Saginaw for a serpentine IDI: brainstorming

Re: Saginaw for a serpentine IDI: brainstorming

|

Administrator

|

It will be Tuesday before I can look, I have a couple of appointments in Virginia Beach tomorrow.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Thanks, no rush on this. It will probably be a few days before I can measure mine also. I appreciate the help.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: Saginaw for a serpentine IDI: brainstorming

|

Administrator

|

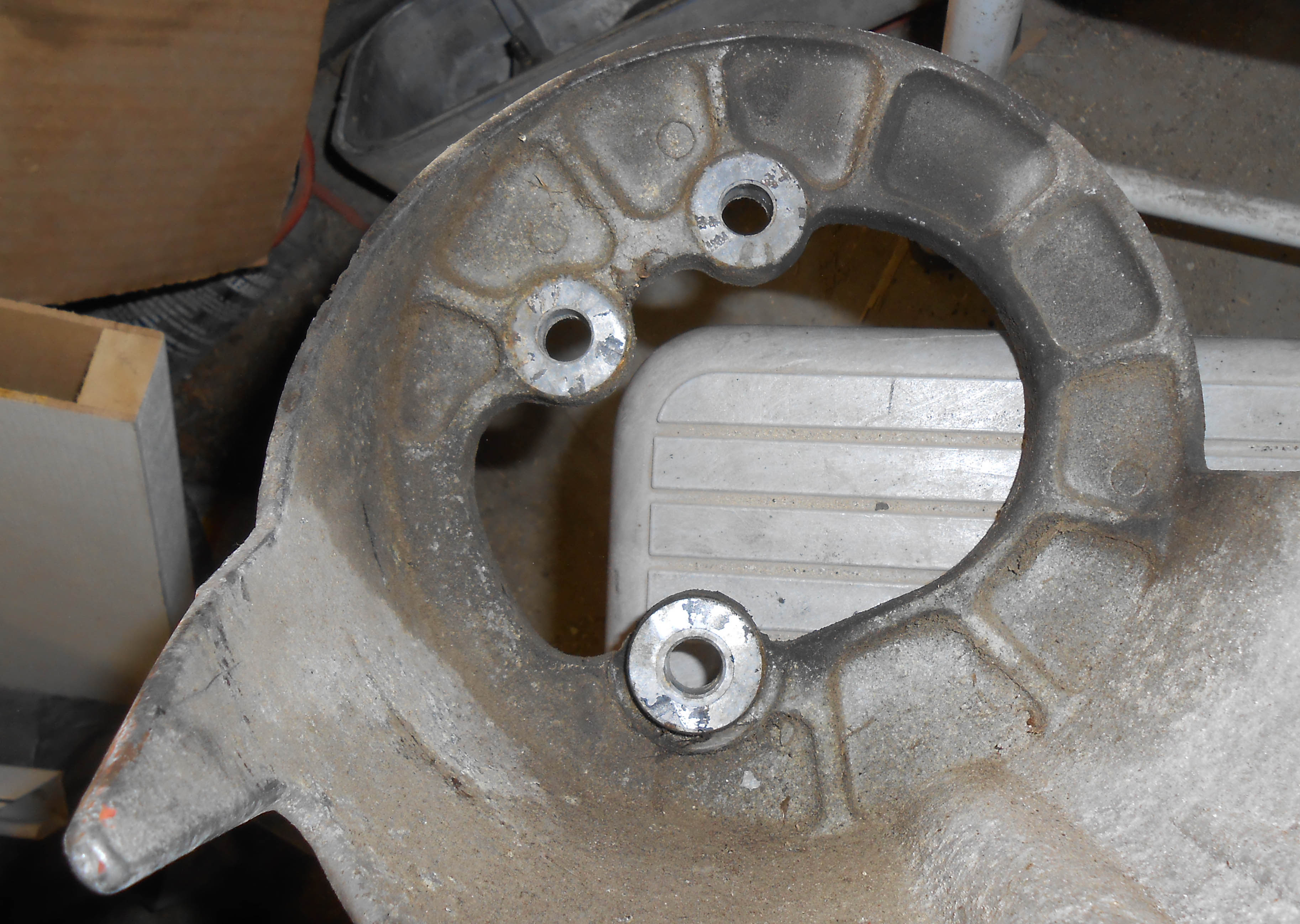

This is the back side of the Saginaw mount, it is 0.180" thick between the ribs as close as I can tell, bosses are 0.475" thick and holes are 0.385" ID. Keep in mind there is a brace from the back of the pump to the exhaust manifold bolt for stiffening. Apparently the C2 pump bracket is thicker or sits differently. This is a 460 EFI mount.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Thank you very much for those measurements. I still have not had the chance to gauge mine, but I probably will work on this some over the weekend. Since the 460 application had a rear steel brace, I should probably try to devise something similar. That side of the engine is pretty crowded because of the big oil cooler tube, so that will have to wait until the engine is assembled.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

Finally got a chance to compare my bracket. Between the ribs I measure 0.160” thickness. Same for the walls around the mounting face. At the bosses it is 0.350” thick. I don’t know what that means for welding, I just know it feels very thin 😬

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: Saginaw for a serpentine IDI: brainstorming

|

Administrator

|

How flat is the front?

Maybe you could solder or braze a plate there.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Saginaw for a serpentine IDI: brainstorming

|

Administrator

|

In reply to this post by Ford F834

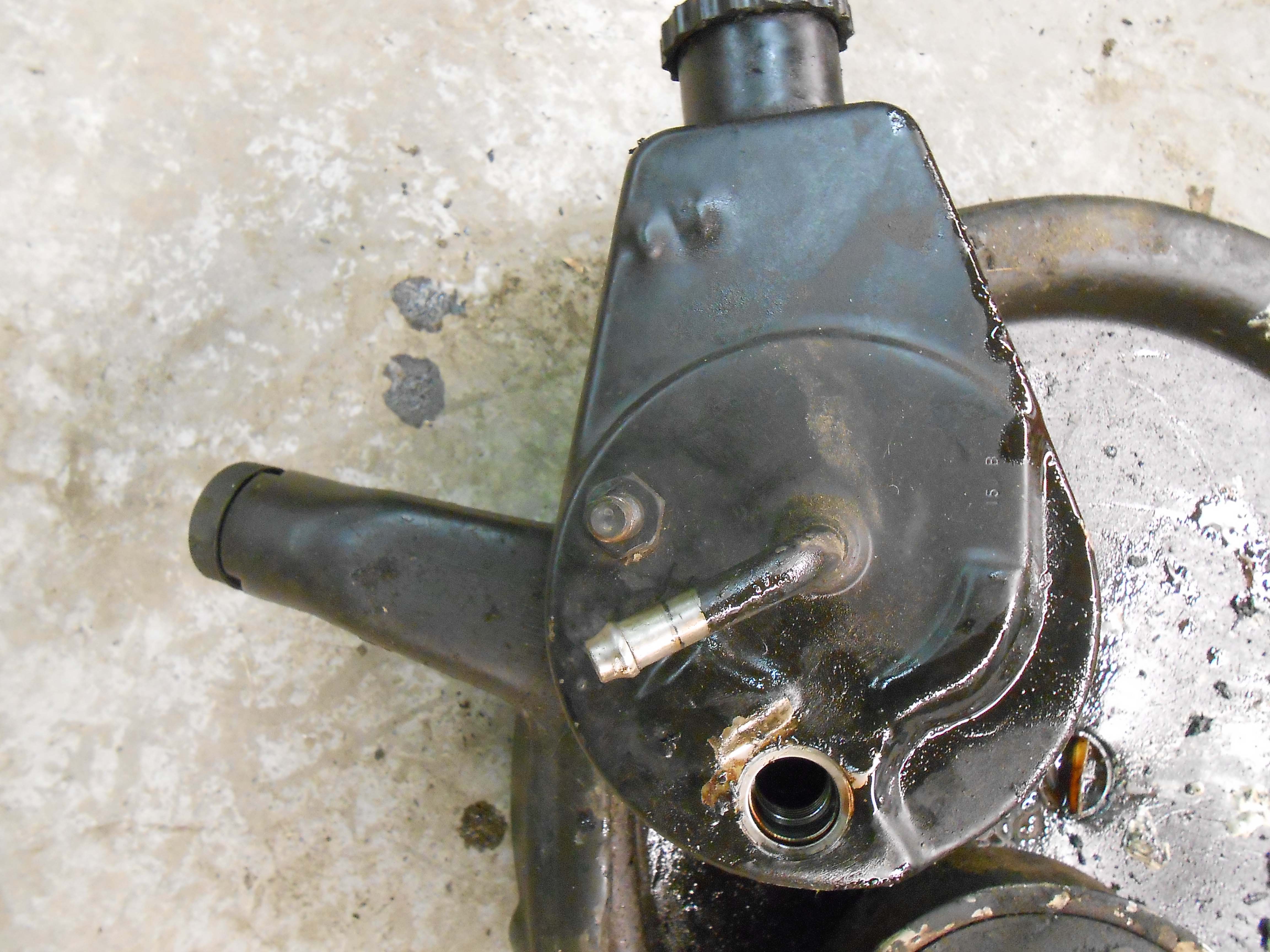

Ok, gentlemen, today I took a Chrysler K car pump and the E-series 460 pump and removed the outlet fittings an flow control/pressure regulator valves out for comparison.

First is front of the Ford pump.  Next, the front of the Chrysler pump  As you can see, not much difference. Next the back of the Ford pump, note only one stud.  Now the back of the Chrysler pump, note two studs as it pivots on the lower stud and matching bolt hole.  Next the valves, here are the pair, Ford on top, Chrysler below. The Ford spring is stronger than the Chrysler one.  Ford outlet fitting, note the size of the hole.  Chrysler outlet fitting, smaller hole.  Control valves disassembled. Ford first, the hex end has a screen in it.  Now the Chrysler, note the 4 shims, obviously for the lower pressure for the rack and pinion vs integral gear, also keep in mind the piston area of a Ford integral gear and a K-car rack.  Hope these will help, if I get a chance and still have one, I will do the same on a GM hydroboost pump off a 350 Diesel.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Very, very, good info right there... thank you! I had read that some pumps put out a little more than others but I was not aware of the specific differences. That is very good to know. My particular pump is from a GMC one-ton dually with hydroboost so hopefully I can make it fit. The reservoir barb and return line barbs are a real problem. I need a reservoir like this, but I got the image from a thread asking what it might have come from and no one knew...

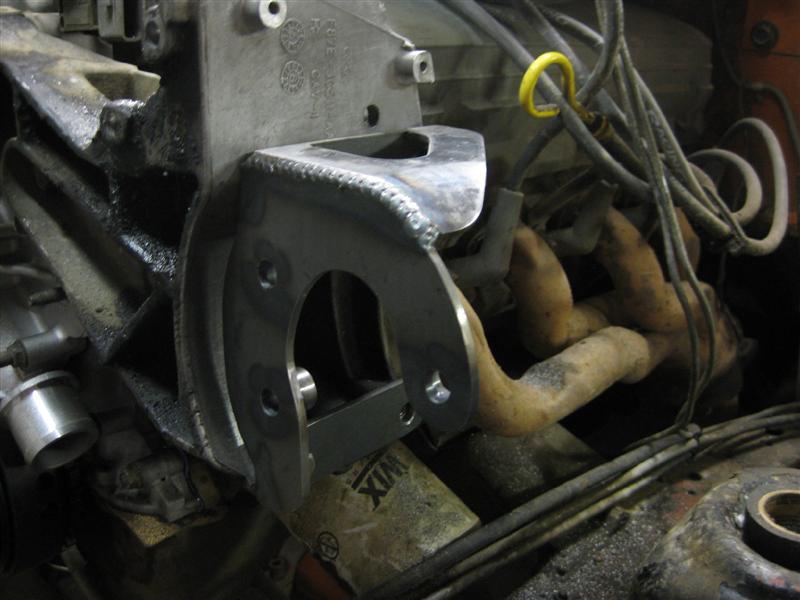

And while it solves the problem of the remote reservoir barb, it has no return. I assume the original application had a return in the remote can. But I read a thread about someone who installed a performance PSC pump and had a problem with the return forming a violent vortex in the remote can and foaming up the fluid and making the pump suck air. Even the big aftermarket PSC remote can with internal baffles didn’t solve it so he had to go back to a standard pump. So as much as I like the idea of circulating the fluid I’m a little nervous to run the returns into that little stock can, especially if my pump may be a higher output one. http://www.gtsparkplugs.com/Super_Duty_Power_Steering.html To answer the question about the face of the bracket, yes, it is smooth and flat. My thought would be to weld a stout aluminum plate onto the front side and proceed from there, but again I know nothing about welding aluminum or whether this would provide enough strength. One thing that occurs to me is that the PSC horseshoe places the Saginaw shaft exactly where the axis of the Ford shaft was (where it needs to be). Looking at the “tips” of the horseshoe I don’t know if that is even possible with the walls of the IDI bracket. I might have to live with a bit of axis shift, or find a way to reinforce the face where I can cut away most of the wall:    Another approach I saw was to make a mounting surface on the aluminum bracket upon which to bolt a separate steel mounting bracket for the pump:  Lots of fabrication! Back converting to V belts sure is looking like a lot less hassle 🙄

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: Saginaw for a serpentine IDI: brainstorming

|

Administrator

|

That could be from a motorhome, they were on a modified P30 chassis (severely overloaded) and may well have had a remote, in front of the radiator reservoir for serviceability. Talk to some RV people as GM was the only one making class A chassis after Chrysler pulled out until Ford went back into the business.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

You are absolutely right, the large motor homes have these types of remote reservoir pumps. I have found 5 of them now, and they have the larger diameter remote reservoir hose like the 6.2 diesel. However, all 5 have so far been hydroboost with two return ports in configurations similar to mine, and all have the remote reservoir barb on the edge of the can rather than the back. I continue to check as they come into the yards though, as they each seem slightly different and I might just get lucky and find the “perfect” reservoir.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

Well... the mystery pump with the single reservoir barb out the back has been solved... Trent dig up a different thread which identified the application as a 1982-1984 Renault Fuego 😬. Yeah. Not something I would have stumbled across by trial and error. The A1 Cardone part number is 20-7989.

Summit and eBay still have units available with the reservoir. They are slightly on the expensive side after shipping and a core charge at Summit, but at least they can be had. My concern is that the hydro boost applications came with the larger diameter reservoir barb and hose, and had two returns. This suggests that forcing all of the return and reservoir flow through the one smaller port might cause problems? What say you all? Perhaps order it and try to fit a larger reservoir barb to it?

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

Re: Saginaw for a serpentine IDI: brainstorming

|

Administrator

|

I am afraid that a single small barb might not be enough for the return. Having said that, I have the C2 pump from the 1995 F450 setting on my work table, and I could measure the ID of the two barbs on it to find out how much area they provide. Forgetting boundary flow, which makes a small diameter hole flow less that it would appear it should, we could at least get a number that might indicate the area needed to make it work reliably.

I'm not going to be in the shop today, but hopefully will be tomorrow and will let you know what I find.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

The returns are one thing. My ‘81 is getting by with just the one T’d port. However the remote reservoir connection is what I’m wondering about. The 6.2 diesels and motor homes with hydroboost have the bigger hose connecting the two. I read that one guy had problems with the pump making noise because the remote reservoir was too small. I’m guessing that may be why they have a bigger hose.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

This post was updated on .

Removed as incorrect.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

Banned User

|

|

Administrator

|

Desirable for someone with a 460!

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

| Edit this page |