Changing belts in my 1985 I6 no AC questions

|

This post was updated on .

After lots of searching for info, belt diagrams, part numbers, etc I think I'm ready to start this work but have a few questions.

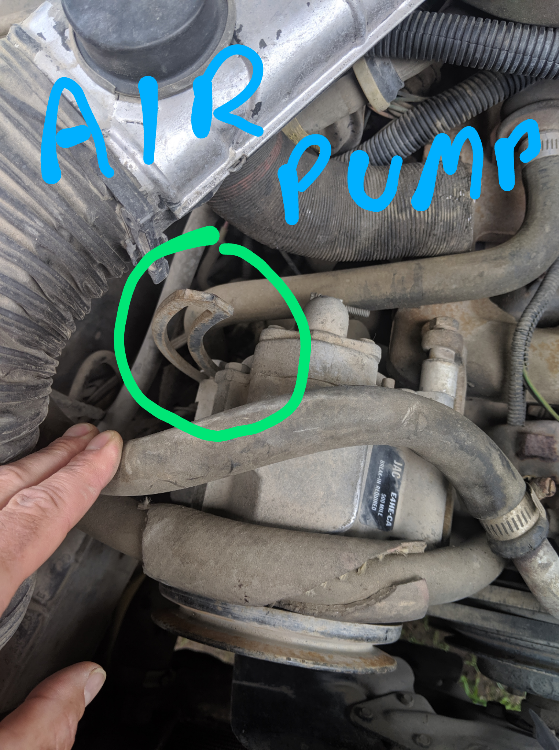

1. There are different size belts depending on the size of the alternator. So how do I figure out what size I have? The 40/60 or the 70/100. 2. There are 4 belts total. I want to be sure I know what bolt to loosen to remove and then tighten after installing. Pictures below. Can someone please confirm that I'm on the right track?    Thanks and I'll hang up and listen now.

'85 F250 I6 300

|

Re: Changing belts in my 1985 I6 no AC questions

|

Administrator

|

You are on the right track as you've picked out the right bolts to loosen.

As for the alternator, only the 40 and 60 amp alternators were used on the F-Series. So, as shown here (Engines/Drive Belts) you either need the ones for A/C or w/o A/C. And, do you want me to move this to the main section?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

In reply to this post by mq

Thanks Gary,

Some followup questions: 1. As you can see in the air pump picture there is no belt currently installed. Is it absolutely necessary? Should it be possible to turn the pulley by hand? If it's ceased up should I just leave well enough alone? 2. For tightening the belts after installation do I use the straight edge and ruler method? Thanks again.

'85 F250 I6 300

|

Re: Changing belts in my 1985 I6 no AC questions

|

Administrator

|

Ok, this is now in the main section.

If the air pump can't be turned by hand it is apparently is seized so there's no reason to put a belt on it. It injects air into the exhaust to help it burn when passing through the catalytic converter, so it isn't absolutely necessary. But, the truck wouldn't pass emissions testing. As for adjusting the belts, I like to see ~1/2" of flex when pushing firmly with my finger. But that is not at all scientific. And I'd rather have a belt a bit loose than a bit tight since too tight can hurt the bearings. Also, when you have two belts on the same device, like your alternator, they should be bought as a set or pair. Belts aren't held to a very close tolerance and buying two run of the mill belts rather than a pair will frequently have one of them tight and the other loose. But it is hard to find paired belts.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by mq

Thanks Gary,

I found paired belts at my local O'Reilly's. I'll tackle the job this weekend.

'85 F250 I6 300

|

Re: Changing belts in my 1985 I6 no AC questions

|

Administrator

|

Good luck with it. Glad you found the paired belts. Someone didn't use a pair on Big Blue and there's no way to get them adjusted correctly.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In reply to this post by mq

For each accessory, there will be at least one adjuster bolt to loosen, and at least one pivot bolt to loosen. If you miss a pivot, you'll be able to move the accessory, but it could be VERY difficult.

This caption explains how to free a seized air pump:  A 60A alternator wouldn't need 2 belts. Most parts stores have a tool for measuring used belts; but not all parts monkeys understand that used belts are stretched, so they shouldn't simply go with the measurement; they should find the next-shorter belt listed for that application. |

| Edit this page |