New guy here

|

Administrator

|

I can see why you are considering selling.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I think I will try and replace the rivet and use a thick hardened washer to clamp the crack stationary since it runs through the centerline of the rivet hole before anything else. I don't see why that wouldn't help at the very least. Worth a try. I did find a pretty good-sized window in the frame itself next to the shock tower and I can almost touch the rivet on the inside with my fingers, so that makes it easier. I shall report back on this one.

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

Administrator

|

It is worth a try. Good luck!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by FordFETruck

Matthew, first drill a small hole at the end of the crack. This is called a stopper and is used to keep it from growing any further.

Second, see if you can find a good welder who can work with you to (a) grind a vee in the crack and (b) weld it together and then while everything is in position install the bolt and torque it. Good luck with it!

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

If I wind up getting that far into it, I can weld it myself, I have a pretty serious powcon welder (both ARC and MIG) and not afraid of doing it, just don't want to do it. From what I saw on the endoscope the crack goes completely to the end/corner of the edge of the crossmember. I cannot see a crack on the outside where it comes out of the frame though, so it's not that bad. I remember seeing new crossmembers for sale a while back, but can't find them anymore? I drove the truck a bit today, it drives pretty well, about as well as it ever has but that crack is allowing a little bit of play into the steering system when everything flexes, isn't much but enough to notice. I'll give the hardened flat washer and grade 8 bolt a try first and see if it keeps everything tight. If not, I guess I'll be gaining access to it and welding the thing up.

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

I'm still curious as to which cross member and which rivet it is. i can assume that it is in the area behind the steering gear. I have not run into anything like this and always want to know more.

|

|

Administrator

|

Gary has this pretty well documented here on the forum. 😆

I'm sure if you search "huck bolt" it will turn up his posts. The TSB listed above is correct.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by mat in tn

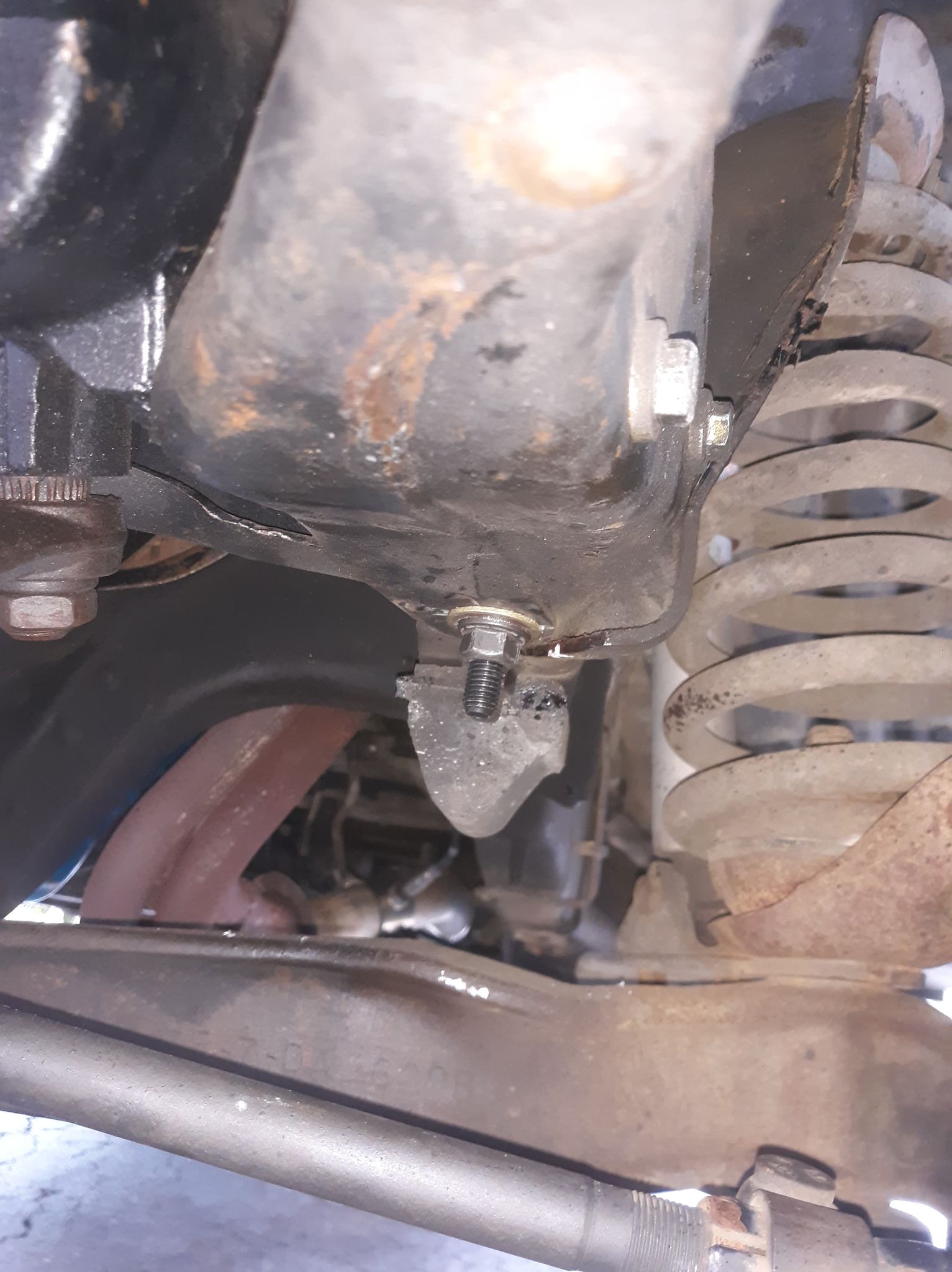

It's this rivet right here.

That is the crossmember repair that was done in March of 2005 at 190,000 miles according to the paperwork in the glovebox. Les schwab charged the original owner $125 for that weld!

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

Well the rivet replacement was a success. I'm not sure where the crack went as I couldn't find it after cleaning all the grease and grime out of the area. A 1/2" shouldered grade 8 flange bolt fit snugly in the wallered out 7/16" rivet hole, I used a hardened washer under the bolt and a hardened washer on the outside of the frame with a grade 8 metal locking nut, torqued to 100 ft lbs with some red loctite. The truck never drove so good the entire 10 years I've had it, I guess I will keep it around now.

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

Administrator

|

Well done!

Glad it worked out so well. Glad it worked out so well.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by FordFETruck

Hey, Matthew.

|

|

I guess i have just been lucky. I have not found this issue before but also have not looked for it. I will! I ha replace a good amount of steering gears and spring buckets so im familiar with the structure. I wonder how much road salt plays a part in the failures? Beyond the the obvious commonality of rust

|

|

Not sure on that one. My frame is rust free and still has quite a bit of paint left on it and it still cracked. I think this issue is more commonly found on high mileage trucks, especially trucks that were worked hard.

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

Administrator

|

The frame on Dad's truck was cracked at the back edge of the steering box. But the frame had no rust. And the truck had never been taken off the road. However, it did pull a travel trailer all over the US, so maybe that put stress on it?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I'm starting to think the stresses of hauling heavy loads and towing trailers is what causes the issue over time. My truck used to have a 5th wheel receiver in the bed, and the bed itself looked like it hauled a lifetime of gravel before I had it lined.

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

Administrator

|

As Jim/Ardwrkntrk has pointed out, if the truck is sitting still and you crank the wheel stop-to-stop the front bumper changes angles a whole lot. That can't be good for the frame.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Yeah, cranking lock to lock especially with the engine not running adds a ton of stress to that area. Even with the crossmember before the repair I had looked at the bumper and had someone turn it lock to lock and it didn't really move any, which surprised me. This only seems to be an issue with 7th, 8th and 9th generation trucks that share the same frame design, anyone ever hear of this happening on 6th or 5th generation trucks? the frames aren't all that different. I suspect the metal used was of a cost saving decision and doesn't like fatigue. After owning both Ford's from the 60's, and some from the 80's and 90's I have noticed a distinct quality difference in the materials that were used, other than obvious paint and anti rust improvements made over the years. Pretty sad when a worn out 64 Ford with trash front end components drives better than a 99 Ford with a completely rebuilt front suspension...LOL

1986 F250 351W, C6, 10.25 Semi float 3.55 gear, 250K Miles

|

|

that's interesting. I never turn the steering wheel unless I'm rolling. I always imagine the tires wearing unevenly. it's been a quirk of mine as long as I have been driving. about 35 years. and I have had my first bullnose since 1991. let me tell you as a young man I was not kind to bubba. he has been "airborne" more than I should say. sunk in sand banks in Memphis tn. bogged in mud in Arkansas. and sideways on as many gravel roads as one can imagine. come to think of it I had better go look there.

|

| Edit this page |