A new tool

|

Administrator

|

Yup, 4" is too small.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by ArdWrknTrk

The rods do not need to get "rained on" or wet to be no good. It is the moister in the air that the rods pull the water from. That is why once the tin is opened they should go into a air tight container or be used fast before they pull the moister in. Some from the middle of the pack to the bottom "might" be ok to use as the moister may not have gotten to them other than the ends where the wire hooks to. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

Yes, I understand how it works.

I don't know if it is reversible. Most weldors I know have a dry box or 'oven'

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In my very limited experience once the flux gets "wet" it gets crumbly. But if it hasn't gotten to that stage then maybe it can be dried out in an oven. I don't know.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

It's not crumbly at all.

In fact it is very difficult to get it started coming off. After work I think I should stop by HF and get some TIG rod.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

If it isn't crumbly then it may be fine. Check with a welder?

Is TIG rod expensive? Good metal. Probably better than coat hanger, which is what I used to use.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Even coat hangers have gone to **** now.

I don't have the power to run a proper stick welder, so they should go to someone who does. I don't need anything with source certs. As long as it's clean and consistent I will be happy.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

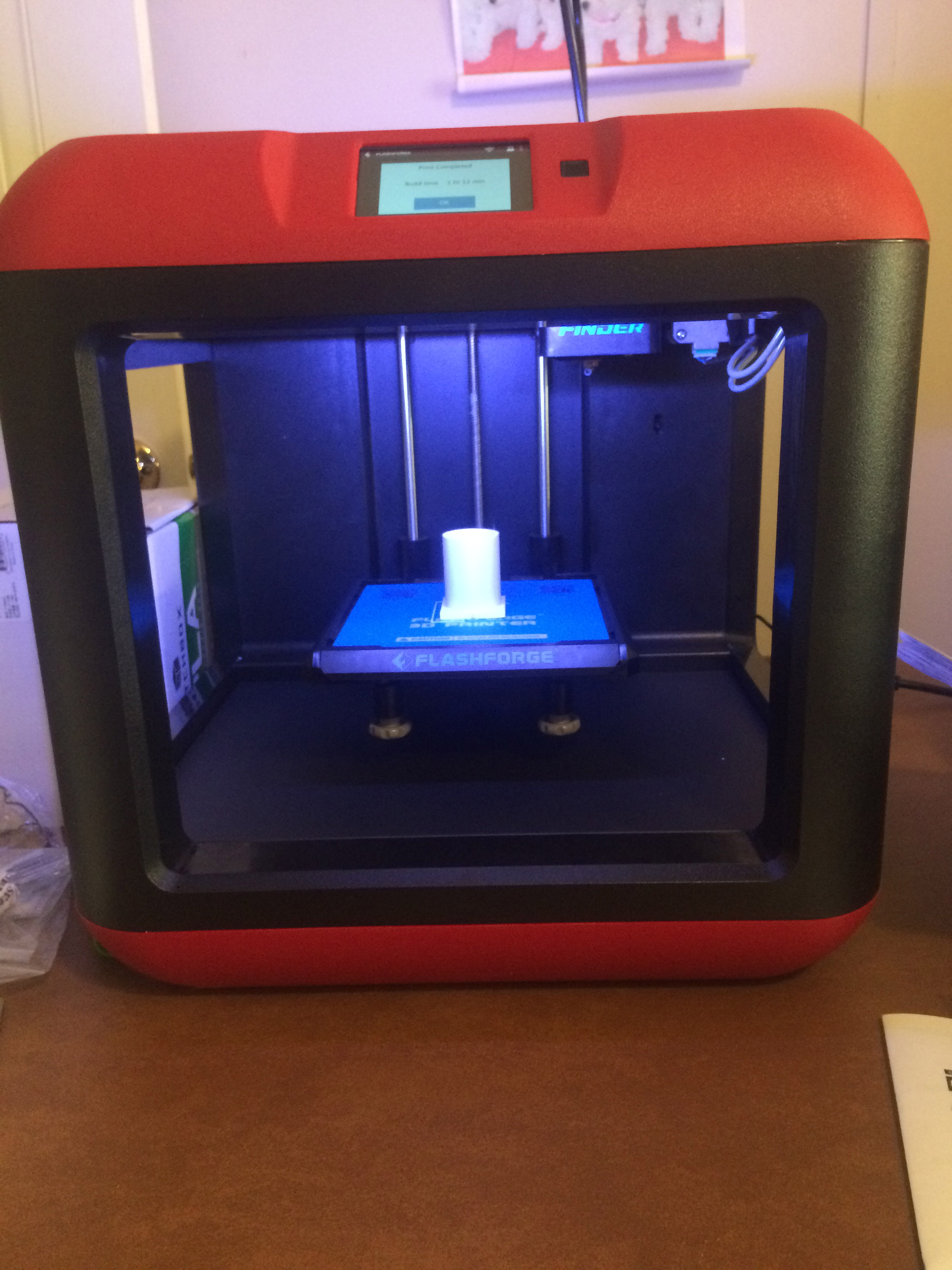

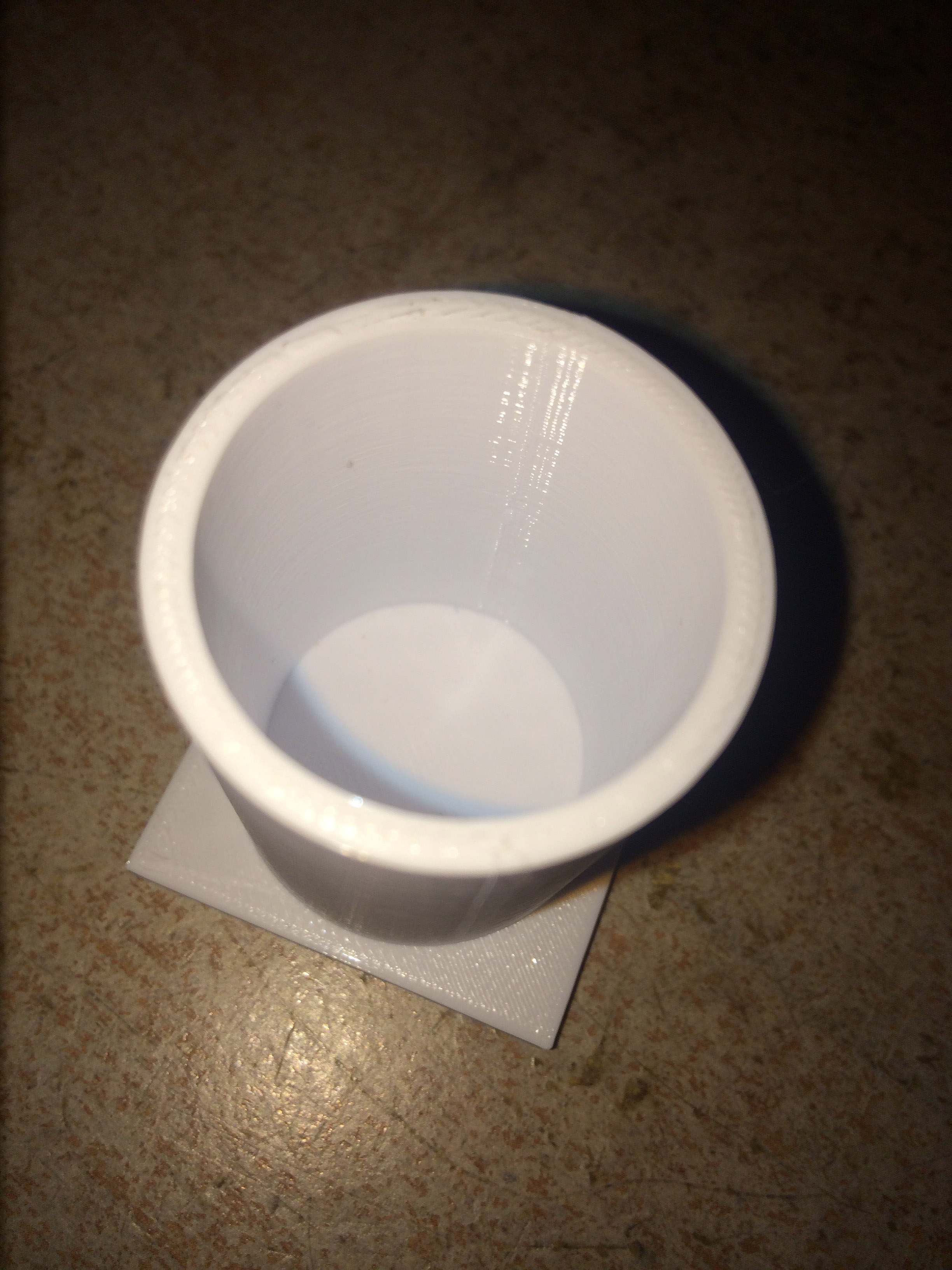

I would say this qualifies as a new tool. My awesome wife got me this for Christmas, a Flashforge 3D printer. Now maybe I can make the NLA trim clips for the LeBaron.

The printer with it's first project, came pre loaded on a USB drive.  The first project, a miniature cup?

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Bill - That is cool! I've been wanting to get into 3D printing for some time, but just never have. However, I'll watch how it works for you and maybe jump in.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

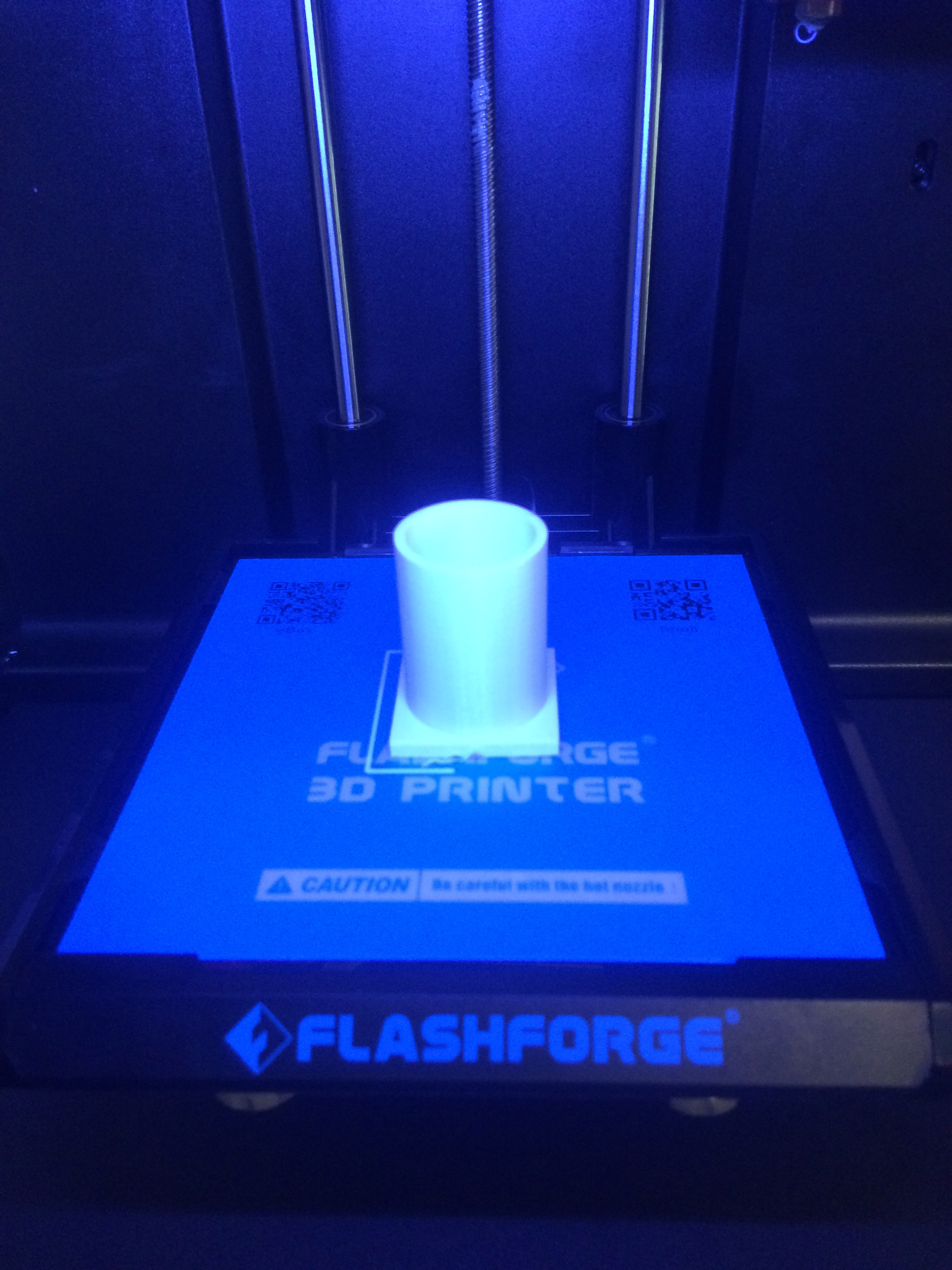

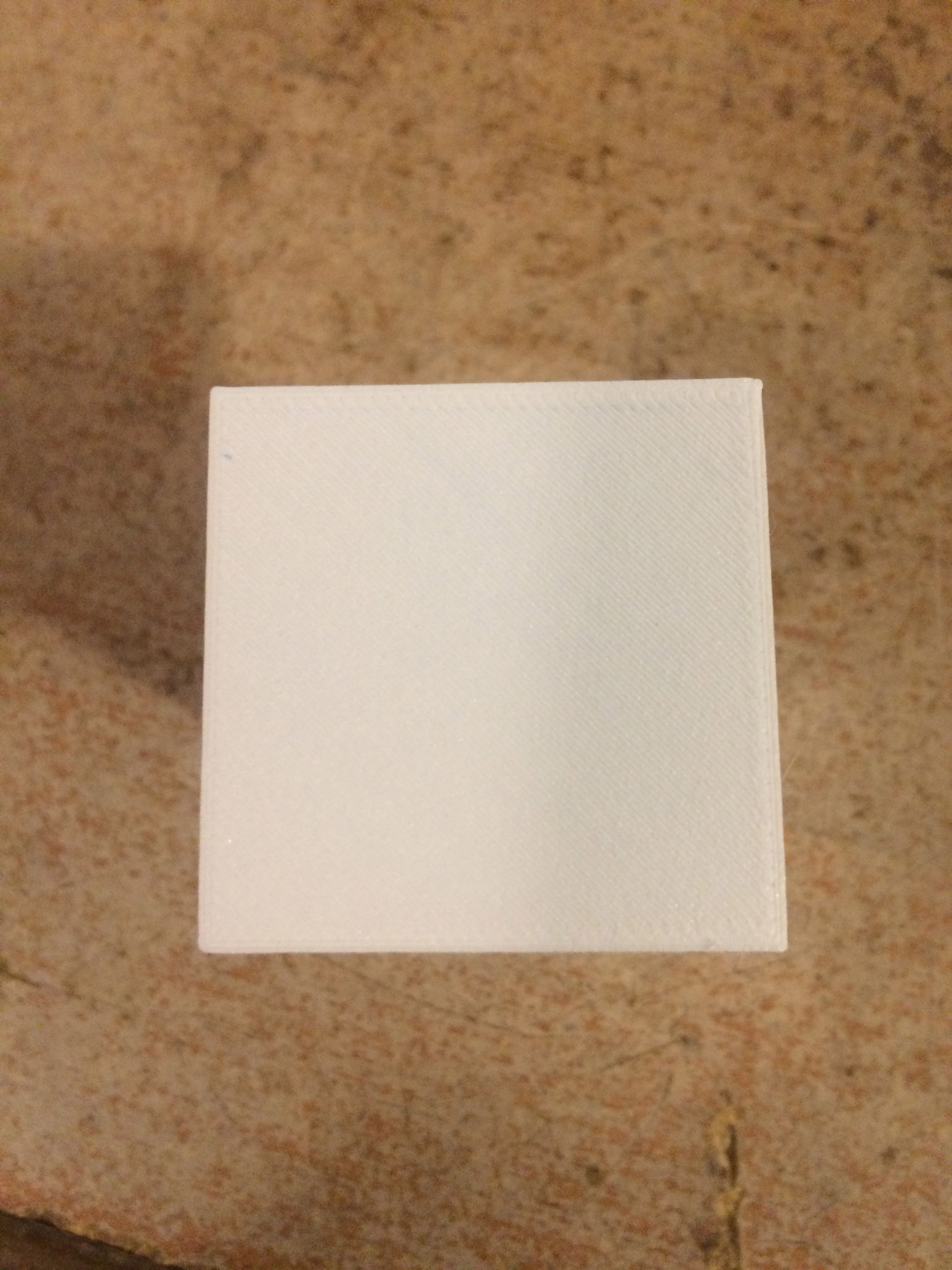

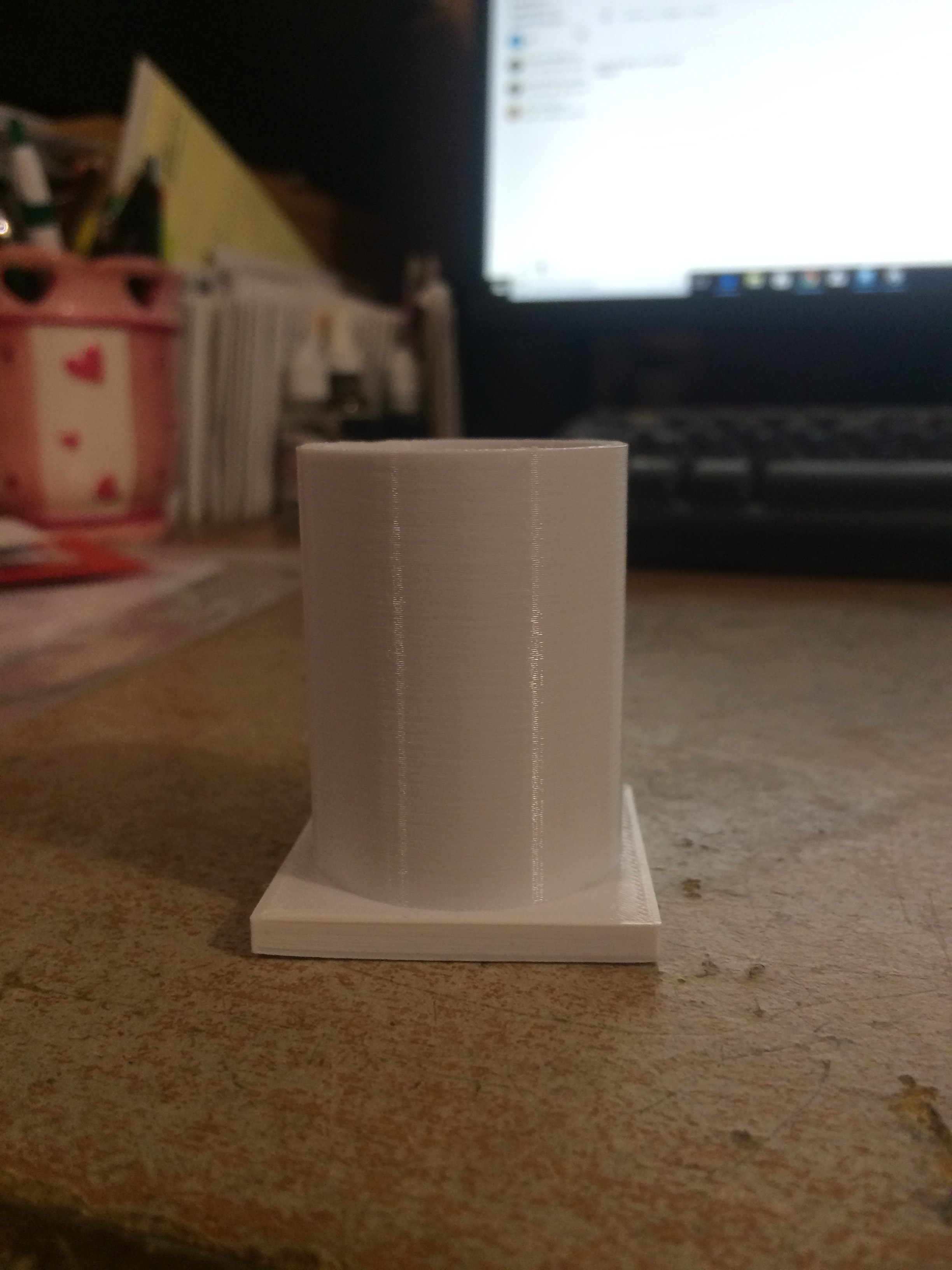

At Gary's request, some close up pictures of the "mouse cup".

Bottom view.  Side view.  Inside view.  Base side = 40mm.  Height = 50mm.  OD = 35mm.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Thanks, Bill. It looks to be pretty smooth on the sides, both inside and out. But the very bottom has more texture. How was it printed - right side up? Or was the bottom printed last? I ask because Ron sent me an HP file of 3D printing tips and it suggested printing lettering and other things you want smooth on the bottom, which would mean printing the fog lamp bezel upside down. So I wondered how yours was printed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

It printed from the bottom up. BTW, here is what I need to make:

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Interesting that there was a pattern on the bottom. Guess I don't understand.

Anyway, on the part, can you also post pics from the side and the bottom. At first blush it looks to have a constant width, a hook on the bottom, and be Z-shaped. Is the bottom end square to the sides? So, here are some measurements that would get me started - when I can start: Width Length Thickness Outer diameter of the hook at the bottom ID of the hook at the bottom Distance from the bottom to the start of the Z Length of the Z Height of the offset caused by the Z Depth of the inset at the top Width of the inset at the top, which gives the width of the two pins that stick out Width between the ends of the "whiskers" at the top Diameter of the "whiskers" Width of the little inset on the bottom Is that some kind of a tab sticking into the little inset on the bottom? Yes, we still need to work out the dimensions on the retaining slots, but we can do that after we get the overall shape established.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Suppose I just mail you one of the good ones? That way you will have the actual piece for measurements. I can also send you a copy of the software it uses so you can see what format's it accepts.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Sounds like a plan. I can measure it and send it back w/the hardware, which is already powder-coated, and your EVTM.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by 85lebaront2

Wow, what a cool gift!

Is that clip made of nylon? I'm not sure if your Finder prints in anything but PLA without hacking. (at least the flashforge page suggests PLA only) You might look into the stiffness/toughness required of the part. I also think the 'cup' is 35mm OD, as it doesn't seem to overhang the 40mm square base in the photos.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Gary Lewis

Cold stage (or bed) causes the plastic to freeze right away, where printing on top of a hot extrusion allows for better adhesion and flow.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Jim - I wondered about the ability of PLA to do that job. Do some printers allow the use of nylon?

And, that makes sense about smoothness on the bed. Perhaps the HP printer that Ron's sending the bezel to has a really hot bed that makes the first layer quite smooth? That would be handy for the top of the bead since it will be painted silver and texture will show.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by ArdWrknTrk

Jim, you are correct on the OD of the cup, I went back and looked at the picture again and corrected it.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

In reply to this post by Gary Lewis

Different plastics have different melting points. What I understand is that PLA prints at around 190C, ABS at ~220C, and 'Nylon' at higher temps than that. So it all depends on how hot the extruder is (or can get) A heated stage is almost a requirement for some plastics because the thermal expansion -or contraction actually- will cause them to pull right off the bed due to distortion.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

| Edit this page |