Hissing whistling noise

|

Administrator

|

I don't know that it is just the time zone. I seem to have lots of conversations with myself as well.

And I think you are doing the right thing by deburring the throttle body and getting the screw lined up again. But I don't know about the different IAC's. It will be interesting to see what difference they make if you swap them out w/o changing the TPS.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Yes, very interesting test, cause I haven't read anything that these both are different such way. Kingfish from FSB told me last year to take the 90th version, cause these were the more reliable ones. He also mentioned that some have an internal diode...but he hasn't mentioned that they have a greater diameter.

FYI: the diameter of the 90rh version is identical to the hole in the counterpart at the plenum. The original 1986 IAC has a smaller diameter. So in the original setup from 1986 a part of the bypass bore from the plenum to the IAC was covered from the gasket. But you have to mention that I only can speak for the original 1986 302 setup. Tomorrow we will see what's happening. I also will put no silicone to the gasket from the throttle body to the plenum. I will mount all gaskets dry, so that I can remove the throttle body and the IAC without destroying the gaskets.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

It works! Yes, it works!

My bronco idles and the engine runs. I have set the initial timing to about 12 degrees BTDC and I have recalibrated the TPS after setting the idle screw. But I haven't got the hissing fixed...seems to be a problem of the throttle body or of the plenum...I have got cleaned all sharp edges inside the throttle body without success... Youtube Maybe I should buy another throttle body? But what if the hissing comes from the plenum? I was driving today and it's fires in to exhaust when I press the pedal...do you think it's better to set more or less initial timing?

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

Administrator

|

If you do not have the hoses and air filter on, you will get a hiss at idle. The factory air intake system pretty well muffles it.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

In reply to this post by ReneH

what do you mean by "fires in the exhaust"/ is your engine backfiring when you try to accelerate?

|

|

In reply to this post by 85lebaront2

Hi Bill,

Ok...have you seen the video I've posted? So I have my intake pipes and filters on... Do you mean the intake will hissing anyway, also if I buy another one?

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

In reply to this post by mat in tn

Hi,

yes, that's exactly what I mean...sorry for my wrong translation...  But the backfire comes only when driving. While the car is in neutral or parking position, it doesn't backfire, also when warm and getting rpm up to 3000.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

wow. it really seems like the issues and symptoms keep moving around. am I correct in assuming that you deleted all air pump and emissions control? is there a catalytic converter in place? is the o2 sensor in the factory position or was it moved further away from the engine (heat source)? what type of exhaust system?

I ask these as a primer for all thinking on this with you also, as it may trigger others as to what may cause this. im wondering if somehow you are way too rich in the loaded, high demand environment adding fuel to be ignited in the exhaust as opposed to being rather lean leaving the engine. how clean are the plugs after you test drive? does the engine feel smooth or does it have any type of pulse or stutter? |

|

Hi,

you are right. No EGR and also all solenoids deleted and replaced by resistors. No catalytic converter. The O2 sensor is heated and mounted in the downpipe of the passenger-side. Exhaust is stainless steel shorty-mainfolds with custom downpipes 2x 2.5" combined with a Y-pipe into a 3" muffler and tailpipe. I will check the plugs and send photos of the plugs, my exhaust and my exhaust mainfolds. The engine runs smoothly at low rpm while driving. Stepping on the pedal causes a power leak in acceleration and very much backfire. So that's why I'm thinking that's a problem of the ignition timing...maybe 12 degrees too much or too less...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

yes, the o2 sensor is a heated unit however it is not in the same environment that it used to be in nor is it in one like the 351 would have had. it is a much more open exhaust able to flow a lot more air and therefore much less back pressure. i like it and i have done the same on the truck I'm building but mine has a carb and no sensors. the exhaust gas oxygen sensor is very environment sensitive. it is possible that all of the components used to carry exhaust and heat away are doing too much. it seems to be getting way too much fuel for some reason. do you remember what size injectors are installed? are they the factory 19lb/hr injectors or did you replace them?

|

|

Yes, I remember. I have installed the 302cui factory injectors.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

In reply to this post by mat in tn

I forgot...there is something more to tell:

As you maybe know, I have the harmonic balancer of the 351W, cause the one from the 302 has the wrong weight for the crankshaft of the stroker kit. I'm also not sure if my timing mark is correct. Maybe it was or is bent a bit... Also as I'm looking back, I remember that i have set the initial timing maybe about 12 to 14 degrees...I think this can be too much...

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

So, today I have checked the timing and idle again.

With connected IAC I have had an idle of about 650-700 rpm with a initial timing of about 12 degrees  When connecting SPOUT, I get an advance of over 40 degrees at about 1,600 rpm. Now I have adjusted to about 10 degrees and 900 rpm idle.   I have the feeling that the whistling gets muted a bit as I have done this setting. Advance is now at about 38 degrees at something over 2,000 rpm. So maybe the 12 degrees were too much...I also still don't know if my scale on the balancer is correct... While turning the distributor, I have set it inadvertently to about 5 degrees initial timing...what should I say...the engine starts without problems and also don't runs bad (without SPOUT connected) with higher rpm...maybe this is an indicator? Tomorrow I will do another test drive to check if something changed.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

Administrator

|

Given what you've said about the crank and balancer I think I'd check to see that the timing mark is correct. If you don't have a piston stop you can make one with an old spark plug and a bolt with a rounded head, like what we call a carriage bolt - see below. You break out the porcelain and tap the body for the next larger size, which I think is 3/8" in SAE. Put the bolt in with a jam nut, and then install it in #1 cylinder.

You want to stop the piston close to TDC, so you may have to adjust how far the bolt stick out using the jamb nut. And you for sure want to be turning the engine over slowly by hand with all the other spark plugs out to make it easy. Note where the pointer is when the engine stops turning in one direction, and then gently go back the other direction. If your timer is right the pointer will be exactly as far from the TDC mark the other way as it was the first time. Saying it another way, let's assume that the pointer is on 10 BTDC when it stops when turning the engine clockwise. If the marks are right the pointer should be on 10 ATDC when the engine stops as you rotate back the other way. If not, you need to either move the pointer so it is correct or note the difference and adjust for it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I like that tool idea Gary!

We had a tool for checking on aircraft piston engines. So I found this at Summit. Handy to have for that price. I know it would cost Rene a lot more to ship it there, but gives you an idea of what the tool looks like. https://www.summitracing.com/parts/sum-900189 This is what I used on aircraft. Taped the degree wheel to the propeller spinner. https://www.aircraftspruce.com/catalog/topages/timing_ind.php

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

Good idea to post that link, Dane. It lets him know what the tool looks like.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

In reply to this post by grumpin

Hi and thanks for the tips and links.

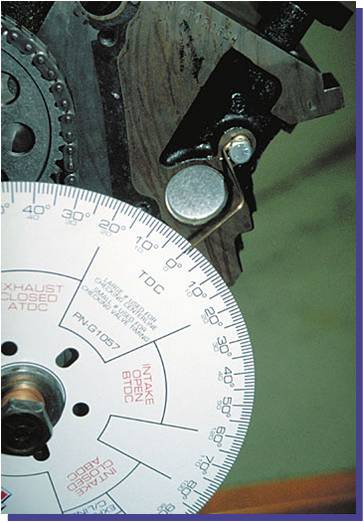

As I only can get non- adjustable types, here in Germany... My thought was to measure with a digital gauge. I have one with a magnetic stand. So if I set the engine to TDC on my balancer and insert the gauge and set it to zero, I will be able to see, when turning the engine slowly if the pointer moves plus or minus. If it moves plus, the TDC is wrong...if it moves minus, the piston is traveling down and TDC marking is correct...or am I wrong in assuming this? Or I can set it to the TDC marking, rotating clockwise, set the gauge to zero. Then rotating it counterclockwise also to TDC marking and see if the gauge also shows zero...if I understand it right, what Gary means with the piston stop manual.

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

This may help:

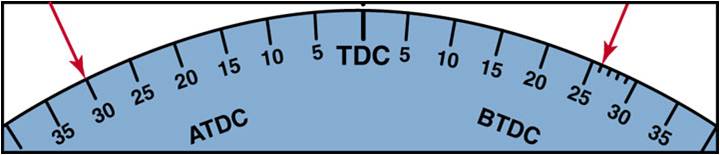

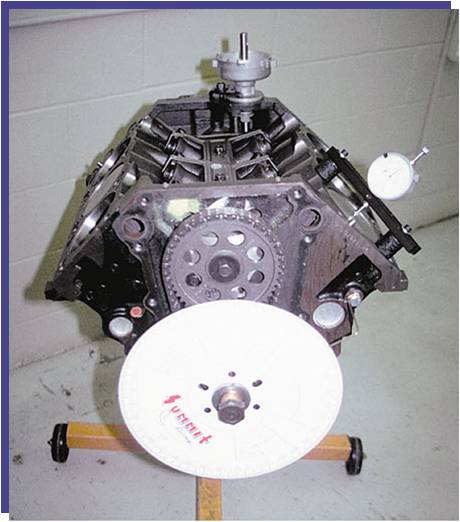

Locate the exact top dead center. Install a degree wheel and bring cylinder #1 piston close to TDC. Install a piston stop (any object attached to the block that can act as a solid mechanical stop to prevent the piston from reaching the top of the cylinder). Turn the engine clockwise until the piston gently hits the stop. Record the reading on the degree wheel, and turn the engine in the opposite direction until it stops again and record that number.  Here the picture indicates a reading of 30° ATDC & 26° BTDC. Add the two readings together and divide by two (30°+ 26° = 56°/2 = 28°) Degree wheel indicating where the piston stopped near top dead center. By splitting the difference between the two readings, the true TDC (28°) can be located on the degree wheel.

1981 F150 4x2 C6 Flareside 302

1986 F150 4x2 Flareside T170RTS 302 Efi |

|

Hi.

Thanks for this manual. So the length of the stopper seems not very important, only so short that I'll stay on my scale. As I have the engine fully build up inside the engine bay (and I won't take it out now) I can't perform every step... I'll see if I build up my own stopper or if I try my version with the gauge first... Today I'll drive again and check if the backfire is better at 10* As I'll use the 351W cam, I have read that a good initial timing is between 6 and 12 degrees. The maximum advance should stay below 36 degrees...what do you think?

René's Profile

Bronco 1986 Ford Bronco XLT 302/347 stroker with 351W EEC-IV and 351W factory cam C6 gearbox. Jeep 1986 Jeep CJ7 256 I6 with T5 gearbox. Buggy 1972 HAZ Buggy 122 Ford Cologne V6 Baron 1994 Chrysler LeBaron convertible 183 V6 4-speed automatic |

|

No need to take out engine, you can use the increments on the damper

1981 F150 4x2 C6 Flareside 302

1986 F150 4x2 Flareside T170RTS 302 Efi |

| Edit this page |