Nothing Special's '71 Bronco

|

Administrator

|

Bob, I don't have an answer for you but came to say I've had a similar situation since I swapped flywheels and installed my 5-speed.

Blew the nose off a few of the older rocking pole style starters then switched to pmgr. Even those didn't last until I relieved the centering boss and shifted the starter tighter into mesh. I still have a torn up ring gear. And my truck starts like a Chevy that needs a shim, but at least it engages every time. You're absolutely right the time is now. "while you're in there" Hope you find a solution, and more importantly the reason for your troubles.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Nothing Special

is the ring gear not part of the flywheel?

|

|

Administrator

|

No. They are heat shrunk on.

Unfortunately one side is beveled so you can't just flip it over to get clean teeth. A new ring gear isn't very expensive but you need a torch and it's a lot of work to install a $20 part.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Nothing Special's '71 Bronco

|

In reply to this post by mat in tn

I could be wrong, but as I understand it, most ring gears are press-fit (or more often heat-shrunk) onto the OD of the flywheel. If I'm wrong then obviously replacing the ring gear will mean replacing the entire flywheel.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: Nothing Special's '71 Bronco

|

In reply to this post by ArdWrknTrk

Thanks. That definitely give me more to think about.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: Nothing Special's '71 Bronco

|

OK, finally a little progress. It took me a little while to be confident in what parts I needed to fix my starter gears. In the end I decided on going with all stock Bronco 302 stuff. Then it took a while to get the parts in. For some reason auto parts stores don't always have everything you need for a project on a 51 year old truck!

But this week I finally got to removing the old ring gear. That went easy enough. I cut most of the way through it with a cut-off wheel in my Dremel, then whacked it with a chisel a couple of times. Getting the new ring gear on was a bigger chore. It had a pretty sharp edge on the inside, so I had to grind a better lead-in on it. Then I heated it with the oxy-acetylene torch at work until it would start on. Finally a bunch of whacks with a big hammer and a punch and it was seated on the flywheel. So today I put the flywheel back on, as well as the clutch, bellhousing and starter. Laying on my back while lifting all of those things into position tired me out enough that I decided to call it quits for the day rather than try to put the trans back in (which is the next step). I did try turning it over with the starter and it cranked over nicely, with no weird noises or anything. So far so good!

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

That’s good progress!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

In reply to this post by Nothing Special

Yes, that's good progress. Well done!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Nothing Special's '71 Bronco

|

More progress today. I got the transmission back in. It takes a lot less time to type that than it does to actually do it! That wraps up the starter gear replacement (since the trans wouldn't have come out if I wasn't doing that) and it brings me to where I can actually start on the real project.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

Well done! Now for the real project.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Nothing Special's '71 Bronco

|

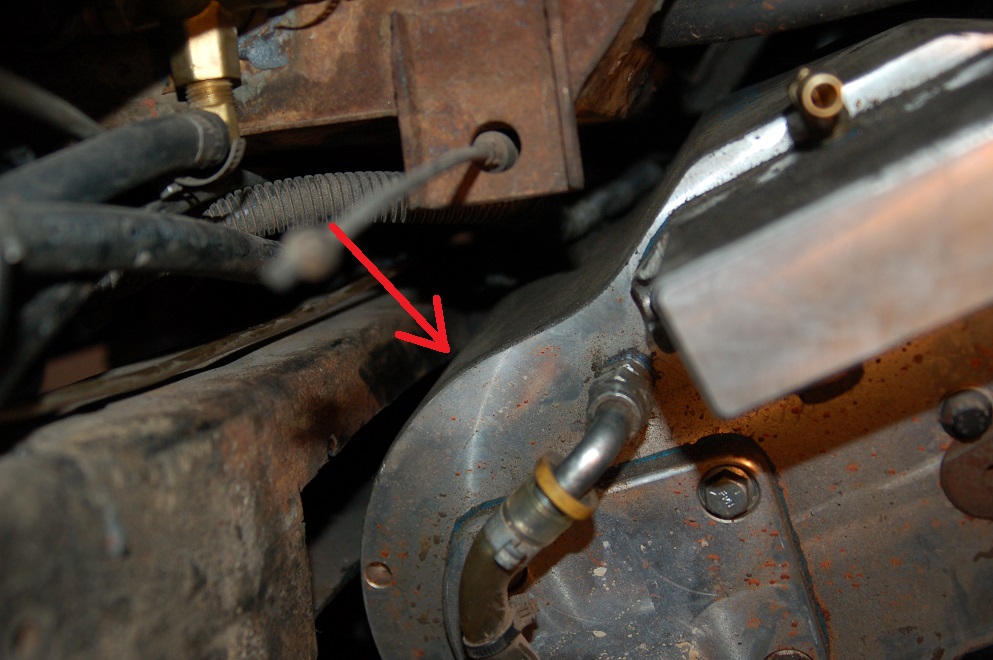

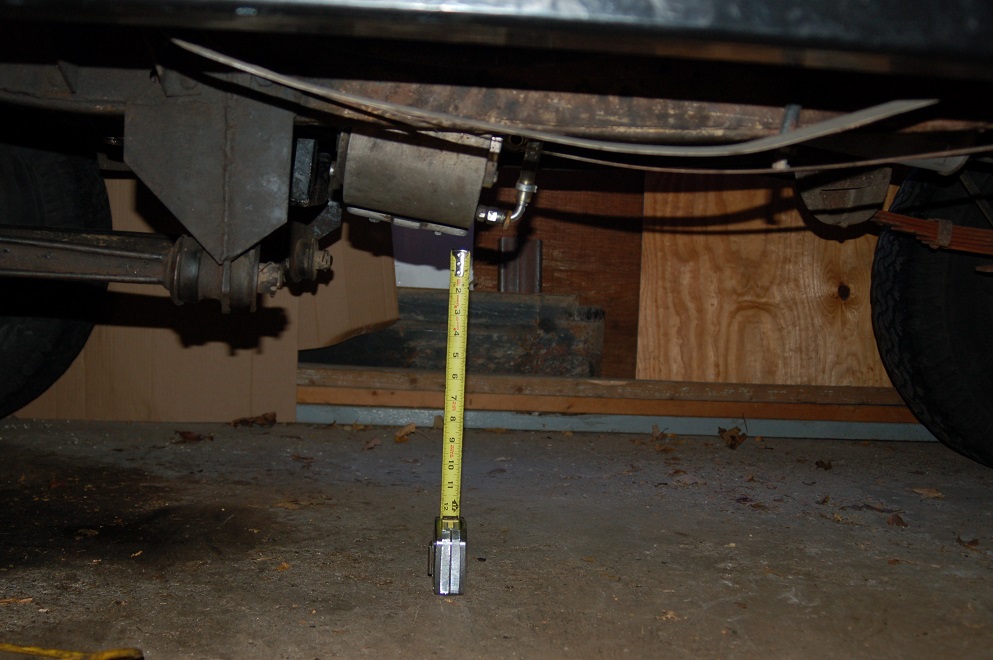

A lot of work with a little to show for it. I decided the first thing to do would be to make clearance to clock the transfer case up. The Atlas 2 transfer case has 4 sets of holes for the mounting studs. Putting the studs in different holes will rotate the 'case up or down. When I first installed the Atlas I found that it had to be clocked in the lowest position to clear the frame.

That hasn't been a huge issue with the dropped radius arm mounts because it was still higher than the arm mounts. But now that I'm going to be raising the radius arms I want to get the transfer case higher. Here's an out-of-focus side view showing the current situation. The tape measure is showing 15.5" clearance under the lowest point on the transfer case.  I started off cutting as little as I thought I could get away with, then tried fitting the transfer case in with the studs moved to the second position. I kept finding where it was hitting and gnawing off a little more metal until I could fit it in position 2. Here's the hole in the frame I ended up with...  ... and here are the places where more material needs to be removed if I'm going to go any higher   I don't really want to cut much higher on the frame, and I'm a little afraid that I might need to even go through the top of the flange to get to the third position. And opening up the hole more to the front would require moving the trans cross member mounting holes which gets a little challenging. (This last picture also shows the original radius arm mounting holes above the current dropped location). On the plus side, going up one position won't require making a new trans cross member (it would have to go below the front driveshaft rather than above if I go up another step. But on the minus side, I only gained about 1/2" under the transfer case  My original plan was to finalize where the transfer case was going to end up and then reinforce the frame where I cut it before moving on to other parts of the project. But I decided to put the transfer case on hold for now. I'm not at all sure that I want to do what it will take to go up another step, so I'll get the radius arm mounts back to stock height, get the wedges cut off the axle and rotate the pinion up to see how the front driveshaft lines up. At that point I'll see if it looks like clocking the transfer case higher will gain me enough to be worth the extra work.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

It looks like with the radius arms back in the stock position that the radius arm brackets and the Atlas will both have about the same clearance. Could you put a plate off the radius arm bracket to protect the Atlas and call it good?

And how are you going to reinforce the frame? Can you lay a piece of channel the same height as the frame on the outside and weld it on?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Nothing Special's '71 Bronco

I think the transfer case will be lower, but time will tell. And I am planning on putting a skid plate under the transfer case. I don't know exactly what it will look like or where it will attach yet. That all is yet to be determined. The plan is to re-box it by welding pieces in. I might also plate the outside of the frame. But I don't have much room for a channel there. It's wide open now, but that's where the aux fuel tank lives. I pulled that out for the drivers side rock slider last year and left it out until this project is done. But I do want to put it back in.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

The strength of a frame is in the top and bottom flanges, with the sides mostly supplying the strength to keep the flanges in place. That's why Ford was able to put holes in the frames, and why bridges have webbing keeping the flanges apart.

Cutting as you have had to do to rotate the Atlas up has significantly weakened the lower flange, so you need some way to give it some strength. If you can't put channel on the outside due to the tank how about a piece of angle with the flange at the bottom? Or, drop down and go under the notch, possibly incorporating the strengthening into the skid plate's mount?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Nothing Special's '71 Bronco

I know. That's why part of the reboxing will be welding a horizontal "flange" across the top of the hole, from the inner frame wall to the outer wall. I know it won't bas as effective as the bottom flange since it's getting so close to the top. But it's one of the best things I can do in the space available. That's also why I don't want to go any higher with the hole, and especially why I don't want to go through the top flange. That's a good idea! I was planning on having the skid plate attach to the outside wall of the frame anyway. I'll have to figure out a good way to attach it that helps with the structure as well as just keeping it in place (and that I can get at to remove, even when the aux fuel tank is in place). But it's definitely something to keep in mind. And another reason to hold off on buttoning up the frame until the end of the project, so I can think about how it all will go together best.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

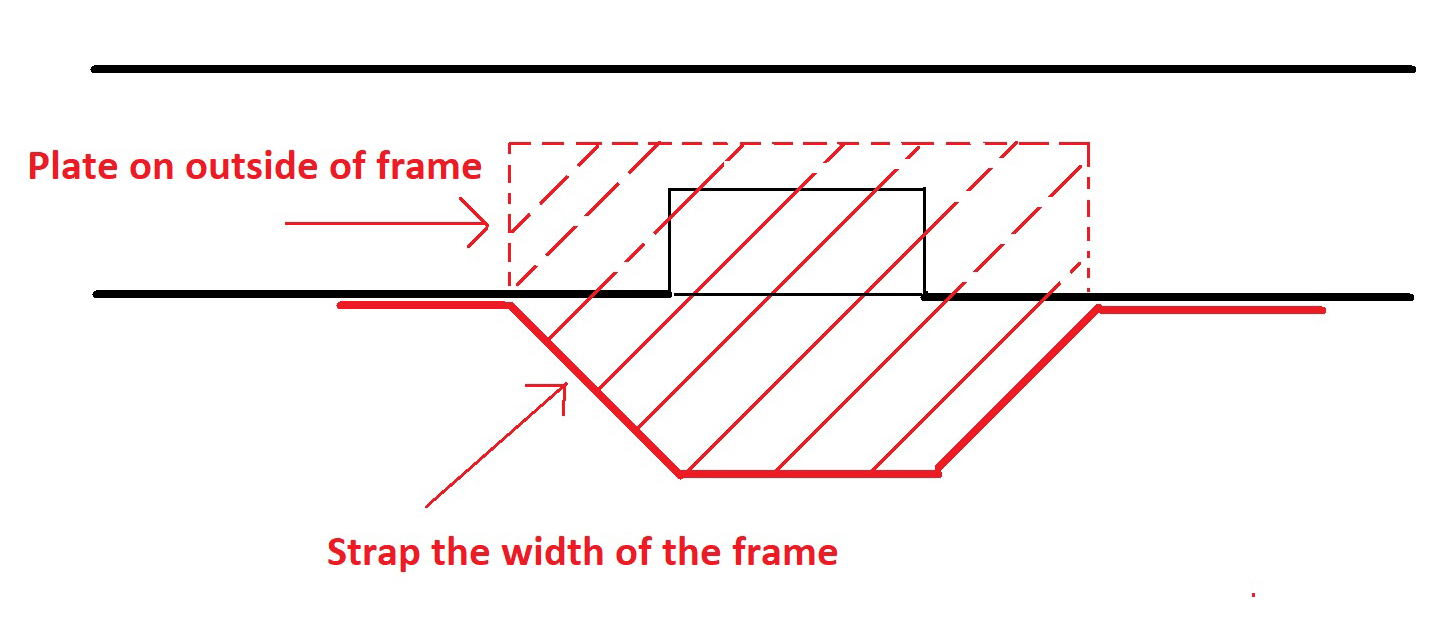

The farther apart the upper and lower flanges are the stronger the beam, all else being equal. So if you can come down at an angle from before and behind the cut with a strap welded to the bottom of the frame, and then fill the outside gap in the strap with plate up to the frame it'll add strength. Then somehow attach the skid plate to that.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

It might be to late but what if you took the part you cut out and flipped it top to bottom and turned it 180* and welded it to the top & bottom then make plates to fill in the ends to close it off.

Is that what you were saying Gary? Sometimes I have a hard time seeing what someone is saying on things like this. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

I don't think so, Dave, but then I'm like you and really haven't gotten my head around what you said. But I wasn't talking about using the bits that came out. Instead I was talking about strap and plate, as shown below.

This view is from the inside of the frame looking out, and the strap would be welded to the bottom of the frame ahead of and behind the cut. The plate would be welded to the outside of the frame, or maybe bolted, and welded to the edge of the strap.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Nothing Special's '71 Bronco

|

What Gary is showing is what I'm thinking about after his previous post. But rather than have the "strap" be the width of the frame rail (which I think is what Gary was saying), I'm thinking of having it be the entire width of the frame, going all the way to the right side of the vehicle. In other words, rather than adding a strap I want to see if I can tie the yet-to-be-designed skid plate in well enough that it's the reinforcement.

The main hurdle will be figuring out how to attach it to the outside of the frame. If it is actually the skid plate I can't weld it. If it's intended to be the frame reinforcement it can't just be a couple of bolts. And the aux fuel tank living there complicates things. If I can't figure that out I'll likely do something like Gary is suggesting with a separate strap. But I'll have to see what it all looks like as I get to that point.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

If it goes under the Atlas to be the skid plate then I think it has to sit lower than if it is just reinforcement. So what if it was two parts - the one I show that is wider than the frame rail by ~2", and a skid plate that bolts onto that with spacers that drop it down enough to go under the Atlas.

The ~2" lip, sticking in, is to bolt to. But that also means it'll have to go lower than if it was just the width of the frame. On the other hand, if the strap was just the width of the frame but was thick enough I think you might get by with two holes in it to bolt to. That would minimize the drop in the strap, but then you'd have even more of a need for spacers to get the skid plate under the Atlas.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |