A Different Approach To "Electric" Fan

A Different Approach To "Electric" Fan

|

Administrator

|

I saw the following on Facebook this evening and thought it was interesting so wanted to share with y'all. Please share your thoughts. But I am attempting to contact Ron to get more info.

A A Ron Ioder |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

It's an interesting approach! 🤷♂️

Personally, I think it doesn't offer me a thing over the available thermal clutch and a whole lot more complexity that I always try to avoid. It's basically coming on at 60% until that is not enough and then it locks up completely? Why would I want to 'force' my fan on? It already knows if the radiator is not keeping up. My distributor vacuum advance knows if the coolant reaches a threshold, and steps up my idle automagically. I will avoid wiring, "electronic modules" of any kind at almost any cost.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by Gary Lewis

Messaged with him on FB and got this response:

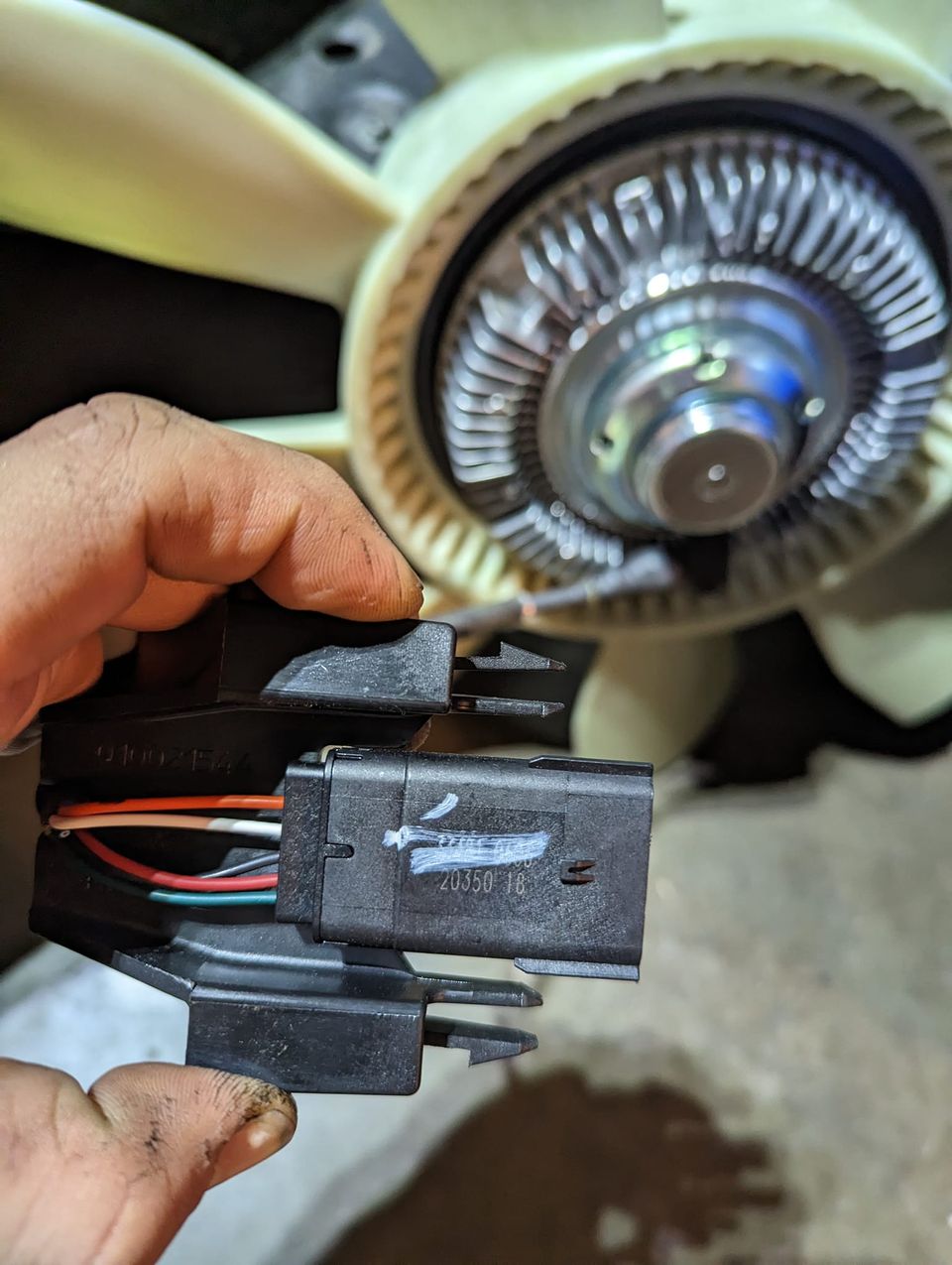

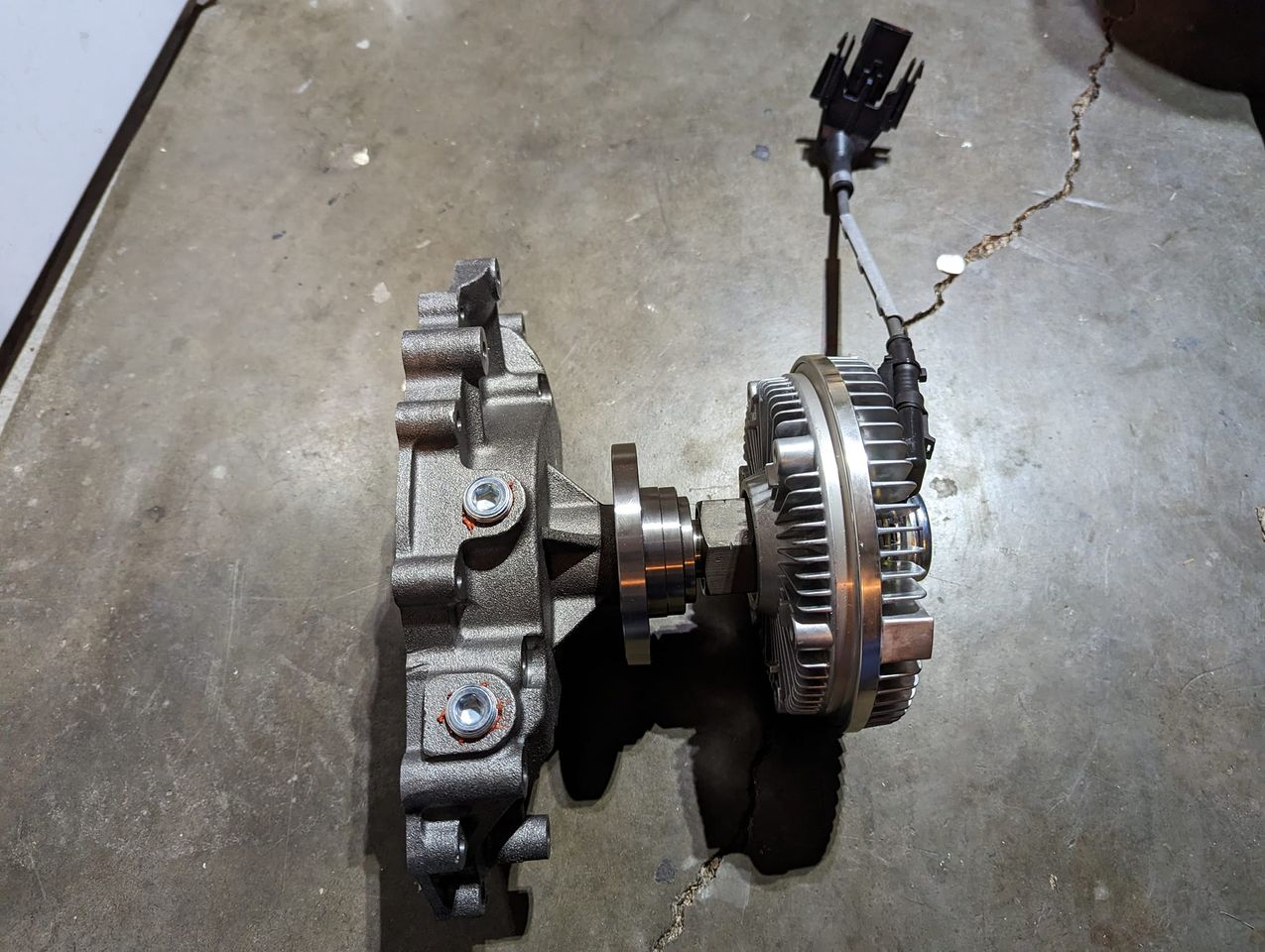

Unfortunately the kit I have is only for ford 6.9/7.3 idi at this point. I have not found a electroviscous fan clutch I could adapt to a 460 water pump because they are 4 bolt rather than thread on.Also by the time you build an adapter to make one work you are into the radiator, and my goal is to keep things as close to bolt on as possible. and I would draw the line at moving the core support forward. lol I am up for suggestions, but at this point I had not come up with anything. I also have looked into it for 12 valve Cummins and 454 and ran into much the same issues. So this isn't going to work for Big Blue, at least not at the moment. But it might for some of the shorter/smaller engines if a 4-bolt-to-thread-on adapter were made. And I found this to explain how the clutches work:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by ArdWrknTrk

In your case, Jim, you are right. But others have been discussing using electric fans and I thought this was an interesting approach that I'd not heard of.

So I did more reading and found this article: Use of electronic viscous drive to optimize fan duty cycle. I've not read all of it by any means, but I did see this summary: The Electronic Viscous Fan Drive Clutch is one of the key components of cooling system in automotive sectors. It is more efficient than the current traditional bimetal operated Mechanical Viscous Fan Drive Clutch in terms of fan power consumption. The comparative change in fan power with both fan drives is studied and it is observed that with electronic fan clutch 86% reduction in fan power is achieved.So I'm going to read more to see how that is achieved and what the advantages or disadvantages are. But it would seem that it has to be a better approach than turning mechanical energy into electric energy and then turning electric energy back into mechanical energy.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: A Different Approach To "Electric" Fan

|

Administrator

|

I guess it could work for Blue???

No one is ever going to beat the laws of thermodynamics. Phase change is inherently energy intensive. I try to make this point every time some idiot starts pushing 'green hydrogen' as a storage solution for automobiles or the grid. I'm really tired of the greenwashing BS

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

That’s exactly my point. Since these trucks have north/south engines they lend themselves to a mechanically-driven fan. Much more efficient than changing from one form of energy to another and then back again.

But the mechanical-viscous fan clutches we have aren’t the most efficient as they never fully quit blowing. Nor do they go to 100% of engine speed so don’t cool as well as they could. Supposedly the electro-viscous clutches do fully coast as well as go to full engine speed so not only are more efficient but they also cool better.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: A Different Approach To "Electric" Fan

|

In reply to this post by ArdWrknTrk

I will avoid wiring, "electronic modules" of any kind at almost any cost. Well Jim, you just spelled out my view on such things.

Bradley

86 f250 supercab longbed, 4x4, 460 bored to 472 cubes, ported heads, ARP rod bolts, EFI pistons, 5.08/5.41 lift 114° lobe separation flat tappet cam, notched lifters, Smith Brothers pushrods, stock rockers, Eddy Performer intake, Holley 1850 or 3310 depending on mood, custom curved points dizzy, MSD analog 6al triggered by Pertronix module, zf5 swap, 3g alternator, custom instrument cluster, dual tanks with 38 Gal rear for 57 Gal of fuel capacity, far too much more to mention. 98 Ranger standard cab, rwd, 5-speed, 2.5L, glass pack muffler, dual plugs wired to fire at the same time, coming up on 300,000 miles before too long. Averaging 26-27 mpg. South Georgia. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

This post was updated on .

In reply to this post by Gary Lewis

I can hold my fan blade in place with one finger.

The viscous clutch is certainly not turning a bunch of horsepower into wasted motion.  If you're moving the fan doesn't have much to do anyway. Back to my point... There is NO WAY turning motion into electricity and electricity back into motive power to drive something as hungry as a fan is EVER going to meet the the efficiency of just using that motion in the first place. Edit: You are not only using the engine to turn the fan at this point, you are ALSO using the alternator (indirectly) to hold the fan TO the engine! And there's not a hundred points of electron failure in between. You need considerable power to lock that clutch (hence, relays and big wires) You don't need to be a rocket scientist to understand this....

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Depends on the clutch. Many of the ones I've worked with have a fair bit of backdrag. And the ones that were looser had bad bearings (or were otherwise junk). Also, a lot of the E-fan reasoning/goals are reductions in rotating mass, which they indisputably are, especially in racing situations, especially drag.

---- I did an e-fan conversion (single speed + PWM controller) on my ranger and gained 1MPG on the highway. But, in that case, Ford already made a drop in alternator upgrade (3G 95A to 130A) so it was mostly an addition than a swap. On my F150, an e-clutch might make sense if the current draw wasn't too terrible, as it still has the stock 60A 1G setup; while I did add a CB radio (which is stock and doesn't draw much), I likely freed some capacity when I added LED headlights. But, due to the generally lower RPMs my F150 runs and the "on-off" nature of such a fan clutch, I doubt the gains would be as nice. And the price tag makes the deal that much sourer. Edit- the OP listing shows the fan as being variable... but the Hayden documentation Gary posted later makes it sound more like an on-off. Depending on how the unit's built, "variable" could mean partially slipping the clutch  ... or just pulsing the clutch (similar to how A/C clutches work in practice). Either way, nowhere near as variable as a PWM E-Fan like I'm running on my Ranger. ... or just pulsing the clutch (similar to how A/C clutches work in practice). Either way, nowhere near as variable as a PWM E-Fan like I'm running on my Ranger.

1984 F150: 300 L6, AOD, RWD. EEC IV / TFI, Feedback Carter YFA Carb. Stock everything but radio (for now).

|

Re: A Different Approach To "Electric" Fan

|

Administrator

|

I forgot what I used to use.... Hayden????

Id get them from my buddy Rick Piper at Portchester Auto Radiator and AC, his family business. Now the only see is Four Seasons (and what I have today) I thought Visteon was doing them, but they were rolled into some "investment group"'s M&A and like everything else (Holley, Prestolite, etc) turned to

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by ratdude747

What I've read talks about duty cycle and PWM, so apparently they are pulsing the clutch to achieve variable speeds.

So, Larry, you've already done it on the Ranger. What was the cost there? Did you use over-the-counter parts? And you said "PWM controller" and "single speed". Were the pulses many seconds long?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: A Different Approach To "Electric" Fan

|

I used a single-speed fan & pigtail (used) from a 2011 Dodge Journey, which I trimmed and JB-welded into a mostly stock fan shroud. Idea being that if the motor fails, the OE fan (and many aftermarkets) can be detached from the plastic frame, allowing the motor to be replaced in this setup.

The controller used is a Derale PWM controller: https://derale.com/product-footer/electric-fans/fan-controllers/pwm-controller/16797-detail (mine is a different discontinued model, but a very similar product). Single speed in that it's not a multi-tap fan (unlike the commonly swapped Volvo and Taurus 2-speed fans that are controlled by relays and a 2-stage thermal switch)... but infinitely variable in that the controller is using "true" PWM (high enough frequency that the motor "sees" it as analog). Fan control speed is based on a temp sensor on the cold-side radiator tank (super glued on) and a feed from the A/C control circuit (before the A/C pressure switches, so always on when HVAC is set to A/C or Defrost).

1984 F150: 300 L6, AOD, RWD. EEC IV / TFI, Feedback Carter YFA Carb. Stock everything but radio (for now).

|

Re: A Different Approach To "Electric" Fan

|

Administrator

|

That's an 'interesting approach ' Larry!

Make do. Reduce, reuse...

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by ratdude747

Ok, I think I misunderstood. You used an electric fan, not an electro-viscous fan clutch. Right?

Obviously that works, but then you are giving up energy on the conversion from mechanical to electrical and vice versa. The electro-viscous clutch approach doesn't have that loss. The study I linked to earlier shows a significant energy savings by going to electro-viscous over mechanical-viscous, and part of their findings show that the electro-viscous gives much better temp control because it is sensing coolant temp rather than air temp. I'd think the electric fan would have basically the same temp control as it is based on essentially the same controller approach. It just has the conversion losses.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: A Different Approach To "Electric" Fan

|

Yes. Not an e-clutch... I thought I made that clear. Sorry!

I'm sure there is some energy loss... but the e-fan can be controlled a lot more efficiently... and due to reduced fan mass and tighter tolerances with the duct around the fan, likely moves air more efficiently than the old clutch fan could. Keep in mind that the clutch does consume power to modulate the fan speed... so there' still a loss there. I don't know how much that is, but it's something.

1984 F150: 300 L6, AOD, RWD. EEC IV / TFI, Feedback Carter YFA Carb. Stock everything but radio (for now).

|

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by Gary Lewis

No it doesn't.

You still use the mechanical energy to turn the fan AND you use electricity to lock it up (plus all the conversion losses, and the minute amount for the "smarts" behind it. How much power does it take to turn the fan? It takes -at minimum- that much to couple the fan to the shaft... on top of that.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by Gary Lewis

Gary, I don't know if you ever measured the space between the water pump shaft and radiator. I believe I measured it at 7" on Darth.

I was looking into using a Crown Victoria fan (big electric one) but the fan shroud was a perfect fit, except the fan motor and water pump shaft needed to occupy the same space. I ended up with a T-bird unit, same motor, almost identical fan, but narrower. Using it I would make a blanking plate on the right side with rubber flap valves to blow open at highway speeds. You have to remember, Ford never intended to use the 460 in these trucks, the engineers figured the 400 would suffice. If some work had been done to the 400, like a better cam, 4 barrel etc. it might have worked. My fan controls would be in the EEC-V with a 200° or AC on low fan and a 220° high fan. These fans use an 80 amp relay for high and really move some air.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

It's almost like they added a JDAM kit and dropped it in from 20k'.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: A Different Approach To "Electric" Fan

|

Administrator

|

In reply to this post by 85lebaront2

Jim - It think it would "only" take 20 ft with the heft of that 460.

Bill - I agree that the longer-stroked 400 would probably have done the job if they'd put a bit of work into it. Like you said, a cam and a 4bbl would have made a huge difference, especially if they'd put a straight-up timing set in it. (I know you are going to tell us about their cheating and its consequences, so I set you up for that.  ) )

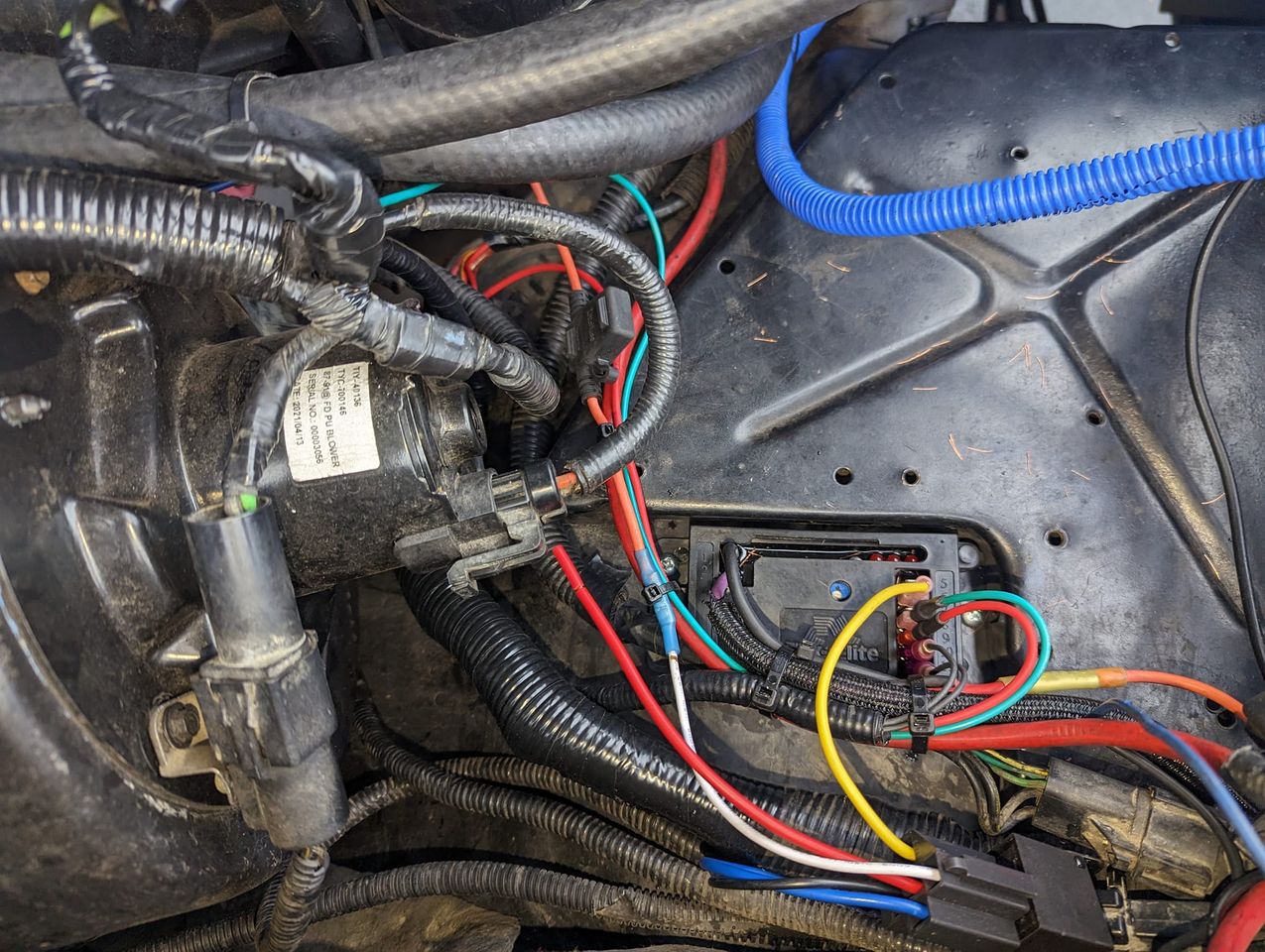

As for the clearance on the radiator, I can't easily measure it the way you did but I do measure 2" between the front of the fan and the rear of the 4-core radiator on Big Blue. So if someone found an electro-viscous fan clutch that is less than 1" thicker than the mechanical-viscous clutches we are using then we could see if we could figure out how to adapt it. And have the EEC-V ECU's control it. You can sorta see that 2" clearance here:

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: A Different Approach To "Electric" Fan

|

In reply to this post by ArdWrknTrk

I don't know about electro-viscous clutches, or if you were talking specifically about that type of clutch or if you were talking more generally. But more generally, the power required to clutch in a load is usually much lower than the power to actually turn the load. It's still an adder to the whole system. As you say, turning a fan takes the power to turn the fan regardless of how (or whether) you clutch it. And if it's a clutch that requires power to operate you have to add that power requirement to the system (and the systemic losses to generate that electric power in the mechanical alternator). But that clutching power isn't necessarily that high. Take the clutch between an engine and a manual transmission. The spring in that clutch doesn't need to be all that strong to transmit the torque of the engine. It's still small enough that you can compress it with your leg, and there's no way your leg can do what the engine is doing. And the wrap-spring clutches that my company makes take a flat amount of power to energize no matter what load they are being asked to transmit. Again, I don't know electro-viscous clutches. I imagine that (unlike wrap-spring clutches) they do require more power to transmit more power. But they probably don't require as much power to operate as they are transmitting. It's an adder, but not a (more than) doubler of the required power.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

| Edit this page |