Clutch Switch Bypass For Big Blue

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

Bob - You are right about the diode allowing the module's relay to bring in the starter relay but keep the LED from coming on when the clutch is depressed. But it would allow the LED to come on when the module's relay was pulled in. Well done!

That might just be enough positive for me to keep the module and add the capacitor. I can get 3300 mfd capacitors easily, and that might be just enough to keep power on the relay through the Run/Start gap. Thanks! That opens up new possibilities.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Clutch Switch Bypass For Big Blue

|

As I've said, more and more I find myself gravitating to the simplest solutions. But I still really like the elegant ones. I'm not trying to talk you out of a simple switch and indicator light, but I know you want a nice, elegant solution, so I don't want you to give up on it unless you WANT to give up on it.

And speaking of simple vs. elegant, rather than capacitors is there a "cleaner" source of power you could use? Something that doesn't drop out when switching to Start? I'm thinking your three general options are Ignition power, Aux power or unswitched power. I'm thinking Aux power is only hot when the key is in the Run position (or the Aux position on the other side of Off and Lock). So I don't think that's an option. But if it is hot during Start maybe that's what you're using? I'm guessing you are using Ignition power, because I'm thinking that's the only switched power source that hot in both Run and Start. But if you are using Aux (see above), maybe Ignition doesn't drop out as you go from Run to Start? Just a thought, but it might be worth looking into. And you should be able to get completely away from any problems of the power dropping out if you use unswitched power. That would mean that the timer module is always getting power, and therefore always draining the battery. But if it's solid state, does it draw so little power that it's not a problem? I'm not saying this will work, and you certainly don't want to trade needing to add capacitors for a dead battery! But soething else to think about over your third cup of coffee!

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

I'll think about that over my 2nd cup. First cup is almost gone and I'm headed to the kitchen for more.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

In reply to this post by Nothing Special

Yes, I'm using "Ignition" power, in theory because it would be hot in both Run & Start. But it isn't during the transition.

And I'd thought about powering the module at all times, but there's already enough electronics in the truck that I keep it on a charger when in the shop. (I think it is the camera system, mainly, which has a cutoff voltage 'cause it knows it'll pull the system down over time.) So I'm reluctant to add to it. And it is no fun wiring up under the dash in order to change power sources. The way I have power to the module wired with 1/4" male/female connectors, it would be easy to insert a diode/cap combo in the middle w/o even getting into the box, which requires pulling the horse collar trim piece below the column, which requires loosening the instrument bezel, which requires removing the headlight and wiper knobs. But to put the diode in, which I really like by the way, I do have to pull all of that. So the easiest approach is to make up the diode/cap circuit and add it 'tween the two 1/4" connectors, then pull the stuff off to add the diode - if the diode/cap combo fixes it. I see some 3300 mfd caps on Amazon so think I'll order a set of them in and make up the circuit with jumpers. If that works well enough I'll make it quasi permanent and then put the diode in the clutch switch circuit. Might as well since I'm close to having the elegant solution working well.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Gary Lewis

I just looked at your schematic and understand it now. I have had the worst luck with "Bosch relays that aren't from Bosch". Have you done a sanity check to ensure the resistance between 30 and 87 is indeed <1 ohm when the timer is activated? Maybe check it 10 times to be sure the resistance value has no variation....

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

I'm pretty sure it is the drop in power that does it, not the relay itself. I say that because you can see the LED come on when you push the "arm" button when in Run, and then go out as you go to Start.

And because w/o a 1000 mfd capacitor it works ~1/3 of the time. With a 1000 mfd cap it works ~2/3 of the time. With two 1000 mfd caps in parallel it works almost all of the time. I've ordered 3300 mfd caps and will test with one of them when they come in. But I could make it work even longer if I were to run the LED off the power ahead of the diode so the cap only has to supply the module. That would only take running one more power wire into the box, so if I break into the box to add the diode so the LED doesn't come on with the clutch switch being closed I'll add that as well.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

The LED will come on even if there was 100+ ohm in series (as you have established with the starter coil resistance)

I would still measure the relay resistance between 30 and 87. Just returned a brand new switch out of box last week as it was measuring 10 ohms contact resistance. The 46 year old factory one was measuring 1.6 ohms but still letting things function on my rear window on the bronco and with alternator 14V it overcomes any vtg drop. This is the upper limit safety switch. I haven’t thought much and I don’t know how you are using the cap but just a gut feel you are using a cap you are overcoming a potential resistance drop. My humble hypothesis. Edit: Just had time to read you are using the cap as a buffer to Power VCC on the module... not the power feed to the starter relay itself. In this case, it would indeed make sense that the timer is cutting out between Run/Start. If that is the case, while holding key in start (crank) when you push the "arm" button it should crank the starter, right ?

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

Yes, I'm powering Vcc for the relay module, and using a diode to isolate it from the rest of the truck's electronics. But if I put the LED ahead of the diode it'll cut the load in half.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

I assume the module is not losing VCC power while in Start, just cutting out between Start and Run.. That would certainly make no sense as the timer wouldn't function.

If the module has power while in start, while holding key in start (crank) when you push the "arm" button it should crank the starter, correct ? That will prove the Bosch relay is good. Still don't get why the LED would cut in and out sometimes... that's why I've been so hung up on the Bosch relay  Overall I get that the 2 options are 1) cap or 2) find another source to power the module... cap does make more sense. Thanks for bearing with my questions. Interesting problems. Love them.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

I'll check that the engine will crank if I arm the system in Start. It should. But I'm out and about and may not get to check it today.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I think I'm almost convinced the Bosch relay is just fine.

I have also been wondering why in your schematic, every time the clutch was pressed the starter relay wasn't energized and running the starter motor. - If that LED wasn't there, there would nothing in between the starter relay and the VCC power (12.5V with truck off and 14.5V with truck running at VCC).. which is similar to an ignition circuit. All that is between the starter relay and VCC is the LED. How does the LED prevent the starter relay from getting energized with the VCC voltage ? I saw an explanation earlier that the LED's max draw is much less than what the starter relay needs. Sounded like the LED was limiting the current (although I had assumed the total current which is Voltage/total resistance in series would flow through whatever was in the circuit)… As long as the starter relay didn't run I was satisfied. Moved on.. but now I'm wondering still. I am interested to see what you find from the Start + 'Arm'. I am thinking while cranking the battery the usual voltage drop would somehow interfere with VCC, and that's you need a capacitor anyway... I always recall how switched power devices like dash cams and head units turn off while cranking... those are acceptable because the duration of crank is small.. but here you are trying to move a while by cranking. Very interesting problem.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

|

This post was updated on .

Another thought.

If you do find that VCC voltage drops too much while cranking and affects module functioning and even 12V Bosch relay switching perhaps a 5V module might work better. Of course you will need something to step down battery voltage to around 5V. Something like a Buck or LDO step down DC-DC converter but it will be stable with any input voltage fluctuation. Some examples I quickly came across https://a.co/d/8b3NjxU https://a.co/d/5SVmjmK

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

Yes, that would work - assuming the voltage is the problem. But I should know that when I arm the system in Start as that is the worst-case test. Will try that later this morn.

Thanks.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Along the same lines here is another contraption that says it will take anything from 5-11V and produce stable 12V (looks an awful lot like DS-II)

https://a.co/d/6iuTZuu Did the timer manual call for input voltage stabilization of any kind, if not then I’m still hoping the 3300uf capacitor will do the job as it’s the simplest solution in front of you. The criteria should be crank&move for up to ? seconds.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

Well....

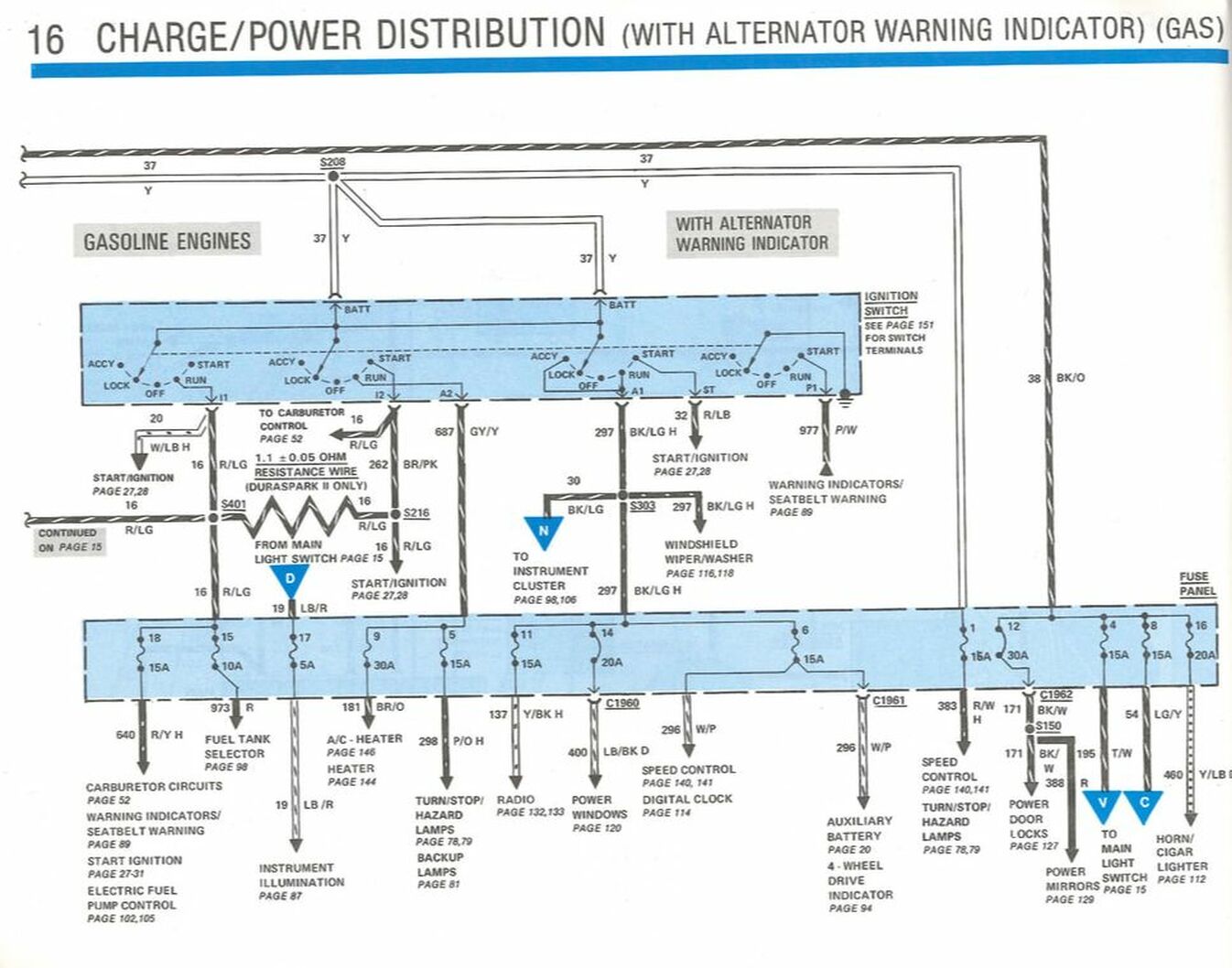

I turned the key to Start and then armed the module: w/o capacitance nothing happened. But with 3000 mfd if you armed it within a few seconds the engine started. So I put a meter on and the voltage was slowly falling off after the caps charged and it you armed while the voltage was north of 10v it started. As it turns out I'm not tied to a circuit with power in both Run & Start. I cannot explain why it even starts at all.  But, having now run a jumper from the ignition coil to the circuit it starts every time, with or without capacitance. With or without a diode. So the nut behind the wheel is, and maybe always has been, loose.  Looking at the EVTM & Big Blue's documentation the circuit I needed to have tapped is #640, the R/Y wire off Fuse 18 that feeds the seatbelt buzzer, warning indicators, tach, and fuel pump control. There's really only two fused circuits, that one and #973, that are hot in both Run & Start.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I went and watched the video again. Sounds like you just need the truck to start after its armed, correct ? Is that the mission profile of this module ?

After being tied to the correct circuit, any difference in behavior when clutch is pressed ? Does the starter relay do anything ? And lastly, is that literal or figurative ? Was the nut actually loose ? Sorry i struggle with metaphors

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

First, I'm the nut behind the wheel.

But there won't be any change to starting when the module is connected to the right circuit. Without arming the module you'll still have to depress the clutch pedal to get it to crank. But once the module is armed you'll have 10 seconds to start it with the clutch fully engaged. And yes, that's the intent for this module - start with the clutch engaged, but only for a brief period of time. That way it pretty much has to be a conscious decision to start it in gear, meaning it is unlikely that someone will arm it and then hit the starter w/in 10 seconds accidentally. And when you do arm it you'll be staring at a very bright red LED that warns you that you've done something dangerous. Speaking of the LED, with just the change to a circuit that is hot in both Run & Start the LED will still light any time that the clutch is fully depressed if the key is in either of those positions. But with Bob's suggestion of adding a diode I'll fix that so that the LED only comes on when the bypass is armed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

In this condition (without the diode) does the starter relay have enough power to be energized ? I still don't understand why the VCC voltage doesn't cause the starter relay to be energized with just the LED in the midst. I know with the diode this is a non-concern (very clever fix by the way). Speaking of that diode, it will cause a forward-bias voltage drop. Might be 1 volt right there?

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: Clutch Switch Bypass For Big Blue

|

Administrator

|

First, you may have missed that the starter relay I'm talking about is one of those large fender-mounted units that Ford used. Not a little Bosch relay.

And it depends on what you mean by "energized". The LED lights at .02A and the starter relay takes 3.5A to pull it in. So all the LED is doing is use the starter relay's pull-in coil as its ground. But the starter relay is not pulled in so the contacts don't close. Yes, the diode is a clever solution. And there will be about a .7v drop across the diode, but that's not a problem because the starter relay would easily be pulled in with a lot less than 12v. I've had a look and I've not found easy access to the R/Y wire for circuit 640. It looks like the best place to get to it is under the dash cover, so I'm going to pull that and do the wiring. But while the dash cover is off I'm about half way to getting to the module, so I'll go ahead and add the diode while things are apart. (We need an emoticon where a guy is wrenching or turning a screwdriver so we can imply to people that "I'm off to solve this problem and I'll be back.")

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by viven44

I assume you are not a fan of using add-a-fuse and just draw power from fuse 18 output.

When you are back, maybe I need to understand more about why the relay won't pull in when simply exposed to voltage. (It will draw the current it needs, right?)... See you soon!

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

| Edit this page |