Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

I think you are off on the timing. Very late timing will make it run very poorly, if at all. So I suggest you put the timing light on and have someone turn it over. If it shows to be right there then maybe the damper has slipped, so find TDC on the compression stroke and check that your timing mark is right.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

certainly clean and properly identify the timing marks.

|

|

Well I finally got it running with the HEI. Feeling both very relieved and accomplished. I had to turn the distributor body, and thus the first plug terminal, a good bit further from the rotor at TDC than I thought would have been necessary. Any clue why?

I'm going to buy a timing light, and get a white paint pen to paint the timing mark so I can see it with a timing light. I believe I need to set the timing light to 10 deg BTDC and rotate the distributor body one way or the other until I achieve that? I haven't timed an engine before but looking forward to trying. Also, since the HEI install, I seem to be getting some squealing now when I give it gas. Could that be from the timing being off? I also noticed I didn't have the A/C compressor ground cable connected, because it was connected to the coil bracket, and I removed that bracket with the coil. Could no power to the compressor have caused the squealing when revving? I did not have the A/C on. Any recommendation on where to connect this ground now that the coil bracket is removed? I understand I should connect a vacuum hose to the HEI. Is there a vacuum port somewhere I should use to provide the vacuum to the HEI? And do I need to adjust the vacuum advance on the HEI? Finally, should I gap my plugs now that I have the HEI in? If so, any harm in waiting a bit on that, or should I go ahead and do that ASAP. That's a lot of questions. Thanks for bearing with me.

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

This post was updated on .

Squealing sounds like a loose belt or perhaps just more alternator load?

I would check for tension and look to see you didn't inadvertently get some grease or something on the belts when you were working on the distributor. Can you just put the coil bracket bolt back in and use that to clamp the compressor ground? If .044" was working fine with the old ignition there's no need to open the plug gap. Doing that will only cause your plug wires to wear out quicker or fail outright. If you get a dial-back timing light you could set it for 10° but I would chalk all the marks and just look for the second one before TDC if your damper is marked all the way up to 30° BTDC in 5° graduations like most. Someone with a YFA of the same vintage as yours could better tell you which of the vacuum ports is "timed" so that it has no vacuum with the throttle plate closed. It should be labeled (S) for 'spark' Tuning the diaphragm and centrifugal weights inside the distributor is not rocket science but you should try driving with the default settings before messing with it.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

My remembrance is that the YFA doesn't have a full-vacuum port with no vacuum at idle. IIRC you'll get a max of 10 or 11" of vacuum from the port.

You'll need a manifold vacuum port to get full vacuum. And with your manual transmission you'll probably be fine with that. (I don't like manifold vacuum with an auto.)

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

See???

I'm no expert at these 1V carbs.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I would start with a question. what type dist. was there before? if it had a vacuum diaphragm. use the same hose/port.

if you are just now learning about these systems then you are in the right room. lots of experience here and with systems many modern mechanics know nothing about. carburetion is more of an art then fuel injection is. if the previous dist. had the ignition module mounted on it then the rest of the system is expecting it to be complete. having an hei in an eec system is like being married to someone who does not speak your language. it does not compute! at best the two may work well enough side by side to be tolerable but they are not working together. and you are not making the best of what you have. as a learning experience you may only be learning how to do it incorrectly. |

|

This post was updated on .

Hi mat, the distributor I pulled out was the original Motorcraft distributor that interfaced with the EEC module and the previously removed feedback carb. So the EEC is no longer controlling the timing correct? What specifically is not marrying well now?

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

So if I understand you right you have swapped out the feed back carb & dist.? If so then the mirage is fine and should last LOL On the carb once the motor is up to temp and the idle speed set check each vacuum port on the carb to see what ones have vacuum and ones dont, make note of them. Now bring the RPM up and check the same vacuum ports again noting what dose and dose not have vacuum. 1 of the ports should not have vacuum at idle and then have vacuum with the RPM raised up. This is the timed port that should go to the dist. As for checking the timing with a dial back timing light mark the "marks" for TDC and 10* BTDC if that is where you want to set it. Motor up to temp, idle set, vacuum disconnected & plugged. Turn the dial back knob to line up the makrs to TDC. Where the knob points is what the timing is set to at that point. You can then turn the dist. so the knob will point to 10* BTDC Or you can set the light to 0 and turn the dist. so the marks you made line up at 10* BTDC. To check that turn the knob so the marks on the motor now line up to TDC and the knob should be at 10* BTDC. Dont forget to hook the hose back up to the dist. and take it for a test run. If you get pining pull the hose & plug and test again and let us know what is going on so we can help more. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Dave, that’s correct. I bought the truck with the feedback carb already swapped out. But the PO did not swap out the feedback distributor, so I put an HEI in.

I just got it timed to -10 deg. Easy stuff. Thanks for your help on that. I can tell it’s idling much better with the HEI. I haven’t test driven it yet since timing it tonight but very soon. I’m also going to get a vacuum hose to run between the distributor and carb. I’ll measure the port diameters unless anyone knows off the top of their head what they should be? Should I fool with the vacuum advance adjustment on the HEI or leave it alone? I have a factory tach so I also need to find the tach wire under the hood and connect it to the HEI. Did the tach wire connect to my old EEC distributor? Assume so.

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

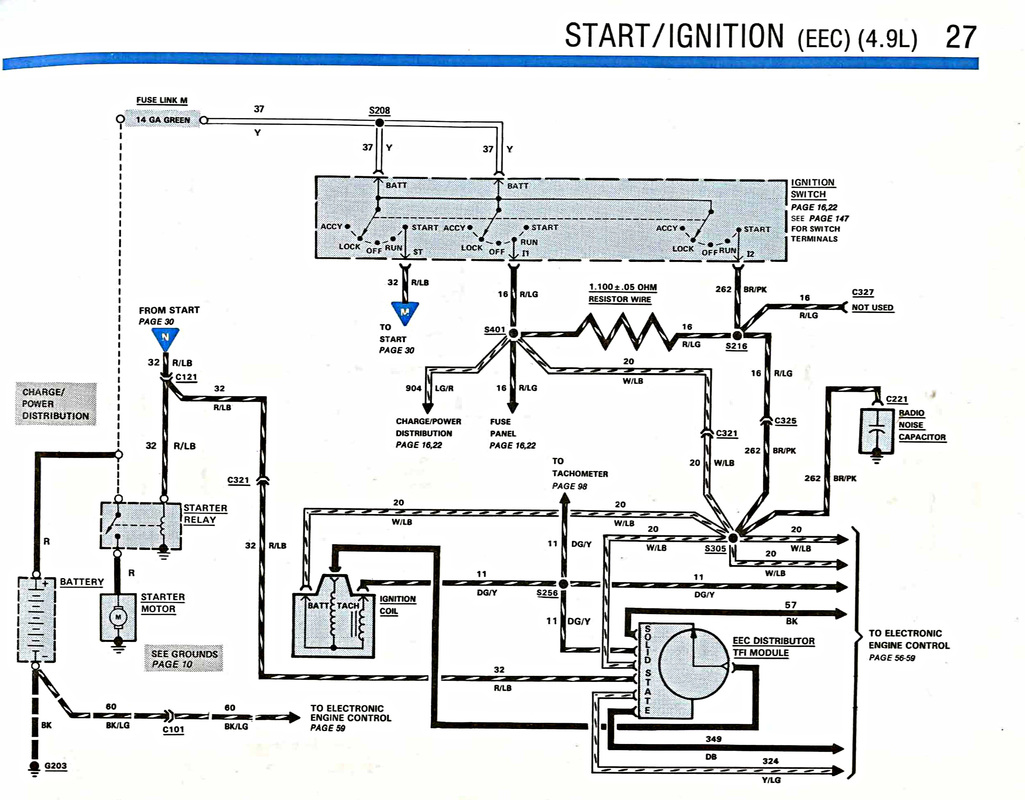

Tach wire was circuit 11 coming from splice 256 between the coil and the old TFI module on the distributor.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

In reply to this post by shosh86

I'm going to say the vacuum hose to my DSII distributor is 3/32", but I've got no idea about your HEI (do you know who manufactured it? -not who sold it-) Drive the truck and see if you need to mess with the advance. If you want a tutorial look for the Crane Cams adjustable vacuum advance instructions. This lays out all the basics and the order in which to do them.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Thanks very much Jim for all the info. I don’t know who manufactured the HEI. I’ll give the ports a measure at the carb and the distributor.

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

|

now that both the carb and distributor have been swapped you can unscrew the o2 sensor and use that spot to run a wideband air fuel gauge. bonus!

|

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

The Crane instructions are on our page at Documentation/Electrical/Ignition and then the Instructions and Crane Cam Instructions tabs.

And I'll say again, I don't think the timed vacuum port on the YFA gives full vacuum. I know that's strange, but I've run into it on more than one carb. So while I advocated ported vacuum for vacuum advance, I don't think it works as well as manifold vacuum on some distributors. I believe, w/o proof I might add, that the vacuum advance units Ford used for the engines with the YF or YFA carbs were more sensitive than those for other carbs. So the one in the HEI may not work well with the limited vacuum I think will be seen on the YFA's port. My first move would be to put a vacuum gauge on the ports and find out if I'm wrong. Does one port show essentially 0 at idle and ~21" just above idle when running in neutral? If so, call me crazy and go with it. If it doesn't have full vacuum above idle then it may not work with the HEI's vacuum advance. In that case I'd switch to manifold vacuum. But please let us know what you find!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

Got the HEI relay wiring in last night, with fuse of course. I also got the tach hooked up. For future folks doing this work, I took the relay trigger and the tach signal right from the two-wire connector going to the old coil. The grounding point I used for the relay trigger ground is the ground screw on the inside of the fender for the front left headlight. High current power through the relay comes from the very large yellow wire under the brake booster. I used a 20 A fuse. That yellow wire is at least 10 gauge. My wire stripper on the 10-gauge notch took off maybe 2-3 strands of copper. I'm mounting the relay and fuse holder on the inside of the driver's side fender, just behind (towards the cab) of the coolant/washer fluid reservoir. It's looking clean and working great.

Gary, I've got a vacuum gauge on the way.

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

Glad it is working out for you. And you'll like using a vacuum gauge to tune.

As for "It's looking clean", I'd say it is looking "clear" as I can't see a thing. Like I'm looking right through it. Hint: We have a saying - pics or it didn't happen.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary, ha! Here you go sir. In this pic, the relay and fuse holder are (obviously) not mounted yet. I'll also likely loom the wires. I'm also going to crimp cap that yellow wire coming off the relay. It's hot when the relay is switched off.

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

Re: Hello All - 1986 F150, 2wd, base trim, 300 engine, 4 speed

|

Administrator

|

Thanks for the pic! Now I see, said the blind man.

But, I have to ask if those yellow connectors are just normal butt crimps? I'm not fond of them as they are open to the elements. We've had quite a debate on here about crimps vs soldering, but we've pretty much agreed that it is best to use a connection that is sealed. My approach is to pull those yellow crimps apart so I have just the metal crimp part. Then I put a piece of heat shrink, the type with adhesive lining, on the wire and crimp the connector on. Next I solder it, but others say not to solder. Then we slide the heat shrink over and shrink it. That way the connection is both solid and weatherproofed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

That's not a bad idea. I do have some liquid electrical tape. I was thinking I'd goop some of that into the ends of the butt connectors, at least for the connectors with positive voltage.

1986 F150, 300 engine, 4 speed, 2WD, base trim

|

| Edit this page |