Search Forum

Stabalizer Bar nut suggestions

123

123

Re: Stabalizer Bar nut suggestions

|

Administrator

|

There is a grade 9, but I haven't seen one on a vehicle except a race car, in forever...

I'm saying screw the book and get some u-bolts that will work to hold the sway bar bushing to the axle housing the way it needs to be. You're hung up about bs that doesn't matter at all. Is this a concours restoration????

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Ok. Grade 5 it is.

Will

-- 1982 F-250 HD 4x4 400/C6 4.10 Dana61 (Borgeson/Bluetop/Lee, 3G) |

Re: Stabalizer Bar nut suggestions

|

Administrator

|

Just get the clamping force right.

Find the chart for the 10mm thread. 42 ft lb on a 3/8 fine bolt is a hell of a lot of pressure.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

You're going to have to explain what you mean by clamping force. I'm not familiar with your context. My plan was to reassemble everything following the instructions in the manual. The only measurement I have from that is the torque which is obviously out.

Will

-- 1982 F-250 HD 4x4 400/C6 4.10 Dana61 (Borgeson/Bluetop/Lee, 3G) |

Re: Stabalizer Bar nut suggestions

|

Administrator

|

This post was updated on .

We understand that a threaded fastener draws two objects together.

That a thread is just a ramp (basic, or prime tool) that is wrapped around a shaft or into a hole. That as you screw something in you are using a captive ramp (or wedge!) to force two objects together. We know that the shallower the slope, or hill, the easier it is to push something up. Therefore, the finer the thread the shallower the hill.... This is simple to understand, right? We understand that common thread profiles -both metric and SAE- are a 60° thread profile, right? And we need to measure from the center of the thread not the root or crest, because those areas don't carry a lot of load. Now, let's consider the 10mm diameter fastener. First, we know that the thread is a 60° and it's on both sides of a bolt, so we double the cut depth to know the working diameter of the thread on the shaft. This is basic Pythagorean theory of a 30, 60, 90 triangle. We use D=H/sin(A). To make this part simple, for the moment we're going to forget about factoring the thread profile cut into it. Okay. Now we have to factor the actual diameters, because 1mm (fine) threads are not cut as deep into the cylinder, so we don't reduce our 31.4159 ramp length as much as the 1.5 mm pitch threads. You can have a coarse pitch (1.5mm for 10) or fine (1mm for 10) The circumference of a 10 mm cylinder is x3.14159 or 31.4159mm So a ramp or wedge that is 1mm high over 31.4159 mm is shallower than a ramp that is 1.5mm over the same distance, correct? If we apply the same force to a skinnier wedge we will drive it deeper. If we apply the same torque to a fine pitch we will wedge the objects tighter together, correct? The bolt is 10mm diameter and the thread is either 1mm or 1.5mm pitch. Again let's simplify and use the whole numbers for pitch to prove a point. 10- 2x1=8 10-2x1.5=7 7x 3.14159 = 21.9911 8x 3.14159 = 25.1327 We can see the finer (1mm) pitch is not only less height, it is more distance (25 v/s 22mm) The clamping force developed by a fine pitch is FAR greater for the same sized fastener. All this stuff is basic formulae, and fastener clamping force by torque can be found on sites like 'engineering toolbox' Figure out how much clamping force is made by the factory U-bolt and choose an available bolt & pitch that can use an appropriate torque to develop the same clamping force. Do you get this? I can try to make it simpler, but I already threw out a bunch of minutiae (like lessening clamping force because of thread stiction) to get us to this understanding.💡 https://peer.asee.org/the-relationship-between-the-tightening-torque-and-the-clamp-force.pdf Carrol Smith's nuts bolts and fasteners handbook is a good read, if you care about things staying together. It's written for every man, not grad students. 👍

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Stabalizer Bar nut suggestions

|

Administrator

|

This post was updated on .

https://www.hfsindustrial.com/news/post/torque-vs.-clamp#:~:text=At%20best%2C%20torque%20is%20an,tension%20applied%20to%20the%20bolt.&text=Clamp%2C%20defined%20as%20the%20load,is%20virtually%20unrelated%20to%20torque.

Torque (twisting force) is factored by distance from the pivot. In our case above we are using foot lbs, so one foot-12" or 304.8 mm lbs v/s 1/2 of 10mm = 5 - thread depth to the center either 1/2 or 1mm The lever arm (one foot, 305mm minus our 1/2 fastener diameter) determines how much clamping pressure is applied.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Jim. I'm beginning to understand your lack of sleep.

|

Re: Stabalizer Bar nut suggestions

|

Administrator

|

I don't want anyone to ever understand what happened to me, that caused my PTSD.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by ArdWrknTrk

It's too early for me to understand all of that after just 1 reading. I do think it makes sense. I at least get your point that I need something with similar clamping force as the factory bolt. Let me read this a couple of times more and I'll get back to you :)

Will

-- 1982 F-250 HD 4x4 400/C6 4.10 Dana61 (Borgeson/Bluetop/Lee, 3G) |

|

In reply to this post by dirtymac

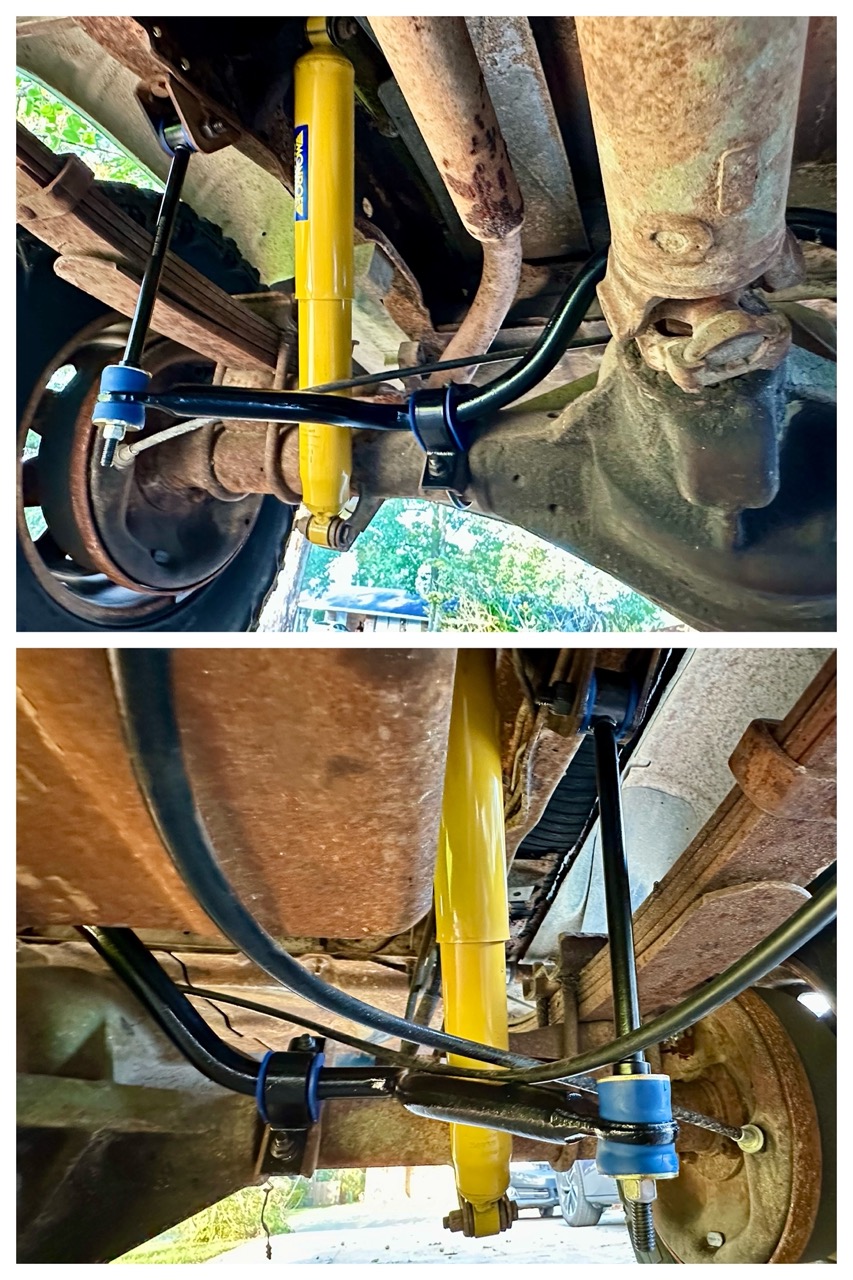

Our old u-bolts are not in great shape but we decided to go ahead and put them back on until the new ones arrive. Below are images comparing what came off with what went back on. Stripped and painted all parts. New endlinks because the old ones were rusted beyond reuse. Moog blue bushings.

This has removed most of the tap-dancer sounds from the rear of the vehicle. The front is next.

Will

-- 1982 F-250 HD 4x4 400/C6 4.10 Dana61 (Borgeson/Bluetop/Lee, 3G) |

Re: Stabalizer Bar nut suggestions

|

Administrator

|

Progress is GOOD!

It's really nice when you don't have to listen to a sloppy or broken suspension any more. 👍

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

We are getting there. Once we get the front done, I want to start looking at the leaf springs.

Will

-- 1982 F-250 HD 4x4 400/C6 4.10 Dana61 (Borgeson/Bluetop/Lee, 3G) |

|

your progress looks great. when you get the front tidied up it will be a great step.

|

|

Thank you! We've had some decent time to work on it lately.

Will

-- 1982 F-250 HD 4x4 400/C6 4.10 Dana61 (Borgeson/Bluetop/Lee, 3G) |

Re: Stabalizer Bar nut suggestions

|

Administrator

|

This is the U-bolt on my 250 HD. I don't think there's any way that's 0.40"/10mm (I shoot my 610 & Delta Elite often enough)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

610? did one get by me? delta elite I get. hehehehe

|

Re: Stabalizer Bar nut suggestions

|

Administrator

|

It's a stainless N frame Smith with a six and a half inch barrel that takes full moon clips.

I used to use it shooting hunter pistol in silhouette. Mine has Millet sights and a crisp 2 1/2# single action trigger.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

not near as active as I once was. too many hobbies. still, I step out back to send a box or two now and then. 22 at home but if I want to make noise I go across the lake to my local (private) range.

|

Re: Stabalizer Bar nut suggestions

|

Administrator

|

Nice!

My brother used to live right down the street from the silhouette range, before the divorce. I don't think there are any silhouette clubs in the Northeast anymore... Had a few barrels for my TC Contender. Everything from 22 hornet to 7.62x39 & 300 whisper..or blackout, or whatever they call it today. J.D. Jones made a lot of wildcats.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Stabalizer Bar nut suggestions

|

Administrator

|

Here's a little video from the maker of what look like Nordlock washers.

I was hoping it would better explain clamping force, but it just goes n abut how their hardened washers will keep the nut from loosening, and you sre already using pervailing torque nuts. https://youtu.be/aD54subok-I?si=SP8VJGkY-O6t7tJR

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |