Search Forum

cold start/choke issues? What to look at?

12

12

Inside that tube in the manifold there is actually a heavy gauge steel wool like rod that pops in to help increase the heating area for the air that flows through. You can actually buy these steel wool like rods still NOS off ebay along with the bottom cap that hammers in to seal it up. I actually picked up a NOS box of both the rods and the caps. The box for the rods came 3 to a box, the caps are just 1 to a box.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Rusty_S85

There is your problem. You have a stumble on your 302 because the carburetor is too big. The correct carburetor for your 302 would have been a 287cfm (1.08) Motorcraft 2150.

Lucille: 1985 Ford F150 XLT Lariat

*Colors: Dark Canyon Red exterior, Canyon Red interior *Engine: 5.0, CompCams 31-230-3, "Thumper" E7 heads, Edelbrock Performer intake, Autolite 4100 carburetor, DuraSpark II ignition, Thorley Tri-Y headers, Flowmaster dual exhaust, H-pipe. *Drivetrain: AOD transmission, 3.55 gears, 2wd. |

|

In reply to this post by Rusty_S85

I have seen all these videos with Snipers and got a little excited. Til I saw the price. This truck is for fun. Never be perfect or anykind of show truck or daily driver, even though I like it pretty good. I am a bit envious of you guys that have patience and funding for stuff like that. While we're not poor, I can't justify EFI costs to me or the wife.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

In reply to this post by Rusty_S85

I'll go a looking for the filter material. Thanks. Probably be a couple weeks before I delve deep into this.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

In reply to this post by LARIAT 85

Maybe but its original to the truck and if the stumble was because the carb is too big then wouldnt increasing the accelerator pump shot make the stumble worse? When I increased the shot by going to the outter most hole the stumble improved and wasnt as bad indicating not enough fuel was squirting for that initial tip in.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by rcarlisle

This engine build is 3 years in the making. Its the only way I was able to source the parts I have including the sniper. I just know I am getting anxious now cause I am close to having my truck back on the road after sitting for 3 years. Only reason I went with the sniper on mine is for precision. If I wanted to I could go up into the mountains and have no problem as the sniper would adjust for change in elevation. Carb wont do that youd have to change the jets out to compensate for that. Like wise I dont have a AC step up solenoid on the throttle and being mine is dealer installed it wouldnt work for me as the solenoid would cut off when the clutch cycles then when the AC kicks back in the truck would stall out as the ford step up solenoids are not strong enough to open the throttle you have to touch the throttle to allow it to extend when powered. With the sniper it uses the IAC to change the idle speed if you have it setup for that.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

This post was updated on .

It might be original to your truck when you bought it, but that doesn't change the fact that it isn't the original carburetor Ford designed for it. I promise you that your truck didn't have a "stumble" when it was new. There was much more engineering going on with these Ford carburetors than you might think. Even though your two Motorcraft 2150 2V carburetors may look exactly the same from the outside, almost everything inside of them are going to be different. (That is why they had carburetor tags on them.) The venturi size, booster assemblies, jet sizes, and even basic adjustments are different from vehicle to vehicle. They are different to precisely accommodate the type of vehicle they are used with. Ford took into account vehicle type, vehicle size, vehicle weight, emissions, engine size, engine family, and even transmission type when they engineered their carburetors for each application. You can't just adjust the idle mixture screws (or accelerator pump shot) and think a Motorcraft 2150 that was designed to run on a 1982 Ford LTD with a 351 engine and an AOD transmission is going to run as good on a 1982 Ford F150 with a 302 engine and a C6 automatic. I think that is misleading. While it is true that a carburetor cannot self-adjust for change in elevation, it's not like a carburetor cannot handle it at all. Vehicles with carburetors have been going up and down mountains for many more years than vehicles with fuel injection systems have, and no one was on the side of the road changing out jets. Yes, an electronic fuel injection system is going to be able to self-adjust and therefore be more "precise" than a carburetor when dealing with changes in elevation. But at what cost? The only real reason to replace a carburetor with EFI is for the ability to self-tune. In exchange, you have to spend a lot of money to get a lot of wires, a lot of sensors, and a computer to make that happen. And you better learn to work on your truck yourself, because no one else is going to want to work on a vehicle with an aftermarket fuel injection system on it. The truth is, if you replace your carburetor with an EFI system and you get a big increase in performance or fuel economy, then something was not right with your carburetor. And just to be clear, I would never replace a perfectly good EFI system with a carburetor, either. BOTH systems work great when they are dialed in and functioning correctly. I just don't think you are being very fair to carburetors. Again, I think that is misleading. I have a solepot (combination idle solenoid and dashpot) on my Lucille and it doesn't have that problem. If your truck completely stalls when the A/C clutch engages and the solepot is retracted, then that means your curb idle speed is simply set too low. Yes, the idle speed will drop a bit until the solepot extends and pushes the throttle up, but it should not stall. And even then this situation would only happen if you are sitting there at idle and do nothing about it. If you are actually driving your truck, it wouldn't be a problem at all because the throttle would be constantly open, allowing the solepot to extend whenever it is energized.

Lucille: 1985 Ford F150 XLT Lariat

*Colors: Dark Canyon Red exterior, Canyon Red interior *Engine: 5.0, CompCams 31-230-3, "Thumper" E7 heads, Edelbrock Performer intake, Autolite 4100 carburetor, DuraSpark II ignition, Thorley Tri-Y headers, Flowmaster dual exhaust, H-pipe. *Drivetrain: AOD transmission, 3.55 gears, 2wd. |

I know all about the internal differences and those internal differences is mainly the venturi booster which is lettered for different applications. Im actually working on compiling a list for a guy on youtube for different applications. Surprising most of those numbers cross over to multiple vehicles. Now with that said the venturi booster will not cause a stumble off idle. There is only one circuit that is involved when you step down on the throttle and that is the accelerator pump. The initial hit is where my problem only arose and it was not noticeable when already moving. Could be a combination of issues such as over sized tires with OE 2.75:1 axle ratio and a 120hp 302. But the carb being too big cause its 351 cfm would not cause this issue. In fact when I was looking at 4V upgrades many have told me to go with 600 cfm as that is what Ford ran on the 302s in the past and I was looking more at 500 cfm. Still any stumble you have when you step on the throttle is in the accelerator pump circuit no where else, its carb diagnosis 101. As far as the jet changes goes, it should be done when you change elevation. you may be fine with in a certain range but once you exceed that the thinner air the higher you go seriously changes your air/fuel mixture and unless you want to let it ride and go super rich then you dont have to change it. But even when carbs were common place people still complained of drastic elevation changes resulting in drastic changes in engine performance. Like I said I wont be making those kind of elevation changes. Its an added benefit for me, the aftermarket EFI is to improve on the overall package. With the ethanol blended fuels we have today you run into more issues with carbs as the fuel in the bowl is directly open to the atmosphere and after a few days in a humid region that fuel will have separated with ethanol/water on the bottom and what remains of the fuel that hasnt evaporated floating up on top. It is a problem I know all too well with my vehicles and its worse with ones where the fuel is exposed directly to the atmosphere. In those instances youd be lucky if the fuel lasts more than 3 weeks before it fully separates. As far as people working on them, there wouldnt be a problem, there are numerous shops that are authorized dealers and installers that you can take one to if you have a problem. But typically you wont have a problem as everything is self contained. If there is a problem you just send the whole unit back to Holley for checking and repairs. There really isnt much you can do with this system on your own as parts such as IAC, MAP, Injectors are holley specific and they have no listing of replacements for people that would change them out themselves. Only thing you can really get is the o2 sensor with a wealth of different part numbers for replacements from a short lead to a long lead. Really the biggest problem you will have with one of these units is RFI if you dont follow the instructions on installation. The next biggest issue is the injectors coming unplugged due to the tiny connector Holley uses to fit the injector assembly with in a carb look alike housing. Many have fixed this issue with a tiny ziptie. There is also a large number of people online on the offical owners group on fb that will walk you through diagnosis as well as repairs or if it needs to be sent back to holley. On the notion of getting better fuel economy with efi over a carb that is a given, its not necessarily your carb is setup bad hence why you got bad fuel economy. Power also plays a part in fuel economy as well, more throttle you have to apply to get moving means more fuel you are burning. In my case I will see a huge increase in fuel economy with my new engine build with EFI over my stock smog 302 with carb because the engine was under powered for my truck how its built. With the EFI with proper tuning of the fuel map with the new engine build I should see at least 18 highway. But fuel economy is not the sole reason why I decided to go fuel injection it is a benefit. There is just so many reasons to go with aftermarket EFI with todays fuels over struggling with carbs and the new issues todays fuels bring about. The idle specs for my truck when its listed with AC is not compatible with dealer AC. the York compressors have a way larger drop in rpm than the rotary style compressor ford was using on the factory setup. The spec is 575 rpm in gear with the AC off, with the AC on the idle speed is supposed to be 650 rpm in gear. So if I set my truck properly at the proper rpm to attain 575 rpm in gear with AC off and switch the AC on it will stall out. 575 rpm is way too low of a rpm with AC compressor that has a high load. Long as it doesnt cycle off and back on you would be fine with the step up solenoid, I dont have that problem on my 78 Mercury but that York compressor doesnt cycle as its an expansion valve system. My truck how ever cycles as there is no blend door to introduce ambient air or hot air to change the output of the vent. To change the temperature out of the vent you have a rheostat that will change what temperature the clutch cycles off at. That poses a big risk when you have your engine idling at 575 with the AC off. I currently dont have a step up solenoid and the AC is set up to idle at 575 with the AC on and with the AC off its around 650/700 rpm. In the end this poses a big problem as if I turn the temp down just a little the compressor will cycle while I am sitting at a redlight even and surely you can see where I am going with this. If you are at a redlight idling at 650 rpm with the AC on and the solenoid extended only for the compressor to cycle off the solenoid collapses idles back down to 575 then the compressor kicks back on and bam your compressor brings your idle speed down to 400 and stall. The solenoid is not strong enough to push your throttle open, Ive never seen a factory one strong enough to push the throttle open. Even installing NOS ones doesnt help as they are weak solenoids and rely on you touching the throttle to allow the solenoid to move out. Like you said wouldnt be a problem on the road driving down the highway but in city driving with dealer AC that has a power hungry compressor with a cycling system to determine how cold the air coming out of the vents are, you would have some serious problems with the OE setup. Maybe it will work fine with the factory style compressor but it wont work properly with a york compressor. I dont believe Ford ever had a cycling switch on York equipped AC systems.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

This post was updated on .

Have you tried rebuilding the carburetor? A complete rebuild kit is only about $35. If that doesn't work, I bet the correct carburetor would fix your problem. For optimum performance, a jet change would be needed to compensate for drastic elevation changes to match EFI. That would require a set of $10 jets, a large-blade screwdriver, and about 15 minutes of your time (with an Autolute 2100/4100 or Motorcraft 2150). And then you are back in the game. Or, you could spend about $2000 on a complete aftermarket fuel injection system so you don't have to do that and enjoy the satisfaction of knowing you have a more precise air/fuel mixture than an outdated carburetor.  I live in the South East and I don't experience that problem at all. But I make a point to drive my Lucille at least once a week for 30 minutes to keep everything circulating and in good running shape. It is not good for any vehicle to sit for a long period of time.

I think you said it all right there. If you are stranded in the middle of nowhere, what are you going to do to get your truck back on the road? Is it worth it just to beat that old carburetor in a drag race up in the mountains because the owner neglected to change out his jets to compensate for a drastic elevation change? I adjusted mine so that the idle speed is the same whether the A/C is on or not. My normal curb idle speed is set to 625 RPM. When the A/C is engaged, the solepot will adjust the idle speed back to 625 RPM. But if I am at idle and the A/C engages without the solepot extending, my idle speed will drop to about 500 RPM. That is about as low as it can go with a stable idle.

Lucille: 1985 Ford F150 XLT Lariat

*Colors: Dark Canyon Red exterior, Canyon Red interior *Engine: 5.0, CompCams 31-230-3, "Thumper" E7 heads, Edelbrock Performer intake, Autolite 4100 carburetor, DuraSpark II ignition, Thorley Tri-Y headers, Flowmaster dual exhaust, H-pipe. *Drivetrain: AOD transmission, 3.55 gears, 2wd. |

The carb has been rebuilt 2 times since 1992 and one repair where a broken accelerator pump diaphragm was replaced. As far as correct carb goes I believe the tag is on the carb still and it breaks down as being correct for my application. Still the problem lies in the accelerator pump circuit not in the venturi boosters which is what changed between carbs for different vehicles. Sure you can quickly change the jets out but how do you know that the jets you are switching out to is the ones you need to switch to? or do you just carry a set of jets and do trial and error a few times to find the right jets? After all im sure you know that no two engines are alike and what one engine likes jet wise at a specific altitude doesnt mean another engine will like it. I experience that problem its not as bad on my truck with the closed evap system but it is way more noticeable on my 56 which has a large vent straight to the atmosphere next to the gas cap behind the license plate. This allows the ethanol to absorb moisture at a extreme rate during high humidity. Then if you run Stabil 360 which is a ethanol stabilizer to stop the ethanol issues does help but its not a end all task for vehicles that dont get driven enough, in my case on my 56 even if I run the car for half an hour once a week it doesnt matter, you cant burn the 15 gallons of gas out of the tank quick enough before it becomes saturated with water. I could run less fuel but that just accelerates the issue as it takes less moisture in the fuel before it separates and settles with water/ethanol at the bottom of your tank. It is a no win situation if you dont burn the fuel out quick enough. Problem is these snipers are not known for having so called drastic problems that will strand you. The most common issue is O2 sensor failure which if you have the handheld unit with you, you can switch off the closed loop and run off the base fuel map just like a modern car does. Many people think modern cars run off the o2 sensor but in reality they are running off the base fuel map with the o2 sensor monitoring for any minor changes it may have to make in extreme cases. Many people have had failed O2 sensors but was able to continue driving without a problem by switching off closed loop mode. The other problem is the injector harness connector but that is not as big as it seems. Ive installed numerous units and never had one come back with a failed O2 sensor nor with a injector connector coming loose. Really these units are quite bullet proof and give no trouble that will leave you stranded. About the only thing that will leave you stranded is a fuel pump which is no different than any other vehicle out there that is fuel injected. That is about the only thing the carb has on it is the mechanical fuel pump can fail and leak but still keep driving at the risk of starting a fire or filling your engine up with fuel. Yeah my york drops more than 125 rpm. Mine drops more around 175 rpm when the AC kicks in. Its why I have mine idled up as much as I do since I dont have the solenoid as it wasnt avaliable for dealer AC. With this new setup I will have the step up in the form of the computer changing the idle speed when the AC is on. I could let it maintain the base idle speed but I am going to program it to idle the engine up by around 100 - 150 rpm. Will play with it to see what the combination likes best. Same with idle speed will start off with 575 idle speed as OE specified but will have to see what my crane roller cam will like for an idle speed. Might prefer 750 as base idle for all I know but I feel 575 rpm would be a good starting point. Now as far as performance/efficency goes I dont care how set up a carb you have the sniper will wake any engine up. I installed one in a engine that was dyno tuned with a carb and the guy wanted to put a sniper on it instead. The engine you thought rev good in neutral and ran great on the street. Throw the sniper on and just hitting the throttle the engine was so much more responsive and so much quicker in reving it was like a kid in a candy store feeling. Driving the car woke it up so much more as well. One have to remember these snipers are 800cfm with injectors capable of feeding 600hp with no problem. Many people actually undersize their carbs on air flow to maintain throttle response for street driving but with the sniper you dont have to worry about that as you are not relying on velocity of the air to pull in fuel from the fuel bowls. That is where the sniper will wake any vehicle up as it is a huge throttle body that can flow more air than your basic street carb and provide way snappier throttle response. Thats why I am concerned about my performer intake manifold selection cause im throwing a 800cfm sniper stealth which is the smallest they offer on a 306 with AFR 165 renegade heads that flow some 250-255 cfm at my cam lift on the intake side. I still feel like the intake manifold is going to be my bottle neck seeing as the Edelbrock Performer intake as cast is as far as I know only flows 205 cfm per runner out of the box but cant verify that.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

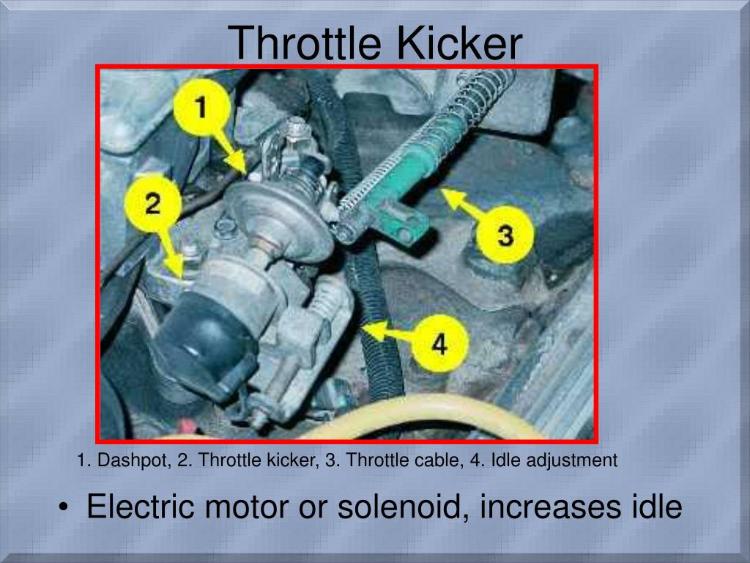

Ford designed the 351 cfm (1.21 venturi) Motorcraft 2150 2V carburetors to work with either the 351 Windsor engine or the 351 and 400 Cleveland engines. For your application, the correct carburetor would be a 287 cfm (1.08 venturi) Motorcraft 2150. If the carburetor you are using was designed for a 351M motor, it will never run right on a 351W engine, let alone a 302W engine. The Cleveland and Windsor engines flow completely different, and the carburetors are set up totally different to reflect that. If the altitude change is temporary, just let it be. If the altitude is great enough, and the time spent at that altitude is long enough, you may want to swap out your jets for optimum performance. Smaller elevation changes can be compensated for by simply turning your fuel mixture screws. If it is necessary to turn them much over 1-1/2 turns, then you may want to replace the jets. A rough estimate is a one jet size reduction for every 1,000-foot elevation increase. If it drops that much, I would make sure my curb idle speed was set to 675 RPM in gear. That is about what any modern fuel-injected vehicle idles at anyway. Then when the compressor turns on, it would only drop to 500 RPM. If everything else is set correctly, your engine should idle just fine at 500 RPM. The solepot is a device that is attached to the carburetor, not the A/C system. (Well, it does wire into the A/C circuit.) There is no reason why you can't bolt one on your Motorcraft 2150 carburetor. When set correctly, it will do the same thing the computer will on the Sniper. The one I had on my original Motorcraft 2150 fit perfectly on my Autolite 4100 and works great.  This is what it looks like:  Assuming the carburetor is sized and tuned correctly, a fuel injection system by itself will add very little - if any - extra power on the same engine. Everything you wrote here that claims the Sniper "woke the engine up" is subjective. If the guy you installed this for had his engine dyno-tuned with his carburetor, how did the actual numbers change with the Sniper? Without actual numbers we are guessing and just going off of feeling. One possible explanation is the Sniper *may* have added some horsepower, but it *may* have lost some torque in the process.

Lucille: 1985 Ford F150 XLT Lariat

*Colors: Dark Canyon Red exterior, Canyon Red interior *Engine: 5.0, CompCams 31-230-3, "Thumper" E7 heads, Edelbrock Performer intake, Autolite 4100 carburetor, DuraSpark II ignition, Thorley Tri-Y headers, Flowmaster dual exhaust, H-pipe. *Drivetrain: AOD transmission, 3.55 gears, 2wd. |

1) If that is the case and the tag was just throw onto the carb from the old one and it truly isnt correct, the flow difference would not cause a stumble on initial tip in of the throttle is the main point. Maybe it contributes to the bad gas miliage I get which is around 12 city with 2.75:1 axle ratio and 31" tires. But basic function of the carb on tip in the accelerator pump is to help with transition from the idle circuit to the main circuit to avoid hestiation, stumble, bog. The fact that upping the amount of fuel squirting resulting in an improvement is a indication that there is not enough shot of fuel on the accelerator pump circuit to cover that transition period. Sure the carb may not be right and may be wrong and too big, but the accelerator pump is still sized properly for the carb and should not have that hesitation. Even my 292 with a 1974 replacement 2100 autolite with a 1.08 venturi didnt have any performance issues even though its 287 cfm compared to the correct holley 4000 being 330 cfm. Only issue I had in this case was no power as the timing was pulled back to 0* initial as they were trying to run the load o matic distributor which was powered by a combination manifold vacuum and venturi vacuum off of straight manifold vacuum which ran the distributor at full advance all the time. I may have to double check my truck maybe it is a 1.08 and I am thinking its a 1.21 like my 351W but I do recall checking years ago and thinking that it was odd that both engines having the same cfm rating. But the truck ran great, it ran great while moving just had that initial tip in hesitation which was almost non existant with the change in accelerator pump setting. 2) Sure one could leave it if temporary but there are cases where you may be on a long trip and be constantly going up in elevation. For me any where I go will be a increase in elevation as I am currently at 25 feet above sea level. So no matter where I go my altitude will increase unless I go to the coast where it drops down to 10 feet above sea level then you have the beach. The property I have about 110 miles west of where I am currently at is right at 398 feet elevation varying between 350 feet to 450 feet. Then if I go to RWP up north of Dallas like I would like to go to just once with my truck just to watch the carnage I would be right around 1,200 feet elevation. Might not be enough to warrant jet changing for a temporary trip but seeing as I work on cars for a living I have lost quite a bit of interest in working on my own vehicles and if I can make a change that reduces the amount of work I have to do on said vehicle and can enjoy driving more I will do it. When I got my '56 I wanted to keep it all original with points but I eventually upgraded to petronix just so I can enjoy driving vs worrying about having to properly adjust the points. Like with my truck, its a daily driver, I dont want to have to be on the side of the road tinkering with changing jets for example because I went from 25 feet elevation to 1,200 feet elevation only to have to make the switch back when I come back to 25 feet elevation. Then who knows if the truck seems to be good for long hauls I might even put my truck in the hotrod power tour that comes through TX. As far as giving the idle mixture screws a little more juice to compensate for the altitude change for a temporary fix, I dont think that would work. The idle mixture screws only adjust the idle mixture once you are off idle those screws have zero effect on the fuel mixture and it is all reliant on the jets themselves. 3) I dont think I have ever idled my 302 down to 500 rpm in gear. I try to keep it around 550 - 600 in gear with the AC on which is about 650 to 750 with AC off. Just general guestimates as I am going by the OE tach. I know when I got the AC working the idle speed I had which was right in line with spec was way too low you put the truck in gear and it would barely idle then finally stall without the solenoid. I also know you can add one in, I never added one in had thought about it but seeing as I wont be using that carb anymore there is no point in worrying about it now. I have a 600cfm summit 4V carb which Holley builds for summit and its their updated version of the 4100 carb with annular boosters. I was going to use that but then after installing so many snipers and seeing the benefits of them decided to do the upgrade and keep the summit 4V for my 351W as I had always wanted to upgrade that from a 2150 and see if I could squeeze some more fuel economy out of it with the smaller primaries than the 351cfm 2V currently on the engine. Then if the sniper doesnt work out for me like it has for all the ones I installed then I will simply pull it off and put the Summit 600 cfm carb on. Its why I planned on putting the fuel pump eccentric on the cam gear and using a block off plate on the fuel pump mount that way I can easily convert back to carb without having to disassemble my engine to install the components. But I dont think I will have an issue with the sniper. Too many people have them and too many good reviews, most of the problems people have with them is improper installation by people not following the directions and hooking battery hot and battery ground for the sniper to something other than directly at the battery. 4) I dont believe he took and had it dyno tuned again to see what kind of improvements were made. But I wouldnt call woke the engine up as subjective. His dyno tuning he had done on the carb which was built by Davinci and dialed in by a local dyno shop that still works with carbs got it dialed in as best as they could. I didnt see the dyno sheet to know the exact numbers but the owner states that it dynoed at 400 hp. Putting the sniper on it had improved throttle response, it reved quicker and it pulled harder when nailing the throttle than it did with the carb. Maybe the carb wasnt dialed in right, I know dyno tuning can be hit and miss depending on who you go to but every carb I took off for a sniper resulted in a sharp snappy throttle response and improved power over the carb. There was also a hotrod article about increasing top end power on a engine they had dynoed switching to a sniper which they said was evident that their carb was a bit on the small side. Which lets face it if you are running a carb on the street youd want it to be more on the small side than on the big side for street performance. Thats where the Sniper as I stated excelles it moves massive amount of air but isnt hindered like a carb as it is capable of spraying the proper amount of fuel for said air volume. This helps pick up power in the top end as well as improve throttle response. In some cases I bet it improves low end power as well. I installed one in a 66 corvette with a 327 small block, took the OE 4V carb off drilled and tapped the snowflake aluminum intake for the temp sensor for the sniper and threw the sniper on. Car idled so much smoother, started up so much better, and reved so much quicker than the OE carb did. On this one I cant vouch for the tune on the carb, I didnt build the car the car was built by someone else that then sold it to this guy who had it brought to us to do a list of work on it from adding off set upper control arm shafts to get it to align properly to adding vintage air and the sniper fuel injection. That is also the only car to ever come back and he kept blaming the sniper for the overheating problem claiming its running lean cause thats what his brother in law who builds race engines told him the fuel injection is going lean causing it to over heat. Even though the 02 sensor was reading a 13:1 air fuel mixture which was a little rich at idle and could in fact be set a bit leaner at idle around 14.5:1 to 15.5:1. He wanted us to put a carb back on it and see if it would still over heat which he believed it wouldnt but he didnt want to pay us for that so we didnt do it. Realistically with how quick that engine was over heating I suspect it was something wrong in the block itself that we told him and he didnt want us to pull the motor and find the problem so we shipped it out back to the new owner. For a engine to over heat due to running lean youd have to be around 17:1 or leaner where the engine is barely running and your exhaust would be glowing so bright it would appear translucent. Power wise it is why I want to dyno tune my truck or at least put it on a dyno after I get the C6 replaced with the Broader Performance C6 unit I want and swap the center chunk out for a 3.00:1 or 3.25:1 currie true trac chunk. I really want to see what kind of power my 306 with sniper is making. Blueprint claims their 306 crate engine dynos out at 370 hp with 9.5:1 compression. I am looking at 9.2:1 compression most likely wont know for sure till my short block comes in, but I am sure my AFR 165 cc heads flow better than their in house produced heads and my crane roller cam is just a smidge smaller than their cam. So in theory my 306 should be making around 370 hp just like blueprints but I honestly dont see it making more than 350 hp. Based off their specs, 370hp/350ft lbs, their heads are in house HP9009 with 60cc chambers and 2.02"/1.60" valves 190cc intake runner with a roller cam 112* lsa @ 0.50, 218*/226* duration, and 0.543"/0.554" lift. Looking up their heads its listed at 28" to flow 249 cfm @ 0.500" and 251 cfm @ 0.600" lift. My specs is AFR Renegade 165 heads with 58cc chambers and 1.95"/1.60" valves, 165cc intake runner with a roller cam by Crane 112* LSA, 216*/224* duration @ 0.050", 0.520"/0.542" lift, 107* ICL. Flow data on my heads out of the box is 251cfm intake @ 0.500" lift, 208 cfm exhaust @ 0.500" lift and 255 cfm @ 0.550" lift intake and 212 cfm @ 0.550" lift exhaust. With this in mind I could actually see my engine making similar power to the blueprint 306 even at a reduced compression ratio but I honestly do not expect my 306 build to make much over 300 hp. If it does then I would be very impressed with the package I assembled together myself for my intended purpose which is a daily driver street truck.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by LARIAT 85

OK,, I have the Dorman kit and extra hose kit in hand. If I do the loop as you described, couldn't I connect the ends inside the dorman housing with a piece of tube bridging the two pieces? Making a constant loop from fresh air up to the choke? Keeps varmints out as well.

If it were using the stock manifold bosses, that would be just a passage in manifold without the filter material correct? I think I see how that works on my stock manifold, but would have to remove the manifold to attempt to drill the passages out.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

This post was updated on .

Yes. And that is exactly what I did. I used a small piece of copper (copper will heat up faster) tubing that fit tight inside the dome, just slightly larger than the two air tubes. Then I put the mesh filter media inside of that copper tube. I ran the fresh air tube into the lower hole of the dome and then the [insulated] hot air tube into the top hole. This is more like what the factory did - a sealed hot air chamber that circulates clean, filtered air. No. There is a filter media inside of the choke stove chamber on the stock exhaust manifold. Your chamber and filter media is probably very dirty and rusty inside at this point with both chamber holes being open to the elements. The only reason I used the choke stove kit was because I am running exhaust headers, and they do not have a choke stove chamber built into them like the stock manifold does.

Lucille: 1985 Ford F150 XLT Lariat

*Colors: Dark Canyon Red exterior, Canyon Red interior *Engine: 5.0, CompCams 31-230-3, "Thumper" E7 heads, Edelbrock Performer intake, Autolite 4100 carburetor, DuraSpark II ignition, Thorley Tri-Y headers, Flowmaster dual exhaust, H-pipe. *Drivetrain: AOD transmission, 3.55 gears, 2wd. |

|

Ok, thanks. I figured out your headers as I was studying the photo.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

In reply to this post by rcarlisle

THis is what you need for in the manifold. https://www.ebay.com/itm/224118208366?epid=1222069255&hash=item342e7c776e:g:lD0AAOSwo2FfNvSx OE part number for our trucks is D3TZ-9A714-B

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

I hope if I get all this, that 1) I can get it installed and 2) that the rest of the choke system will cooperate and work.

Thanks

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

|

In reply to this post by Rusty_S85

Offered $5 and seller accepted. Yayyyy. I guess. If I can get it to work.

Randy

Mt. Airy, NC 81 F-150 STYLESIDE regular cab 2wd. 302 Auto Zone crate. 5 spd M5od-R2 |

Hardest thing you might run into is getting the meal cap on the bottom of the manifold out. I bought a NOS one as well but wasnt able to get the cap out on the truck. If the manifold is in a vise I think the cap can be gotten out easily.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |