How a LockRight works - Illustrated

How a LockRight works - Illustrated

|

Gary asked me if I could write something up on traction-aiding differentials for the "documentation" page. I'm having to start learning CAD at work (not the Cardboard Aided Design I've been doing for decades) so I thought I'd take a shot at making some sketches that show how a LockRight works. LockRight is a "lunchbox locker" that I've had apart and am familiar with. I believe that most other "lunchbox lockers" are pretty much the same, but I don't know for sure. I do know that a Detroit locker functions exactly the same as a LockRight, even though the internal design is very different. So this should illustrate how all automatic lockers work, even if the mechanisms they use to do it are quite different.

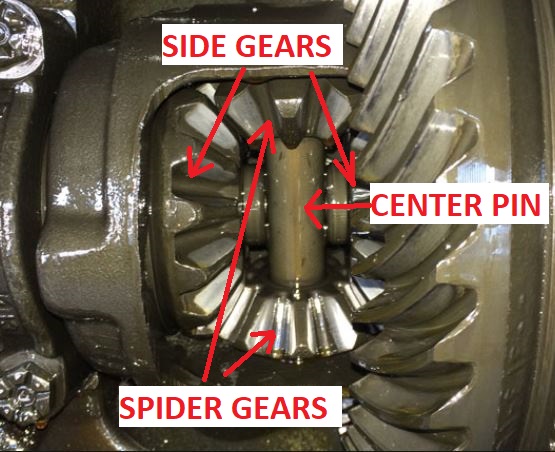

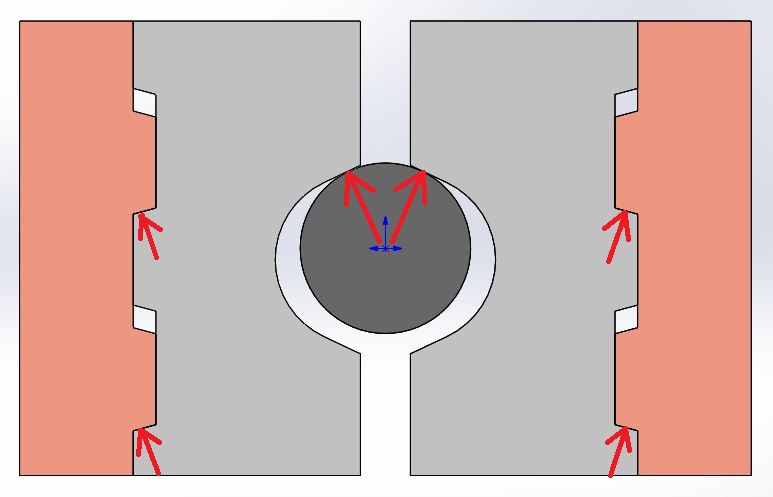

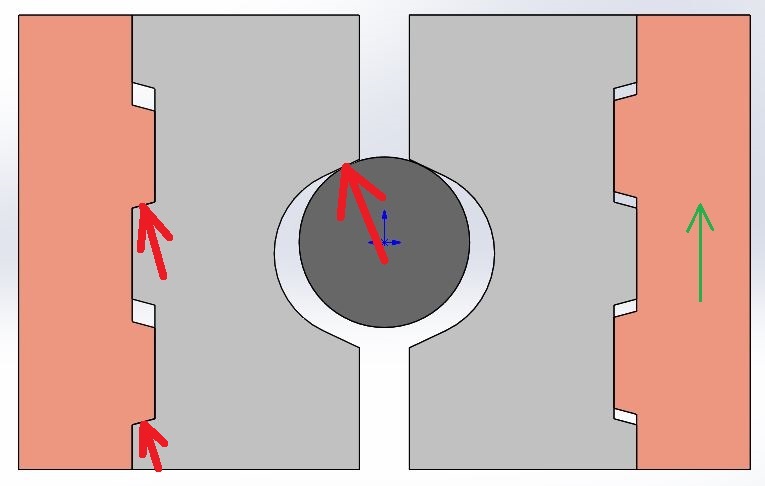

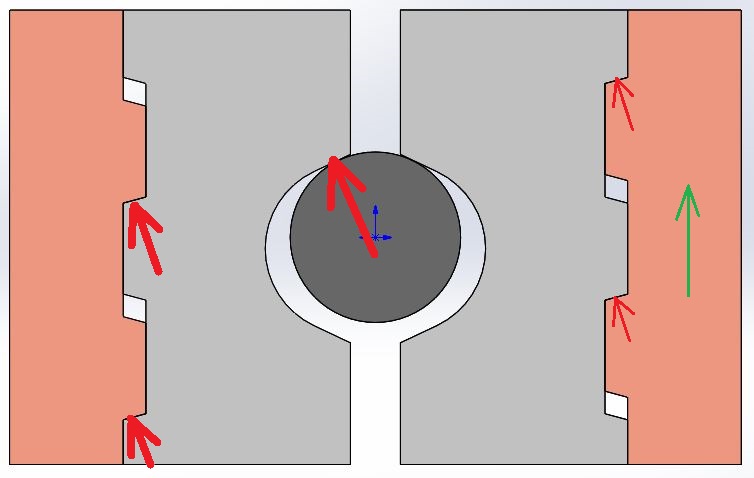

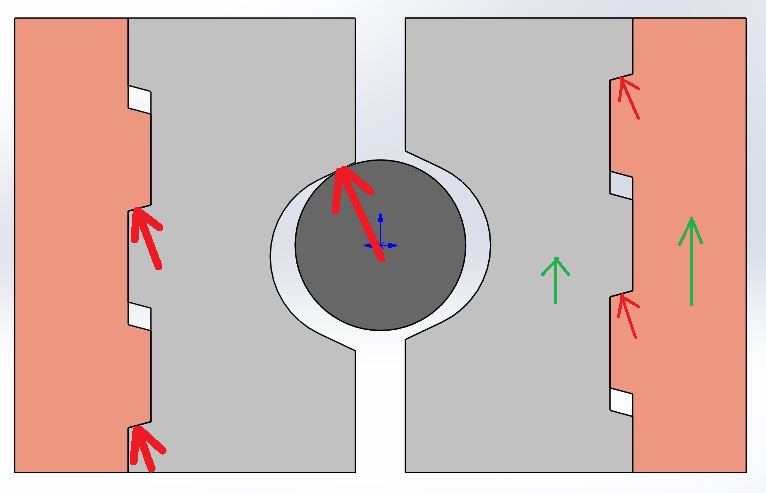

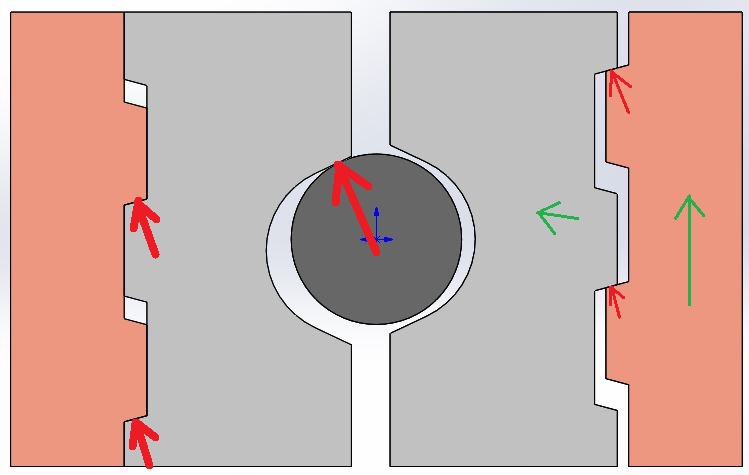

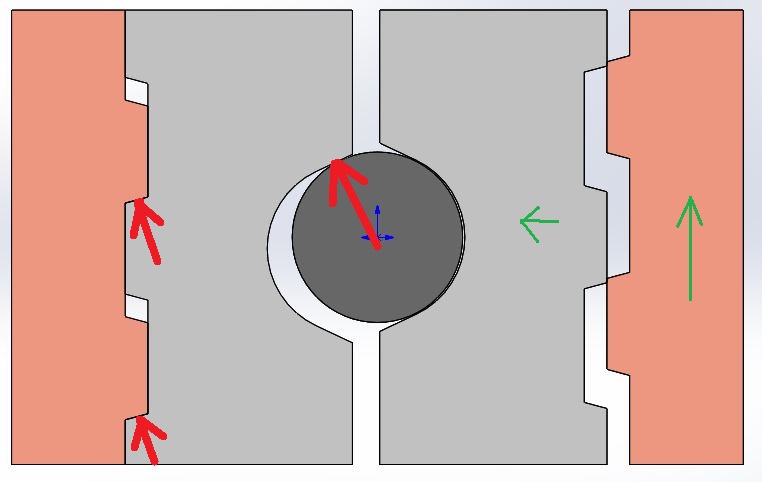

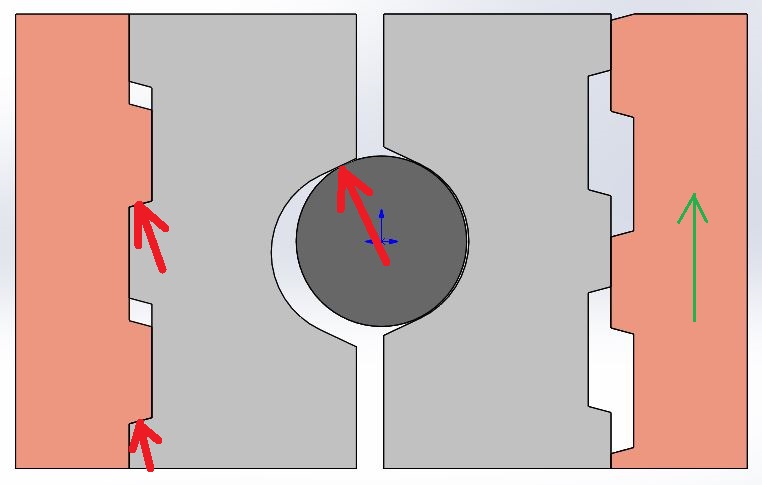

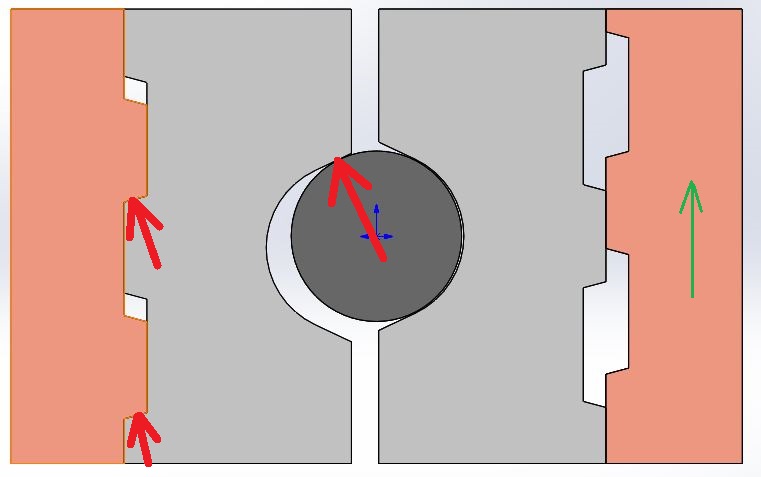

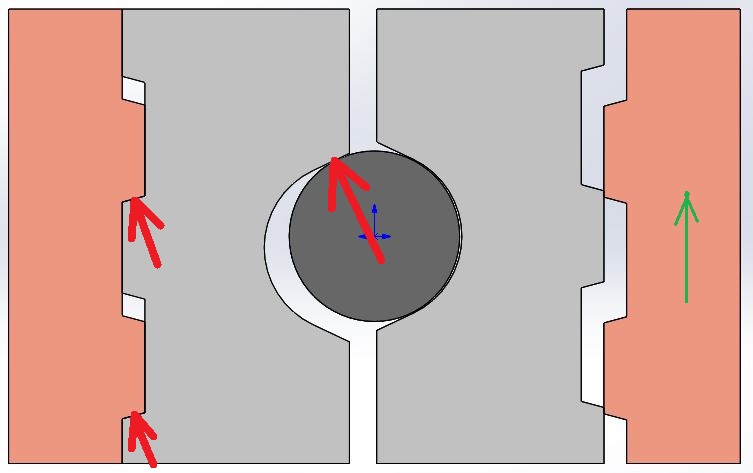

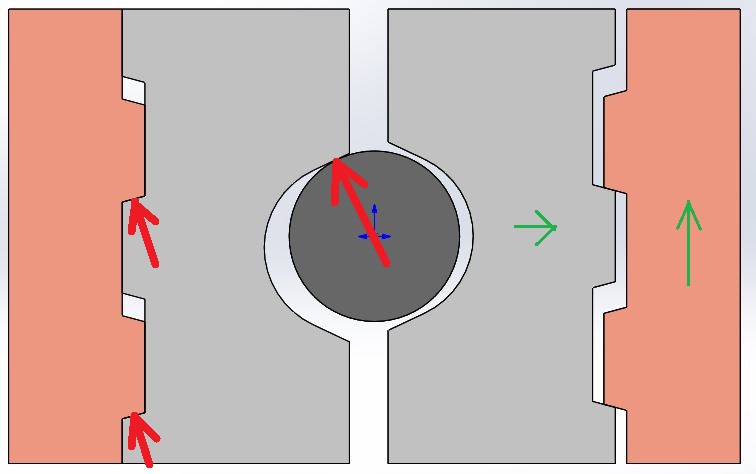

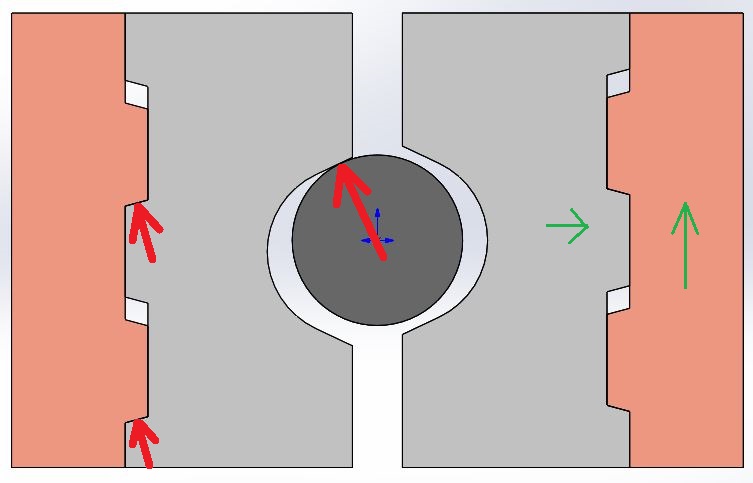

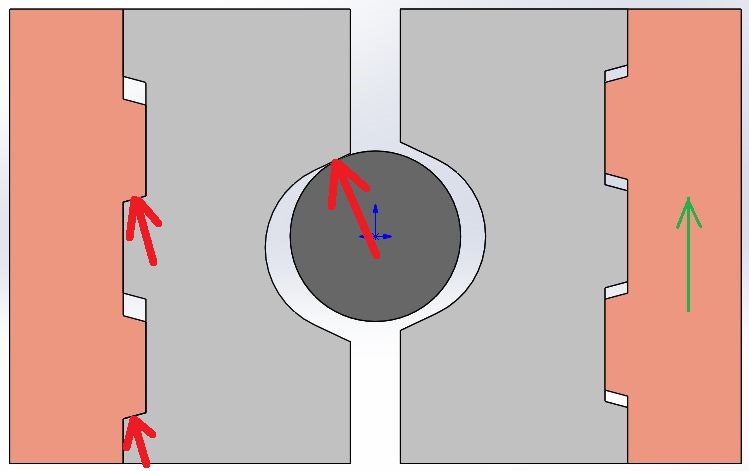

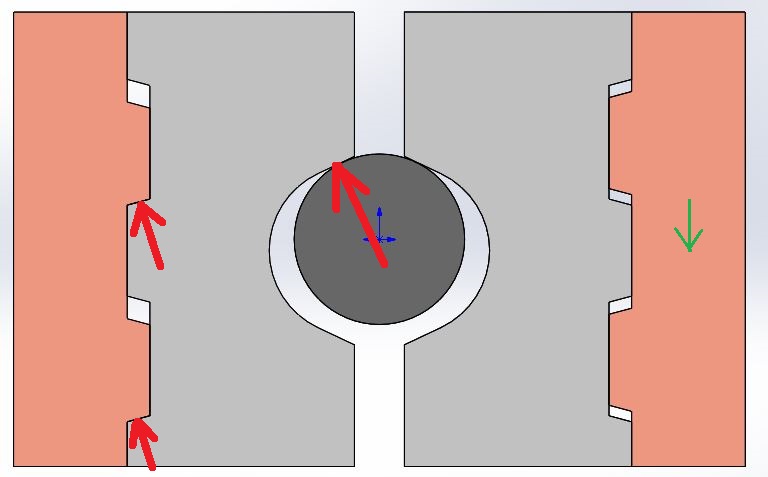

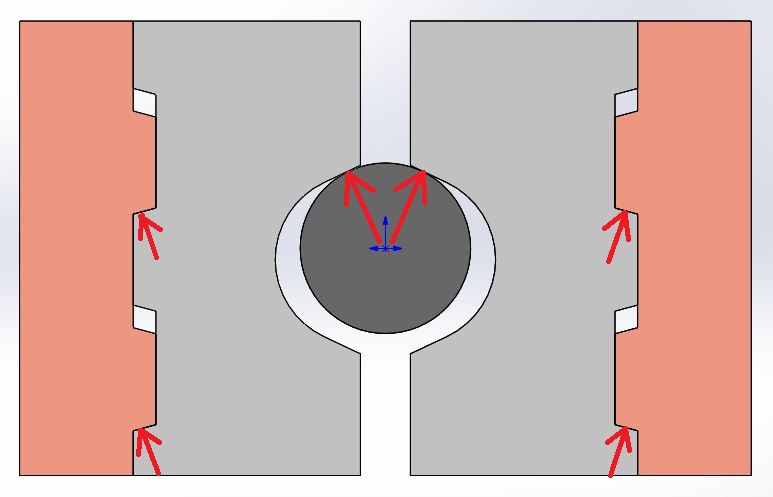

Since I'm trying to work this up for the documentation page, please let me know if anything seems unclear, or if there are any changes I should make. I'm posting this here so I can refine it if needed before it goes to its permanent home. A "lunchbox locker" is an automatic locker that replaces a few parts in an open differential, turning it into a locker. Here is a picture of a differential with the affected parts labeled. The side gears are removed and replaced with the outer clutch parts. The spider gears are removed and the inner clutch pieces are installed around the stock center pin.  In all of the pictures below, the center pin is shown in dark gray, the inner clutch parts are light gray and the outer clutch parts are pink. Forces are shown with red arrows and relative movement is shown with green arrows. The view is always looking straight in on the end of the center pin. Since the center pin is rotating with the differential carrier, that means that the point of view is moving too. Not shown in the sketches are light springs which push the two inner clutch parts out toward the outer clutches and some dowel pins that limit how far the inner clutch parts can move with respect to each other. Also the sketches are not to scale, but hopefully they still illustrate what's going on. In this first picture both sides of the locker are engaged and it's driving both tires. The center pin pushes between the two inner clutches, causing them to rotate but also pushing them outward against the outer clutches. The teeth on the clutches are tapered, so the contact pressure tries to push the inner clutch away from the outer clutch. But the angles are designed such that the inner clutches stay out against the outer clutches and drive the tires.  In the next picture the right outer clutch is starting to pull ahead of the right inner clutch. This is what would happen as you make a left turn. As it pulls away the forces in the right side of the locker go away because there's nothing to push on. That means the forces on the left side are higher since it's now carrying the entire load. You can also see that there would be no tendency for the locker to try to stay engaged under power, or to bind up in any way. There's nothing preventing the right outer clutch from moving forward, and once it does there's no way for there to be any force put on the right inner clutch.  As the right outer clutch keeps moving forward it contacts the next tooth on the right inner clutch. With the angle tooth face this results in a force pushing the inner clutch forward and in.  First the inner clutch moves slightly away from the center pin...  ... then when the dowel pins (not shown) stop the inner clutch from moving farther forward the angled teeth push the inner clutch inward...  ... until it moves in far enough that the teeth disengage and the outer clutch can start moving past the inner clutch.  The outer clutch keeps moving past the inner clutch...    ... until it gets past that next tooth. At that point the light springs between the two inner clutches (not shown) start pushing the inner clutch out...  ... until the teeth are fully engaged again (but still with all of the force going through the left side as the right outer clutch is still moving faster than the inner clutch).   As you continue around the curve this keeps repeating, often with an audible "click" as the inner clutch snaps out against the outer clutch. When you straighten out the right outer clutch will eventually drop behind a bit, allowing the inner clutch to catch up.  When the leading edge of the inner clutch tooth contacts the mating face of the outer clutch tooth, then there is a force path again, and the right side of the differential reengages, so we're back to the first picture.  So that's what I came up with. I welcome any feedback

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: How a LockRight works - Illustrated

|

Administrator

|

This post was updated on .

Looks good Bob!

I was watching a very good animation of a Torsen diff on YouTube the other day. https://youtu.be/JEiSTzK-A2A

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: How a LockRight works - Illustrated

|

Administrator

|

Yes, I like it as well. Good job!

On how to present it, we can put several pictures side-by-side in rows and/or in columns. So we can play with what looks best and conveys the thought. In addition, we can both put text immediately above or below pictures, but we can add captions to the pictures that pop up if you hover over them. So some of your descriptions might go into the captions.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Good job! Clearly understood.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

Thanks a lot Bob

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

|

In the other post I mentioned I’d like to try a locker. And Bob recommended a lunchbox locker with good reasons.

Silly me! After having to drive in snow, packed snow and ice, ice with a lot of, let’s say, inexperienced drivers, in my Xterra. I thought of what my truck would do with a locker. I’m convinced the back would try to pass the front too much! Made me think that an Eaton Posi or Truetrac would be much better. The Truetrac is maintenance free. Then again, I drove my truck the other day in snow and ice and thought I should probably leave well enough alone.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

Re: How a LockRight works - Illustrated

Having driven pickups with a LockRight and with a TrueTrac as winter daily drivers, I don't think it's significantly harder to keep the back end behind the front with a locker than it is with a TrueTrac. You have to pay just a little more attention to the locker, so it's not great for someone who isn't used to it. And the locker is a lot more annoyingly noticeable, so the TrueTrac is probably a better choice for most people. But a little too much power in a corner and either one will come around on you pretty quick. And having driven a couple vehicles with a clutch-type limited slip, I'd say they are the worst choice if stability on ice and snow is the issue (my opinion, I know others feel otherwise). You can enter a curve at significantly higher speed with an open diff, TrueTrac or automatic locker than you can with a clutch-type limited slip without having the back end slide out. I'm not talking about being on the power here, just coasting around the curve. Ant if you are on the power too much I think a (working) clutch-type limited slip is somewhere in the narrow range between a TrueTrac and a locker, so I'd say they're all in the same ballpark there (the worn out ones are better, but still usually worse coasting around a corner) Might be the right call. There are relatively few situations where an open diff isn't almost as good for traction as a traction-aiding diff. And an open diff is always the smoothest and gives the best stability. So it comes down to how often do you encounter the "relatively few situations", and how much are you willing to compromise most of the time for better traction in those times? I have a TrueTrac in my current truck and I think it's probably the best choice for me in that truck. But if I had paid $2000 (parts and labor) to put it in in place of an open diff I don't think I'd think I got my money's worth. I actually paid ~$1000 (parts only, the labor was already needed to deal with a different problem) to replace a worn out clutch-type limited slip, so I think it was the right call.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: How a LockRight works - Illustrated

|

Administrator

|

Bob - What are your thoughts on a remote-controlled locker in the rear? I'm thinking that's the best combo as it is open unless you tell it to lock.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Nothing Special

It’s interesting, and I may have mentioned this, I had a clutch type limited slip installed in my 94 F250 that I used to own. I didn’t think it was worth the money. I didn’t feel I gained traction where I should have.

My Bronco has a factory limited slip in it and I like it. I’ve never noticed it wanting to slide out on me in curves. But, I do have 190K on it. And I do slow down. I’m heading up in the snow today to watch some snow bike racing, never seen it in person, should be interesting. I’m taking the Bronco, I’ll be more aware now and see if I notice anything.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

Re: How a LockRight works - Illustrated

|

In reply to this post by Gary Lewis

I'm assuming you mean a selectable locker, like an ARB or an OX. For winter driving it may well be the best. Open diff stability almost all of the time, spool traction the few times you need it. And from what I've heard from people who do much mountain snow 'wheeling it's all they'll use (driving sidehill with anything other than two open diffs can do downhill in a hurry, pun intended). The main downside to selectable lockers in the cost. They are the most expensive diffs out there. But you're only talking a few hundred bucks, so it's not an overwhelming thing. Another downside is needing to do something to use them. Not saying that should be a big factor, but for instance when trail riding it's kind of nice to not have to think about when to engage the locker. Another way to look at it is that a selectable CAN provide the WORST of both worlds, spool binding and lack of stability when you don't need it, open diff lack of traction traction when you need it. Obviously it doesn't have to be that way, it just depends on how much you're staying on top of it. And for the scenario of winter daily driving it wouldn't be much hassle. One more thing I guess is that a lot of selectables are air-actuated, so if you didn't have your compressor running before needing it you might need to wait a bit while the pressure builds up before you can use it. Something to consider. Of course there are also electrically actuated selectables, including most (all?) of the factory-offered lockers. I don't know much about them, but I do hear of people replacing a factory locker with something from the aftermarket (I suspect that's due to factory lockers being more cost-conscious and less over-built than some aftermarket, but that's just a guess). And I've heard a few people less than entirely pleased with some aftermarket selectables (slightly flaky operation at times). There's also the OX locker that is mechanically actuated. You can also put an air cylinder on the cover (like I have) and make it air-actuated, or put an electric actuator on the end of the mechanical cable (like Gary is doing) and make it electrical. The biggest hassle with mechanical is routing the cable (it can't bend as sharply as an air line or wire) and mounting the hand lever (bulkier than a switch or valve). Bottom line is that nothing's perfect, but there are a lot of good options.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: How a LockRight works - Illustrated

|

Administrator

|

Yes, I meant selectable lockers like OX or ARB. Or the one that came from Ford on Blue's rear axle. Here's what the owner's manual says about it:

• In 4x2, 4x4 Auto, and 4x4 High modes,

|

| Edit this page |