Maybe I can find it via size instead of the number.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

304743-S101 .. Bolt-Hexagon Head - National Coarse Thread 7/16" -14 x 1 3/8" long.

https://www.ebay.com/itm/NOS-FORD-304743-S101-BOLT-LOT-OF-7-NEW-GENUINE-FORD-/362899363995

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by ArdWrknTrk

I think it is full floating. The only places it touches anything are at the splines where it slides into the center section and the hub flange where it bolts to the hub. Nothing else touches it.

Carl

1980 F-350 4X4; 400 C6; Dana 61 rear, Dana 50 TTB front 1984 F-250 4X4; 6.9L T19; Dana 70 rear, Dana 44 TTB front |

|

In reply to this post by Gary Lewis

That drawing is not completely correct to what I have. That drawing shows two nuts and a lock ring in between them. Mine has one nut with a nylon locking ring built into the nut. There is a small metal key that gets driven into the key way and into the nylon portion of the nut to secure it.

Carl

1980 F-350 4X4; 400 C6; Dana 61 rear, Dana 50 TTB front 1984 F-250 4X4; 6.9L T19; Dana 70 rear, Dana 44 TTB front |

|

Administrator

|

In reply to this post by ArdWrknTrk

Good find, Jim. Although 7 of them seems an odd number to sell.

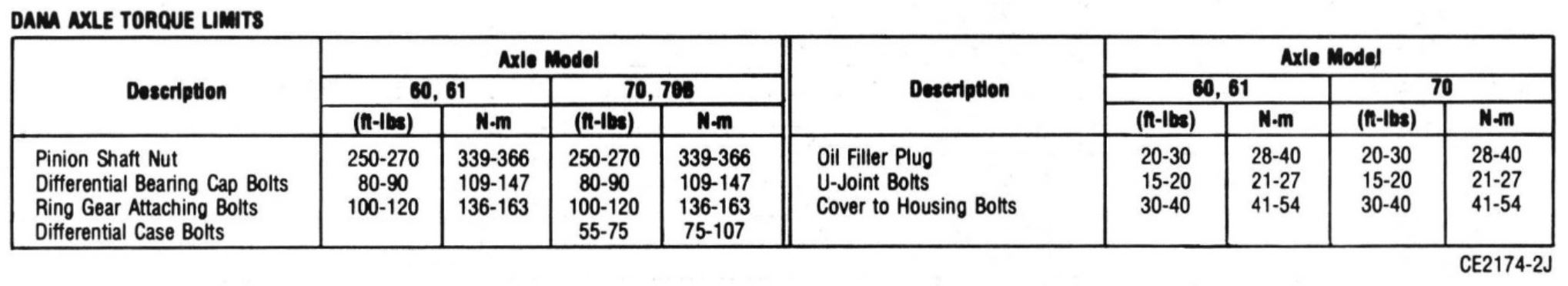

Anyway, I was wondering what the torque spec is on them and found the following in the factory shop manual. But that doesn't list those bolts, unless I'm missing something. However, on line I'm finding that a 7/16-14 G5 would normally be torqued to 50 lb-ft, and a G8 to 70. So, are they torquing them past that?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |