Big Blue's Transformation

|

Banned User

|

|

Administrator

|

Why didn't I think of that? Good idea! I do have a ball joint press.

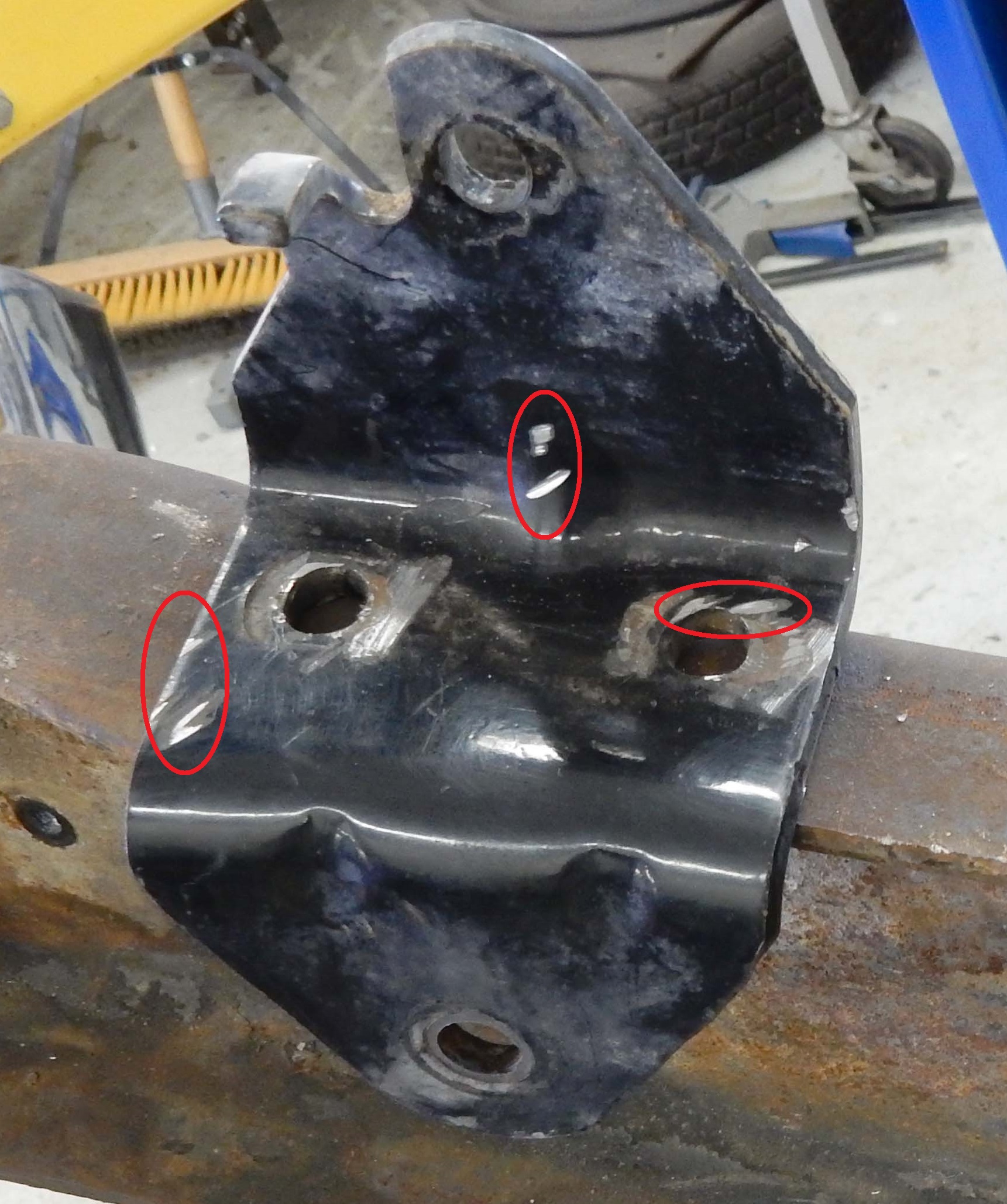

As for what the problem is, I've circled the spring eye bolt on the right side of the first pic, below. But I think your suggestion will do the trick. Here's what I got done today: Passenger's side spindle off & driveshaft outTie rods offBoth knuckles offU-bolts off the springs & shock plates as well as the driver's side wrap-around bracket offDriver's side spring offPassenger's side sway bar mount off - by drilling the rivets out. Lotsa work.Drained the lube out of the axleThe axle is now sitting on jack stands, not connected to the frame. I have a bit more to do to the frame, like get the driver's side sway bar bracket off as well as the spring off, and then I can put it out back. That will then let me use the shop crane and put the axle in Blue, and I'm set up to take it to Boom's Garage next week. He's going to put the new 3.54 gears in as well as the OX locker, and replace all the bearings and seals.  And here's the the passenger's side sway bar mount. Boy, am I glad that the plan is to cut a patch out of the cross member to repair Big Blue's as just removing those three rivets was a lot of work.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I have found that knocking off the rivet heads with a pneumatic chisel-tip goes easier/faster than a cutoff wheel/grinder. And it ends up cleaner. It looks like you used a grinder/cutoff wheel...? Maybe? Just checking.

Ford Grand Wagoneer - 1990 Jeep Grand Wagoneer preparing to receive a Ford drivetrain...

A Keeper - 1993 F-150 XLT Super-Cab 5.0 EFI 2WD E4OD 8.8" with 3.55 gear Sold it for my Grand Wagoneer project! |

|

Administrator

|

Steve - I don't have a chisel for my pneumatic hammer. Guess I'd better get one.

However, I think the only knicks from the cutoff wheel are as circled below. The marks to the right of the bottom holes are from the cold chisel I used w/the sledge. It took the paint, but didn't really mark the metal. The issue with those holes is that the top of the rivets for that bracket are a huge irregular mess. So I used the cutoff wheel to take them down to where I could figure out where the actual stem of the rivet was, and then drilled the stem. But you cannot drill straight down since the upper lip of the frame is in the way. So I had to drill at an angle and, not wanting to enlarge the holes in the bracket, couldn't drill the rivet completely out. Given that, I used a chisel to take the remaining top of the rivet off.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Big Blue's Transformation

|

In reply to this post by Gary Lewis

Gary,

Have you decided on how you want to operate the OX? I know you were first talking about the electric actuator, but not sure if you are locked in on that. Not that it matters much yet. The diff itself is the same no matter what actuation method you use. There's a different diff cover if you are going to use the integrated air actuator (that's what I have). But I'm pretty sure the cable, electric, and add-on air actuators all work with the standard diff cover. So until you buy a diff cover your options are wide open, and with the standard cover your options are still pretty open until you buy the actuator.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

Bob - I want to go electric, and that's what is priced into the quote. (See Post #1 for where I am with this.

) What I don't know is how long of a cable I want as the cable goes from the cover to the electric motorized unit. ) What I don't know is how long of a cable I want as the cable goes from the cover to the electric motorized unit.

I found one Youtube where a guy wrapped the shift cable in a big circle and put the shift motor on the other side of the axle. But I want the motor up higher, and won't know where that is until I get lots farther into this. So I guess Monday, after the root canal, if I can talk I'll call and see what they recommend. Maybe they know a good spot on an F350, or at least how long of a cable to get. Or maybe they'll agree to swap cables if the first one I get is too long or two short. I need to find one of the F600ish radio bezels. My plan/hope is that the OX switch will go into one of the slots on that, and another switch will bring on the air compressor, and yet another will parallel the batteries. Maybe another for lights? And then the slots above the switches will be used for readouts for the Arduino.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

Glad to hear the endodontist can get you in right away.

Hope you're back to 100% in a couple of days. You have me thinking of a puller that is hybrid between your and Bob's with the advantage of not needing a nut and having a more conventional implementation. Do you know the thread and what's the OD of the flange on the bottom of the spindle?

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I'm not going to make it out to the shop today as we have things going on at church all day. And with the root canal at 8 in the morning, I'm not sure I'll make it tomorrow. But, hope to on Tuesday and will check the dimensions you asked about.

But the flange OD is roughly 6 1/2" and the thread is just less than 2", although I don't know the pitch. Will check it out for you. However, if you found a nut, that could be welded to one of the cheap sockets like I have, you'd have the adapter for the slide hammer. Plus if it didn't work, and I'm not sure it would have in this case, you could still use it as the nut for Bob's puller. And, if the standoffs were actually hardened bolts or all-thread with inside & outside nuts welded to the channel, they could be used as a conventional puller as well as striking point.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

A plate of 5/8 or 3/4" (square or triangular) with all holes threaded could be spun onto the spindle, and like you said, then fully threaded hardened bolts (or even something like a clamp screw with a pad on the end and fine acme thread) could pull the spindle off.

Just need the inside edge of the pusher holes to clear the flange. With a CNC and 3D modeling you could start with even thicker plate for more thread engagement if needed and relieve a lot of the weight while still being stiff enough.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I was impressed with how well the 3" channel did. I didn't notice any bending. And while it only gives you two stand-offs, that was enough. Three would be better, although I don't think you could get four bolts in contact with the knuckle as the back edge of the knuckle stops 3/8" ahead of the spindle.

But, given the way the knuckle falls away from the edge of the spindle's flange, the bolts/stand-offs have a habit of angling out. That's why I suggested nuts welded to both the front and back of the plate, as that would give over an inch of support to the bolt. And fine-threaded Acme bolts would be ideal. I hope to not have to do this again. I'm going to clean the spindles and knuckles up very well and then paint them with anti-seize before re-installing them.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Big Blue's Transformation

That's the right solution! (unfortunately you can't use this solution until you have it apart) In the past year or so I've taken the spindles off both my Bronco and my F-250. In both cases I was the one that put them on and that was 5 - 10 years earlier. Both came off by hand.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

Good to know, Bob.

I watched a Youtube about taking D60 spindles off, and it was obviously not rehearsed. The guy explained that getting them off can be a real bear, and that the first approach is to hit the end of the spindle with a mallet to work it out. So he hit the end of the spindle and it fell off in his hands. Boy, was he surprised! Unfortunately mine didn't quite come off that easily. So, what do you think about the electric shift idea and the cable question?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Big Blue's Transformation

As you know, I chose the integrated air actuator and have been very happy with that choice in the limited time I've had it. If I didn't have on-board air and was installing it in an early Bronco, or Jeep CJ, I think I'd go with the manual cable. But if I was doing that in a more modern vehicle (like an '85 F-250  ) where it would be harder to find a place to mount the lever, then I think I'd go with the electric. ) where it would be harder to find a place to mount the lever, then I think I'd go with the electric.

I really don't think any of them are bad options. They all have their good and bad points with respect to mounting the valve/lever/switch and routing the cable/air line. Oh, and on the cable question, I don't think there's any way to know how long you need until you're ready to mount stuff up. So I'd look into either not getting the cable at all until you're ready, or else finding out if they will take it back in exchange when you do know what you need.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

Administrator

|

Thanks, Bob. The idea of swapping the cable is what I'm hoping to discuss with them tomorrow.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

I keep hearing Bill Cosby doing his bit about "I-b-b-b cab-b-b-b feeb-b-b-le my-b-b-b feb-b-b-th." https://www.youtube.com/watch?v=w9FB8R1mdjw |

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

In reply to this post by Steve83

Yeah, well maybe the juxtaposition of those two things isn't quite the best.

But maybe later today I can talk? Anyway, that was a good skit.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Well, although I was in the chair for 4 1/2 hours, I got home at 12:30 and went out to the shop as I felt pretty good. However, Jim has already pointed out that whatever anesthetic they used probably hasn't worn off, so I may hit a wall later.

And I called OX and talked to Chip. He suggested that I should go with a 48" cable as that's what they sell to most of the Ford guys. But, if I want a longer, like 58", or shorter, like 36", then I can return that one to get the other if it hasn't been used. However, he thinks it'll be a lot easier to figure out where to put the shift unit if I have it in my hand. Then I set up delivery of the D60 to Boom's Garage for Thursday morning. That means I have to get everything off the frame and it as well as all the parts out of the way and then load the D60 in Blue. Steve/FoxFord33 is coming over Wednesday and will help me load it. So that means I have to get a few things done. Given that, I drilled and chiseled the rivets out of the LH sway bar bracket. Then I turned to the recalcitrant rear spring eye bolt, but that didn't go well as even though the ball joint press was able to move the bolt some I couldn't get it to come out. I suspect the metal sleeve, to which the bolt is rusted, is folding up inside the rubber bushing. So in the end I removed the two bolts and drilled out the four rivets holding the rear spring perch to the frame and got the spring off. And if I need it in the future I'll set the rubber bushing on fire and get it out that way. Anyway, everything that I think I could possibly want, with the exception of the patch out of the cross member, is off the frame at this point. And here's what the shop looks like - a mess. Tomorrow is clean-up time!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

One technique I use for getting bushings out without setting it on fire and making a lot of nasty smoke is to walk a drill around and around the rubber bushing.

1/4" bit or a little more. Plunge 3/4 - 1" and let it chew through it. Then a bit deeper, again and again. It goes fast and really eats its way through. Check some videos for technique. Mustang guys use this on control arms all the time. *Edit one of MANY :. https://youtu.be/P7PvxtVLTKs

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Good idea! I'll give that a try. Thanks.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |