Search Forum

Need help diagnosing these noises

12

12

Re: Need help diagnosing these noises

|

Administrator

|

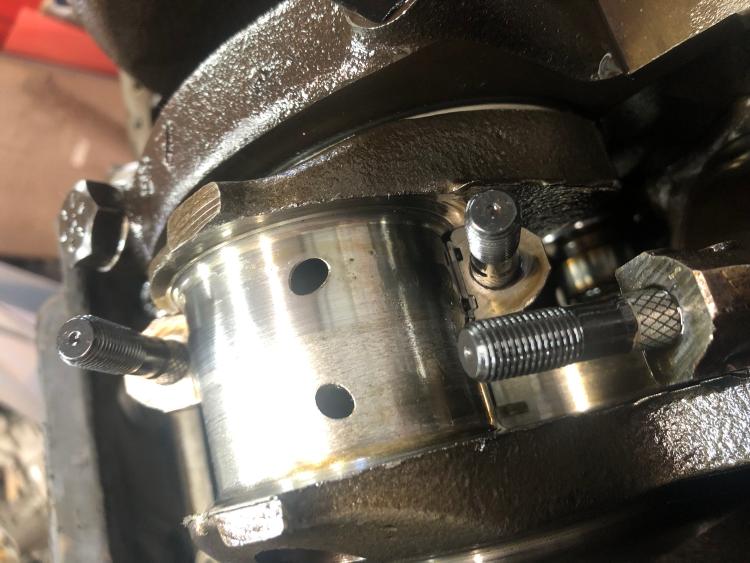

The pic looks fine to me. As long as they aren't rough.

My screen protector sees dirt and greasy fingers every day (night?) when I log VIN and registration numbers for calls, so it's not even close to pristine. 😆

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

|

Administrator

|

In reply to this post by Pete Whitstone

What does your aftermarket efi use for a knock sensor?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

The ProFlo 4 has no provision for a knock sensor, unfortunately. I guess it just runs a fairly conservative tune.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Need help diagnosing these noises

|

Administrator

|

My understanding is that it's still a speed density system that allows for updating the lookup tables so you can use cams with more duration and/or tighter LSA's.

Are you using an Edelbrock cam as part of a package? Did you put it on the Dyno before & after install? Are you able to share a single TPS with whatever tranny controller you use?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

It is a speed density system, yes. You can update tables and such but I really didn't buy it to do any tuning with it, I just wanted it for drivability reasons over the carb I was running. The engine currently has a stock cam in it, but while it's out I'm putting in a very mild upgrade. I did not put it on the dyno either before or after. I did not have an expectation of a horsepower upgrade. There is a single TPS which is shared with the trans controller, via some kind of doubler thingee sold by the trans controller people.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Need help diagnosing these noises

|

In reply to this post by Pete Whitstone

OK found the problem. I had pulled all the main caps and 1 rod cap, and they looked fine. Today I went down the line and pulled all the rod caps. The 3rd rod from the front had a spun bearing. While the bearing looked bad, the crankshaft looked worse.

The crank looks very chewed on, I'm not sure it can be undercut and cleaned up.  I'll have to take some measurements. But I'm looking at stroker kits too. Unfortunately as far as I can tell those all use oversize piston bores so I would need block machining to make that feasible. Still weighing my options. In the meantime, what would cause one bearing to spin while the rest look fine? I measured everything when it went together, and used plastigage to double check. So i don't think it was too tight, but I could have missed something. Thoughts?

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Need help diagnosing these noises

|

Administrator

|

This post was updated on .

Was the crush good when you assembled the engine?

Did you plastigauge all the rods? (I missed your final statement (after the photos) The only other thing I could think is a lack of oiling to that one rod.... or sometimes stuff happens. 🤷♂️ The Pro-Flo seems an awful long way to go to fix a carburetion problem. Id be throwing a lot more cam in it if I had a roller cam (from an Exploder?)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

Doesn't the rod journal get oiled by the oil galleries that zig-zag through the crank? I don't see how the journals on either side can look fine and this one be bad, but I'm not sure of the exact oiling path. When I rebuild the engine all those passages got cleaned with brushes similar to gun-cleaning brushes. I wanted FI and I didn't think assembling all the parts for a 30 year old factory system was going to be feasible or cost effective or easy to troubleshoot or have much support. I don't want to give up low end torque so I can have a higher HP number higher up, where I really don't spend any time. It's more of a work truck to me, not a hot rod. Mileage is bad enough already (10-11) so I'm not going to be wringing its neck very often. My cam selection was pretty conservative, 213/219 @ .050.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Need help diagnosing these noises

|

In reply to this post by Pete Whitstone

Rough measurements with dial calipers show that the damaged journal is about .040 smaller than the undamaged ones. I think the crank would have to be turned .050 or possibly .060 to clean up. The only advantage to trying to save this crank is that I won't have to have the reciprocating mass rebalanced. Just the machine work for undercutting the journals. New cast cranks from Scat are running around $400, then of course that would have to be rebalanced. Stroker kits can be had, but they all require oversized bores, so major machine work there, plus they need to be balanced (I think, not sure). Lotta money to spend down that path. The truck is my primary form of transportation, although I have other vehicles. So I don't really want it down for too long, which if I went down the stroker path I bet it would be. I'll have to see what kind of timeframes the machine shop is quoting.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Need help diagnosing these noises

|

Administrator

|

In reply to this post by Pete Whitstone

I didn't mean to suggest that oiling passages in the crank are blocked, just that one bearing may have smeared and/or shifted.

Something caused that one bearing to grab and spin. Cams aren't only about high rpm horsepower. (I have an RV cam in my truck and it doesn't do nearly as well as the stock cam did on top (with a straight up timing set) But I can put 2 ton in the bed, or 12 ton on a trailer and hardly know it's there, except for starting on a hill. If I had FI and the ability to tune it I'd be looking for a lot more than I'd get from a stock SD cam. Most strokers I know of are 408 (.030 overbore, 4.00 stroke) and it really doesn't make sense to spend that kind of $$$ to get a dozen bags of concrete at Home Depot.  Have the crank turned on the rod journals and fit whatever undersize bearings you need.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

|

Administrator

|

In reply to this post by Pete Whitstone

Scat offers pre balanced rotating assembly's 0.040 is huge! (Like plug gap huge!) I can't imagine you even have bearing shells left if it's that far gone. Bring it to a crank shop and bring the rod and bearing too. Maybe the rod is out of round or tweaked? I need to go back and study your build thread to make more sense of this....

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

The bearing shells are very thin at this point. The biggest undersize bearings I can find are .060, and the one source I saw for them say they are backordered til March. I'll have to do some more looking around if that's the way I go, or maybe the crank can clean up at something smaller than .060. I do need to take a closer look at the rod big end. If the crank got chewed on that badly, no reason to think the same thing has not happened to the rod.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Need help diagnosing these noises

|

Administrator

|

I looked back through your build thread and see where you say the crank was just under dimension on all journals.

Also that you didn't check or recondition the rods. Id definitely be looking at/for twist or ovalation in that #3 rod. Could explain how that one bearing lost pressure and failed once the bearings bedded in.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Need help diagnosing these noises

That makes a lot of sense. I did re-use parts from the 95 donor engine that I assumed were ok because they looked ok. I can't remember if the .001 undersize was on all journals or just the mains. I did address it on the mains by using oversize bearings as I recall. I can't remember doing anything with the rod bearings, but my memory kind of sucks these days. In light of needing a new crank (or cutting that one under if possible), wanting new rods (cause I maybe shouldn't trust these), needing an engine teardown to get all the bearing material that is no doubt everywhere, and having always wanted a stroker 351w, I am going to get a 408 stroker kit and rebuild the engine. Hope the wait time for the machine work is not lengthy.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |