Gary's Trailer Quest

|

One other option to consider is a toolbox. Not so much for tools (although that might be helpful to), but more to carry/store tie-down straps. It's nice to keep them where you're going to need them.

Having said that, storage on a trailer isn't ideal. Trailers tend to live outside and get tons of road spray. So if the box isn't completely waterproof stuff will get wet and stay that way. One way I've seen that dealt with is to use expanded metal for the bottom of the box. That lets everything get in, but also lets it dry out. So I'm not saying you should get a toolbox. Just that it's something to consider.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

A 20mm ammo can is 14x18 x8 and under $20.

They make great panniers for KLR's. Lol

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I had originally asked each manufacturer to quote the trailer with a tool box. My intention was to put the battery for the winch in there. But, as I thought about it more I decided that having the battery in with tools and chain wasn't a good idea, especially since I'm going to wire the battery into the hot wire coming from the truck so that it'll charge while going down the road, or while using the winch if you run the truck. Plus, I'll be charging the battery with a trickle charger over the winter. So that might not be good on tools or chain.

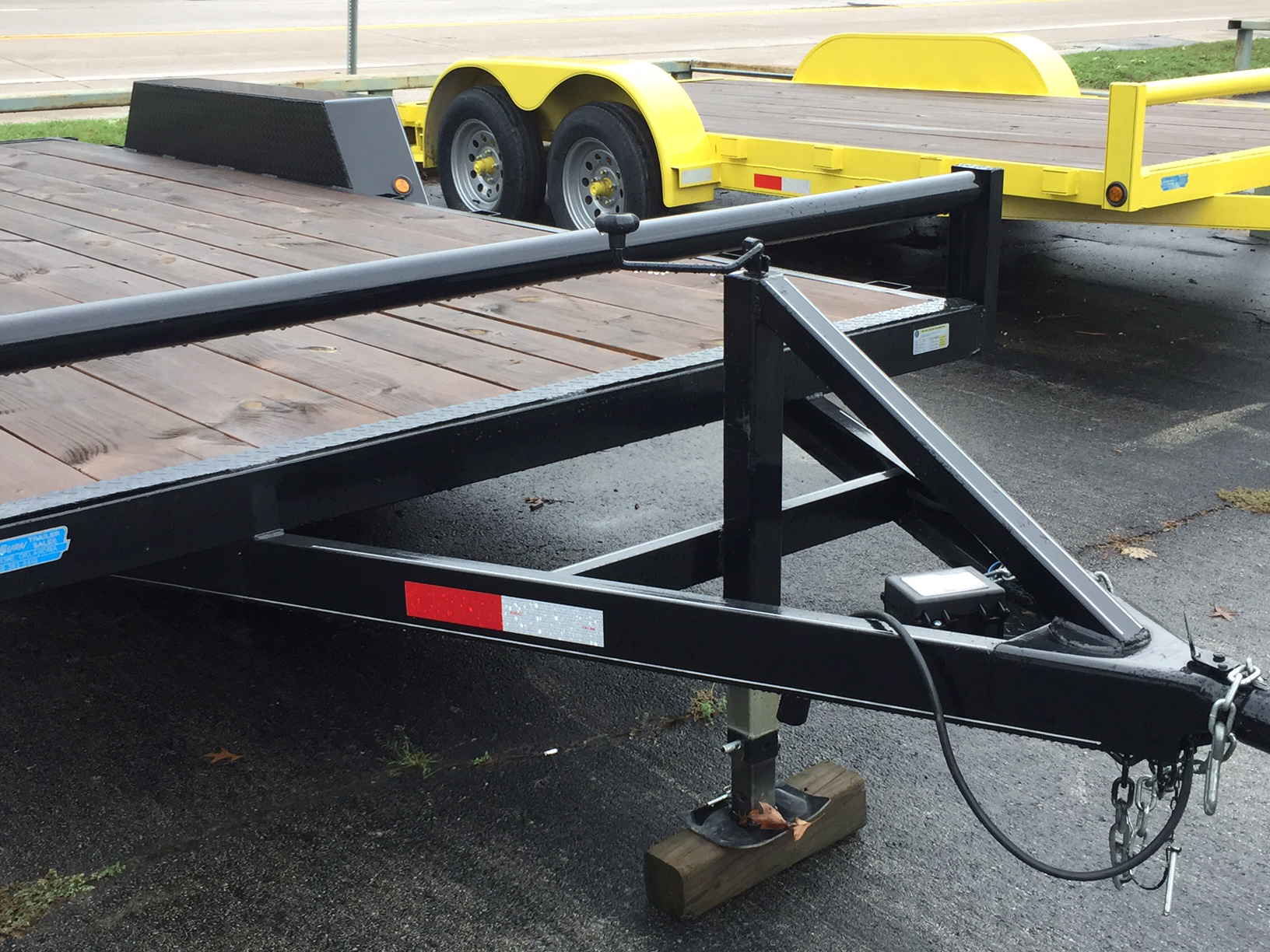

I finally decided that the better thing to do is to have them put a plate on the bottom of the tongue on which I can mount a battery box. And I'll keep the tools and chain in the toolbox in Big Blue's bed. Or, if I'm towing a long distance where I'll want to use my new truck, Blue, then I'll move the tools and chain over. And then I decided I want to go with a Turn & Burn trailer - and I haven't even seen one, although I will in the morning. However, I've seen one on their Facebook page, and there isn't a place to put a tool box, assuming mine will be like the one below. Note the winch plate that's down at deck level. I've asked that mine be raised up to the bump-rail level, as indicated by the green arrow. And, in case I need to have the winch line run just off the deck, I've asked that a D-ring be installed in the deck 16" back of the leading edge. That way I can put my snatchblock on it and run the winch line through it and along the deck for a low-slung vehicle. Also pointed out in this pic is the adjustable hitch, as shown in the orange oval. This one has 5 positions where most of the others I looked at have 3 positions. Last is the TrailerJailer hitch lock, which is shown at the end of the yellow arrow. One is being included with the trailer, and you can watch the video here.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Try this again, On the battery charge/winch system, the winch will draw probably 50-60 amps possibly more. The charging circuit will either trip the breakers or blow the fuse. I told a friend to use a cutoff relay so when the winch is activated, the charging circuit is shut off.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Good point, Bill. I'd wondered about leaving the truck's engine off, which would probably keep the voltage differential low enough that the current transfer wouldn't be a problem. But, then when you start the truck there'll be an even greater voltage differential and, therefore, a larger potential current draw.

So, what's the solution?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

It will still try to draw from the truck battery or batteries. Cutoff relay allows only the battery on the trailer to be used, but will resume charging if the truck is running as soon as the winch is off.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

I agree it will try to draw from the truck battery/batteries, but with the resistance of what may be a 12 ga wire the current may be mainly drawn from the trailer battery instead of the truck.

I think I'll have to find out. Maybe I should wire it in temporarily and see what happens. I wonder if going with a fusible link instead of a fuse would reduce the current flow given its smaller size.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

A fusible link is simply 'the weakest link'.

Fusible links are sized two wire sizes under the circuit wire (I.e. 12Ga. circuit =16Ga. link) You don't want to do this if running a load like a winch. Auto reset circuit breaker is the way to go. imho CB's idea is a good one. I could see that whole triangle from the front of the deck up to the hitch with expanded metal welded to the bottom of the rails. Handy for chocks, chains, tarps etc.. A weatherproof box for straps and such is a necessity up here in the salty, icy, North East. .... ever try to use a strap that has been rolled up, wet, and frozen? It takes a LONG time to thaw out by the floor blower.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I was thinking that a roll of fusible link, being two sizes smaller, might give enough resistance to reduce the current while winching so the breaker or fuse in the truck doesn’t trip. And, its heat-resistant insulation shouldn’t melt.

The problem I see with a fuse or breaker is that it will just trip and won’t charge the battery. So, once the voltage differential between the trailer’s battery and the vehicle’s battery reaches a certain point you will never be able to charge the trailer battery. What is really needed, in addition to circuit protection, is a current limiter. Something that will limit the current to maybe 20A max, but allow unhindered charging up to that value. And that’s a tall order since both batteries would eventually be at the same voltage, meaning no voltage drop is desireable. 😩

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

An auto reset breaker (like you use with a winch or plow) will come right back online as soon as it cools off.

Which is it's purpose in the first place. Current limiting diode banks are going to screw you when there *needs* to be a surge, or tug.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Perhaps the thing to do is to try it, probably starting with a 20 amp auto reset breaker. Maybe the length of small wire on the tow vehicle and the trailer’s pigtail will provide enough resistance that a reasonably-charged battery won’t pull enough current to trip the breaker. But, I doubt it’ll ever be able to charge a “dead” battery.

Hmmm, a large light, like a headlight, wired across the breaker would charge a dead battery, albeit slowly, while the breaker is tripped. And each time the breaker was tripped the battery would come up a bit more, allowing the breaker to stay in longer. So, eventually even a dead battery might come up enough that the breaker would stay in. 😎

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

I did something like that on my old slide-in camper. I had 2 charging circuits in parallel. The backup circuit had a power resistor that would trickle-charge the camper battery without drawing enough current to blow the 30A fuse. The main circuit had an automatic breaker. So if it took less than what the breaker could handle the main circuit would charge the battery with essentially no power or voltage loss. If it took more than that the breaker would trip and the backup system would trickle charge it. Later the breaker would reset and if the battery was charged up enough it would go back to charging through the breaker, otherwise it would trip again. I never had a high-draw item like a winch on that camper. But I set that up after parking it too long with the electric fridge running. When I started the truck (which closed an isolator relay) I blew the fuse. I didn't realize that until a while later, so the fridge was getting a little warm! I never had that trouble afterward.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

In reply to this post by Gary Lewis

Idiot light charging systems have a resistor in parallel with the battery light so if the bulb burns out the alternator still gets excited current.

It would have to be a big resistor, but I think you have one on the firewall of the 'Bee.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Jim - If the ballast resistor is 1 ohm and there’s a 4-volt difference (14-10=4) then I=E/R and the current flow will be 4 amps. But wattage is I*I*R = 16 watts. Is that ballast resistor good for that?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

It was more of a joke,(scavenging the Bee for a Ford pickup) but you would need a big wire wound resistor to pass charging current.

What are the ohms of the taps on a blower resistor?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I missed the joke.

I can check the EVTM for the resistor values, but doubt they'll work as they get quite hot even when they are in the moving airstream caused by the blower. And when winching the trailer will be stationary. Maybe a current-limiting diode across the relay? Anyway, on to the more immediate problem - picking a color for the trailer. Basically the guy said it should be bright so it can be spotted if stolen - which happens all too often. 😡 I don't know what I want to do re color, but picked up a color chart at a Home Depot and will look it over. And, as you have surely guessed, the trailer is on order, with about 4 weeks the guesstimated time before deliver. But, there is still one aspect I'm not thrilled about - the electrical connections. The butt connectors they use do have a shrink aspect to them, but from what I saw aren't water tight by any means. So I've asked if I can come over and make the connections myself when the time comes. On the other hand, there are many things I'm happy about. One is the fact that my deck will extend around the fenders and be 102" wide. All of the other decks I looked at were 82" wide. But, if your vehicle is wider than 82 and you need to drive over the fenders, where do the tires sit? On mine they sit on the deck. 😉 Another is the D-rings he uses. They are 15K # units as opposed to 6K on a leading brand. And they are not only recessed and welded to the deck, they are welded to the crossmember. I'll post some pics when I get home.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

It's gotta be blue to go with your tow rigs....

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Which blue? Big Blue has two shades, and Blue has another one.

Here is a pic of one of the D-rings:  And here's a shot of the tongue of a car hauler somewhat like mine. On the left is the TrailerJailer tongue lock. Then just to the right is the 5-position hitch height adjustment. And to the right of that you can see the rings to hold the safety chains - I'm having them move the rings back so the chains don't just hang down. Next to the right is the jack - welded to both the hitch and the tongue so it isn't going to move. And, that jack has an interesting spring arrangement that pops the drop-leg up/down when you turn the handle, thereby limiting the amount of jacking required. But, from there this trailer is much different than mine as I don't have either the tool box or the gravel shield. Instead, I'll have a treadplate on the bottom of the tongue on which to mount the battery box, and a winch stand 12" up from the deck.  And, speaking of the winch stand, my trailer will have a header bar like this trailer, the top of which is 12" off the deck. The winch stand will attach to that so the winch will sit just above it.  Last, here's my lame attempt to show what the deck will look like on my trailer. The fenders will actually be set into the deck, so the deck fore and aft of the fenders will be the full legal 102" wide. In other words, if you drive a big-tired vehicle onto the trailer and over the fenders there'll be somewhere for the tires to sit.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

I'd stay away from metallics, if anything for ease of touchup. how about one (or both!) Of the Ford engine blues? You'd certainly never be far away from the right color for repair. How about French Blue? ;)

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

This post was updated on .

Oddly enough, the guy showed me a picture of a trailer they painted in what he called Ford Blue. He initially said it was Ford's engine blue, but when I asked which one he said it is really "Miller Blue" from Sherwin Williams. I assumed he meant Miller welders, but the blue appeared closer to New Ford Blue to me.

But, what I don't want to do is to pick a color that will clash with either of my tow trucks. Here's Big Blue:  And, here's one of Blue:  And, Dad's engine is painted Ford Dark Blue, which is the color on the left:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |