Rembrant's new non-Bullnose project

Re: Rembrant's new non-Bullnose project

|

Administrator

|

I didn't realize deleting the A.I.R. pump had made the tensioner inoperable.

Might be a good idea to keep that belt sleeve in the glovebox so the next owner can figure it out (because back side contact is going to wipe those numbers right off.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Yes, I save everything in a big file for that reason. I think the back side of the belt contacts the tensioner regardless, so those numbers will be gone quickly.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

a friend of mine deleted his on a 5.8 and wound up putting it back due the lowered belt tension applied to the belt in this routing.

The 93-96 belt tensioner for the 3g alt. system has a very limited swing and leverage compared to the previous top mounted design. with this routing the swing of the tensioner goes more "along" with the belt instead of pressing against it meaning the range of tension is lost. belts will squeak much sooner and accessory drives less positive especially if wet. the best solution would be an idler like the ac compressor delete assembly. but who would dare manufacture an emission delete device under the watchful eye of the world police? |

Re: Rembrant's new non-Bullnose project

|

Administrator

|

Old trick from the early days of "smoke grinders" (what we called air pumps in the 60s and 70s), take the pump apart and pull the vanes out. reassemble it with just the shaft, but make sure the bearings are good. It you plug the lines and reconnect them, it passes a visual inspection.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

I have "seen" that done before.

|

|

In reply to this post by mat in tn

Yes sir, you're right. If you try to run the belt in the stock routing without the smog pump (like pictured below) the tensioner barely works at all...it moves through it's whole arc without being able to really tension the belt properly.  The way I have it now, in the non-stock routing, the tensioner is pushing down on the belt and is at less than half of it's full travel, so it should be good here. There's actually more belt wrap on the alternator, and maybe a tiny bit less on the crank pulley. Either way, it should be getting the same tension now as in the original position with the smog pump. Even if it is less than perfect, it will likely be fine for a truck that will only see a couple thousand miles per year on the sunny days. I'll report back after I've had a chance to run it, which will hopefully be soon!

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Rembrant's new non-Bullnose project

|

In reply to this post by Rembrant

I Love It!!!!

Crazy bout a Mercury!

1- 1981 F100 Flareside,

1- 1982 F150 Flareside 1- 1985 M150 Flareside 4X4 |

|

Thanks Jeff! If you didn't read through it all, it's a '52 Mercury M1 pickup. I swapped in a 1996 roller block 302 with 4R70W 4spd auto and an 8.8 3.55 diff from a 2001 Explorer. I'm just rewiring it now...couple weekends away from finishing and being able to turn the key to see how many things are wrong LOL. I'm sticking with the original look and nothing different other than the chrome wheels and wider tires. I'm not into all the current trends with classic trucks. I like the old school look.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

I had another small victory this week!

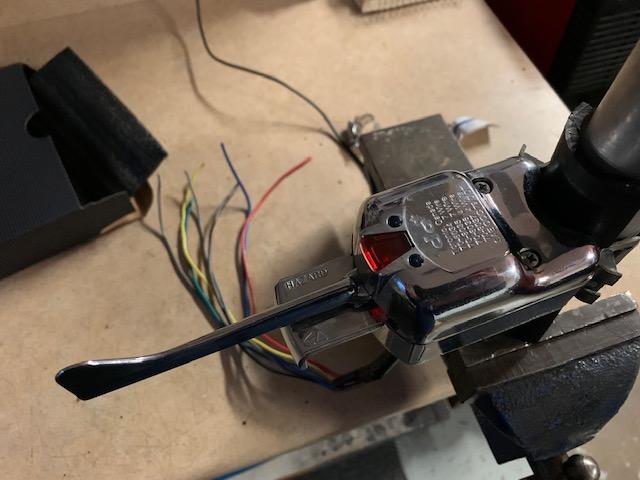

This truck has an old clamp-on style metal housing signal light switch. Picture of it below, clamped to a piece of pipe in my bench vise:  I couldn't find a wiring diagram for it for the life of me. There are 25 different companies making duplicates of this...most of them plastic, with cheap levers and knobs. I really wanted to make this old metal one work, and after umpteen Google searches over the winter, I happened to find that Truck-Lite makes a replacement that is the same as mine, and they have a wiring diagram for it! https://www.truck-lite.com/amfile/file/download/file/770/product/25753/ I wired it up on the bench and tested it and it works perfectly!

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Rembrant's new non-Bullnose project

Feel good moment!

Jeff / 1984 F350 Crew Cab 4x4/5.8L w351 4V/ T18/ D50 4.10 front/ 8' bed.

Restored 2019-2022. Nicknamed «Big Brother 1984», due to its soooo-looong shape & nod to George Orwell's 1984 famous novel. |

Re: Rembrant's new non-Bullnose project

|

Administrator

|

In reply to this post by Rembrant

That's gotta feel good!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Rembrant

Nice!

Man that's a nice looking pickup!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Thanks Dane,

I'm dying to drive it. It's been off the road now since fall 2021, and between the weather and the truck not being finished yet, I still can't drive it. I'm hoping to be able to start it by the end of the month though, so if all goes well I will. Then we will see how many "bugs" are in my build lol.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

|

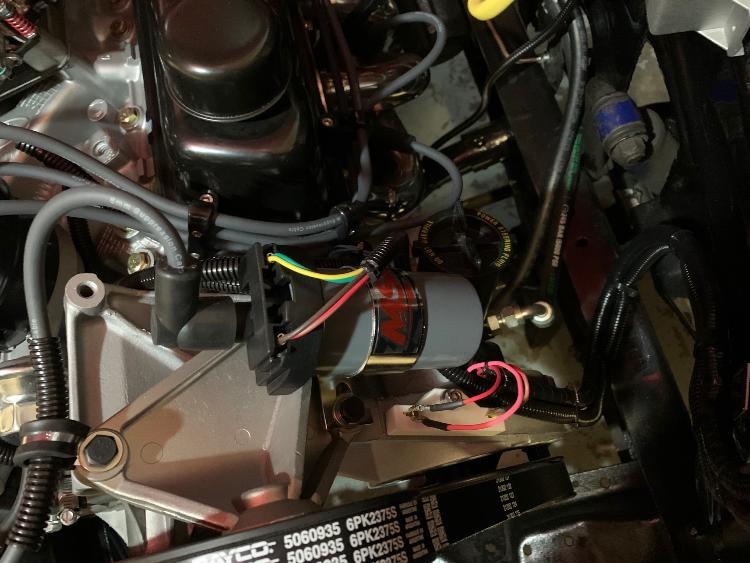

I don't think I posted pics yet, but here is what the engine bay looks like now. The engine bay wiring is almost 100% complete. I just need to install the oil pressure sender and then cut the wire to fit. After that, all I will have to do it connect the electric ran fan to the Derale controller. In any case, here's what it all looks like jammed into a 1952 engine bay (Radiator is not re-installed yet as it is much easier to work in there without it).

In hindsight, I probably would have/should have done things differently. I added a lot of things that create a lot more work to install. I see loads of old street rods at the car shows and when you think about it, if all you need to wire up is a one-wire GM distributor with the coil on it, you're done! I added A LOT of electric items to this build that in hindsight I could have easily done without. Oh well, I'll know better for next time lol.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Rembrant's new non-Bullnose project

|

Man, this is fabulous!

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

Re: Rembrant's new non-Bullnose project

|

Administrator

|

In reply to this post by Rembrant

That looks great! Well done!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I need to continue with my in-cab wiring, but only had a brief amount of garage time yesterday so I decided to finally throw some oil in this little 302. I used my little primer rod with the cordless drill and the oil pressure came up pretty quickly. Had a temporary gauge hooked up and seems to top out around 52.5 PSI, which I assume is OK. This is with 10w30 at room temperature...not hot obviously. I seem to recall my other 302 build hitting 50+ PSI oil pressure on the dyno as well.

I also primed the power steering pump and steering box. I pulled the serpentine belt off and then spun the power steering pump up also with the cordless drill. This worked pretty good as I ran the steering left to right and burped the system. It took about a quart to fill which seems OK. This is a C2 Ford pump with custom hydraulic lines running an early 80's Toyota power steering box. So far no leaks, but at least the engine is ready to crank over when I get the wiring and fuel lines finished! Back to wiring today, then to finish installing the fuel lines, and then the radiator and hoses, etc. I might actually be ready to turn the key next weekend if everything goes well;).

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Rembrant's new non-Bullnose project

|

Administrator

|

Yippee!!

Yes, 50 psi with the drill is fine. In fact, pretty good. I find that my drill spins happily until the pressure comes up and then it slows down quite a bit. So I'd guess that your pressure will go higher with the engine running, although 50 is very good anyway. Hadn't thought of spinning the power steering pump with the drill. How did you connect it? Maybe your C2 has a hollow input shaft with a hex inside it and you used a hex bit? And you ran the steering left to right, but with the drill running? Otherwise the C2 would have puked all over everything. So, you taped the trigger on the drill so you could reach around and turn the wheel?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary,

Yes, My C2 pump has a hollow shaft and a 3/8" Allen fits perfectly. I have one of those 3/8" drive bits that I bought for a little impact driver I have, but it fits in the drill also. So I just hooked up the drill and put a zip tie on the trigger, and then got in the truck and ran the steering left and right a couple times. The level stabilized and seems to have burped all the air out. Was it necessary? No, not really, but it's one less thing I'll have to deal with and worry about when trying to get the engine fired up. If it happens to run right away, I won't have to stop it to re-fill the power steering. My cordless drill spun the oil pressure up pretty easily, but it started to labor at the higher pressures...I'd say over 40 PSI. I switched to one of my larger 4ah batteries and that seemed to handle it a little better. It seemed to reach 50 PSI with relative ease, but it did hit the 52.5 PSI mark if I spun it faster. However, I couldn't get it over the 52.5, so that seemed to be the limit with the drill at least. When I had my other 302 built/dyno'd a few years ago, I seem to recall it hit hitting 55 PSI, but my memory is getting fuzzy on the topic. That might have been at 5500 RPM...I'm not sure.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Re: Rembrant's new non-Bullnose project

|

Administrator

|

Good trick on the power steering pump. I'll have to remember that.

And not only do you not have to stop and top off the system when the engine starts, you know that there's no huge leak in the system that would prevent you from breaking the cam in.  I think your oil pressure is great. I think I've been seeing more like 40 psi with the drill, but I didn't really pay much attention to how much pressure, just that I have pressure to ensure that the engine is well lubed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |