1950 Chevy Pickup Resurection

|

Administrator

|

I don't think #5 is broken. I punched the rod bolt out trying to get the cap off, so maybe that is what you are seeing.

And yes, it is scrap and I've seen better. Man, this is toast.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 1950 Chevy Pickup Resurection

|

Administrator

|

If you have had a chance to go through that article I shared with you, one item he mentions is the oil filter. He suggests going to a remote spin on type with the remote mount where the original bypass filter sat. You could get a remote mount kit for a Ford spin on filter (also same filter fits Roadrunners).

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

In reply to this post by ArdWrknTrk

Jim has a way with words. To me "slice" implies "like a hot knife through butter". This is more like a dull knife through cast iron. I first tried a bi-metal sawzall blade and all that happened was the blade turned blue and the teeth departed. Then I remembered that cranks are frequently nitrided to make them hard on the surface, and while I don't know that this one was, it sure is hard. So I then took to the cutoff disc and got about as far as I could reach with it, as shown below. I can get a bit farther with the cutoff wheel, but after I get as far as I can I'll try the sawzall again to get the other half of the crank. But if that doesn't work I'll try a chisel to see if I can break the crank. And yes, you see hammer marks on the rod. I've tried to move it down but everything is frozen. NOTHING is moving.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by 85lebaront2

Bill - I'll follow up on that oil filter idea. Thanks!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

Pearl abrasives 5" .045 disc.*

Cut as deep as you can and smack it with a 4# drilling hammer. It will snap.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I'm almost as deep as I can go. A bit more and I'll be there.

As for smacking it, the main part of the crank is well supported so I need the flywheel end to tilt away - and crack off. That's why I'm thinking that using a chisel to wedge it apart is the way to go. That will tilt the flywheel away and, hopefully, break the crank.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

The flywheel doesn't look too well supported?

Cast cranks are generally pretty brittle, though I know nothing about 1950 Chevrolet's. You'll get it, and have things ready for Ian's return!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: 1950 Chevy Pickup Resurection

|

Administrator

|

In reply to this post by Gary Lewis

I would suspect that the crank is probably forged steel. I am pretty sure it is forged steel, no casting lines. Like this one:

I believe Ford was the first to seriosly dabble in cast cranks and that was the first Windsor engines (221, 260, 289) The HiPo 289 had a high nodular iron cast crank.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Well, if it is forged I'm gonna have a problem. It'll probably eat saw blades and I can't get far enough with the little cutoff wheel to get through it. Maybe with a bigger cutoff wheel I can?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

This post was updated on .

If you can get it slightly hot with a torch, then try to work it back and forth with some leverage somewhere... maybe you can create enough plastic deformation to break it...

that is if you cannot get a big enough cut off wheel in there... if a 7" angle grinder can get it there, it should make short work of it

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

|

Administrator

|

In reply to this post by Gary Lewis

Try the Diablo carbide sawzall blade for thick metal.

When I had to cut through the forged suspension components of my brother's car it was astounding how easy it went after hours of instantly dulling and overheating conventional bi-metal blades..

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Vivek - I only have a MAPP gas torch, and that's not going to get it warm, much less HOT.

Jim - I may have to resort to that blade. But I have a few more things to try first. Yesterday I had a few minutes so I tried my battery-powered grinder with a 5" cutoff wheel on it. But since the cut from the smaller wheel was narrow the larger, thicker wheel kept binding. So I took a wide chisel and drove it into the gap and was able to get the gap wide enough that I could get the larger wheel in. That worked for a while but I finally overheated the battery and since I was essentially out of time I quit at that point. The next thing will be to put that wheel on the 110V grinder and see what I can do. I'm probably about 2/3 of the way through the crank and with the oil pump off I have good access so hope to be able to get most, if not all the way, through. But there is NO flex yet. The rear main doesn't wiggle. Hitting the flywheel doesn't cause any movement, although I have to be very careful as the whole thing is resting on two jack stands & a 2/x4 so I can't hit too hard. Maybe when I get as much cut as I can I'll be able to rotate the flywheel with a pry bar and get the crank to let go. But, there are no parting lines on the crank so I think Bill is right - it is forged.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Forging should still leave a line....

So, your 5" cutoff disc is thicker than.045"??? I've got a 7 & a 9" grinder and a gas powered 14" Stihl, you might remember when I cut The Giving Truck to pieces.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Found this online.. Interesting. I just assumed all cranks were forged.. or maybe I never gave it any thought.... Once tooling is setup, I don't imagine it being really difficult to forge all the time

There would be an extra manufacturing step.. sure... but still. There would be an extra manufacturing step.. sure... but still.

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

|

Administrator

|

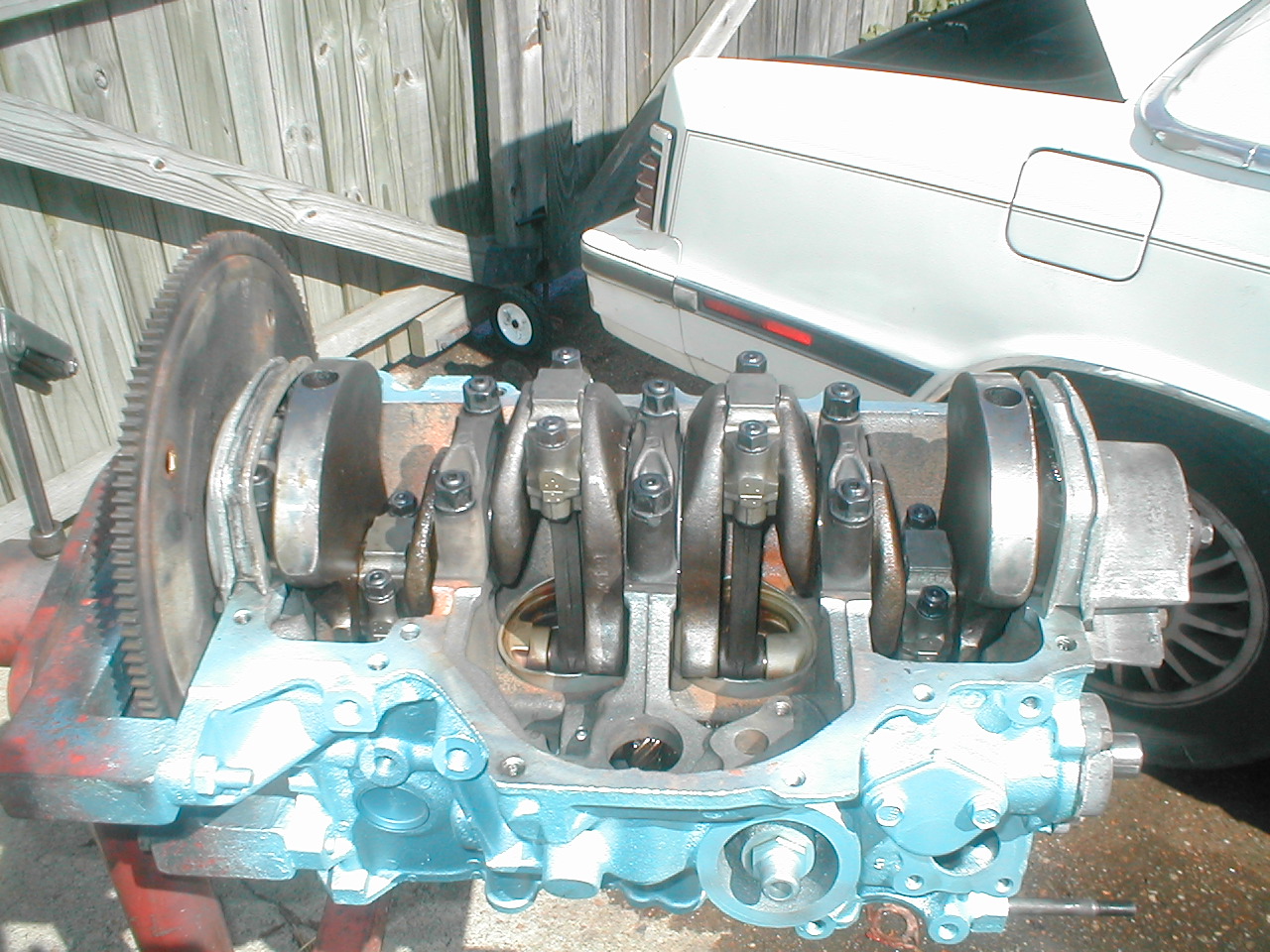

I don't know if this one is forged or cast, but it is in two parts. Here are some pics to prove it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Progress is Gooooood!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Gary Lewis

Yay that's great!! Looks like Jim's idea of slicing turned out to be the solution after all! I wouldn't have thought of that.

(Looks like forged because the edges are rounded.)

Vivek

- BB 2WD - 1984 F350 RWD 460/C6 - 1978 Bronco with a 460 from an 86 Bullnose/C6 |

Re: 1950 Chevy Pickup Resurection

|

Administrator

|

In reply to this post by Gary Lewis

Nice pile of scrap metal! Glad you finally got it off. How does the flywheel look?

As Jim would say "progress is good". If you find that the later pan and the front axle have too close a relationship and you end up using that pan, you will probably have to remove all of the splash lube system for clearance 216 = 3.5 X 3.75, 235 = 3.5625 X 3.9375 but the rod caps on the 235 might clear, but the feed pipe for the jets will need to be cut as I do not believe the feed hole is there (not that you would want to use it anyway).

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Yes, it is a lot of scrap metal. I still need to check the pans, and there I'm thinking I'll cut a piece of cardboard to profile the 216 pan and see if it fits the 235 pan. Then I'll know if it'll clear.

And I still need to pull the front mount off the timing cover on the 216, although I think it has seen better days an may need to be repaired or replaced. Plus I need to replace the rear mounts as they are toast - literally on one as I caught it on fire with the welding. Then a HUGE cleanup of the shop. Tools are everywhere and so is dirt and rust. EVERYWHERE, like Chicken Man. And I have to get rid of the 216. As for the flywheel, it looks fine. But I can't use it as Chevy changed the tooth count on the ring gear between a 216 and a 235. So 6 volt starters work on a 216 and 12 volt starters on a 235. So I have to get a new flywheel and I want to get a new clutch and pressure plate as well so it doesn't have to come back apart.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: 1950 Chevy Pickup Resurection

|

Administrator

|

Look up the pan gaskets and see if they are different.

On the flywheel, I thought you were going to change the ring gear anyway. FWIW, 1953-54 and maybe even 1955 were 6 volt and the Powerglide cars got the 235 engine to make up for the serious loss of pep with a Powerglide. As near as I can tell, all 235s are full pressure oiling, so if the rods and troughs get too friendly the troughs can be eliminated.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

| Edit this page |