300 six clutch pivot 💩💩💩😩

|

Administrator

|

Having that boss on the threaded stud turns flex force into withdrawal.

Without it you've created a fulcrum at the thread root. I seriously doubt Ford would have created a taper on the pivot if it weren't needed. As the clutch feeds torque there's definitely going to be some flex in the motor/transmission mounts. I don't have a mechanical clutch truck to look at, nor a decent lathe to spin one up.  Thanks for your input Dave.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by ArdWrknTrk

Alright folks…

The stud was broken below the block surface. Luckily it was not crazy hard. The extractors I bought at harbor freight were useless… they were for rounded out screw heads not broken bolts. Oddly enough they didn’t have regular easy outs. The right angle drill adapter was a great $20 solution though, and the extractor made enough of a dimple that I was able to get a bite on it with a chisel tip and back it out with rotational tapping. Success! The makeshift pivot was not as straightforward as I hoped. I perhaps bought the wrong flange bushings as they did not fit the 9/16” bolt. I was in a rush at true value as I was told the register would be closed down in 5 min and after that no sales… so I was grabbing parts… fast! I had to file the inside diameter from 1/2” to 9/16”. Then I discovered the large spacer was also tight in the Z bar and it needed to be reduced (also about 1/16”). It is not an elegant solution, but it is a viable, get-you-back-on-the-road fix:      The clutch actuation is smooth and it shifts great. It will probably require more attention going forward than the nylon bushing, as there is no rubber boot to keep dust and moisture out. I will call it a hack, because that it what it is, but it seems to be a decent one. It will at least buy me some time to find other solutions…and decide the ultimate scope of this truck once I get the others running. I was actually planning to start work on the F-Superduty this weekend ☹️ until other priorities prevailed…

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

Limited success is still SUCCESS Jonathan!

The little burro is back to hauling water, for now

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by Ford F834

Well done, Jonathan! That looks like a very good solution, and if the bolt isn't bottoming in the block and you are able to tighten the nut against the block it should hold up well.

Does your Z-bar have a grease fitting in it? If not, I'd consider installing one and pumping the thing full of grease every once in a while. That will tend to push the dirt out.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

As I think about it I see what might be a problem. Since the bushing is a cylinder instead of a sphere, as the engine rocks back and forth it'll try to lift or depress the whole Z-bar. Maybe as long as the engine mounts are good there won't be a problem, but if one of them fails there may well be.

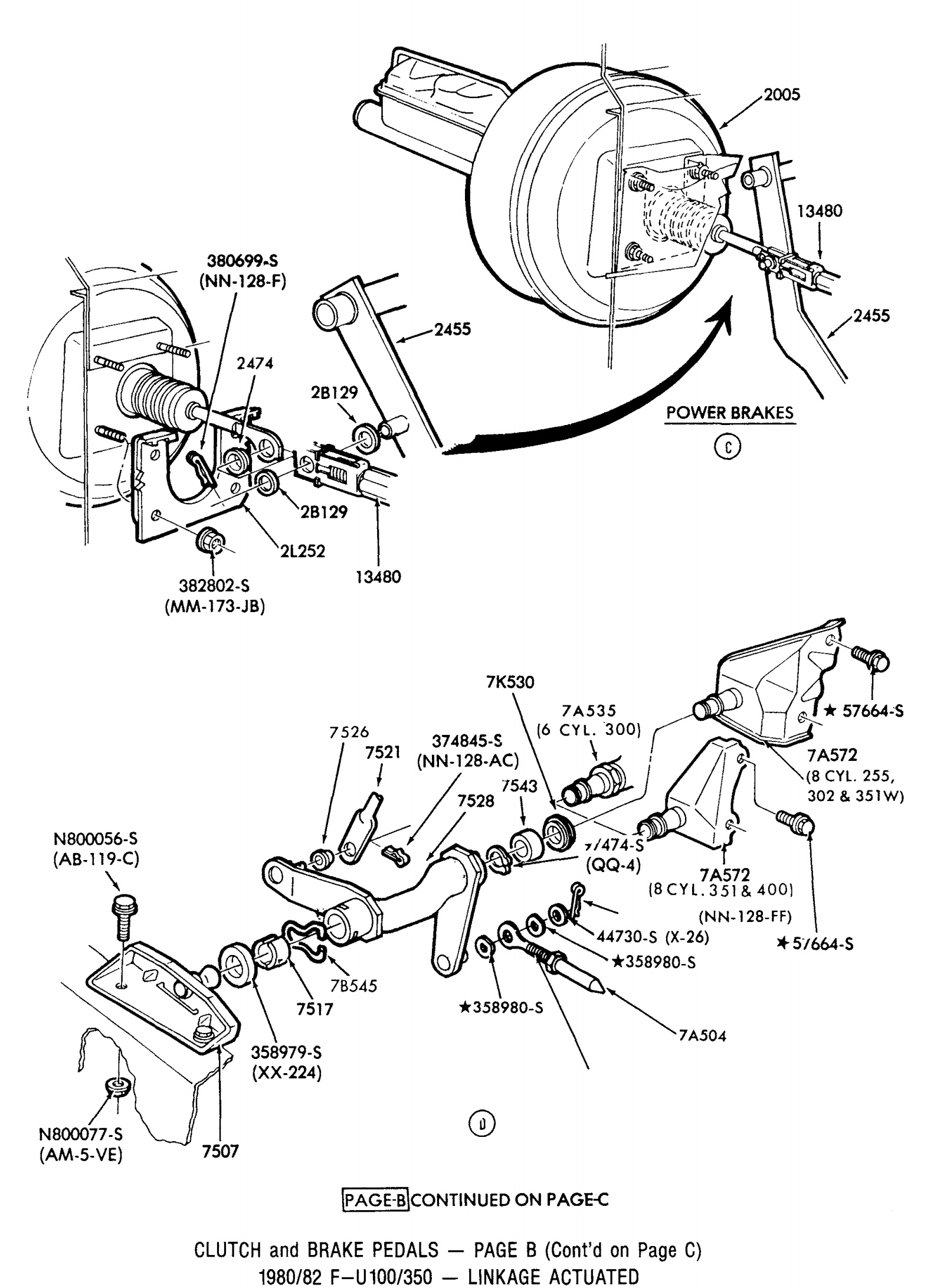

Was 7543 rounded? Did it form a sphere?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Ford F834

Great job! Nice fix!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

This post was updated on .

In reply to this post by Gary Lewis

Yes, this is approximately spherical, but with a flattened wear point. I am sure it is meant to articulate with frame flex and engine torque twist. My bushing could be forced into the Z bar but was snug. I didn’t want it to stick and not return, and I didn’t want it to bind as you describe. I filed it, and it has some movement but is approximately conical instead of spherical. I am counting on excess tolerance and overall wear in the linkage system to allow it to move. I hope it’s enough 😅. I think I should carry a spare bolt. Also, the stock part is 3” overall. I used a 3” bolt so it is ~3.5” overall. The head gives the Z bar extra leverage in a binding situation. Like I said… this is a fix but probably not a solution. I’m sure there are better ways to make one of these.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Administrator

|

In reply to this post by grumpin

Impressive, Jonathan!

|

|

Administrator

|

In reply to this post by Ford F834

Maybe the looseness will be enough to allow movement w/o binding.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Nice job on a "get me by" fix, kind of like my bolt welded to what was left of the pivot LOL.

The only thing I see with the "fix" is it looks like the Zbar is to the frame pivot to far. If you were to hold the motor pivot up I think you will see the Zbar is almost falling off the pivot. Or is it just the way the picture was taken? I think there is a clip that fits the Zbar so it cant move to far to the frame side? This is what that bushing looks like - kind of round to allow for movement of the motor.  I should get a picture of mine now that it is working as the factory wanted it to. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

Dave, it looks to me like the Z bar sits pretty close to the frame pivot bracket. It did not separate readily so I just unbolted the bracket/Z bar assembly and slid it onto my makeshift block pin. The frame pin to Z bar relationship did not change, and there is now more bearing length on the block side than it had originally. If there is a retainer on the frame side to prevent lateral Z bar movements I didn’t see it or mess with it.

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

|

Gary's post #7B545 clip I cant remember what it is for now but I did put it back on mine.

Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

That’s probably why the Z bar wouldn’t readily separate from the frame pivot on mine! 😅

SHORT BED 4-DOOR DIESEL: 1986 F350 4x4 under construction-- 7.3 IDIT ZF5+GVOD

STRAIGHT SIX 4X4: 1981 F150 2wd to 4x4-- 300 I6 close ratio diesel T19, hydroboost brakes, Saginaw steering BIG F: 1995 F-Superduty under construction— converting to 6.9L IDI diesel ZF5+DNE2 |

| Edit this page |